Call us: +86-137-2353-4866

Many engineers pick force sensitive resistor brands like SOUSHINE, Interlink, SparkFun, Adafruit, and Tekscan for their projects. Force sensitive resistors are important in new sensors. They help measure force and pressure fast and accurately. People care about accuracy, how long it lasts, price, how many ways you can use it, and if it is easy to add to other things. These sensors are used in many areas. Look at the table below to see where they are used:

| Industry | Common Applications |

|---|---|

| Automotive | Seat sensors, dashboards, steering controls |

| Healthcare | Prosthetics, patient monitors, rehab devices |

| Robotics | Tactile feedback, control systems |

| Consumer Electronics | Touchpads, gaming devices, smartwatches |

| Industrial | Manufacturing, automation, safety assurance |

| Aerospace & Military | Navigation, control systems, R&D |

Table of Contents

Key Takeaways

- Force sensitive resistors (FSRs) can sense touch and pressure. They do this by changing resistance when you press them.

- Top brands like SOUSHINE, Interlink, SparkFun, Adafruit, and Tekscan make sensors. Each brand has special features for different uses.

- FSRs are thin and flexible. They do not cost much. People use them in cars, healthcare, robots, and electronics.

- These sensors are simple to use in projects. They work well with microcontrollers like Arduino. You only need easy circuits.

- FSRs react quickly but are not as exact as load cells or strain gauges. They are best for basic force sensing.

- Picking the right FSR depends on things like how strong it is, where you use it, its size, how sensitive it is, and your budget.

- To use an FSR well, connect it the right way. You should also calibrate it with known weights. Mount it carefully for the best results.

- Wearable sensors with FSRs help track health and activity. They make sports training and medical checks better.

Top Picks Overview

Quick List of Best Force Sensitive Resistors

Here are the best force sensitive resistor products. Engineers and makers use these the most:

| Brand | Model / Series | Notable Features |

|---|---|---|

| SOUSHINE | Force Sensing Resistors | Custom shapes, low power, easy integration |

| Interlink | FSR 402 | Small size, affordable, flexible |

| SparkFun | FSR Series | Simple interface, good for prototyping |

| Adafruit | FSR Sensors | Reliable, easy to use, hobby-friendly |

| Tekscan | FlexiForce | High accuracy, wide force range, premium build |

Each brand has something special. SOUSHINE lets you pick different shapes and sizes. This helps people use them in special projects. Interlink FSR 402 is small and cheap. Many people like it for lots of uses. SparkFun and Adafruit are good for beginners. They are easy to use and work well for hobbies. Tekscan FlexiForce is very accurate and strong. It is great for hard jobs.

Why These Force-Sensitive Resistors Lead the Market

People pick these force-sensitive resistors because they fix real problems. SOUSHINE makes sensors that do not cost a lot. Their sensors use little power. This is good for things that run on batteries. SOUSHINE sensors last long and work well. The company helps users from start to finish. This makes projects easier.

Interlink FSRs work in many places. A study says Interlink sensors need to be set up for where they will be used. Changes in temperature and surfaces can change how well they work. They are cheap and can be used in many ways. But users should check them for best results. SparkFun and Adafruit are easy for new users. Their simple design helps people connect them fast.

Tekscan FlexiForce is very accurate. Tests show FlexiForce sensors give steady results over time. They measure force better than other types. They work well even when the load area changes. Data from the maker shows FlexiForce can measure many different forces. This makes them useful for many jobs.

These brands care about quality. Users get sensors that work the same every time. They also help with problems fast. You can pick custom shapes and sizes for your project. These sensors use little power and are easy to add to devices. People use them in medical tools and smart home gadgets.

People use force sensitive resistor products in many fields. These top picks are special because they are new, accurate, useful, and not too expensive.

Force Sensitive Resistor Basics

What Is a Force Sensitive Resistor?

A force sensitive resistor is a sensor that changes resistance when pressed. People use these sensors in many products because they are thin and bend easily. They are simple to add to different things. When you press the sensor, more electricity can move through it. This makes it good for finding touches in touchpads, smart devices, and robots.

