Call us: +86-137-2353-4866

Force-sensitive resistors help measure force in many real-life uses. SOUSHINE’s force sensing resistors are sensitive and not expensive. This makes them popular in cars, healthcare, robots, and electronics. Accuracy is important in these areas. Good force detection helps keep people safe. It also makes things work better and easier to use. Users can count on these resistors to work well. They are flexible and fit many jobs.

| Feature | SOUSHINE FSRs | Industry Averages |

|---|---|---|

| Sensitivity | Good sensitivity, finds small force changes | Changes, sometimes more precise |

| Accuracy | Not the most accurate, signal can drift and change with temperature | Usually more accurate, especially in load cells |

| Cost-effectiveness | Made to save money | Changes, often costs more for better precision |

| Application suitability | Great for flexible use and low power | Best for jobs needing high precision |

Table of Contents

Key Takeaways

- Force-sensitive resistors (FSRs) cost less and work in many ways. They are good for cars, healthcare, robots, and electronics people use.

- SOUSHINE FSRs are usually accurate within about ±10%. This is fine for most jobs that do not need perfect measurements.

- You need to check and adjust FSRs often to keep them working well. People should do this before starting new work and after things change around them.

- Things like heat and wetness can change how FSRs work. Putting FSRs in the right spot and protecting them helps keep their readings correct.

- FSRs are simpler to put in and take care of than other sensors like strain gauges and load cells. This makes them a smart pick for lots of projects.

- There are different FSRs, like single zone and array sensors. These fit many needs, from easy uses to more tricky touch screens.

- To help FSRs last longer and work better, you should clean and check them often.

- SOUSHINE FSRs can be changed for special projects. This lets engineers make solutions that fit their own needs.

Force-Sensitive Resistors Overview

Operating Principle

Force sensing resistors change resistance when you press them. This helps measure how much force is used. Engineers use science to explain how these sensors work. The table below shows the main ideas from books and articles:

| Operating Principle | Description |

|---|---|

| Percolation | Happens when there are enough particles. Resistance goes up when you press harder. |

| Quantum Tunneling | Resistance goes down with more stress. More paths for electricity form when pressed. |

| Contact Resistance | Changes in contact area affect how electricity moves. Force changes resistance. |

SOUSHINE uses smart technology for good measurements. This helps designers make devices that react to touch or weight fast.

