Call us: +86-137-2353-4866

SOUSHINE is a top company for force sensing resistors in cars. Drivers and engineers trust these smart devices. They use membrane FSRs and piezoresistive sensors. These help cars stay safe and smart. A seat belt sensor works when you buckle up. A seat occupancy sensor tells who is sitting in the front seat. The SBR system uses force sensing resistors for reminders. These sensors help braking and hydraulic systems work better. TPMS also uses force sensing resistors for good readings. People choose force sensing resistors because they last long. They are not expensive and work well. They give results without problems.

Table of Contents

Key Takeaways

- Force sensing resistors help keep cars safe. They can tell if someone is sitting in a seat. They also check if the seat belt is being used.

- Membrane FSRs are thin and bend easily. They fit well in small spaces. This makes them good for seats and pedals.

- Piezoresistive sensors work well in tough places. They give good data for brakes and tire pressure systems.

- FSRs need to be checked and fixed often. This helps them give correct readings and last longer.

- SOUSHINE’s FSRs do not cost much. This lets car makers add safety parts to all kinds of cars.

- Force sensors help brakes work better. This makes stopping smoother and gives drivers more control.

- Things like heat and wet air can change how sensors work. So, sensors must be made and tested with care.

- New force sensing technology will make cars smarter. Cars will have better safety and can fix problems before they get worse.

Types of Force Sensing Resistors

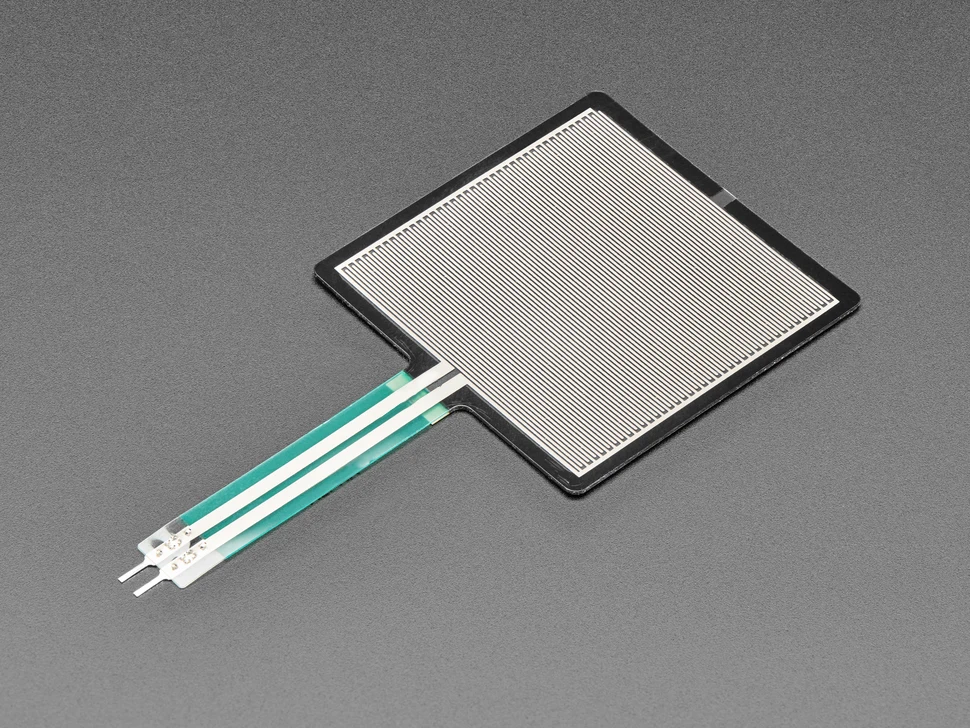

Membrane FSRs

Construction

Membrane FSRs look like thin, bendable patches. Engineers put them inside seats, pedals, and belts. SOUSHINE builds these force sensors with special layers. Each layer reacts when someone pushes down. The top layer touches the bottom layer. When you sit or press, the layers squeeze together. This changes the resistance inside the sensor.