How Force-Sensitive Resistors Work

Force-sensitive resistors use something called the piezoresistive principle. Inside, there is a special film with tiny particles. When you press down, the particles get closer together. This makes new paths for electricity to move. The resistance gets lower when this happens. At first, the sensor has very high resistance if no one touches it. When you press harder, the resistance goes down. People can measure this change to know how much force is used.

- The sensor has high resistance when not pressed.

- When you press it, resistance drops to lower values.

- This happens because the inside material changes with pressure.

- The link between force and resistance is not perfect, but you can adjust the sensor for better results.

- Many people use a simple circuit to read the sensor and match it to the force.

This design lets the sensor notice even small touches. It helps in places where gentle touches matter.

Key Features and Limitations

Force sensitive resistors have some clear good points. They are light, bendy, and cost less than other sensors. People like them for fast projects and things that need to sense touch or pressure. They work well in small spaces or where the sensor needs to bend.

But these sensors are not as exact or steady as load cells or strain gauges. Load cells and strain gauges give very exact and repeatable results. They also need less fixing over time. Force sensitive resistors need to be checked more often and may not work well in tough places. They are best for rough guesses, not for jobs that need exact numbers for many years.

Here’s a quick comparison:

| Sensor Type | Accuracy | Durability | Cost | Best Use Case |

|---|---|---|---|---|

| Force Sensitive Resistor | Moderate | Moderate | Low | Touch, pressure detection |

| Load Cell | High | High | Higher | Industrial force measurement |

| Strain Gauge | High | High | Moderate | Precision measurement |

People pick force sensitive resistors when they want a simple, bendy, and cheap way to sense force or touch.

Product Comparison

SOUSHINE Force Sensing Resistors

Features

SOUSHINE makes force sensing resistors that use the piezoresistive principle. These sensors have a bendy base with a printed circuit and a layer that carries electricity. You can pick different shapes and sizes for your needs. The sensors use little power and fit many types of devices. SOUSHINE helps people connect their sensors to other electronics and gives technical support.

Pros

- You can choose shapes and sizes for special projects.

- They use little power, so they are good for battery devices.

- It is simple to add them to new or old products.

- The design is strong for hard places.

- They work in cars, hospitals, robots, electronics, factories, and planes.

- They do well in pressure mapping systems.

Cons

- No big problems have been reported.

Interlink FSR 402

Features

Interlink FSR 402 is a well-liked force sensitive resistor. It is thin and bends, so it fits in small spots. The sensor finds force by changing its resistance. Many people use it for learning and making things at home. It works in pressure mapping and wearable gadgets.

Pros

- It is small and bends to fit tight places.

- It does not cost much, so it is good for cheap projects.

- It is easy to use with simple circuits.

- It helps people learn about sensors and electronics.

- People use it in smart insoles, fun devices, and pressure mapping.

Cons

- There are no outside tests for how long it lasts.

- It only gives a rough idea of force, not exact weight.

- The plastic is thin and must be handled with care.