Construction

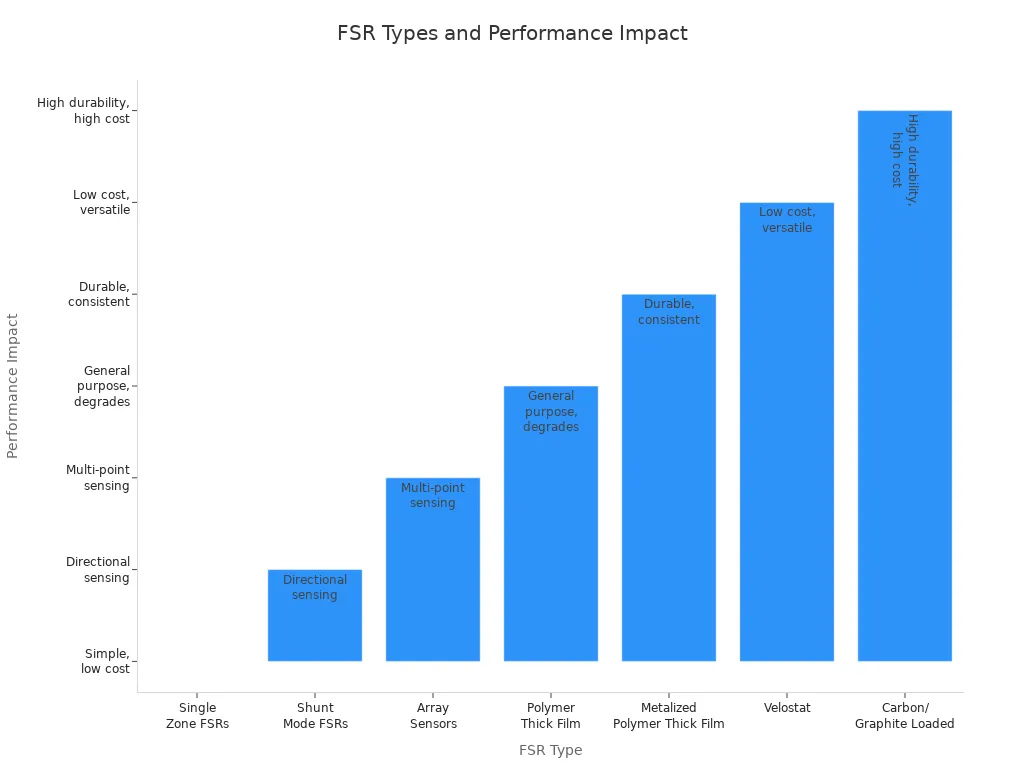

Manufacturers use different materials and ways to make force sensing resistors. The material chosen affects how well the sensor works and how long it lasts. The table below shows common types and how they are made:

| Type of FSR | Materials/Construction Methods | Performance Impact |

|---|---|---|

| Single Zone FSRs | Two electrodes with special ink on one spot. | Makes resistance lower in one area. Simple and cheap. |

| Shunt Mode FSRs | Uses certain electrodes based on force direction. | Senses which way force is applied. |

| Array Sensors | Many single zone FSRs on one base. | Senses force at many spots. Good for keypads or touch screens. |

| Polymer Thick Film (PTF) | Uses thick film inks. | Works well but gets worse over time. |

| Metalized Polymer Thick Film | Thick film with metal bits added. | Lasts longer and works better. Costs a bit more. |

| Velostat | Special plastic that conducts electricity. | Cheap and works in many ways. |

| Carbon/Graphite Loaded | Has carbon or graphite in rubber or silicone. | Very tough and works well, but costs more. |

SOUSHINE makes force sensing resistors in many shapes and sizes. Customers can ask for special designs for their needs. The company uses strong materials so sensors last long, even in hard places.

Applications

Force sensing resistors are used in lots of modern devices. They help make things safer, more comfortable, and work better. The table below lists common uses and what each needs from the sensor:

| Application | Description | Performance Requirements |

|---|---|---|

| Athletic Apparel | Put in shoes to check foot pressure for better design. | Must sense different pressures to help performance and stop injuries. |

| Medical Applications | Measures force for medicine and bed pressure. | Needs to sense light and strong forces to keep patients safe. |

| Robotics | Tells how much pressure robot arms use when grabbing things. | Must sense many force levels to avoid breaking things. |

| Inventory Control | Checks shelf weight to track inventory. | Should sense weight changes to help manage stock. |

| User Interface Controls | Used as buttons for different actions. | Must sense different forces for each user action. |

SOUSHINE force sensing resistors are found in cars, medical tools, robots, and electronics. They are flexible, use little power, and can be made to fit many jobs. This makes them a good pick for engineers who need sensors they can trust.

FSR Accuracy Range

Quantitative Data

Engineers want clear numbers when picking force sensing resistors. Most force sensing resistors are accurate between ±6% and ±50%. Usually, they are about ±10% accurate. This means the sensor can be off by up to 10%. SOUSHINE force sensing resistors fit in this range. They work well for many real-life jobs. These sensors are good for projects that do not need super high precision like load cells. They still give reliable force measurements.

| Sensor Type | Typical Accuracy Range |

|---|---|

| SOUSHINE FSRs | ±10% |

| General FSRs | ±6% to ±50% |

| Load Cells | ±0.03% to ±1% |

Note: Force sensing resistors are a good choice for many uses. They balance cost and performance well. They are accurate enough for most designs, especially when small size and flexibility are important.

Precision and Limitations

Force sensing resistors act in special ways when measuring force. Their readings can change slowly over time. Different sensors might show different results with the same force. How you press the sensor or the shape of the object can change the reading. Engineers need to look at the data carefully, especially in healthcare. For example, lower limb prosthetics need exact force measurement to keep users safe and comfortable. If the sensor changes or drifts, it can affect how the device fits or works.

Common errors in force sensing resistors include:

- Hysteresis: The sensor may not go back to its first reading after you stop pressing.

- Non-linearity: Force and resistance do not always change together in a straight line.

- Drift: The reading can slowly change even if the force stays the same.

SOUSHINE force sensing resistors use smart materials and design to help with these problems. Their sensors give steady and repeatable results for most real-life uses.

Repeatability

Repeatability means how close the sensor’s readings are when you press it the same way many times. Force sensing resistors are repeatable in controlled settings. Some things can change their readings. Non-linear pressure response and how you press can make small differences. Engineers check repeatability by seeing how much the resistance changes after pressing and releasing, and by comparing different sensors.

