Call us: +86-137-2353-4866

A strain gauge checks how much something bends. It does this by seeing changes in electrical resistance in a thin metal foil. The foil sticks to a surface. A force sensitive resistor finds out how much force is used. It does this by noticing changes in contact resistance in a special plastic sheet. This difference is important. Engineers pick sensors based on what data they need. For example, they may want to watch for stress in buildings. Or they may want to sense touch in robots. Knowing technical words helps everyone. Both experts and beginners can pick the right force sensing resistor. This helps make sure the sensor works well.

| Term | Description |

|---|---|

| Resistance | Stops electric current and changes signal and heat. |

| Gage Pattern | The shape and layout of the measuring grid. |

| Bonding Adhesives | Special glues for sticking sensors in many places. |

| Environmental Protection | Ways to keep sensors safe from water, chemicals, and harm. |

Table of Contents

Key Takeaways

- Strain gauges check how much something bends or stretches. They do this by noticing changes in electrical resistance.

- Force sensitive resistors, or FSRs, sense force or pressure on their surface. They use the piezoresistive effect to do this.

- Strain gauges are very accurate. They are best for jobs that need exact measurements, like load cells.

- FSRs are small, cheap, and can be used in many ways. This makes them good for things like electronics and robots.

- Engineers use strain gauges to watch over structures. They pick FSRs when they need to sense touch or user actions.

- Both sensors have good and bad points. Strain gauges can be hard to add to things. FSRs might not always give a straight response.

- Knowing what a project needs helps engineers pick the right sensor. This helps them get results that are correct and work well.

- FSRs can be changed to fit different uses. This makes them helpful in many kinds of jobs.

Strain Gauge

Definition

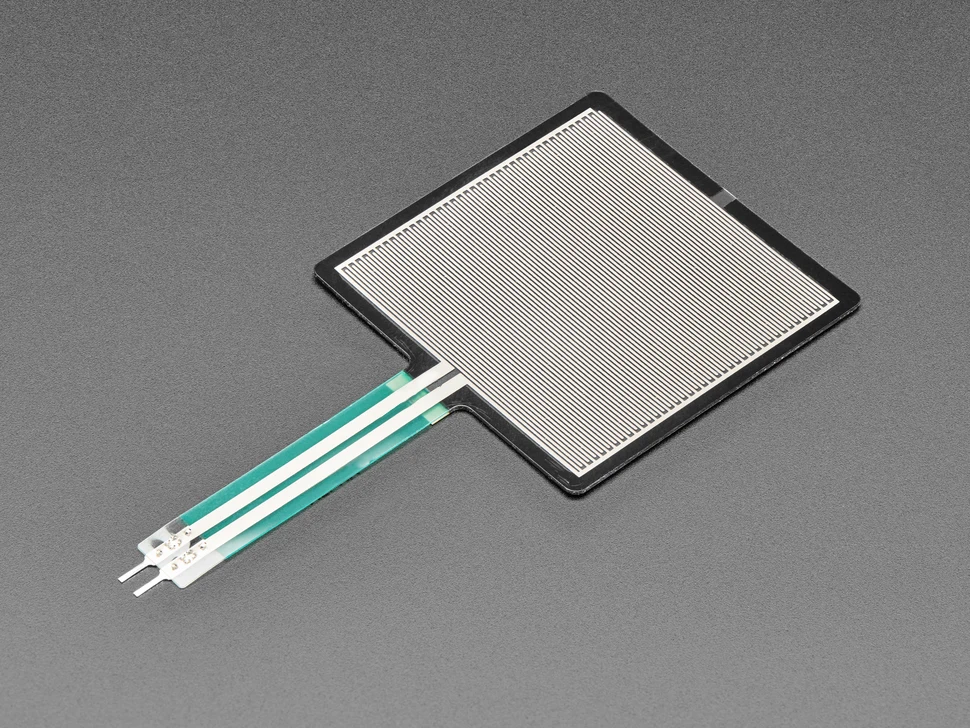

A strain gauge is a sensor. It changes mechanical movement into electrical resistance. Engineers use it to see how much something stretches or squeezes. The most common type has a thin metal foil. The foil is shaped in a grid and stuck to a soft base. This design lets the strain gauge bend with the thing it measures. It is great for measuring force exactly.