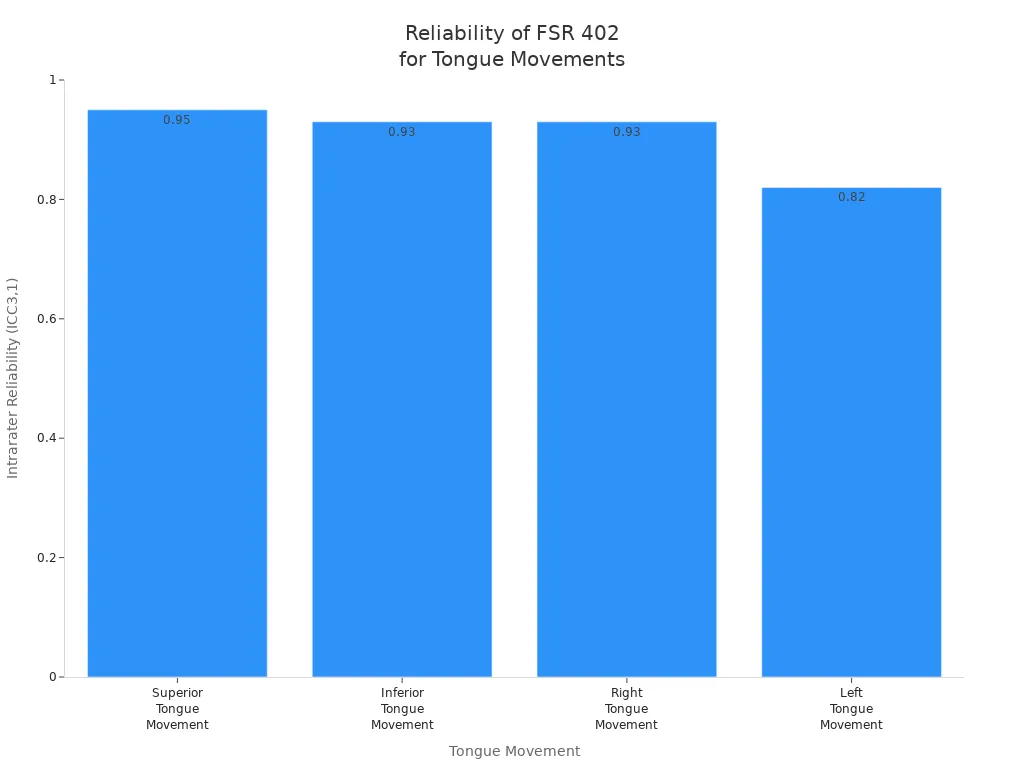

The Interlink FSR 402 works very well for measuring tongue force. Tests done by others show it gives the same results for different tongue moves. This sensor is good for school and business projects.

| Tongue Movement | Intrarater Reliability (ICC3,1) | Notes on Reliability Comparison |

|---|---|---|

| Superior Tongue Movement | > 0.95 | Highest ICC; better than IOPI (0.77-0.90) and KSW (0.92) devices |

| Inferior Tongue Movement | > 0.93 | Excellent reliability |

| Right Tongue Movement | > 0.93 | Excellent reliability |

| Left Tongue Movement | > 0.82 | Good reliability |

- Some ways people use it:

- Smart insoles for checking pressure

- Wearable tech

- Fun interactive gadgets

- School sensor projects

SparkFun FSR

Features

SparkFun FSR sensors are easy to use with microcontrollers like Arduino. They fit into breadboards and need simple wires. You use a voltage divider circuit to read force changes. These sensors are good for basic force checks in test projects and hobbies.

Pros

- They are easy to use with Arduino and other microcontrollers.

- They fit breadboards, so you can build fast.

- They are cheap for projects that need to save money.

- They are good for learning and trying new things.

- There are lots of code examples for beginners.

Cons

- They are not good for jobs that need high accuracy.

- They are less exact than load cells.

SparkFun FSRs are great when you care more about price than perfect results. They work well for simple force checks. You can use them to change things like how bright an LED is. The setup is simple but you need to know about voltage dividers.

Adafruit FSR

Features

Adafruit FSR sensors are thin and light. They can measure force from 30 grams to 1,000 grams. The sensor reacts very fast, in less than 1 millisecond. It can be pressed over 5 million times before it breaks. The sensor works in cold and hot places, from -30°C to +85°C. It gives a smooth analog signal, so it can sense small pressure changes. You can use it with breadboards, alligator clips, or terminal blocks. You can solder the tabs, but you must be careful. The plastic tabs can melt if they get too hot.

| Specification | Details |

|---|---|

| Dimensions | 60.4mm x 18.33mm x 0.56mm |

| Weight | 0.9g |

| Force Sensitivity Range | 30g to 1000g |

| Force Resolution | Continuous (Analog) |

| Stand-off Resistance | >20MΩ |

| Force Repeatability (single part) | 2% |

| Force Repeatability (part to part) | 10% within a batch |

| Response Time | <1ms |

| Life Cycle | >5 Million cycles |

| Operating Temperature | -30°C to +85°C |

Pros

- Beginners and hobbyists find the sensor easy to use.

- It fits well in breadboard projects.

- The sensor reacts quickly to force changes.

- It can handle millions of presses.

- There are guides and tutorials to help you.

- You can use it in touchpads, robots, and pressure maps.

Lab tests show Adafruit FSR sensors can track heart rate and breathing during sleep. The sensor works for both men and women. The error stays low, even when people move in bed. The setup is simple and does not need much fixing. This makes it good for long-term checks that do not bother people.

Cons

- The sensor does not give exact force numbers. It shows a range, not a single value.

- Each sensor can be about 10% different from others in the same group.