Here is a table showing membrane FSRs in seat belt systems:

| Specification | Value |

|---|---|

| Size | Customized |

| Working temperature | -30~80℃ |

| Single sensor point trigger force | 150g~180g |

| Seat trigger force | 30~ ∞ kg |

| Working voltage | <50V DC |

| Working current | <100mA |

| Response time | <5 ms |

| Insulation impedance | 20MΩ |

| Static resistance | 10MΩ |

| Closed resistance | 0-150Ω |

| Work life | 1 million times |

These force sensors can handle lots of presses. They work in cold and hot weather. Their flexible shape lets them hide under seat covers or inside buckles.

Operating Principle

Membrane FSRs act like magic carpets for force. When someone sits or pushes, the resistance drops. The car’s computer sees this change. The system knows if a seat is empty or full. It can tell if a belt is buckled or loose. The sensor responds in less than five milliseconds. That is faster than a blink!

Membrane FSRs are quick and use little power. They ignore most electrical noise. Their thin size lets them fit almost anywhere. SOUSHINE’s force sensors help cars stay smart and safe.

Tip: Membrane FSRs cost less than many other force sensors. They also resist shocks and last a long time.

Here is a table comparing membrane FSRs to other force sensors:

| Metric | FSRs | Other Force Sensors |

|---|---|---|

| Sensitivity | 2-10% accuracy | Varies by sensor type |

| Response Time | <5ms for dynamic use | Typically slower |

| Operating Range | 0.1-100kg | Varies by sensor type |

| Temperature Range | -40°C to 85°C | Varies by sensor type |

| Size | Thin and flexible | Varies by sensor type |

| Power Requirement | Low | Varies by sensor type |

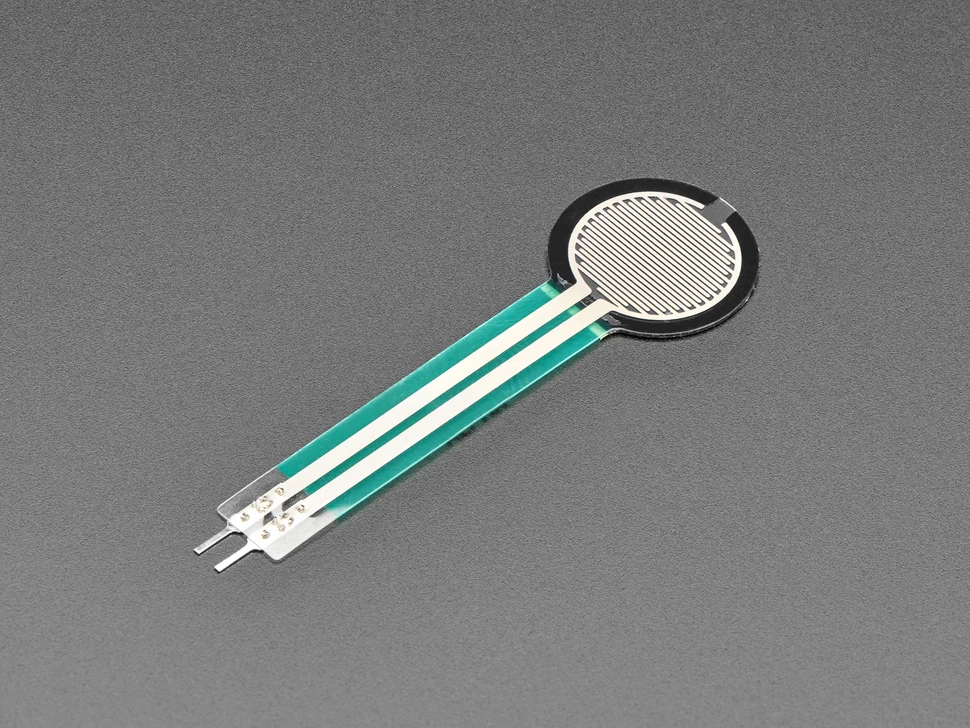

Piezoresistive Sensors

Technology

Piezoresistive sensors like tough jobs. They measure force by changing resistance when squeezed or stretched. SOUSHINE uses advanced printing to make these force sensors. Engineers use multi-layer printing and special inks. These upgrades make sensors more sensitive and flexible.

