Call us: +86-137-2353-4866

A seat weight sensor detects the presence and weight of an occupant in a vehicle seat. This sensor plays a crucial role in electric vehicles by ensuring accurate airbag deployment, activating seatbelt reminders, and supporting advanced driver assistance systems.

- Manufacturers rely on seat weight sensor technology to meet strict safety regulations and enhance occupant protection.

- Modern electric vehicles use advanced solutions like SOUSHINE Automotive Seat FSRs, which employ force sensing resistors (FSRs) to deliver reliable detection and system optimization.

Table of Contents

Key Takeaways

- Seat weight sensors detect if someone is sitting and measure their weight to help control airbags and seatbelt reminders.

- These sensors improve safety by adjusting airbag deployment based on occupant size, protecting children and adults alike.

- Different sensor types include strain gauges, bladder sensors, capacitive sensors, piezoelectric sensors, and force-sensitive resistors (FSRs).

- FSRs, like SOUSHINE Automotive Seat FSRs, offer fast response, durability, and easy integration for reliable occupant detection.

- Regular calibration of seat weight sensors is essential after seat repairs or collisions to keep safety systems accurate and effective.

- Common sensor problems include false alarms caused by heavy objects, water damage, or wiring issues; regular maintenance helps prevent these.

- If airbag warning lights or sensor errors persist, seek professional help to ensure the vehicle’s safety features work properly.

- Keeping the seat area clean, avoiding heavy items on seats, and following manufacturer guidelines help maintain sensor performance and passenger safety.

Seat Weight Sensor Basics

What Is a Seat Weight Sensor

A seat weight sensor is a key component in modern vehicle safety systems. It detects both the presence and the weight of an occupant in a seat.

- These sensors form part of the Supplemental Restraint System (SRS) in electric vehicles.

- They help the vehicle determine if a seat is occupied and by whom.

- The main goal is to inform the airbag control unit about the need for airbag deployment.

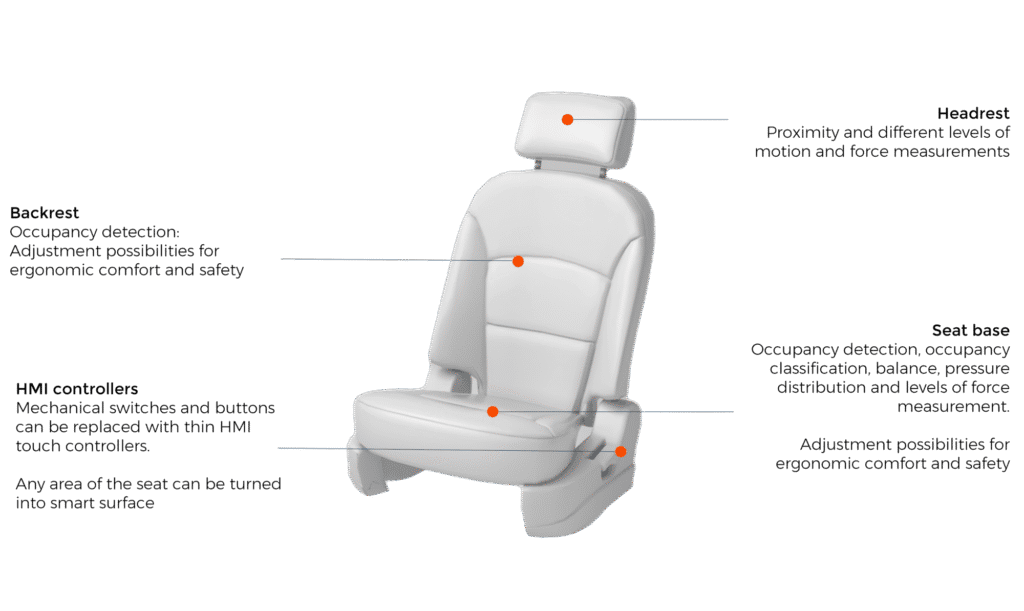

Seat weight sensors appear in both the driver seat and passenger seat. The driver seat weight sensor ensures the system recognizes when the driver is present. The passenger seat sensor identifies if a passenger or a child seat occupies the seat. This information helps prevent unnecessary airbag deployment and reduces the risk of injury.

How It Works

Seat weight sensors use several technologies to measure weight and presence.

- Strain gauge sensors measure mechanical strain when weight presses on the seat.

- Capacitive sensors detect changes in electrical fields caused by an occupant.