- Soldering the tabs can hurt the sensor if you are not careful.

- It is best for simple force checks, not for jobs that need perfect numbers.

Tekscan FlexiForce

Features

Tekscan FlexiForce sensors are very accurate and can measure many force levels. The sensor gives steady results, even if the force is spread out. Some models work in very hot places, up to 400°F. The sensor is thin and light, so it fits in small spaces. Tekscan checks every custom sensor before sending it out. The company follows strict rules for medical devices. You can order custom sensors in small or big amounts. The company also helps with design and technical questions.

| Feature | Description |

|---|---|

| Superior linearity & accuracy | ±3% accuracy for precise measurements |

| Wide force measurement range | Measures small and large forces |

| Output independent of loading area | Consistent readings, no matter where force is applied |

| High temperature versions | Operates up to 400°F |

| ISO 13485:2016 Registered | Meets medical device quality standards |

| 100% tested custom sensors | Each sensor tested for quality |

| Thin, lightweight, durable | Fits in compact medical and industrial devices |

| Expert technical guidance | Support for design and customization |

| Scalability in production | Orders from 1,000 to millions possible |

Pros

- The sensor gives results that are both accurate and repeatable.

- It works in medical and industrial places.

- The sensor can measure both small and big forces.

- It works in very hot places.

- The thin design fits in tight spots.

- Tekscan gives custom options and technical help.

Cons

| Limitation | Description | Impact / Notes |

|---|---|---|

| Nonlinearity at high forces | Accuracy drops above 250 N | Linearity error rises to 13.2% at 2000 N |

| Need for individual calibration | Each sensor needs its own calibration, especially after trimming | Calibration is key for best results |

| Sensitivity reduction on small area | Force on a small spot lowers sensitivity | May underestimate force if pressure is too high |

| Vulnerability to shear forces | Shear forces can damage the sensor | Users should avoid shear in their designs |

| Sensitivity decrease with usage | Sensor loses sensitivity over time | Long-term reliability may drop |

| Output saturation | Some sensors reach a limit and stop increasing output | Limits the range and accuracy of measurements |

| Variation in sensitivity | Sensitivity can differ between sensors | Placement and calibration are important |

| Linearity and hysteresis | Good linearity and low hysteresis below 120 N | Works well for both static and moving force measurements |

| Sensor trimming | Sensors can be cut to fit, but need recalibration | Offers flexibility, but users must recalibrate |

Other Brands

Features

Many other companies make force sensitive resistors. Some well-known ones are Nissha, New Degree Technology, Citizen Electronics, Memtronik, Butler Technologies, Hanwei Electronics Group, FSRTEK, NextInput (Qorvo), Ohmite, Techprint, TAIWAN ALPHA ELECTRONIC, Tangio Printed Electronics (Sytek), Ruihu, Sensitronics, Legact, Cubbison, CERADEX, and Reid Industrial Graphic Products. These brands have many shapes, sizes, and force ranges. Many work on new ideas to make their sensors better. Some focus on smart features and flexible ways to make sensors.

Pros

- Many brands let you pick custom sensor shapes.

- Some companies give strong technical help.

- Many sensors work in lots of industries, like electronics and factories.

- Brands often add new features to their products.

- Some companies work on smart sensors that use AI.

Cons

- Quality and how well they work can change between brands.

- Some brands do not give much technical help.

- Not all sensors are easy to use with every system.

- You may need to try a few brands to find the best one for your project.

Applications of Force Sensitive Resistors

Automotive

Force sensitive resistors make cars safer and smarter. Engineers put these sensors in car seats. The sensor can tell if someone is sitting down. This helps airbags work at the right time. Car makers also use them in dashboard and steering wheel controls. Drivers can change settings with a soft touch. These sensors are thin and bendy, so they fit in small spaces. They do not use much power, which is good for battery parts. Car companies like them because they are cheap and easy to connect.

Common automotive uses for force sensitive resistors:

- Seat occupancy detection

- Airbag deployment systems

- Touch-sensitive dashboard controls

- Steering wheel pressure sensors

Sensors in cars must work fast and be accurate. This is important for safety. Their thin shape lets engineers hide them in seats and panels. Using little power helps batteries last longer. Low cost and easy setup make force sensitive resistors popular in new cars.