| Advancement Type | Description |

|---|---|

| Sensitivity | Detects tiny pressure changes with fast response times. |

| Flexibility | Bends and twists to fit curved surfaces. |

| Multi-layer Printing | Combines force sensing with other features. |

| Conductive Inks | Boosts accuracy and durability. |

| Printing Techniques | Inkjet and screen printing lower costs and improve performance. |

Automotive Use

Piezoresistive sensors work well in tough places. They handle high heat and bumpy rides. SOUSHINE’s force sensors work inside engines, brakes, and tire systems. These sensors keep working when things get hot.

| Sensor Type | Characteristics |

|---|---|

| Piezoresistive Sensors | Excellent stability, good temperature compensation, rugged, perfect for extreme environments. |

| Membrane FSRs | Limited temperature range, not ideal for very hot spots. |

Piezoresistive force sensors help cars measure pedal pressure and tire force. They send quick signals to the car’s computer. The system uses this data to adjust brakes or warn drivers. These sensors do not mind the heat.

Note: Piezoresistive sensors work well in extreme environments. They keep working when other force sensors might stop.

Other Force Sensors

Capacitive Sensors

Capacitive sensors are also used in some cars. They measure force by detecting changes in electrical charge between plates. These sensors use little power and repeat their measurements well. They work in many temperatures.

| Sensor Type | Advantages | Disadvantages |

|---|---|---|

| Capacitive Sensors | – Robust and simple | – Output can change if the gap between plates shifts |

| – Low power use | – Sensitive to vibration | |

| – Good repeatability | – Output changes with temperature |

Capacitive force sensors sometimes have trouble with vibration and temperature changes. They need steady conditions for best results.

Strain Gauges

Strain gauges measure force by stretching thin wires or films. These force sensors are very sensitive and give linear output. Engineers use them in load cells and pressure sensors.

| Sensor Type | Advantages | Disadvantages |

|---|---|---|

| Strain Gauges | – High sensitivity | – Output changes with temperature |

| – Linear output | – Needs complex circuits for signal processing |

Strain gauges help cars measure weight and force in seats and axles. They need careful calibration to stay accurate.

Fun Fact: The world of force sensors includes optical, ultrasonic, hydraulic, pneumatic, piezoelectric, and magnetostrictive types. Each one brings its own strengths to the automotive industry.

In summary:

SOUSHINE’s membrane FSRs and piezoresistive sensors are leaders in car force sensing. Capacitive sensors and strain gauges also help. All these force sensors help cars measure force, keep drivers safe, and make rides smoother.

Automotive Applications of Force Sensing Resistors

Seat Belt Systems

Activation and Reminders

Seat belt systems use smart technology in cars. SOUSHINE’s force sensors hide in seat belts and seats. They wait for someone to sit or buckle up. When this happens, the sensors send signals to the car’s computer. The reminder light or sound tells people to buckle up.

- FSRs help the car know if someone is sitting. This is important for the Seat Belt Reminder (SBR) system.

- Their thin shape does not change how the seat feels.

- These sensors last a long time and do not make mistakes. This makes using them easy and trouble-free.

- Knowing if someone is sitting helps more people use seat belts. This keeps everyone safer.

A seat belt system with force sensors works every time. The sensors can tell if someone sits, stands, or moves. They make sure reminders are right and on time. There are no wrong alarms or missed warnings.

Safety Impact

Safety is very important in car design. SOUSHINE’s force sensors help seat belts work the right way. The sensors can tell if a real person is there. They do not get tricked by heavy bags or things. The car’s safety system only works when it should.

| Feature | Benefit |

|---|---|

| Accurate Occupant Detection | Stops false alarms and keeps people safe |

| Thin Profile | Seats stay comfy and look good |

| Durability | Works after many uses |

| Compliance | Passes tough car safety rules |

Force sensors in seat belts help cars follow safety laws. They remind everyone to buckle up. The sensors keep working, even after lots of clicks.

Seat Occupancy Detection

Airbag Deployment

Seat occupancy detection helps keep people safe. SOUSHINE’s force sensors hide under the seat cover. They watch for someone to sit down. When someone sits, the sensors measure the force. They send this data to the car’s computer. The system decides if the airbag should go off in a crash.