- Fluid-filled bladder systems sense pressure changes when someone sits down.

- Piezoresistive sensors, such as SOUSHINE Automotive Seat FSRs, change resistance based on applied force.

The sensors send data to the Occupant Classification System (OCS). The OCS processes this data and communicates with the airbag control unit. The system then decides whether to deploy the airbag and at what force. Calibration tools and standardized weights keep the sensors accurate. The sensors also support other features, such as seat belt reminders and child seat protection.

Note: The passenger seat sensor often includes a weight measurement option to distinguish between adults, children, and objects.

Role in Electric Vehicles

Electric vehicles rely on seat weight sensors for several safety and comfort functions.

- The sensors help adjust airbag deployment based on occupant type and weight.

- They activate seat belt reminders only when someone occupies the seat.

- The system can adjust seat belt tension for added protection.

- The sensors support advanced driver assistance features by providing accurate occupant data.

Manufacturers use seat weight sensors in both the driver seat and passenger seat to meet safety regulations. The sensors work with the vehicle’s control units, using analog voltage, CAN, or LIN signals for communication. Technical specifications include a 5V operating voltage, 20mA current, and a response time of less than one second. The sensors operate in a wide temperature range and withstand over a million cycles, ensuring durability in daily use.

Seat Weight Sensors and Safety

Airbag Deployment

Seat weight sensors play a direct role in improving airbag deployment accuracy. These sensors measure the weight of the person sitting in the seat. The system uses this information to decide if the airbag should deploy and at what force. For example, if a child or a lightweight adult sits in the passenger seat, the system can suppress or adjust the airbag to prevent injury. A weight-based sensor system offers a clear advantage over pattern recognition methods. By measuring weight directly, the system reduces the risk of inappropriate airbag activation. This approach helps protect smaller occupants and supports compliance with safety regulations.

Note: Direct weight measurement allows the vehicle to adapt airbag deployment strategies for different occupants, making the system more reliable and precise.

Occupant Detection

Seat weight sensors form the backbone of passenger seat occupant detection systems. These sensors gather data on both the presence and classification of the person in the seat. Tesla’s patent application describes a system that uses sensors to estimate occupant weight and presence. The system processes this data to classify the occupant as a child, small adult, or large adult. It also detects posture by measuring changes in capacitance. The occupant classification system uses this information to inform safety features and adjust responses. Environmental factors like temperature and humidity can affect sensor readings, so the system compensates for these variables to maintain accuracy. This technology ensures that advanced safety systems respond correctly to each occupant’s needs.

Preventing False Triggers

Seat weight sensors must avoid false triggers to maintain safety and reliability. Several factors can cause incorrect signals, leading to unnecessary airbag deployment or missed alerts. Common causes include:

- Everyday items like heavy bags or spilled liquids placed on the seat

- Water damage from leaks or moisture exposure

- Wiring connection problems due to seat adjustments or wear

These issues can cause the sensors to malfunction or send incorrect data. Regular inspection and maintenance help prevent such problems. Technicians recommend checking for loose connections and keeping the seat area dry. By addressing these factors, manufacturers ensure that seat weight sensors continue to support occupant classification and advanced safety systems without interruption.

Seat Weight Sensor Technologies

Strain Gauge

Strain gauge technology forms the foundation of many seat weight sensors in electric vehicles. Manufacturers embed these sensors into the seat frame, often at the corners, to measure the mechanical stress produced when an occupant sits down. The sensor converts this stress into an electrical signal, which the system uses to determine the occupant’s weight and position. Strain gauges offer good accuracy and linearity, making them suitable for both static and dynamic load measurements. They also provide high vibration resistance and long-term stability, which are essential for automotive environments.

However, strain gauges require temperature compensation to prevent measurement drift. Without proper calibration, the sensor may lose accuracy over time. The installation process can be labor-intensive, but the benefits of precise occupant classification and reliable performance make strain gauge seat weight sensors a popular choice for electric vehicles.

Strain gauge sensors help classify occupant weight categories, supporting advanced safety features like adaptive airbag deployment.

Bladder Sensors

Bladder sensors use a fluid-filled bladder placed beneath the seat cushion. When someone sits down, the occupant’s weight increases the pressure inside the bladder. A pressure sensor then measures this change, providing a signal proportional to the occupant’s weight. This design ensures consistent and linear output, regardless of occupant size or seat orientation. Bladder sensors can use either liquid or gas, and internal seams help prevent bulging and adjust sensitivity.

