Call us: +86-137-2353-4866

The main difference between a force sensor and a pressure sensor is what they measure. A force sensor finds the total push or pull on something. A pressure sensor checks how much force is on each small area. Force sensing helps people watch loads in robots. Pressure sensors check liquids and gases in things like pipes. Knowing this difference helps make products safer and work better.

- The global force measuring sensor market may grow from USD 2.5 Billion in 2024 to USD 4.0 Billion by 2033. This shows a CAGR of 6.5% from 2026 to 2033.

- The pressure sensor market may rise from USD 13.07 billion in 2025 to USD 17.70 billion by 2030. The CAGR for this time is 6.2%.

Table of Contents

Key Takeaways

Force sensors check the total push or pull on something, but pressure sensors check how force spreads over an area. Force sensors are important in robots and factories to watch loads and keep things safe. Pressure sensors are needed to watch liquids and gases, find leaks, and keep systems safe. Picking the right sensor is very important for good measurements and to stop expensive mistakes in many jobs. Force sensors use units like Newtons (N) or pounds-force (lbf), but pressure sensors use Pascals (Pa) or pounds per square inch (psi). Both force and pressure sensors use things like strain gauges and piezoelectric sensors to turn physical changes into electrical signals. Knowing where and how each sensor works helps engineers choose the best one. SOUSHINE’s capacitive force-torque sensors give correct readings and work well in robots and research.

Force Sensor Basics

What Is a Force Sensor

A force sensor checks the total push or pull on something. These devices turn force into electrical signals. People use them to find weight, tension, or compression in many things. The signal from a force sensor helps control machines. Force sensors are important in robots, factories, and electronics.

| Characteristic | Description |

|---|---|

| Sensitivity | Finds small changes in force for accurate results. |

| Durability | Works well for a long time in many places. |

| Response Time | Changes fast when force changes, which helps with quick jobs. |

How Force Sensors Work

Measurement Principle

Force sensors work by noticing changes when force is used. The sensor bends a little when you push or pull on it. This bending changes something electrical, like resistance or capacitance. The sensor turns this change into an electrical signal. The system then uses the signal to show the exact force.

Tip: Force sensors can check weight, tension, and compression. Their signals help run robots and machines.

Technologies Used

There are different kinds of force sensors:

- Strain gauge force sensors notice resistance changes when a material bends.

- Piezoelectric force sensors make an electric charge when force is used.

- Capacitive force sensors find changes in capacitance between metal parts.

- Magnetoelastic force sensors sense changes in magnetism when force is used.

SOUSHINE’s Capacitive Force-Torque Sensors use special capacitive technology. These sensors measure capacitance between two metal pieces. The design uses a metal block that bends in a known way. This helps the sensor give correct and steady force readings. The sensors block out electrical noise, so they work well in factories and labs. SOUSHINE sensors give six signals for force and torque, which helps robots and machines. Their strong build means they last long and stay accurate.

Force Sensor Applications

Industrial Uses

Force sensors help with many jobs in factories:

- Robots use force sensors to push or pull just right during work.

- In factories, force sensors help machines hold soft things, like food or electronics, without breaking them.

- Car factories use force sensors to make sure parts fit together.

- Electronics makers use force sensors to check quality.

- Airplane and food factories use force sensors to make work safer and better.

Consumer Uses

Force sensors are also in things we use every day:

- Scales use force sensors to check weight.

- Game controllers use force sensors to feel how hard you press.

- Medical devices use force sensors to watch how much effort a patient uses.

- Hospital tools use force sensors to help care for patients.

- The market for force sensors in electronics is getting bigger. Experts think it will grow from US$2.7 billion in 2025 to US$3.9 billion by 2032.

Note: SOUSHINE’s capacitive force sensors are very accurate and strong, so they work well in both robots and home devices.

Pressure Sensor Overview

What Is a Pressure Sensor

A pressure sensor checks force spread over an area. This device turns pressure changes into electrical signals. People use pressure sensors to watch liquids and gases in many places. The sensor helps keep pipelines, HVAC systems, and machines safe. Pressure sensors help find leaks, blockages, and changes in flow.