The sensors know if a child or adult is sitting. They measure force carefully. This helps the car’s safety system make good choices. Airbags only go off when needed to keep people safe.

| Application | Benefit | Comparison to Alternatives |

|---|---|---|

| Seat Occupancy Sensors | Finds who is sitting for better airbag use | Safer than old ways |

Force sensors make sure airbags protect the right people. The sensors do not guess. They measure and send the right data.

Comfort Features

Comfort is important too. SOUSHINE’s force sensors help make seats feel better. They show how weight spreads on the seat. Car makers use this to design seats for all body types.

- FSRs show where people put weight on the seat. This helps measure how weight spreads out.

- Car makers use this to make seats for all shapes and sizes. This makes seats more comfortable.

- Force sensors help find the best way to sit. They also help safety by knowing who is in the seat and their size.

The sensors help everyone find a good seat position. They keep drivers and passengers comfortable. The car’s computer uses the data to adjust the seat. Every ride feels better.

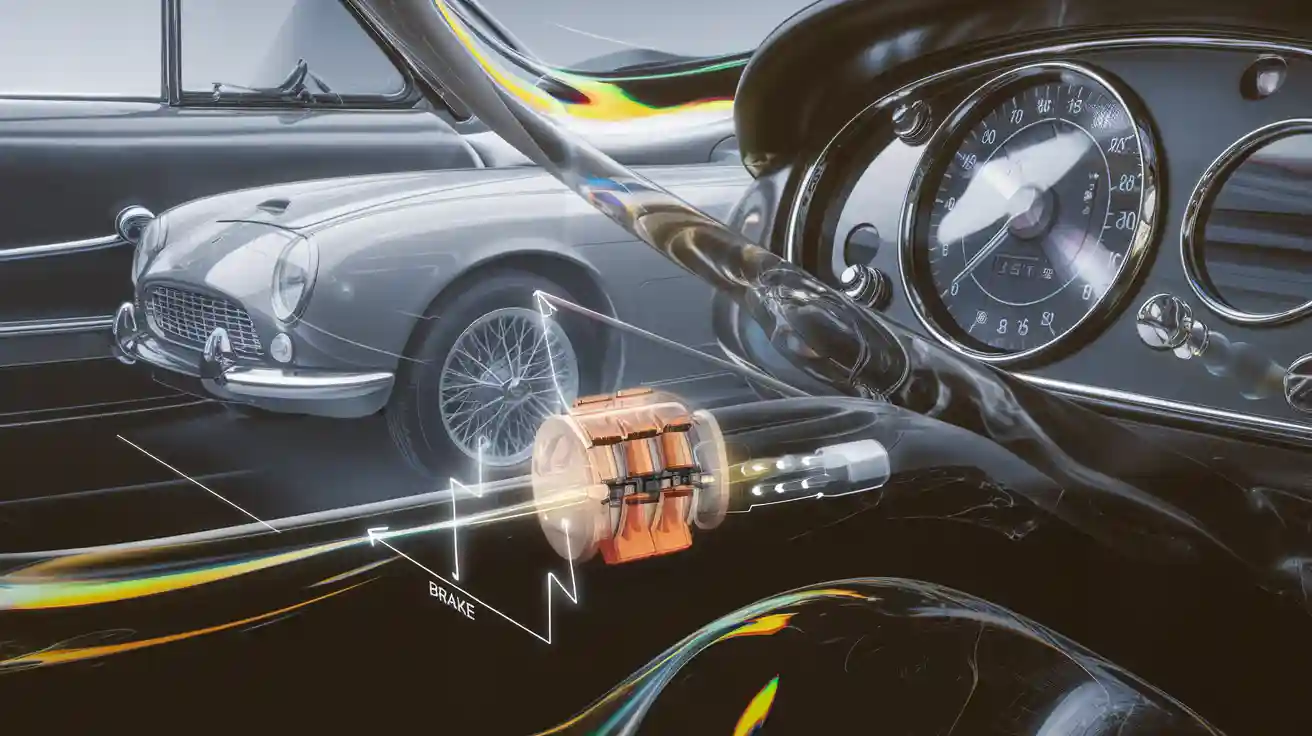

Braking Systems

Pedal Force Measurement

Braking systems need force sensors to work well. SOUSHINE’s force sensors go under the brake pedal. They measure every push, from soft to hard.