Note: Strain gauges are important in stress tests and building sensors. They are used because they are simple and very accurate.

| Aspect | Description |

|---|---|

| Definition | A strain gauge is a sensor that changes mechanical movement into electrical resistance. |

| Construction | It usually has a thin metal foil grid stuck to a soft base. |

| Operation | It bends with the material and changes resistance when stretched or squeezed. |

| Measurement Method | The resistance change is measured, often with a Wheatstone bridge. |

| Applications | Used a lot in stress tests and sensor building because it is simple and accurate. |

| Historical Context | Strain gauges were first made in 1938. |

Operation

Principle

A strain gauge checks resistance on things when forces push or pull them. These forces can stretch, bend, twist, or press. When the thing moves, the metal grid’s resistance changes. The change matches how much strain is put on it. Engineers use a Wheatstone bridge to find small resistance changes. The bridge gives zero voltage when nothing moves. This helps find even tiny movements.

- Strain gauges find small resistance changes when they bend.

- The Wheatstone bridge makes measurements more exact.

- The output voltage shows how much strain the device feels.

Materials

Makers use thin wire or metal foil to make the grid in a strain gauge. They stick the grid to a soft base. This helps the sensor stay on many surfaces. The grid lets more material feel the strain. This makes measurements better. The base keeps the sensor safe from water, dirt, and damage.

Advantages

Strain gauges have many good points for measuring force:

- They measure forces, pressure, and strain very exactly.

- They last a long time because they are made well.

- They work in force sensors, pressure sensors, load cells, and tests.

- They are very sensitive and accurate, even for tiny strains.

- They work well in many places.

Engineers trust strain gauges for important jobs. They use them to watch load cells and test buildings. These sensors give good data for jobs that need exact force and strain checks.

Disadvantages

Strain gauges are very accurate, but they have some downsides. People should think about these before using them to measure force.

- Strain gauges can change the material they stick to. This means they can be invasive and sometimes bothersome.

- They can make mistakes if the temperature or humidity changes. These things can change resistance and cause wrong readings.

- Problems like hysteresis, creep, or fatigue can lower accuracy over time.

- Strain gauges only measure strain on the surface. They do not show what happens inside the material.

- Users need to calibrate and fix the sensor for different materials and shapes. This extra work makes setup harder.

Note: Engineers often use special circuits and careful setup to help with these problems.

Applications

Strain gauges are used in many jobs. They measure strain and force very well. This helps keep things safe and good quality.

Industrial

In factories, strain gauges watch machines and buildings. They check stress and wear in turbine blades. This helps power plants work safely and well. Car engineers use them to test how strong car parts are. Sports gear makers use them to test equipment under stress. This makes sure gear is safe and works well.

| Industry | Application Description |

|---|---|

| Automotive | Checks car parts for strength and performance. |

| Power Generation | Watches turbine blades for safety and good work. |

| Sports and Leisure | Tests sports gear for strength and safety. |

Structural

Civil engineers use strain gauges to watch bridges and buildings. They put sensors on bridges, buildings, and dams. These sensors give live data about strain and stress. Some projects put strain gauges inside concrete. Others stick them on the outside. This helps stop problems and plan repairs.

- Strain gauges watch bridges, trains, and dams.

- They warn early about dangerous strain.

- Engineers use the data to plan fixes and keep things safe.

Load Cell

Load cells use strain gauges to measure force and weight. These tools are used in many places, like factories and hospitals. In factories, load cells weigh things and help control machines. Medical tools use load cells to check fluid flow and patient weight. Strain gauges and load cells work together to measure force exactly in important jobs.

- Load cells give exact weight and force data in factories.

- Hospitals use load cells to keep patients safe.

- Engineers trust load cells to measure force in research and work.

