Call us: +86-137-2353-4866

Membrane switches are a core component in the design and function of modern remote controls. Their application spans a vast array of consumer electronics, from television and air conditioner remotes to audio system controllers. This technology offers a reliable and efficient interface for user commands, combining functionality with a streamlined design. SOUSHINE specializes in the research, development, production, and sale of high-quality membrane switches tailored for the consumer electronics sector.

What Are Membrane Switches in Remote Controls?

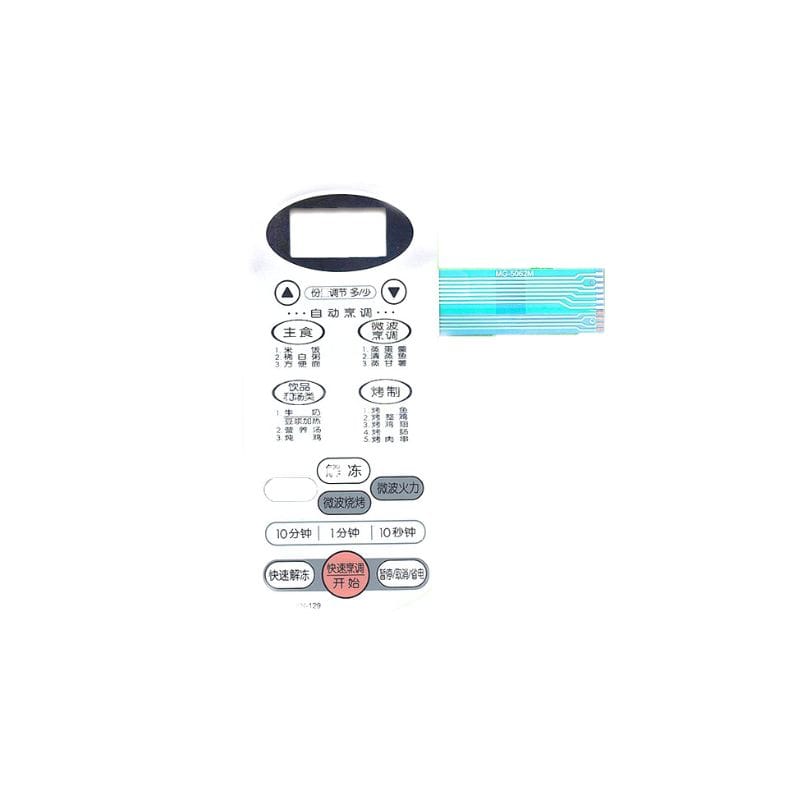

A membrane switch is a momentary electrical contact device that opens and closes a circuit. In the context of a remote control, it is a multi-layered assembly that functions as the keypad. Unlike traditional mechanical buttons, a membrane switch is constructed from thin, flexible polymer films with conductive traces printed on them. When a user presses a button on the remote’s graphic overlay, it actuates the switch mechanism beneath.

The typical construction of a membrane switch for a remote control includes:

- Graphic Overlay: The top layer, made from materials like polyester or polycarbonate, which displays the button graphics and provides the user interface. It is resistant to environmental factors.

- Adhesive Layers: These layers bond the different functional films of the switch together.

- Circuit Layers: These are typically PET (polyethylene terephthalate) films with screen-printed conductive inks (e.g., silver) forming the circuit paths. There is an upper and a lower circuit layer separated by a spacer.

- Spacer Layer: This layer contains cutouts at the switch locations, creating a gap between the top and bottom circuit layers to prevent accidental actuation.

- Rear Adhesive: This final layer allows the entire membrane switch assembly to be mounted to the remote control’s housing.

How Do Membrane Switches Function in Remote Controls?

The operation of a membrane switch in a remote control is based on a straightforward principle. The upper and lower circuit layers contain the two halves of a switch at each button location. These are held apart by the spacer layer.

- Actuation: When a user presses a specific button on the graphic overlay, the flexible top layer deforms.

- Contact: This pressure pushes the conductive contact on the underside of the top circuit layer through the opening in the spacer layer.

- Circuit Closure: The top conductive contact touches the bottom conductive contact on the lower circuit layer, closing the circuit.

- Signal Transmission: This closure generates an electrical signal that is sent to the remote control’s integrated circuit (IC), which then processes the command and transmits it (typically via an infrared LED) to the receiving device (e.g., TV, air conditioner).

- Release: When the user releases the button, the top layer returns to its original position, separating the contacts and opening the circuit.

For tactile feedback, metal or polyester “snap domes” can be integrated into the switch construction, providing a distinct “click” sensation upon actuation.

Why Use Membrane Switches for Remote Controls?

The selection of membrane switches for remote control applications is driven by several key technical and performance advantages:

- Low Profile and Design Flexibility: The thin-film construction allows for very slim and lightweight remote control designs. The graphic overlay can be custom printed, offering significant freedom in aesthetics and layout without the constraints of individual mechanical buttons.

- Sealed Design and Durability: The top surface is a continuous, sealed layer, providing excellent resistance to dust, dirt, and liquid spills. This enhances the longevity and reliability of the remote control. The sealed design is also easy to clean and maintain.

- Cost-Effectiveness in High-Volume Production: The materials and manufacturing processes for membrane switches are highly efficient for large-scale production, making them a cost-effective solution for the consumer electronics market.

- High Reliability: With fewer moving parts compared to mechanical switches, membrane switches offer a long operational life, often rated for millions of actuations.

- Integration Capabilities: Membrane switches can be designed to incorporate backlighting (e.g., LEDs) for use in low-light conditions and can be integrated with other electronic components seamlessly.

SOUSHINE’s Capabilities for Remote Control Applications

As a company with expertise in R&D and production, SOUSHINE can provide customized membrane switch solutions for remote control manufacturers. Our capabilities include:

- Custom Graphic Overlays: Tailored designs, colors, and button configurations to match brand identity and product functionality.

- Tactile and Non-Tactile Feedback: Solutions with integrated metal or poly-domes for tactile feedback, or non-tactile designs for a flat, silent operation.

- Material Selection: A range of substrate and overlay materials to meet specific durability, chemical resistance, and environmental requirements.

- Integrated Electronics: Embedding of LEDs for backlighting or status indication directly into the membrane switch assembly.

- Connector and Termination Options: Various tail connector types to ensure compatibility with the product’s PCB.

Display

FAQ

What is the typical lifespan of a membrane switch in a remote control?

Membrane switches are highly reliable and are typically rated for one million to ten million actuations, depending on the specific materials and construction used. This ensures a long operational life for the remote control under normal use conditions.

Can membrane switches provide the same “clicky” feel as traditional rubber buttons?

Yes. By incorporating small, domed metal or polyester discs (snap domes) under each button location, a membrane switch can provide distinct tactile feedback that confirms to the user that the button has been pressed.

Are membrane switch-based remote controls resistant to spills?

The top surface of a membrane switch is a single, sealed overlay. This construction provides a high degree of resistance to liquids and dust, making the remote control more durable and easier to clean than many designs using individual mechanical buttons.

Is it possible to have backlighting on a remote control with a membrane switch?

Yes. Light Emitting Diodes (LEDs) can be embedded within the layers of the membrane switch assembly to provide backlighting for the keypad, enhancing usability in low-light environments.

How does the cost of a membrane switch compare to a traditional mechanical switch keypad?

For high-volume consumer electronics like remote controls, membrane switches are generally more cost-effective. The manufacturing process is highly scalable, and the integrated design reduces the need for assembling numerous individual components.