- Measurement Range: They measure from 0 to 2.5 kN. This covers normal and hard braking.

- Output Signals: They can send different signals, like analog voltage or digital outputs.

- Safety Compliance: They meet car safety rules and last in tough conditions.

- Performance Optimization: They help the car stop smoothly or quickly.

- Future Technologies: They are important for new brake-by-wire systems. This helps cars be lighter and use less fuel.

Drivers trust force sensors under their feet. The sensors react fast and send data to the car’s computer. The system changes the brakes for smooth or quick stops.

Safety Enhancements

Force sensors in brakes always work hard. They measure force so cars stop safely. SOUSHINE’s force sensors are better than old mechanical sensors.

| Application | Benefit | Comparison to Alternatives |

|---|---|---|

| Braking Systems | Measures force well for safe stops | More flexible and lasts longer than others |

The sensors help advanced driver systems work better. They help cars react faster and smarter. Force sensors make stopping safer in any weather.

Tire Pressure Monitoring

Sensor Integration

Tire pressure monitoring systems use force sensors in cars. These sensors sit inside each tire. They watch for changes in air pressure. When air pushes on the sensor, it feels a force. The sensor turns this force into an electrical signal. The car’s computer reads the signal. It knows if the tire needs more air.

SOUSHINE’s force sensors use piezoresistive or capacitive methods. Engineers make these sensors tough for bumps and shakes. They work in hot and cold weather. The sensors always measure force from air pressure. They work when the car goes fast or slow.

- Force sensing technology is key for direct TPMS in cars.

- Special force sensors measure tire pressure very well.

- These sensors use piezoresistive or capacitive ways to change air pressure into signals.

Force sensors in TPMS give drivers updates right away. The dashboard shows a warning if a tire loses air. No one wants a flat tire, especially in bad weather. SOUSHINE’s force sensors help drivers avoid problems and keep trips smooth.

Reliability

Force sensors in tire pressure systems do hard work. They work in cold winters and hot summers. The sensors ignore mud, water, and dust. SOUSHINE’s force sensors keep measuring force all the time.

Engineers trust these sensors because they give good results. The sensors send true readings to the car’s computer. The system warns drivers before a tire gets unsafe. Force sensors help stop blowouts and keep families safe.

Here is a table showing why SOUSHINE’s force sensors are great for TPMS:

| Feature | Benefit |

|---|---|

| Fast Response | Warns drivers before trouble starts |

| High Durability | Works in tough tire places |

| Consistent Accuracy | Gives true readings every trip |

| Low Power Use | Saves battery in sensor modules |

Force sensors in TPMS do more than check pressure. They protect tires, save fuel, and keep everyone safe. SOUSHINE’s force sensors help every trip go well.

Tip: Drivers who use force sensors in TPMS feel safe. No one wants to guess if a tire is low. The sensors do the hard work, so drivers can watch the road.

How Force Sensors Work in Vehicles

Signal Processing

Analog and Digital Output

Force sensors send signals to the car’s computer. These signals can be analog or digital. Analog signals change smoothly as force changes. Digital signals switch between two values, like on and off. Engineers use both types in seats, pedals, and tires.

A sensor under a seat sends an analog signal when someone sits. The signal gets stronger as the person’s weight goes up. The engine control unit reads this signal. It decides if the seat has someone in it. In brakes, force sensors send digital signals. These show if the pedal is pressed hard or soft. The engine control unit uses this to change braking power.

Here’s a table showing how force sensors send signals:

| Signal Type | Description | Example Use |

|---|---|---|

| Analog | Smooth, changes with force | Seat occupancy |

| Digital | Jumps, on/off with force | Brake pedal sensing |

Force sensors work all the time. They keep sending signals every second. This helps the car know what is happening.