Healthcare

Doctors and nurses use force sensitive resistors in many medical tools. These sensors help drug pumps find blockages. If pressure changes, the pump warns the patient. In micro-needle therapy, the sensor checks if the device is in the right spot. It makes sure medicine goes where it should. CPR tools use these sensors to measure how hard someone presses. This feedback can help save lives.

Medical device makers must follow strict rules. They use safe and recyclable materials. Sensors must pass tests for accuracy and reliability. Groups like the FDA and EPA set these rules. Many companies buy from ISO 13485-certified suppliers. Engineers want sensors that use little power and fit in small devices. They also need to send data to doctors quickly. Wearable sensors track patient movement and vital signs. These sensors let doctors watch patients without wires or big machines.

Healthcare applications for force sensitive resistors:

- Drug-delivery pumps

- Micro-needle therapy devices

- CPR assistive tools

- Patient monitoring systems

- Wearable sensors for health tracking

Robotics

Robots need to feel touch and pressure to work well. Force sensitive resistors help robots sense objects. Engineers put these sensors in robot fingers, feet, and fake skin. The sensor measures force right away. Robots use this to hold things without dropping or breaking them. The thin and bendy design lets sensors fit on curved parts like fingers and feet.

Robots use these sensors to control grip and balance. Many sensors on the robot’s body can sense touch from all sides. This helps robots work safely with people and things. Fast sensors let robots change their grip quickly. Engineers can pick sensors for light or strong forces. Wearable sensors in robots help track movement and improve control. Some robots use force sensitive resistors with other sensors to check temperature and moisture.

Robotics applications for force sensitive resistors:

- Tactile sensing in robotic hands and feet

- Grip control for object handling

- Balance and gait stability

- Human-robot interaction safety

- Wearable sensors for movement tracking

Consumer Electronics

People use force sensitive resistors in many gadgets. These sensors help devices know when you touch or press them. They make electronics smarter and easier to use. Engineers put them in things people use every day.

- Cursor control devices move the pointer when you press harder.

- Musical instrument controllers change sound with more or less force.

- Stylus signature controllers help record handwriting and signatures.

- Matrix arrays let one device have many buttons or touch spots.

- Interactive dolls react when you squeeze or touch them.

- Remote controls use force sensors for better control.

- Joysticks work with different pressure levels.

- Musical toys play notes when you press them.

Force sensitive resistors make devices more fun and interactive. Kids like toys that react to their touch. Gamers enjoy controllers that sense how hard they press. Musicians use instruments that change sound with pressure. These sensors help people with disabilities use devices more easily.

Wearable sensors in electronics track movement and pressure. Smartwatches and fitness bands use them to count steps and activity. People like gadgets that give feedback when touched. These sensors make technology feel more personal.

Industrial

Factories use force sensitive resistors to make work safer and faster. Workers use these sensors to control machines and check pressure. Engineers pick the right sensor for each job. They mount the sensor tightly and connect it to the system. Calibration helps the sensor give correct readings.

1. Workers pick the sensor for the force range needed. 2. They put the sensor where it can measure pressure best. 3. They mount the sensor so it stays in place. 4. They connect the sensor to the automation system. 5. They calibrate the sensor for the process.

Regular checks keep sensors working well. Workers look for damage and clean sensors to stop sensitivity loss. Recalibration keeps measurements correct. If problems happen, they check the mounting, wires, and software.

Robotic grippers in factories use force sensitive resistors as tactile sensors. These sensors help robots hold things gently. Robots can pick up fragile items without breaking them. The sensors help robots know where objects are and how to move. Haptic feedback lets workers control robots better.

Wearable sensors in factories help track worker movement and safety. These sensors can warn workers if they use too much force or move in unsafe ways. Factories use them to stop injuries and help with training.

Aerospace

Aerospace engineers use force sensitive resistors in planes and spacecraft. These sensors help measure pressure and force in control systems. Pilots use sensors to check if controls work right. The sensors fit in small spaces and work in tough conditions.

Force sensitive resistors help watch seat pressure and control stick movement. They also help test new materials and designs. Engineers use them in research to make things safer. The sensors work well with vibration and temperature changes.

Aerospace companies pick sensors that last long and use little power. They need sensors that work in very hot or cold places. Force sensitive resistors help keep systems safe and reliable.