Manufacturers favor bladder sensors for their ability to deliver accurate weight detection without affecting seat comfort. These sensors also address some drawbacks of other technologies by offering improved sensitivity and cost-effectiveness. Bladder sensors play a vital role in controlling safety restraint systems, such as airbags, by enabling variable restraint capacity based on occupant weight. They also help prevent unnecessary airbag deployment when the seat is empty.

Capacitive Sensors

Capacitive sensors detect changes in the electric field around the seat to determine occupancy. These sensors can differentiate between adults and children, which enhances airbag deployment safety. Some systems integrate capacitive sensing with seat heating elements, allowing the seat to maintain heating functionality while still detecting occupants. Synchronous detection techniques improve the reliability of capacitance measurements.

Capacitive seat weight sensors offer non-contact detection, working through clothing and seat materials. This feature makes them biocompatible and non-invasive. However, motion artifacts and road vibrations can affect sensing accuracy, especially in dynamic driving conditions. Designers must address these challenges to ensure consistent performance. Capacitive sensors reduce the number of components in the seat, lowering weight and cost, but integrating them with seat heaters can present design constraints.

| Sensor Type | Accuracy and Reliability Characteristics | Limitations and Challenges |

|---|---|---|

| Strain Gauge | Converts mechanical stress to electrical signals; used for posture, fatigue, and respiration monitoring. | Accuracy affected by vibrations and body positioning. |

| Bladder | Fluid-filled bladder with pressure transducer; improved accuracy in controlled conditions for heart and respiratory rates. | Still challenged by vibration and movement during driving. |

| Capacitive | Used for pressure and posture monitoring; moderate accuracy (e.g., 87% in static simulator). | Studies often lack consideration of road noise and vibrations, limiting reliability in dynamic environments. |

Seat weight sensors using these technologies form the backbone of occupant detection and safety systems in modern electric vehicles.

Piezoelectric and FSRs

Piezoelectric sensors and force-sensitive resistors (FSRs) represent advanced solutions for seat weight detection in electric vehicles. Both technologies use changes in electrical properties to sense pressure, but they operate on different principles.

Piezoelectric Sensors

Piezoelectric sensors generate an electric charge when subjected to mechanical stress. Manufacturers often use materials like quartz or certain ceramics for these sensors. When an occupant sits on the seat, the sensor experiences pressure. This pressure creates a voltage signal that the vehicle’s control system can interpret.

- Piezoelectric sensors respond quickly to changes in force.

- They provide high sensitivity, making them suitable for detecting even small pressure variations.

- These sensors excel in dynamic environments, such as during sudden braking or acceleration.

However, piezoelectric sensors primarily detect changes in force rather than static loads. For this reason, they often work alongside other sensor types to provide comprehensive occupant detection.

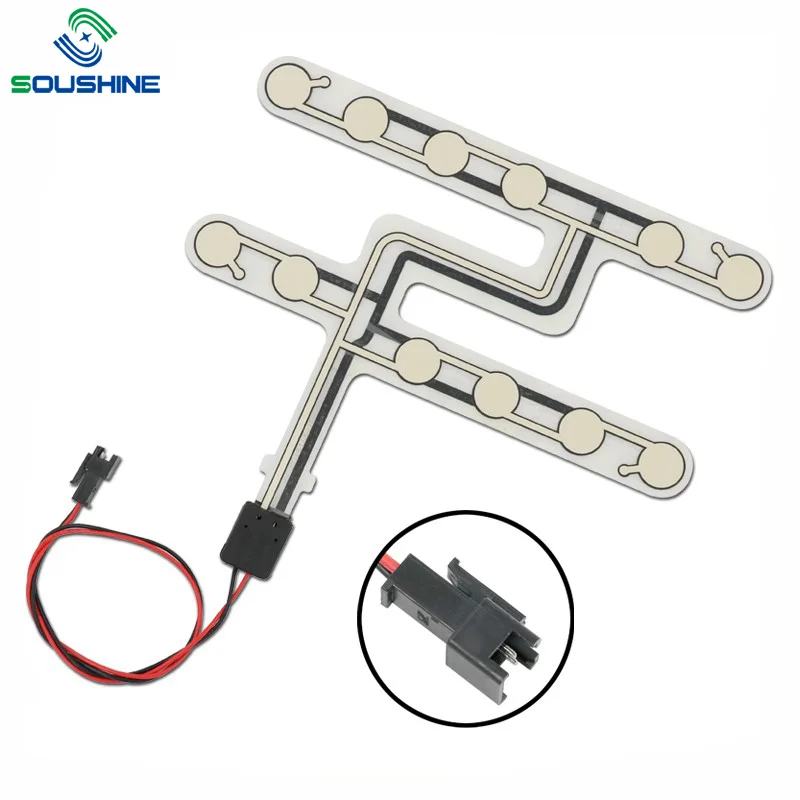

Force-Sensitive Resistors (FSRs)

FSRs use a piezoresistive material that changes its electrical resistance when force is applied. SOUSHINE Automotive Seat FSRs serve as a leading example of this technology in modern electric vehicles. Engineers integrate these sensors into the seat cushion or frame.