ECU Integration

The engine control unit is like the car’s boss. It listens to force sensors all day long. When a sensor feels force, it sends a signal to the engine control unit. The unit checks the signal and makes choices. If a seat sensor says someone is sitting, the engine control unit turns on the airbag. If a tire sensor feels low force, the engine control unit shows a warning on the dashboard.

Force sensors and the engine control unit work together. They help keep drivers safe and cars working well. The engine control unit trusts force sensors to give good information. This keeps every ride safe.

Tip: The engine control unit can read hundreds of signals from force sensors at once. It always keeps up!

Calibration

Accuracy

Force sensors need to be accurate. Calibration helps them measure force the right way. Engineers use smart methods to check force sensors. They put special weights on the sensor. They use a 3D printed plate to press down evenly. This makes sure each reading matches real force.

- Engineers use special weights to check force sensors.

- A 3D printed plate spreads force across the sensor.

- Calibration keeps force readings correct for seat, pedal, and tire sensors.

A force sensor that gets checked often gives true readings. The engine control unit needs these good readings to make smart choices.

Maintenance

Force sensors need care to work well. Engineers check them during regular car checkups. They use mats with flexible force sensors to test them. If a sensor does not work right, they recalibrate it or replace it.

- Maintenance teams use mats to test force sensors.

- If a sensor is off, they recalibrate with weights and plates.

- Sensors that pass the test keep working in the car.

Force sensors that get good care last longer. They help the engine control unit do its job. Drivers stay safe, and cars run well.

Note: Regular calibration and care help force sensors stay reliable. The engine control unit always gets the best data.

Why Choose Force Sensing Resistors

Durability

Harsh Conditions

SOUSHINE’s force sensing resistors work well in tough places. Rain can fall, snow can cover the car, and the sun can get very hot. These sensors keep working through it all. Engineers make them strong for hot, cold, and dusty days. They even work if someone spills a drink. The force sensors hide under seats and pedals. They do not stop working. Drivers can count on them to measure force every day.

Longevity

Some car parts break down quickly. SOUSHINE’s force sensors last much longer. They measure force for many years. They can handle one million presses without trouble. The sensors keep sending data without problems. Mechanics almost never see these sensors fail. This means drivers visit the shop less. The force sensors last longer than most other car parts.

Cost-Effectiveness

Production Costs

Car makers want to save money. SOUSHINE’s force sensing resistors help with that. The sensors use simple parts and smart designs. Factories can make many sensors fast. The low price lets more cars have good safety features. Even cheaper cars get the same force sensing as fancy cars.

OEM Benefits

Original Equipment Manufacturers (OEMs) need parts that fit and work well. SOUSHINE’s force sensors are thin and bend easily. They fit in small spaces. The sensors work with many car systems. OEMs can use the same sensor in seats, pedals, and tires. This makes building cars easier and cheaper. The force sensors help make safe cars for less money.

Reliability

Consistent Performance

SOUSHINE’s force sensing resistors always do their job. They measure force the same way every time. No matter the weather or road bumps, the sensors send good data. The car’s computer uses this data to keep people safe. Drivers get the right warnings when they need them.

Safety Compliance

Car safety rules get harder each year. SOUSHINE’s force sensors help cars pass these tests. The sensors measure force very well. Airbags go off at the right time. Seat belt reminders always work. The force sensors help cars meet safety rules and keep families safe.

Note: Force sensing resistors are tough, cheap, and work well. Strain gauges and capacitive sensors are good too, but they cost more or need more care. SOUSHINE’s force sensors are simple and strong.

| Sensor Type | Durability | Cost | Reliability | Flexibility |

|---|---|---|---|---|

| FSR (SOUSHINE) | High | Low | High | Excellent |

| Strain Gauge | Medium | High | High | Good |

| Capacitive Sensor | Medium | Medium | Medium | Good |

SOUSHINE’s force sensing resistors win in every way. They help cars be safer, smarter, and cost less.

Limitations of Force Sensing Resistors

Environmental Sensitivity

Temperature Effects

Temperature can change how force sensing resistors work. When it gets hot or cold, the sensor might measure force differently. The sensor’s electrical parts can shift, so the readings may not show the real force. Engineers use temperature compensation to help keep things correct. But big changes in temperature still make sensors act up.