- SOUSHINE force sensing resistors have medium repeatability. They work well for many daily uses.

- Tekscan FlexiForce sensors are more repeatable and accurate. They are better for tough industrial jobs.

- SOUSHINE sensors are good for hobbyists and engineers who want easy and cheap solutions.

- Tekscan is for professionals and industries that need the best performance.

Tip: To get the best results, users should calibrate their force sensing resistors often. They should also use the same way to press each time.

Factors Affecting Accuracy

Nonlinearity

Nonlinearity is a big reason why force sensing resistors can be less accurate. If the sensor does not react in a straight line to force, it can make mistakes. The reading might not show the real force, especially at the highest or lowest points. Some sensors, like Interlink FSR-402 and Flexiforce A201-1, work well in the middle but not at the ends. On a graph, this looks like a curve, not a straight line.

- Nonlinearity can make the sensor say the force is too high or too low.

- This problem is easier to see with very light or very heavy things.

- Calibration helps fix nonlinearity. Engineers use weights they know to make a correction chart.

- Good calibration makes the sensor’s reading match the real force better.

Tip: Calibrating often and using the sensor in its best range helps keep force readings correct.

Hysteresis

Hysteresis changes how force sensing resistors act when pressed again and again. When you press and let go, the number might not go back to where it started. This delay can cause mistakes, especially if you need fast and repeated measurements.

Hysteresis happens when the inside of the sensor does not bounce back right away after pressing. This can make the sensor less exact, so it is not as good for jobs that need the same answer every time.

- Hysteresis can make the sensor give different numbers for the same force, depending on if you are pressing harder or letting go.

- This problem is bigger when the sensor is used quickly or many times.

- Engineers can lower hysteresis by picking better materials and making the sensor better.

- Special ways of reading the signal can also help fix hysteresis.

Note: Using the same way to press each time and letting the sensor rest between uses can help stop hysteresis problems.

Thermal Drift

Thermal drift means the sensor’s numbers can change if the temperature goes up or down. When it gets hotter or colder, the sensor’s parts can act differently. This can make the reading change, even if the force stays the same.

- Changes in temperature can cause mistakes because the sensor grows or shrinks and its resistance changes.

- Force sensors work best if you calibrate them at the same temperature where you use them.

- If the sensor is on a curved or bumpy spot, drift can get worse, like in prosthetics.

- Companies use special tricks to keep the sensor’s numbers steady when it gets hot or cold.

SOUSHINE’s force sensing resistors work well from -25° Celsius to 85° Celsius. This big range helps them measure force right in many places, like factories or outside.

Engineers can make sensors more accurate by calibrating them where they will be used and by keeping them safe from quick temperature changes.

Environmental Effects

Environmental conditions can change how well force-sensitive resistors work. Engineers test sensors in labs, but real places are different. Things like temperature and humidity can change how FSRs react to force.

| Environmental Factor | Impact on Performance |

|---|---|

| Temperature (55 °C) | Makes the sticky layers inside the sensor weaker or stronger. This can change how long the FSR lasts and how well it works. |

| Humidity (90% RH) | Lets water get inside the sensor. This changes how the sticky layers act and can make the sensor readings different. |

Hot weather can make the sensor’s parts softer or harder. When it gets hot, the glue inside may not hold as well. This can change how the sensor feels pressure. In hot places or near engines, FSRs might show different numbers than in cool places.

Humidity also changes how FSRs work. Water can get inside and change the sensor’s layers. When it is very humid, the sensor can soak up water. This can make the sensor less steady and change its resistance. In places like hospitals or kitchens, humidity can go up fast and make the sensor less accurate.

Engineers use different ways to help sensors work better:

- They cover sensors with special coatings to keep out water.

- They pick materials that do not change much with heat.

- They set up sensors in the same place where they will be used.

- They put sensors away from things that are hot or wet.

Tip: Calibrating sensors often and putting them in the right spot helps keep readings correct when the environment changes.

SOUSHINE makes FSRs that work in many kinds of weather. Their sensors do well in both hot and wet places. By using strong materials and smart designs, SOUSHINE helps people get good results even when things around the sensor change.