SOUSHINE Automotive Seat FSRs detect occupant presence by measuring resistance changes when someone sits down. The system sets a pressure threshold. When the applied force exceeds this threshold, the sensor signals the vehicle’s safety systems.

Key benefits of FSRs include:

- Simple construction and easy integration into various seat designs

- Fast response time, typically less than one second

- High durability, withstanding millions of cycles in daily use

- Reliable performance across a wide temperature range

FSRs support critical safety features, such as seatbelt reminders and airbag deployment decisions. They help the vehicle distinguish between an adult, a child, or an object on the seat.

| Feature | Piezoelectric Sensors | FSRs (e.g., SOUSHINE) |

|---|---|---|

| Sensing Principle | Voltage from pressure | Resistance from pressure |

| Response Time | Very fast | Fast (<1 second) |

| Static Load Detection | Limited | Excellent |

| Integration | Often supplemental | Direct seat integration |

Note: FSRs may sometimes detect heavy objects as occupants if the pressure exceeds the set threshold. Regular calibration helps maintain accuracy and system reliability.

Piezoelectric and FSR technologies continue to shape the future of occupant detection in electric vehicles. Their unique properties allow manufacturers to design safer, smarter, and more responsive safety systems.

Types of Seat Weight Sensors

OEM vs. Aftermarket

Automotive manufacturers install original equipment manufacturer (OEM) seat weight sensors during vehicle assembly. These sensors meet strict industry standards and integrate directly with the vehicle’s safety systems. OEM sensors often work seamlessly with the airbag control unit and the occupant classification system. Engineers design these sensors for long-term reliability and compatibility with the vehicle’s electronics.

Aftermarket seat weight sensors offer an alternative for vehicle owners who need replacements or upgrades. These sensors can fit a wide range of vehicles, including older models. Some aftermarket options provide features that OEM sensors may not include, such as enhanced sensitivity or easier installation. However, users must ensure that aftermarket sensors match the vehicle’s specifications. Compatibility issues can affect the performance of the driver seat weight sensor and the passenger seat sensor.

Tip: Always check the vehicle’s manual or consult a professional before installing an aftermarket seat weight sensor. Proper installation ensures that safety features like airbag deployment and seatbelt reminders function correctly.

A comparison table helps clarify the differences:

| Feature | OEM Sensors | Aftermarket Sensors |

|---|---|---|

| Integration | Direct with vehicle systems | May require adapters |

| Reliability | High, meets manufacturer standards | Varies by brand and model |

| Warranty | Usually included | Depends on supplier |

| Customization | Limited | Sometimes available |

SOUSHINE and Other Brands

SOUSHINE stands out in the market for its advanced Automotive Seat FSRs. These sensors use force-sensitive resistor technology to detect pressure changes in the seat. Manufacturers trust SOUSHINE products for their fast response time and high durability. The sensors withstand millions of cycles and operate in a wide temperature range. SOUSHINE Automotive Seat FSRs integrate easily into both OEM and aftermarket applications.

Other brands also produce seat weight sensors for electric vehicles. Some companies focus on traditional technologies like strain gauges or bladder sensors. Others develop occupant classification sensor mats that use multiple sensing elements to improve accuracy. Brands may offer different features, such as adjustable sensitivity or compatibility with specific vehicle models.

The passenger seat sensor plays a critical role in modern safety systems. It detects if a person or object occupies the seat and communicates with the airbag control unit. SOUSHINE and other leading brands design their sensors to support these functions reliably. The passenger seat sensor must distinguish between adults, children, and objects to prevent false airbag deployment.

Note: High-quality seat weight sensors help maintain the effectiveness of the vehicle’s safety systems. Choosing a reputable brand ensures consistent performance and long-term reliability.