How Pressure Sensors Work

Measurement Principle

Pressure sensors notice changes in force on each area. The sensor reacts when pressure goes up or down. It turns these changes into signals for machines. Some sensors compare pressure to a vacuum. Others compare it to air pressure or between two spots. The sensor’s design depends on what kind of pressure it needs to check.

| Type of Pressure Sensor | Mechanism Description |

|---|---|

| Absolute Pressure Sensors | Check pressure compared to a perfect vacuum. |

| Gauge Pressure Sensors | Check pressure compared to air pressure. |

| Differential Pressure Sensors | Check the difference between two pressures. |

| Strain Gauge Pressure Sensors | Use strain gauges to see how a diaphragm bends under pressure. |

| Capacitive Pressure Sensors | Check changes in capacitance when a diaphragm moves under pressure. |

| Piezoelectric Pressure Sensors | Use materials that make electric charge when pressed. |

| Optical Pressure Sensors | Notice pressure changes by using light. |

| MEMS Pressure Sensors | Tiny sensors with high sensitivity and electronics. |

Technologies Used

Pressure sensors use different ways to measure pressure. Common types are resistive, piezoelectric, capacitive, inductive, Hall element, and MEMS. Each type works best in certain places. For example, capacitive sensors use a diaphragm that moves when pressure changes. This changes the capacitance. Piezoelectric sensors make electric charge when squeezed. Inductive sensors use coils and magnets. The technology chosen depends on what is being measured, especially in tough settings.

| Type of Pressure Sensor | Description | Typical Uses |

|---|---|---|

| Differential Pressure Sensor | Checks the pressure difference between two places. | HVAC systems, filtration monitoring |

| Vacuum Pressure Sensor | Checks pressure lower than air pressure. | Vacuum packaging, vacuum systems |

| Potentiometric Pressure Sensor | Uses moving parts to check pressure. | General pressure measurement |

| Inductive Pressure Sensor | Uses LVDT to check pressure changes. | Tough places, factories |

| Capacitive Pressure Sensor | Checks capacitance changes when a diaphragm bends. | Sensitive jobs, low power devices |

| Piezoelectric Pressure Sensor | Makes electric charge when pressed hard. | Engine combustion monitoring |

| Strain Gauge Pressure Sensor | Checks resistance changes when stressed. | Moving and still pressure jobs |

| Variable Reluctance Sensor | Checks magnetic changes when a diaphragm bends. | Precise pressure measurements |

Pressure Sensor Applications

Industrial Uses

Pressure sensors do many jobs in factories. They watch for leaks or blocks in hydraulic presses. They check injection pressure in molding machines. Air compressors use sensors to spot pressure changes. Boilers use sensors to track steam or water pressure. Concrete pumps use sensors to stop line bursts. Gas pipes use sensors to watch line pressure. These sensors help keep things safe and working well.

Consumer Uses

Pressure sensors are in many things we use daily. Cars use sensors to check tire pressure and engines. The car industry uses lots of these sensors. The market may be USD 13.53 billion in 2025 and could reach USD 16.96 billion by 2030. Asia Pacific is the biggest market. Home machines like washers and dishwashers use sensors to control water. Medical tools use sensors to check blood pressure and breathing. HVAC systems use sensors to control air flow and keep rooms comfy.

Tip: Pressure sensors help keep things safe and working well by giving real-time data about liquids and gases.