Force Sensor Comparison

FSRs vs. Strain Gauges

Engineers look at both force-sensitive resistors and strain gauges when picking a force sensor. Strain gauges are very accurate for measuring small changes. They are great for science and industry jobs that need exact numbers. But, putting in strain gauges takes time and care. You have to set them up just right and check them often. This can make things harder and slower. Force-sensitive resistors, like SOUSHINE’s, are easier to put in. You can also check and adjust them often. They work well when you do not need perfect accuracy but want something flexible and not too expensive.

| Feature | Strain Gauges | Force-Sensitive Resistors (FSRs) |

|---|---|---|

| Accuracy | More precise for small strain measurements | Suitable for applications where high accuracy is not critical |

| Installation | More complex installation | Easier to install and maintain |

| Calibration | Requires careful calibration | Can be calibrated regularly |

SOUSHINE FSRs come in many shapes and sizes. This helps engineers make sensors for special jobs. Their ribbed surface makes them more sensitive. This is useful for many new devices.

FSRs vs. Load Cells

Load cells are the best for measuring force in labs and factories. They are very sensitive and give exact numbers. This is important for scales and checking big structures. But, load cells are stiff and cost a lot. This means they are not good for projects that need to bend or save money. Force-sensitive resistors are not as sensitive. But, they are good at showing changes in force. They are thin and bendy, so you can use them in many ways. For example, they work in touch buttons or tools that measure grip strength.

| Feature/Aspect | Force-Sensitive Resistors (FSRs) | Load Cells |

|---|---|---|

| Sensitivity | Lower sensitivity, suitable for detecting relative force changes | High sensitivity, ideal for precise measurements |

| Flexibility | Thin and flexible, can be used in various configurations | Generally rigid, designed for specific applications |

| Cost | Lower cost, making them accessible for various uses | Higher cost, reflecting their precision and reliability |

| Application Examples | Touch-sensitive buttons, grip strength measurement | Weighing scales, structural load monitoring |

| Precision | Less precise, repeatability can vary by 10% or more | High accuracy and reliability in measurements |

| Use Cases | Impact sensing, safety detection | Heavy machinery, industrial weighing |

SOUSHINE FSRs last longer because they use strong, bendy materials. They keep working even in tough places. Their low price means more people can use them for different things.

FSRs vs. Capacitive Sensors

Capacitive sensors and force-sensitive resistors are different in what they work with and how they handle tough places. Capacitive sensors work best with glass or plastic. They do not work well with metal or wood. Force-sensitive resistors, like SOUSHINE’s, work with many materials. This gives more choices for design. Capacitive sensors can have problems if it is wet or hot. This can make them less reliable. Force-sensitive resistors keep working well even when it is humid or the temperature changes. This is because they are made with strong materials.

- Capacitive sensors work best with glass or plastic, but not other materials.

- Force-sensitive resistors work with metal, wood, and plastic, so they fit more designs.

- Capacitive sensors can stop working right if it is too wet or hot.

- Force-sensitive resistors are tough and keep working in hard places.

SOUSHINE’s force sensors are flexible, sensitive, and strong. Engineers can change them for special jobs. They work well even when things get rough.

Tip: When picking a force sensor, think about how accurate you need it to be, how easy it is to put in, and where you will use it. SOUSHINE FSRs are strong and can be changed to fit many new projects.

Force Sensing Resistors in Applications

Automotive

Car engineers use force sensing resistors in many car systems. These sensors help tell if someone is sitting in a seat. This lets airbags open only when needed. They also check seat pressure to change lumbar support and make drivers more comfortable. In electric cars, these sensors help control touch buttons on dashboards and steering wheels. Their thin and bendy shape fits well in small car spaces. They do not add much weight, unlike load cells. These sensors are a cheaper way to find force changes. Car makers pick them because they work well in hot or cold places. They last a long time, even if used a lot.

Healthcare

Healthcare tools use force sensing resistors to measure force well. These sensors are important for watching patients and giving medicine. They are also used in smart beds. The table below lists some healthcare uses and how these sensors help:

| Application Area | Description |

|---|---|

| Patient Monitoring | Sensors watch patient moves and change settings for safety. |

| Drug Delivery | Devices use force feedback to give the right amount of medicine. |

| Smart Beds | Sensors check where patients are and help stop bedsores. |

| Infusion Pumps | Sensors make sure fluids are given right by checking pressure. |

| Respiratory Equipment (Ventilators) | Sensors help measure pressure better for patient care. |

| Blood Pressure Monitors | Sensors make blood pressure readings more correct. |

| Prosthetics with Sensory Feedback | Sensors give feedback to help prosthetics work better. |

Doctors and nurses trust these sensors to give good data. High accuracy is very important for patient safety. This is true for giving medicine and using breathing machines. Force sensing resistors give exact force feedback. This helps medical devices work right. Their small size and bendy shape fit well in tiny medical tools. This makes them a top pick for new healthcare devices.