Seat Weight Sensor Calibration

Why Calibration Matters

Seat weight sensor calibration ensures that safety systems in electric vehicles function as intended. The Occupant Classification System (OCS) relies on accurate readings from these sensors to control airbag deployment and seatbelt tensioners. If seat weight sensor calibration is not performed correctly, the system may misjudge the occupant’s weight. This can result in airbags failing to deploy or deploying with the wrong force, which increases the risk of injury or death. Manufacturers require seat weight sensor calibration after any collision or seat removal. Even minor seat repairs can affect sensor accuracy and trigger diagnostic trouble codes. Electric vehicles depend on advanced occupant classification systems, making calibration necessary for seat weight sensors to maintain safety and reliability.

Accurate seat weight sensor calibration protects passengers by ensuring that airbags and seatbelt systems respond appropriately to real-world conditions.

Calibration Process

Technicians follow a structured process for seat weight sensor calibration. The procedure begins with preparing the vehicle. The car must sit on a level surface, and the seat must be free of extra weight. The technician connects specialized diagnostic equipment to the vehicle. The system then initializes the sensors. Some vehicles require manual calibration steps, while others use automatic routines. The technician places known weights on the seat to verify sensor accuracy. The system checks that readings match expected values. If the readings fall outside the acceptable range, the technician repeats the calibration process. Manufacturers provide specific instructions for each vehicle model. Calibration necessary for seat weight sensors often follows seat removal, airbag deployment, or any repair involving the seat structure.

A typical calibration process includes:

- Vehicle preparation and sensor initialization.

- Placement of standardized weights on the seat.

- System prompts for manual or automatic calibration steps.

- Verification of sensor readings.

- Final confirmation that the system operates within specifications.

Tip: Always use manufacturer-approved tools and follow the recommended procedure for seat weight sensor calibration.

Signs of Miscalibration

Several warning signs indicate problems with seat weight sensor calibration. Drivers may notice the airbag warning light turning on and off, especially when the seat moves or a passenger sits down. Diagnostic Trouble Codes (DTCs), such as negative system weight readings, often appear during system checks. The Occupant Classification Module (OCM) may classify the occupant incorrectly, which can disable airbags or trigger warning lights. Inconsistent or zero weight readings during sensitivity checks also signal miscalibration. Technicians sometimes find broken sensors, damaged wiring, or seat track issues during inspections. Weight sensor outputs that do not match expected values, such as zero or negative readings, require immediate attention. Calibration necessary for seat weight sensors becomes clear when these symptoms appear.

Common signs include:

- Airbag warning light illumination

- DTCs related to seat weight sensors

- Incorrect occupant classification

- Inconsistent or unexpected weight readings

- Visible damage to sensors or wiring

Regular seat weight sensor calibration helps prevent these issues and keeps safety systems reliable.

Common Issues and Maintenance

Faulty Sensor Symptoms

Seat weight sensors in electric vehicles can develop faults that affect safety systems. Drivers and technicians often notice several clear signs when a sensor malfunctions:

- Persistent airbag warning lights or fault codes that do not clear with standard OBD readers

- Erratic seat belt warnings or alarms, especially when the seat is empty but the system detects a passenger

- Increased frequency of alarms during hot weather, which can affect sensor sensitivity

- Physical damage or disrupted wiring under the seat, sometimes caused by objects like soda bottles

- The sensor mat, located beneath the seat upholstery, makes replacement complex and costly

- Temporary clearing of faults after unplugging and reconnecting the sensor connector, due to sensitivity to resistance or oxidation

These symptoms highlight the sensor’s critical role in detecting occupant presence and controlling airbag deployment and seatbelt reminders.

Troubleshooting

Diagnosing seat weight sensor issues requires a systematic approach. Technicians and vehicle owners can follow these steps:

- Restart the vehicle to clear temporary software glitches that may cause false error messages.

- Inspect all seat connections and wiring harnesses for security, damage, or corrosion.

- Check for physical damage, such as liquid spills or worn wiring, that could impair sensor function.

- Reset the airbag system by disconnecting the vehicle battery for several minutes or using manufacturer diagnostic tools to rebalance sensors and clear faults.

- Update the vehicle’s software to the latest version to address bugs and improve sensor communication.

- If problems persist, verify compatibility with the current software version and consider reverting to a previous stable version if necessary.

- Handle all components carefully to avoid accidental airbag deployment during inspection or repair.

Tip: Always consult the vehicle’s service manual or a qualified technician before attempting repairs on airbag-related systems.