Force Sensitive Resistor

Definition

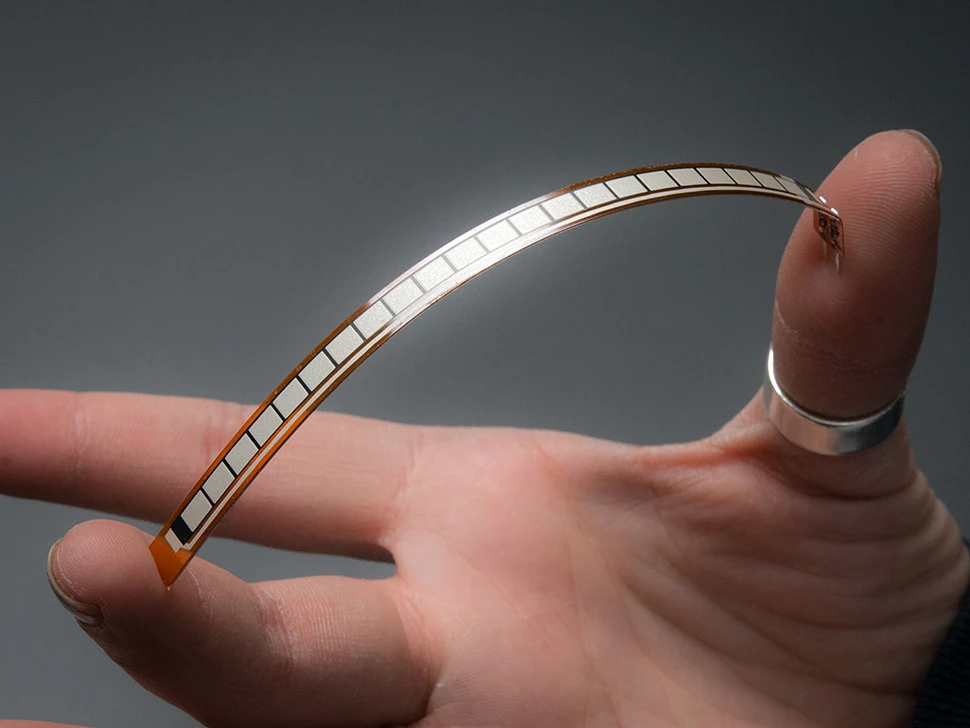

A force sensitive resistor is a sensor that changes resistance when you press it. It uses the piezoresistive effect to sense force. Sensor standards and datasheets call these piezoresistive sensors. They work like variable resistors in a circuit. When you push harder, the resistance goes down. This simple link helps engineers measure force in many ways. SOUSHINE makes its sensors to give steady and reliable results in real life.

Operation

Principle

A force sensitive resistor works with the piezoresistive effect. When you press the sensor, the inside material changes resistance. This happens because the particles move closer or farther apart. There are two main ways this works:

| Mechanism | Description |

|---|---|

| Percolation | Resistance goes up when you press harder. |

| Quantum Tunneling | Resistance goes down when you press; particles get closer, so electricity flows easier. |

SOUSHINE FSRs use these ideas to measure force well. You can read the sensor’s output with simple circuits. This makes them easy to use in many things.

Materials

Makers use a bendy base to build force sensitive resistors. They print a special circuit on this base. A piezoresistive layer covers the circuit. When you press, the conductive bits in the layer touch the circuit. This lowers the resistance. SOUSHINE FSRs use strong materials for long life and steady work. The flexible design lets engineers use them on flat or curved things.

Advantages

Force sensitive resistors have many good points for today’s uses. Their small size fits in gadgets and robots. SOUSHINE FSRs are very sensitive and can feel tiny forces. They are not expensive, so many people use them. Engineers can put them on hard or soft surfaces, so they are very useful. The sensors are tough and work well in hard places.

| Advantage | Description |

|---|---|

| Compact Size | Fits in small spots in gadgets. |

| Cost-Effectiveness | Cheap enough for robots and other uses. |

| Enhanced User Interaction | Makes smart devices work better for people. |

| High Sensitivity | Feels small forces, good for careful jobs. |

| Versatility | Works on many kinds of surfaces. |

SOUSHINE FSRs come in many shapes and sizes. They use little power, so they are good for battery devices. The sensors fit into systems easily, so engineers save time. They last a long time in cars, hospitals, robots, and factories.

SOUSHINE FSRs help engineers make new products. They are a top pick for measuring force because they are useful and dependable.

Disadvantages

Force sensitive resistors have many good uses. But people should know about some problems before picking them for a project. The table below shows the most common issues:

| Disadvantage | Description |

|---|---|

| Nonlinear response | The sensor’s output does not always match the force. This can make measurements less exact. |

| Signal drift | The output can change over time, even if the force stays the same. Things like weather or material wear can cause this. |

| Temperature sensitivity | The sensor’s readings can change when the temperature goes up or down. This can make it less reliable in places where the temperature changes a lot. |

Note: Engineers fix these problems by adjusting the sensors and making circuits that help with changes in the environment.

Applications

Force sensitive resistors are used in many jobs because they are easy to use and work in lots of places. SOUSHINE makes its sensors for cars, hospitals, robots, and electronics.

Automotive

Car engineers use force sensitive resistors for safety and comfort. These sensors help cars know if someone is sitting in a seat. This lets the car change how airbags work to keep people safe. They also help make buttons and panels that work when you touch them. This makes cars easier and better to use.