Force Sensor vs Pressure Sensor Differences

Measurement Principles

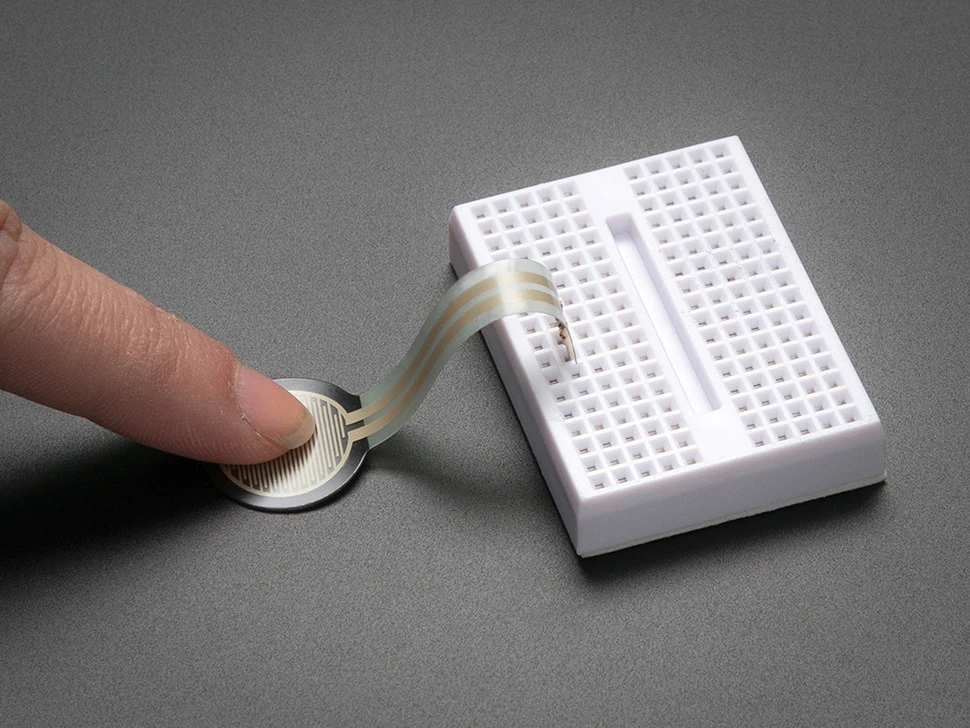

Force sensors and pressure sensors work in different ways. Force sensors find the total load on an object. They turn this load into an electrical signal. Some force sensors, like Force Sensing Resistors (FSRs), change resistance when force is used. The sensor has a film inside that bends when pressed. This bending makes resistance go down. This way can change how accurate and repeatable the sensor is.

Pressure sensors check force spread over an area. They use a diaphragm that bends when pressure changes. The shape and material of the diaphragm matter for accuracy and reliability. Pressure sensors often compare pressure to a reference, like a vacuum or air pressure.

Note: How a sensor measures force or pressure affects how well it works. In places like HVAC systems, car factories, airplanes, medical tools, and factories, the right sensor gives good data.

Units Used

Force sensors and pressure sensors use different units. Force sensors measure total force. They use Newtons (N) or pounds-force (lbf). These units show the push or pull on something.

Pressure sensors measure force on each area. They use Pascals (Pa) or pounds per square inch (psi). These units show force on a small spot.

- Force sensors measure total load with Newtons or pounds-force.

- Pressure sensors measure force spread out with Pascals or psi.

- Force sensors are best for total force. Pressure sensors work best when force spreads over a surface.

Picking the right unit helps people choose the right sensor. For example, scales use Newtons to show weight. Tire gauges use psi to show air pressure.

Use Cases

Force sensors and pressure sensors are used for different jobs. Force sensors help in robots, factories, and testing. They help robots hold things, measure weight, and test materials. Pressure sensors are used with liquids and gases. They watch pipelines, control HVAC, and check engines.

Using the wrong sensor can cause problems:

- Environmental monitoring: The wrong sensor can miss events or give false alarms.

- Factory control: Bad sensor choice can lower quality and make more waste.

- Healthcare: Wrong sensors can hurt patient safety.

- Self-driving cars: Sensor mistakes can cause accidents.

Tip: Always pick the right sensor for the job. This helps avoid mistakes and keeps things safe.

Design Differences

Engineers make force sensors and pressure sensors for different jobs. Each sensor has its own way to measure force or pressure well.

Force sensors use strong materials that bend when force is used. The sensor notices this bending and makes an electrical signal. Many force sensors have metal blocks, beams, or discs. Some, like SOUSHINE’s capacitive force sensors, use a special metal block that bends in a certain way. This helps the sensor measure force and torque very well. The sensor gives clear signals so robots and machines can act fast.