Note: Medical device makers choose force sensing resistors because they measure force well, even in busy hospitals.

Robotics

Robotics engineers use force sensing resistors to help robots feel touch. These sensors go in robot hands, grippers, and feet. They let robots know how hard they are holding things. This helps robots pick up breakable items without breaking them. These sensors also measure grip force in control tools. This lets people control robots better. The sensors are light and easy to fit in moving robots. Some problems can happen, like noise or sensor wear. Engineers fix these by picking strong materials and using smart signal tricks. Force sensing resistors are still a favorite in robots. They are cheap, flexible, and measure force well.

- Engineers put sensors in robot grippers to hold things safely.

- People use control tools with these sensors to move robots.

- Robots use light sensors that do not slow them down.

Tip: Checking and caring for sensors often helps them last longer in robots.

Consumer Electronics

Consumer electronics use sensors to make devices react to touch. Force sensing resistors are important in this field. Engineers put these sensors in things like smartphones, game controllers, smart watches, and touch screens. These gadgets need to measure force well so people have a good experience.

SOUSHINE makes force sensing resistors for new electronics. These sensors are thin and bendy, so they fit in small spaces. Designers pick them because they can sense both soft and hard presses. This helps the sensors do many jobs, like turning on buttons or reading hand movements.

Manufacturers like force sensing resistors for many reasons:

- They work well for both soft and hard touches.

- They can go into many kinds of devices.

- The sensors help make electronics smaller and thinner.

- Their simple shape makes them easy to use and fix.

- They cost less, so more products can use them.

| Application Area | Example Devices | Benefit of FSRs |

|---|---|---|

| Mobile Devices | Smartphones, tablets | Touch controls that react fast |

| Wearables | Smart watches, fitness bands | Senses pressure well |

| Gaming | Controllers, VR gloves | Makes games feel more real |

| Home Automation | Smart switches, remotes | Finds force for better control |

| Audio Equipment | Headphones, speakers | Lets you press for different actions |

SOUSHINE’s sensors make using devices easier. For example, smart watches use them to feel how hard you swipe and change the screen. Game controllers use them to check how hard you grip or press buttons, making games more fun. Smart home gadgets use these sensors for touch switches and remotes.

Engineers still use force sensing resistors even if they are not perfect. They are a good choice because they are cheap, small, and do many things. These sensors are easy to add to new products. They also work in lots of places, so they are good for everyday gadgets.

Tip: To keep sensors working well, check them often and put them in the right spot.

SOUSHINE keeps making new sensor ideas for brands that want good force sensing. They work hard to give quality and help, so companies can make products people like.

Maximizing FSR Accuracy

Calibration

Calibration helps force sensing resistors give the right numbers. Engineers use calibration to match sensor readings with real weights. They put a weight on the sensor and write down the resistance. They do this again with other weights. This makes a chart that shows how resistance changes with force.

SOUSHINE says to calibrate often for best results. Users should check sensors before starting each project. They should use the same weights and press the sensor the same way every time. Doing this helps stop mistakes and keeps the numbers steady.

Tip: Use a simple chart like the one below to watch how your sensor works.

| Applied Force (g) | Sensor Resistance (Ω) |

|---|---|

| 0 | 10,000 |

| 100 | 7,500 |

| 200 | 5,000 |

| 300 | 2,500 |

| 400 | 1,000 |

Engineers use this chart to turn resistance into force numbers. They should make a new chart if the sensor moves or if it gets hotter or colder.

Circuit Design

Circuit design changes how well force sensing resistors work. A good circuit helps the sensor give clear signals. Engineers often use a voltage divider circuit with FSRs. This setup makes it easy to see resistance changes.

A simple voltage divider uses the FSR and another resistor. The sensor connects to a microcontroller or data logger. The microcontroller reads the voltage and turns it into force.

[Power]---[FSR]---[Fixed Resistor]---[Ground]

|

[Microcontroller]

SOUSHINE says to use good resistors and cover wires to block noise. Engineers should keep wires short and not put sensors near strong magnets or motors. These steps help stop signal mistakes.

Note: Try different resistor values in your circuit to find what works best for you.