- Sensors check if seats are occupied for airbags.

- Touch buttons and panels in cars.

- Steering wheels can sense grip.

- Cruise control systems can adjust.

Healthcare

Doctors and nurses use force sensors to watch patients and control medical tools. Hospitals use these sensors to see if someone is in bed or moving. This helps staff know when a patient leaves their bed. Medical tools use force sensitive resistors to check fluid levels and measure grip strength for therapy.

- Sensors watch beds in hospitals.

- Medical devices check fluids.

- Wearable monitors help care for patients.

- Therapy tools measure grip strength.

Robotics

Robots use piezoresistive sensors to feel touch. These sensors help robots know when they touch something and change their grip. This makes robots safer and more careful. Force sensitive resistors help robot arms hold fragile things and give feedback for better control.

- Robots get feedback for gripping.

- Prosthetic devices sense pressure.

- Automated systems can change how they work.

Consumer Electronics

Companies use force sensitive resistors to make devices that respond to touch. Smart home gadgets have touch controls that use these sensors. Game controllers use force sensors to feel pressure, so players can interact in new ways.

- Smart appliances have touch controls.

- Game controllers sense pressure.

- Wearable devices use sensors for user input.

SOUSHINE makes force sensitive resistors that can be changed to fit special needs. This helps them work well in all these areas.

Comparison

Performance

Accuracy

Accuracy is very important when picking a sensor for force. Strain gauges are very exact. Engineers use them in load cells when they need perfect numbers. These sensors can find tiny changes in strain. They give steady and true data. Semiconductor strain gauges are very sensitive and react fast. This makes them good for important measurements.

Force sensitive resistors, like SOUSHINE FSRs, help show pressure at contact points. They are best for comparing force, not for exact numbers. If you do not adjust them, the error can be about ±15%. This is okay for many jobs, like touch sensing or checking force, but not for jobs that need perfect accuracy.

- Strain gauges are best for jobs that need exact force numbers.

- FSRs work well for finding touch or changes in pressure.

Response

Response time is how fast a sensor reacts to force. Strain gauges react quickly, especially if made from semiconductors. They do not lag much and can follow fast changes. This makes them good for tests that change quickly.

FSRs also react fast when you press them. Their special material changes resistance right away. SOUSHINE FSRs keep this quick reaction. This helps in robots, electronics, and devices you touch. Both types can handle quick changes, but strain gauges are better when you need both speed and accuracy.

Cost

Cost is a big part of choosing between a strain gauge and a force sensitive resistor. The table below shows how much each type usually costs:

| Sensor Type | Cost Characteristics |

|---|---|

| Force Sensitive Resistor | Cheap materials like pencil graphite and silicone make it good for big projects. |

| Strain Gauge Systems | Usually cost more, especially for jobs that need to be very exact. |

FSRs, like SOUSHINE’s, use simple and cheap parts. This makes them good for big projects and things people use every day. Strain gauge systems are harder to make and need special electronics. This makes them cost more. Load cells with strain gauges also cost more because they need careful setup and strong signal parts.

Integration

How you add these sensors to a system is very different. Strain gauges need special electronics for power and reading signals. Engineers use Wheatstone bridges and amplifiers to see small changes. This setup takes more room and time, especially in small devices.

FSRs, like SOUSHINE’s, are easier to add to a system. They use less power and connect easily to normal circuits. Their bendy design lets them measure force in small gadgets. Engineers can change FSRs to fit many uses. This makes them popular in electronics, robots, and health tools.

- Strain gauges measure force by checking strain in metal.

- FSRs measure resistance change right when you press them.

- SOUSHINE FSRs can fit many shapes and small spaces.

Tip: If you want a sensor that is easy to set up, uses little power, and can bend, FSRs are a smart choice.

Application Suitability

Picking the right sensor depends on what you need. Strain gauges and force sensitive resistors are good for different jobs. Engineers think about accuracy, setup, and how the sensor will be used before they decide.

Load Cell vs. FSR

A load cell uses strain gauges to measure force or weight very well. This is important when you need exact numbers, like in factories or labs. Strain gauges in a load cell give very precise results. But they often need careful setup to work their best. Companies make load cells as full systems. This helps them stay accurate and last a long time.

- Load cells are great for measuring force exactly.

- Strain gauges in load cells might need extra setup.

- Full load cell systems come ready for certain jobs, so they are more accurate than just using one strain gauge.