Pressure sensors measure force spread over an area. Most pressure sensors have a thin diaphragm. When pressure changes, the diaphragm bends. The sensor sees this movement and sends out a signal. The diaphragm can be made of metal, ceramic, or silicon. The choice depends on where the sensor will be used and what fluid or gas it will check. Pressure sensors often have layers to protect them from damage or strong chemicals.

| Feature | Force Sensors | Pressure Sensors |

|---|---|---|

| Main Structure | Solid block, beam, or disc | Thin diaphragm |

| Measurement Focus | Total force or torque | Force per unit area (pressure) |

| Signal Output | Direct force readings, often multi-axis | Pressure readings, single or differential |

| Material Selection | Metals for strength and durability | Metals, ceramics, silicon for flexibility |

| Integration | Robotics, industrial machines | Pipelines, HVAC, medical devices |

Note: Engineers pick the sensor design based on what they need to measure. Force sensors are best for total load or torque. Pressure sensors are great for checking fluids and gases.

Manufacturers make force sensors strong so they last a long time. They use tough materials to handle lots of force again and again. Pressure sensors need to be flexible and sensitive. The diaphragm must bend with small pressure changes but not break.

Some force sensors have built-in electronics for easy data use. SOUSHINE’s capacitive force sensors have electronics inside and strong signals. This design cuts down noise and makes them more accurate in busy places.

Pressure sensors are often small. They fit into tight spots like pipes or engines. The sensor must not leak and must handle high pressure.

Engineers test both sensor types to make sure they work well. They check how the sensor reacts to force or pressure over time. The design must fit the job to keep things safe and working right.

Choosing the Right Sensor

Application Scenarios

Picking a force sensor or a pressure sensor depends on the job. Force sensors check the total push or pull on something. Pressure sensors check how much force is on each small area. In robots, engineers use a force torque sensor to control how the robot grabs and moves things. Research labs often need multi-axis force sensors to measure tricky forces in tests.

SOUSHINE’s capacitive force torque sensor works well for robots and research. It gives clear readings for both force and torque. This helps robots hold things safely and lets researchers get good data. If you need to measure total load or torque, use a force sensor. If you need to watch fluids or gases in pipes, use a pressure sensor.

Tip: Use force sensors for solids and pressure sensors for liquids or gases.

Selection Factors

Engineers must think about many things before picking a sensor. The place where the sensor works can change how it acts. Temperature, humidity, and shaking can make sensors work differently. The table below shows how these things can change measurements and ways to fix problems:

| Environmental Factor | Impact on Measurement | Mitigation Strategy |

|---|---|---|

| Temperature | Drift, sensitivity change | Compensation, shielding, stabilization |

| Humidity / Moisture | Instability, corrosion | Sealed sensors, IP-rated protection |

| Vibration / Shock | Signal noise, mechanical fatigue | Damping mounts, filtering |

How much money you have and how exact you need to be also matter. Some sensors, like strain gauge force sensors, cost more because they are more complex. Putting in and setting up sensors adds to the price. Engineers should check the measurement range. Smaller ranges can be more exact. Where the sensor is used, how often it is used, and how it is cared for also change how well it works.

- Strain gauge force sensors cost more at first.

- Putting in sensors can cost a lot.

- Setting up sensors costs more over time.

- The range you pick changes how exact it is.

- Where you use the sensor, like hot or wet places, can change results.

- Using a sensor a lot can make it less exact.

- Checking and fixing sensors often keeps them working well.

SOUSHINE’s capacitive force torque sensor works well in noisy places. It blocks out electrical noise and gives steady readings. This makes it a good pick for robots and research when you need good data.

Common Mistakes

Many projects fail because people make simple mistakes when picking sensors. The most common mistakes are:

- Measuring Range: Sometimes people pick a sensor with the wrong range. This gives bad data.

- Accuracy and Precision: Some mix up accuracy and precision. The sensor must fit what the project needs.

- Sensor Type and Where It Works: Using the wrong sensor or not thinking about the place can make it break early.

- Digital Technology: Analog sensors can make mistakes. Digital sensors help stop this problem.

- Flexibility: Projects can change. Flexible sensors can handle new jobs.

Other problems happen when people forget about how to put in the sensor or if it needs to touch what it measures. Picking the wrong sensor can cost a lot or even be dangerous.

For example, a sensor mistake caused the Lion Air Flight JT610 crash in 2018. Wrong sensor data led to a deadly mistake in the plane’s controls.

Engineers should always match the sensor to the job. They must check the place, how exact they need to be, and the budget. SOUSHINE’s capacitive force torque sensor gives good data for robots and research. This helps people avoid big mistakes.

