Call us: +86-137-2353-4866

Accurate and reliable level measurement is a critical requirement in numerous industrial processes. Traditional methods can be invasive, complex, or unreliable with certain materials. SOUSHINE’s force sensing technology offers a robust, non-contact solution for determining the level of liquids, powders, and granular solids within a container by precisely measuring its total weight. This method provides high reliability and is suitable for a wide range of vessel types and materials.

What is Force Sensor-Based Level Sensing?

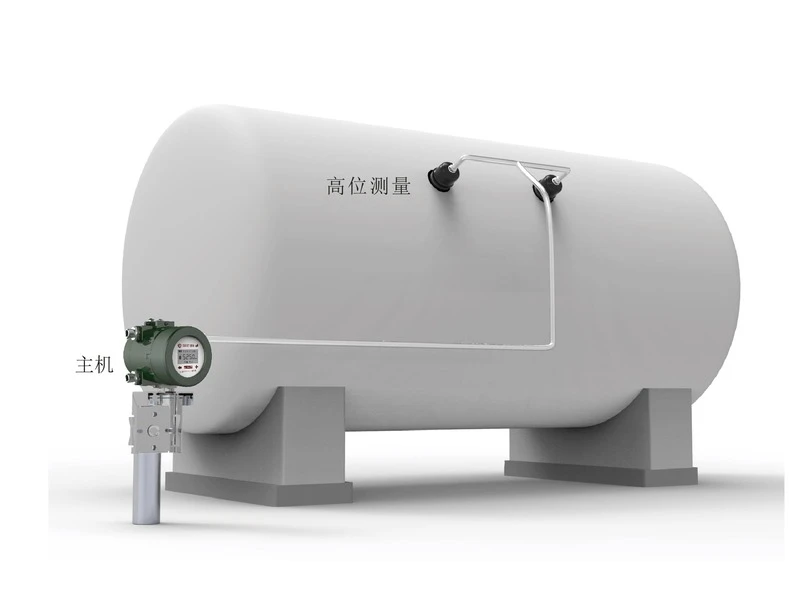

Force sensor-based level sensing is an indirect measurement technique. Instead of using a probe or sensor inside the container that comes into contact with the material, this method places high-precision force sensors, such as Force Sensing Resistors (FSRs), at the container’s support points.

The system works by continuously measuring the total weight of the container and its contents. As material is added or removed, the corresponding change in weight is detected by the force sensors. This weight data is then converted into a level reading based on the known geometry of the container and the density of the material being measured.

How It Works: The Measurement Principle

The implementation of a force sensing level measurement system is straightforward and effective.

- Sensor Installation: One or more force sensors are installed under the legs, feet, or supporting structure of the tank, silo, or vessel. The number and capacity of the sensors are selected based on the total weight of the filled container.

- System Calibration (Tare): An initial measurement is taken with the container empty. This “tare weight” is recorded by the system’s electronics and is subtracted from all subsequent measurements, ensuring that only the weight of the contents is measured.

- Force Detection: As the container is filled, the increasing weight exerts a proportional force on the sensors. A Force Sensing Resistor (FSR) responds to this force with a predictable change in its electrical resistance.

- Signal Processing: An electronic interface module reads the change in resistance from the FSRs and converts it into a standardized electrical signal (e.g., analog voltage, 4-20mA current loop, or digital output).

- Level Calculation: The system’s controller or PLC (Programmable Logic Controller) uses the weight data, along with pre-configured parameters like the vessel’s cross-sectional area and the material’s specific gravity, to accurately calculate the real-time level of the contents.

Why Use Force Sensing for Level Measurement? Key Advantages

Integrating force sensors for level measurement provides distinct technical and operational advantages over other technologies.

- Non-Invasive Measurement: The sensors never come into contact with the stored material. This is critical for applications involving corrosive chemicals, hygienic products (food, pharmaceuticals), abrasive solids, or high-purity substances.

- High Reliability & Low Maintenance: The system has no moving parts inside the vessel, eliminating issues like material build-up, clogging, or mechanical failure. This results in significantly reduced maintenance requirements.

- Material Versatility: The measurement is unaffected by material properties such as conductivity, dielectric constant, viscosity, foam, or dust. It performs reliably with liquids, slurries, powders, and granular solids.

- Simplified Installation & Retrofitting: Force sensors can be installed on existing vessels without requiring tank modifications, welding, or process downtime, making it an ideal solution for retrofitting.

- Comprehensive Inventory Management: By measuring weight, the system provides a direct measurement of mass, which is often a more valuable metric for inventory control than volumetric level alone.

SOUSHINE’s Force Sensing Solutions for Level Measurement

SOUSHINE specializes in the research, development, and manufacturing of high-performance Force Sensing Resistors designed for demanding industrial applications, including level sensing. Our FSRs offer:

- High Durability: Built to withstand the harsh conditions of industrial environments.

- Customizable Designs: We can engineer sensors in various shapes, sizes, and force ranges to meet the specific structural requirements of your vessels.

- Consistent Performance: Our manufacturing processes ensure high lot-to-lot consistency for predictable and repeatable measurements.

Contact our engineering team to discuss your level sensing application and how our force sensing technology can be integrated into your system.

Display

FAQ

How accurate is level sensing using force sensors?

The accuracy of the system depends on several factors, including the quality of the force sensors, the stability of the vessel’s support structure, proper calibration, and the resolution of the electronics. A well-designed system can achieve high levels of accuracy, often within 0.5% to 1% of the vessel’s full capacity.

Can this method be used for irregularly shaped tanks?

Yes. While linear level calculation is simplest with vertically uniform tanks (e.g., cylinders), this method can be adapted for irregularly shaped vessels. It requires creating a more complex calibration curve (a “strapping table”) in the system’s software that correlates specific weight values to corresponding liquid levels.

How do temperature fluctuations affect the measurement?

Significant temperature changes can cause thermal expansion and contraction of the vessel and its support structure, which can influence force readings. For high-precision applications, temperature compensation can be integrated into the system electronics. SOUSHINE can provide detailed technical specifications on the thermal performance of our sensors.

Is this technology suitable for environments with heavy vibration?

Yes. The signal processing electronics can incorporate advanced filtering algorithms to average out the signal noise caused by vibration from nearby machinery or mixing processes, ensuring a stable and accurate output.

What kind of data output can be provided?

The raw sensor provides a resistance output. This is typically fed into a signal conditioner or transmitter that can provide industry-standard outputs, including 4-20mA, 0-10V, RS-485, or other digital protocols compatible with PLCs, SCADA systems, and other industrial controllers.