Maintenance Tips

Regular maintenance helps prevent seat weight sensor issues and extends sensor life. Technicians recommend the following practices:

- Keep the area under the seat clean and free of debris or liquids that could damage wiring or connectors.

- Avoid placing heavy objects on the seat, which can trigger false occupant detection.

- Inspect seat wiring and connectors during routine vehicle maintenance.

- Address warning lights or unusual alarms promptly to prevent further system faults.

- Use only manufacturer-approved cleaning products and avoid excessive moisture near the seat base.

Routine care and early attention to warning signs help maintain the reliability of seat weight sensors and the safety systems they support.

When to Seek Help

Seat weight sensors play a vital role in the safety systems of modern electric vehicles. While many issues can be resolved with basic troubleshooting and regular maintenance, some situations require immediate attention from a professional. Recognizing these scenarios helps drivers maintain the integrity of their vehicle’s safety features and avoid unnecessary risks.

Vehicle owners should contact a qualified technician or dealership when they encounter the following situations:

- The airbag warning light turns on repeatedly, even after basic troubleshooting steps. This persistent indicator signals a recurring problem that may compromise the airbag system.

- The seat weight sensor or its wiring connection appears faulty or loose. Only a professional can accurately diagnose and repair these components to restore proper function.

- Electronic devices inside the vehicle cause interference, leading to airbag system malfunctions. Persistent interference requires inspection by a dealer or certified technician to prevent further complications.

- The vehicle remains under warranty. In this case, the dealer should address any sensor or seat pad issues to ensure compliance with manufacturer standards and maintain warranty coverage.

- Faults with the seat weight sensor or seat components occur consistently or can be reproduced. These issues often indicate the need for replacement parts or more extensive repairs.

- The sensor fails to reset or continues to display error codes after multiple attempts. This situation suggests a deeper problem that basic troubleshooting cannot resolve.

⚠️ Safety Alert: A malfunctioning seat weight sensor can disable the airbag system. In the event of a crash, this failure increases the risk of injury to occupants. Professional help ensures that all safety systems operate as designed.

Technicians possess the tools and expertise to perform advanced diagnostics, recalibrate sensors, and replace faulty components. They follow manufacturer guidelines to guarantee that repairs meet industry standards. Attempting complex repairs without proper training can lead to further damage or accidental airbag deployment.

Drivers should never ignore warning lights or persistent sensor issues. Timely intervention by a professional protects both the vehicle and its occupants. Regular checkups and prompt attention to warning signs help maintain the reliability of seat weight sensors and the overall safety of electric vehicles.

Seat weight sensors protect passengers in electric vehicles by ensuring airbags deploy at the right time and force. Regular calibration and maintenance keep these systems accurate. SOUSHINE Automotive Seat FSRs offer reliable detection with features such as fast response, thin size, and strong durability:

| Feature | Value / Details |

|---|---|

| Working Voltage | 5V |

| Response Time | <10ms |

| Thickness | 0.85mm |

| Certifications | ISO9001:2015, RoHS, UL, CE |

| Applications | Automotive seat detection |

Drivers should consult professionals for sensor issues or calibration to maintain safety and system performance.

FAQ

How often should seat weight sensors be calibrated?

Technicians recommend calibration after seat repairs, airbag deployment, or any collision. Regular calibration ensures accurate occupant detection and optimal safety system performance.

Can seat weight sensors detect the difference between a child and an adult?

Yes. Modern seat weight sensors classify occupants by weight. The system adjusts airbag deployment and seatbelt reminders based on the detected category.

What happens if a seat weight sensor fails?

A failed sensor may trigger warning lights or disable safety features. Drivers should seek professional inspection and repair to restore system reliability.

Are SOUSHINE Automotive Seat FSRs compatible with all electric vehicles?

SOUSHINE Automotive Seat FSRs fit many vehicle models. Always check compatibility with the specific make and model before installation.

Do heavy objects on the seat affect sensor accuracy?

Yes. Placing heavy items on the seat can trigger occupant detection. Remove objects to prevent false seatbelt or airbag alerts.

How can drivers maintain seat weight sensors?

Keep the seat area clean and dry. Inspect wiring during routine maintenance. Address warning lights promptly to avoid further issues.

What certifications do SOUSHINE Automotive Seat FSRs have?

SOUSHINE Automotive Seat FSRs are certified with ISO9001:2015, RoHS, UL, and CE.

When should a professional inspect the seat weight sensor?

Contact a technician if warning lights persist, sensor errors repeat, or after any seat-related repairs. Professional diagnostics ensure safety systems work as designed.