Environmental Controls

Environmental controls help sensors stay correct in real life. Temperature and humidity can change sensor numbers. Engineers should keep sensors safe from too much heat, cold, or water.

SOUSHINE FSRs work well in many places, but extra care helps. Users can cover sensors with waterproof tape or put them in boxes. They should keep sensors out of sunlight and away from water. In factories, putting sensors in rooms with steady temperature helps keep numbers steady.

- Use covers for sensors outside or in wet places.

- Store sensors in cool, dry spots when not using them.

- Check sensors often for damage or wear.

Alert: Checking sensors and using simple covers helps SOUSHINE FSRs last longer and stay correct.

Maintenance

Force-sensitive resistors need regular care to stay accurate. Engineers know sensors can change as time goes by. Dust, water, and lots of use can make sensors work less well. Doing maintenance helps find problems early and keeps things working.

A good plan starts with cleaning often. Technicians use soft cloths or air to clean off dust. They do not use strong chemicals that could hurt the sensor. Clean sensors work better and give steady numbers.

Checking is important for maintenance. Engineers look for cracks, color changes, or loose wires. They check the sensor’s output for drift or sudden changes. If they see a problem, they fix it fast. This keeps the sensor working right.

Recalibration helps force-sensitive resistors stay correct. Over time, things like heat or use can change the readings. Technicians recalibrate by using known weights and adjusting the output. This fixes mistakes and keeps the sensor working well.

Sometimes, sensors need to be replaced. If a sensor keeps making errors or fails checks, engineers put in a new one. This stops bad readings and keeps the system safe.

SOUSHINE says to do maintenance based on how much the sensor is used and where it is. In busy places like hospitals or factories, technicians check sensors every month. In quieter places, they check every few months. Regular checks help find problems before they get worse.

Tip: Write down all maintenance steps. Record cleaning dates, inspection results, recalibration, and replacements. This helps track how the sensor works and makes fixing problems easier.

| Maintenance Task | Frequency | Benefit |

|---|---|---|

| Cleaning | Monthly/Quarterly | Removes dust, improves response |

| Inspection | Monthly | Finds wear, prevents failure |

| Recalibration | As needed | Corrects drift, ensures accuracy |

| Replacement | When required | Maintains reliability |

Regular care, like calibration and testing, helps force-sensitive resistors give good readings for a long time. These steps help engineers find and fix problems like drift or odd output. By following a plan, SOUSHINE FSRs keep working well in many jobs.

Studies show force-sensitive resistors can measure force well if built and set up right. Calibrating the sensor before each use keeps it accurate. This is important when offset voltages change. SOUSHINE FSRs work best in things like foot pronation systems, car sensors, touchpads, musical instruments, keypads, and small electronics. To get the best accuracy, engineers should calibrate often. They should use a soft load concentrator and pick the right resistor value. It is also important to check the wiring and recalibrate if the environment changes. SOUSHINE makes FSRs that are dependable for projects needing flexible and low-cost force measurement. For more tips, check out SOUSHINE’s technical guides and product information.

FAQ

What is a force-sensitive resistor (FSR)?

A force-sensitive resistor can sense when you press on it. Its resistance gets lower when you push down. Engineers use FSRs to measure touch, weight, or pressure in many things.

How accurate are SOUSHINE FSRs?

SOUSHINE FSRs are usually accurate within about ±10%. This is good enough for most jobs that do not need super exact numbers.

Can SOUSHINE FSRs handle extreme temperatures?

SOUSHINE FSRs work well from -25°C up to 85°C. This means they can be used in very hot or cold places.

How often should users calibrate FSRs?

Engineers should calibrate FSRs before starting a new project. They should also do it after moving the sensor. Calibrating often helps keep the results correct and steady.

What industries use SOUSHINE FSRs?

SOUSHINE FSRs are used in cars, healthcare, robots, and electronics. These fields like that the sensors are flexible, strong, and not too expensive.

Do FSRs require special maintenance?

Technicians should clean FSRs often and look for any damage. Checking and recalibrating helps the sensor stay accurate and last longer.

Can users customize SOUSHINE FSRs for unique projects?

Yes. SOUSHINE makes FSRs in many shapes and sizes. Customers can ask for special designs to fit their needs.

What circuit works best with FSRs?

A voltage divider circuit is a good choice for FSRs. This setup turns resistance changes into voltage that microcontrollers can read.

Tip: For best results, use good resistors and short wires. This helps stop electrical noise.