Wearable Sensors

Wearable sensors help people track health and activity. These small devices fit into things people wear, like watches, shoes, and fitness bands. Force sensitive resistors are important in these devices. They measure pressure and force right away. Many people use wearable sensors to check heart rate and breathing. Some sensors can even check blood pressure. Doctors use them to watch patients with breathing problems. They also help people recover from injuries.

New technology makes wearable sensors more flexible and comfy. Companies use materials that bend and stretch. This helps sensors fit better on the body. People can wear them while running, swimming, or sleeping. The sensors keep working, even if you move a lot. Smartwatches use force sensitive resistors to track pulse and steps. Shoes with these sensors check how someone walks or runs. This helps doctors see if a patient is healing after a broken bone. Coaches use them to watch how athletes move.

In sports, wearable sensors help coaches and trainers. The sensors collect data on how hard someone pushes or how fast they move. Some systems use artificial intelligence to study this data. They can find problems before someone gets hurt. For example, a runner’s shoe can show if they put too much pressure on one foot. The coach can use this to change the runner’s training. Swimmers can wear sensors that work in water. These sensors track how the swimmer moves and how much force they use.

Wearable sensors help people in daily life too. Fitness bands count steps and watch sleep patterns. Some smart clothes have sensors that check posture. People who play music or games can use gloves with force sensitive resistors. The gloves sense how hard they press keys or buttons. This makes playing music or games more fun.

Tip: Pick wearable sensors that feel comfy and give clear data. Make sure the sensor works well when you move. Check if it connects easily to your phone or computer.

Wearable sensors keep getting better. They help people stay healthy and improve sports performance. They also make daily life easier. As technology grows, these sensors will become even more useful and common.

Choosing Your Force Sensitive Resistor

Matching Product to Project

Choosing the right force sensitive resistor for a project can feel tricky. Each project has its own needs. Some need a sensor that fits in a small space. Others need a sensor that can handle rough use. The table below shows what to think about when picking a sensor:

| Factor | What to Consider |

|---|---|

| Durability | The sensor should handle bumps and pressure. FSRs work well in tough spots and last longer than some other sensors. |

| Environment | The sensor must work in dust, moisture, or big temperature changes. FSRs can handle -25°C to 85°C. |

| Form Factor | Some projects need thin or bendy sensors. FSRs fit in tight or odd-shaped spaces. |

| Repeatability | If you make many devices, you want each sensor to work the same. Some brands, like Interlink, do this well. |

| Sensitivity | Think about how much force you need to measure. Some FSRs can sense up to 150 N. |

| Cost | Pick a sensor that fits your budget. Sometimes a cheaper sensor works just as well for your needs. |

People who build force measurement systems often look for sensors with good sensitivity to low forces. This helps them get better results in their projects.

Tip: Make a list of what your project needs before you shop for sensors. This helps you find the best match faster.

Budget and Value

Price matters for most projects. Some sensors cost more because they offer higher accuracy or special features. Many FSRs give good value for the price. If a project does not need perfect accuracy, a lower-cost sensor can work well. Makers and students often pick budget-friendly sensors for learning and testing ideas.

- Compare prices from different brands.

- Check if the sensor gives the features you need.

- Think about buying in bulk for bigger projects.

- Look for sensors that come with support or guides.

A sensor that costs less but meets all your needs is a smart choice. Sometimes, paying a little more gives you better support or longer life.

Durability

Durability is key for sensors that see a lot of use. The way a sensor is built affects how long it lasts. FSRs have two layers that touch when pressed, with a spacer in between. Good assembly keeps the sensor working longer. High conductivity helps the sensor pick up even small forces.

- Sensors with strong insulating layers last longer.

- Textile-based FSRs can handle over 1,000 presses at 15 N without losing performance.

- Quick response and recovery times show the sensor can keep up with fast changes.

- Materials like TPU and special inks help the sensor stay flexible and tough.

When connecting FSRs, people use breadboard tabs, IC hooks, or alligator clips for quick tests. For long-term use, soldering works best, but it needs care. The sensor’s materials can melt if the soldering iron gets too hot or stays on too long. Experts use low heat and work fast to avoid damage.

Note: If you plan to use the sensor for a long time, learn the right way to solder. This keeps your sensor working and safe.