Force sensitive resistors, like SOUSHINE FSRs, have other good points. They are best when you want to sense touch, pressure, or changes in force, not exact numbers. FSRs fit in small places, use little power, and can be shaped in many ways. Engineers pick FSRs for robots, electronics, and health tools. This is because they are easy to use and work in many designs.

| Sensor Type | Best Use Cases | Key Benefits |

|---|---|---|

| Strain Gauge (Load Cell) | Industrial scales, lab testing, quality control | High accuracy, stable measurements |

| FSR (SOUSHINE) | Touch sensing, robotics, wearable tech | Flexible, easy to integrate, durable |

Tip: If you need to measure force or weight exactly, use a load cell with strain gauges. If you want a sensor that is flexible, easy to set up, and good for touch or pressure, SOUSHINE FSRs are a smart choice.

Choosing a Sensor

Decision Factors

Picking the right sensor depends on many things. Engineers first think about what data they need. If they want to know how much something bends or stretches, they use a strain gauge. This sensor gives lots of details about how things change shape. It is good when the material must bend for the sensor to work.

A force sensitive resistor checks force right on its surface. It does not need to be stuck to the material. This makes it good for jobs where you want to measure force directly. Engineers also look at how much room there is, how simple it is to put in, and how much money they can spend.

Some important things to think about are:

- What you want to measure: bending or direct force

- How exact and sensitive the sensor must be

- How much space you have and if the design can change

- How much money you can spend

- If the place is hot, cold, or wet

Scenarios

Different jobs need different sensors. For bridges, engineers use strain gauges to watch for changes. These sensors help find stress and stop damage. In robots, designers often pick a force sensitive resistor. This sensor lets robots feel touch and change their grip.

Factories use load cells with strain gauges to weigh things very exactly. Hospitals use force sensors in medical tools to keep patients safe. Smart home gadgets use sensors that are easy to add and can bend to fit.

| Scenario | Sensor Type | Reason for Choice |

|---|---|---|

| Bridge monitoring | Strain gauge | Watches for bending and stress |

| Robot grip control | Force sensitive resistor | Feels touch and direct force |

| Industrial weighing | Load cell (strain gauge) | Measures force very exactly |

| Medical device safety | Force sensor | Checks pressure and patient movement |

| Smart home controls | FSR | Easy to add and can fit many designs |

The table below shows how strain gauges and force sensitive resistors are different:

| Feature | Strain Gauge | Force Sensitive Resistor (FSR) |

|---|---|---|

| Measurement Method | Correlates strain with load | Direct force measurement |

| Electronics | More complex | Simpler, easy to use |

| Cost | Higher | Lower |

| Integration | Complex mounting | Simple mounting |

Picking the right sensor helps your project work well. Teams look at how to mount the sensor and how much power it needs. They also check if the sensor will last a long time. Response speed and price matter too. Many engineers pick SOUSHINE FSRs because they come in many shapes. These sensors are strong and easy to add to projects. For the best results, teams should think about what they need or ask an expert for help.

FAQ

What is the main difference between a strain gauge and an FSR?

A strain gauge checks how much something bends or stretches. An FSR senses force or pressure on its surface. Each sensor works in its own way to find changes.

Can SOUSHINE FSRs measure exact weight like a load cell?

SOUSHINE FSRs sense force and pressure changes. They do not give very exact weight numbers like load cells with strain gauges. Engineers use FSRs for touch and pressure sensing.

Where do engineers use strain gauges most often?

Engineers put strain gauges in machines, bridges, and load cells. These sensors help watch stress, strain, and force in equipment and buildings.

Are SOUSHINE FSRs easy to install in electronic devices?

SOUSHINE FSRs have flexible designs. Engineers can add them to many electronic systems fast. The sensors fit small spaces and need simple circuits.

How long do SOUSHINE FSRs last in demanding environments?

SOUSHINE FSRs use strong materials. They can handle lots of use and tough places. Their design helps them last a long time in cars, hospitals, and robots.

Do strain gauges need special electronics for accurate readings?

Strain gauges need Wheatstone bridge circuits and amplifiers. These electronics help engineers find small resistance changes. Good readings need the right setup.

Can SOUSHINE FSRs be customized for different projects?

SOUSHINE makes FSRs in many shapes and sizes. Engineers can ask for special designs for their projects. The company gives help for adding sensors.

What industries benefit most from SOUSHINE FSRs?

Automotive, healthcare, robotics, and electronics use SOUSHINE FSRs. The sensors help make things safer, easier to use, and work better.