Comparison Table

Quick Reference

You need to know how force sensors and pressure sensors are different. The table below shows important things to compare. Each row tells you what matters for picking a sensor. These points help you see which sensor works best for each job.

| Criteria | Force Sensor | Pressure Sensor |

|---|---|---|

| Measuring range | Measures total force, often in Newtons or pounds-force | Measures pressure, often in Pascals or psi |

| Sensitivity | Detects small changes in force | Detects small changes in pressure |

| Resolution | Provides fine increments of force measurement | Provides fine increments of pressure measurement |

| Accuracy | Matches measured force to true force | Matches measured pressure to true pressure |

| Precision | Repeats force readings under same conditions | Repeats pressure readings under same conditions |

| Durability | Handles repeated force cycles, robust in tough settings | Handles repeated pressure cycles, resists corrosion |

| Size of sensor | Varies from compact to large, fits machines or robots | Often small, fits pipes, engines, or medical devices |

| Response time | Responds quickly to force changes | Responds quickly to pressure changes |

| Measuring speed | Takes force readings at high rates | Takes pressure readings at high rates |

| Measuring depth | Measures force at contact points | Measures pressure at specific depths in fluids/gases |

| Linearity | Output follows input force directly | Output follows input pressure directly |

| Drift | Output stays stable over time | Output stays stable over time |

| Hysteresis | Output remains consistent when force changes direction | Output remains consistent when pressure changes direction |

Tip: Always check measuring range and sensitivity first. These two things help you know if the sensor is right for your job.

A force sensor is best for checking the total load on something. Engineers use force sensors in robots and machines. Pressure sensors are better for watching fluids and gases. Technicians use pressure sensors in pipes, HVAC, and medical tools.

- Force sensors measure push or pull.

- Pressure sensors measure force spread out over an area.

Both sensor types have good points. Force sensors are tough and very exact for mechanical jobs. Pressure sensors are quick and small, so they fit fluid systems.

Engineers should look at the table before picking a sensor. They need to match the sensor’s features to the job. SOUSHINE’s capacitive force-torque sensors are very accurate and strong for robots and research. Pressure sensors are great for checking liquids or gases.

Note: Always compare accuracy, durability, and response time. These things help you get good measurements and keep things safe.

Force sensors find the total load on something. Pressure sensors check force on each small area. You need to pick the right sensor for your job. This helps keep things safe and working well.

- Pressure sensors watch pressure changes as they happen. This is important for jobs like extrusion that need steady control.

- Force sensors can be used in lots of places. They might not show changes right away.

Tip: Think about what you need before you choose. Do you want to see changes right away? Is accuracy or strength most important? For robots or research, SOUSHINE’s capacitive force-torque sensors work very well.

FAQ

What is the main difference between a force sensor and a pressure sensor?

A force sensor checks the total push or pull on something. A pressure sensor checks force on each small area. This difference helps people pick the right sensor for their needs.

Where do engineers use force sensors most often?

Engineers use force sensors in robots, factories, and tests. These sensors help machines work, measure loads, and keep systems safe.

Can a pressure sensor measure force directly?

A pressure sensor does not check total force by itself. It checks force for each area. To get total force, you multiply pressure by the area.

Why do robots need force-torque sensors?

Robots use force-torque sensors to control grip and movement. These sensors help robots hold things safely and not drop or break them.

How do SOUSHINE capacitive force-torque sensors improve measurement?

SOUSHINE capacitive force-torque sensors use special capacitive technology. This design blocks electrical noise and gives steady, correct readings in tough places.

What units do force and pressure sensors use?

Force sensors use Newtons (N) or pounds-force (lbf). Pressure sensors use Pascals (Pa) or pounds per square inch (psi). Each unit fits the kind of measurement.

Can one sensor type replace the other?

One sensor type cannot do the other’s job. Force sensors work best for solids. Pressure sensors work best for liquids and gases.

How should users choose between a force sensor and a pressure sensor?

People should think about what they want to measure. For total load or torque, pick a force sensor. For watching liquids or gases, pick a pressure sensor.

Tip: Always pick the sensor that matches your job for the best results.