- Temperature can make the sensor expand or shrink. This changes how it reacts to force.

- Sudden cold or heat can cause mistakes in force readings.

- Calibrating sensors in the same temperature as the car helps keep measurements right.

Humidity

Humidity can get inside the car and affect sensors. Water in the air can change the materials in the force sensing resistor. This makes the readings less accurate. Most car sensors are sealed to keep out dust and water. High humidity can still cause small changes in force readings.

- Water can sneak past seals and change the sensor’s resistance.

- Humid days might make force readings drift a bit.

- Sealed sensors block most humidity, but regular checks help keep data correct.

Crosstalk and interference can also cause problems. Forces on one side can mess with readings on another side. Electromagnetic fields from other electronics can add noise. Engineers design sensors to fight these issues, but sometimes a little interference gets through.

Wear and Tear

Maintenance Needs

Force sensing resistors need checkups to keep working well. Pressing and releasing the sensor wears it down over time. Mechanics test sensors during regular car maintenance. This makes sure they still measure force the right way. If a sensor acts strange, recalibration or replacement fixes it.

- Regular calibration keeps force readings correct.

- Maintenance teams use mats and weights to test sensors.

- Sensors that pass tests keep working hard in the car.

Replacement Signs

Force sensors do not last forever. After many presses, they can wear out. If the sensor stops sending good data, the car’s computer may show a warning. Mechanics look for slow response or weird readings. When these show up, it is time for a new sensor.

| Sign of Wear | What Happens | Solution |

|---|---|---|

| Slow response | Delayed force readings | Replace sensor |

| Inconsistent output | Force data jumps around | Recalibrate/replace |

| Signal loss | No force data at all | Replace sensor |

Strain gages also wear out, but they need more complex fixes. Force sensing resistors are easier to repair when something goes wrong.

Accuracy Challenges

Signal Drift

Force sensing resistors can have signal drift. This means the sensor’s output changes slowly, even if the force stays the same. Temperature, humidity, and aging can cause this. The car’s computer might see force readings that go up or down over time. This can make things confusing.

“The study looks at how temperature, bending, and softness affect Force Sensitive Resistors (FSRs). These things change how the sensor works and what force it reads. Calibration should happen in the same conditions as the car to avoid mistakes.”

Calibration Solutions

Engineers use calibration to keep force readings correct. Calibration means testing the sensor with known weights. They adjust the system until the force data matches the real force. Mechanics use mats and plates to spread force evenly during calibration. This keeps the sensor working well and the car’s computer happy.

- Calibration fixes signal drift and keeps force readings true.

- Testing in real-world conditions helps match force data to what drivers feel.

- Regular calibration makes force sensing resistors more reliable than strain gages in many cars.

Strain gages need careful calibration too, but force sensing resistors make it faster and easier.

Future of Force Sensors in Automotive

Material Innovations

Sensitivity

Engineers like trying new materials. They want sensors that feel tiny touches, like a cat’s whisker on glass. SOUSHINE’s team uses advanced polymers and nanomaterials. These make sensors more sensitive. Sensors can notice very small pressure changes. Imagine a seat sensor that feels a feather land. Cars react faster to every move. This helps keep drivers and passengers safe and comfortable.

- New materials let sensors feel softer and smaller forces.

- Sensitive sensors help seat and pedal detection be more exact.

Durability

Car interiors get messy and face tough weather. Heat, cold, spilled drinks, and mud can hurt sensors. SOUSHINE’s force sensing resistors have strong coatings and bendy bases. These materials protect sensors from damage. Sensors keep working after many seat slams and pedal pushes. Durable sensors mean fewer repairs and happier drivers.

| Material Type | Benefit | Fun Fact |

|---|---|---|

| Advanced Polymers | Resist wear and tear | Used in space suits! |

| Nanomaterials | Boost sensor life | Smaller than a virus! |

Smart Vehicle Integration

Connected Systems

Cars can talk to each other and to the world now. Force sensing resistors help with this. They hide in dashboards, seats, and controls. These sensors send live data to the car’s computer. The car uses this data to change safety and comfort settings. Pressure-sensitive dashboards let drivers tap to control music or air. Sensors help smart cars learn about people and their surroundings.