Integration

Getting a force sensitive resistor (FSR) to work in a project takes a few steps. Many people want to know how to connect the sensor, read its data, and use it with other parts. Good integration helps the sensor give better results and last longer.

1. Connecting the Sensor

Most FSRs have two pins. People often use a breadboard or solder the pins to wires. The sensor works well with microcontrollers like Arduino, Raspberry Pi, or ESP32. To read the sensor, users set up a simple voltage divider circuit.

Tip: Use a pull-down resistor between 10kΩ and 100kΩ. This helps the sensor give a clear signal.

2. Reading the Output

FSRs change resistance when pressed. The microcontroller reads this change as a voltage. People use an analog input pin to get the data. The code then turns the voltage into a number that shows how much force is on the sensor.

Here is a simple code example for Arduino:

int fsrPin = A0;

int fsrReading = 0;

void setup() {

Serial.begin(9600);

}

void loop() {

fsrReading = analogRead(fsrPin);

Serial.println(fsrReading);

delay(100);

}

3. Calibration

Each sensor can act a little different. Users press known weights on the sensor and write down the readings. This helps match the sensor’s output to real force values. Calibration makes the sensor more useful for real-world tasks.

4. Placement and Mounting

People place the FSR where it will get the right amount of force. The sensor should sit flat and not bend too much. Some use foam pads to spread the force. Good mounting stops the sensor from wearing out too fast.

5. Compatibility

FSRs work with many boards and systems. Users check the voltage and current limits before connecting. Most FSRs run on 3.3V or 5V. They do not need much power, so they fit well in battery projects.

6. Software Integration

Many libraries and guides help users add FSRs to their code. People can find sample code for Arduino, Python, and other languages. Some projects use the sensor to control lights, motors, or sounds.

| Step | What to Do | Why It Matters |

|---|---|---|

| Connect sensor | Use breadboard or solder wires | Makes setup easy |

| Build circuit | Add pull-down resistor | Gets clear signal |

| Read data | Use analog input on microcontroller | Turns force into numbers |

| Calibrate | Test with known weights | Matches output to real force |

| Mount sensor | Place flat, use foam if needed | Stops damage, gets good data |

| Check compatibility | Match voltage and current | Keeps sensor safe |

| Add code | Use sample libraries | Saves time, avoids mistakes |

Note: Always test the sensor after setting it up. Small changes in wiring or code can change the results.

Good integration means the FSR works well and gives useful data. People who follow these steps can use FSRs in many projects, from robots to smart gadgets.

SOUSHINE, Interlink, SparkFun, Adafruit, and Tekscan all make good force sensitive resistors. People want different things from these brands. Hobbyists like SparkFun or Adafruit because they are simple to use. Professionals pick SOUSHINE or Tekscan for better accuracy and help. Teachers choose Interlink for school projects.

Before you buy, think about what your project needs. If you have questions or want to tell your story, write a comment below!

FAQ

What is a force sensitive resistor used for?

People use force sensitive resistors to measure touch or force. These sensors are found in cars, robots, and medical tools. They help machines know when something pushes on them.

How do you connect a force sensitive resistor to a microcontroller?

You connect two pins from the sensor to a circuit. One pin goes to power, and one goes to ground. The microcontroller checks the voltage change to measure force.

Can force sensitive resistors measure exact weight?

Force sensitive resistors give a rough idea of force. They do not measure exact weight like load cells do. They work well for simple touch or pressure checks.

Are force sensitive resistors reusable?

Yes, you can press and release these sensors many times. Most brands make them to last for thousands or millions of presses.

Do force sensitive resistors work in cold or hot places?

Many force sensitive resistors work in cold and hot places. They often work from -25°C to 85°C. Always check the datasheet for the exact limits.

What is the difference between an FSR and a load cell?

An FSR senses touch or pressure and reacts fast. A load cell measures weight with high accuracy. Load cells cost more and need extra setup.

Can you cut a force sensitive resistor to fit your project?

Some brands let you trim the sensor to fit your project. After cutting, you should recalibrate the sensor. Always follow the instructions from the maker.

How do you calibrate a force sensitive resistor?

You put known weights on the sensor and write down the readings. Use this data to match the sensor output to real force values. Calibration helps make the sensor more accurate.