Tip: Smart cars use force sensors to make driving safer and more fun. Dashboards that react to taps feel magical!

Autonomous Features

Self-driving cars need to sense things. Force sensing resistors give cars a sense of touch. They help decide when airbags go off or seats move. These sensors work with cameras and radars for safety. Autonomous cars use force sensors for quick feedback. The car knows who is inside and how they use controls.

- Pressure panels and seat sensors help self-driving cars react to people.

- Force sensors make sure safety systems work at the right time.

Emerging Applications

Predictive Maintenance

Mechanics used to guess when parts would break. Now, force sensing resistors help cars spot problems early. Sensors watch force and pressure in seats, pedals, and tires. The car’s computer looks for strange patterns. If something is wrong, it sends a warning. This keeps cars running well and saves money on repairs.

- Sensors work with AI and IoT to find problems early.

- Predictive maintenance means fewer breakdowns and safer trips.

Advanced Safety

Safety is always important. Force sensing resistors help in new ways. They team up with other sensors to protect people. In crashes, sensors help airbags go off at the right time. In healthcare, similar sensors watch patient movement and pressure. In factories, they help machines stay safe. The future will have even smarter safety systems powered by force sensing technology.

| Application | How Sensors Help |

|---|---|

| Airbag Deployment | Perfect timing |

| Health Monitoring | Tracks movement |

| Machine Safety | Prevents accidents |

🚗 The future looks great for force sensing resistors. SOUSHINE keeps improving them to make cars safer, smarter, and more fun.

SOUSHINE’s force sensing resistors are important in regular cars. Membrane FSRs and piezoresistive sensors are used a lot. These sensors are found in seat belts, seats, brakes, and tires. Drivers like them because they are strong and not expensive. They also work well every time. Engineers are always making new materials and better features.

Want to know the answer? SOUSHINE’s FSRs help cars be safer, smarter, and ready for what comes next!

FAQ

What makes SOUSHINE’s force sensing resistors special in vehicles?

SOUSHINE’s force sensing resistors stand out because they last long and work well in tough places. They help cars measure force, pressure, and weight. Drivers trust them for seat belts, brakes, and tire pressure systems. Engineers love their reliability.

How do load cells compare to force sensing resistors in cars?

Load cells measure force with high accuracy. They use strain gauges to sense weight and pressure. Force sensing resistors work faster and fit in smaller spaces. Load cells often appear in heavy-duty parts, while force sensing resistors handle everyday tasks.

Where do engineers use load cells in traditional fuel-powered vehicles?

Engineers put load cells in axles, seats, and sometimes pedals. Load cells help measure weight for safety and comfort. They also check how much force a driver uses on the brake pedal. Load cells make sure cars stay balanced and safe.

Why do some cars use load cells instead of other sensors?

Load cells give very accurate readings. They help with tasks that need exact force measurement. Engineers choose load cells for weighing seats, checking axle loads, and testing brakes. Load cells work well in places where precision matters most.

Can load cells and force sensing resistors work together in a car?

Yes! Load cells and force sensing resistors often team up. Load cells handle heavy loads and tough jobs. Force sensing resistors take care of quick, light touches. Together, they help cars measure force in many ways, making driving safer and smoother.

What are the benefits of using load cells in seat occupancy detection?

Load cells measure who sits in a seat and how much they weigh. This helps the car decide if the airbag should go off. Load cells give clear data for safety systems. Engineers use them to make sure airbags protect the right people.

How do load cells help with tire pressure monitoring?

Load cells measure the force inside tires. They check how much pressure pushes on the sensor. The car’s computer reads this data and warns drivers if a tire loses air. Load cells keep tires safe and help prevent blowouts.

Are load cells easy to maintain in vehicles?

Load cells need regular checkups. Mechanics test them during car service. If a load cell stops working, they replace it. Load cells last a long time when engineers calibrate them and keep them clean. Drivers enjoy fewer problems with well-maintained load cells.