Call us: +86-137-2353-4866

Force sensors work well in wet places if engineers design them right and pick materials that do not let water in. Studies show sensors in water break more often than ones in dry places. Water can hurt sensor parts and solder joints. Makers fix these problems with new force sensor technology, special coatings, and strong sensing methods. SOUSHINE’s Force Sensing Resistors use a bendable base and special materials to work well in tough wet spots.

Table of Contents

Key Takeaways

Force sensors can work in wet places if made with good materials and coatings. Water can hurt sensors. It can cause rust and short circuits. This makes sensors not work well. Picking sensors with high IP ratings gives better safety from water and dust. Special coatings, like parylene, help keep sensors safe from water and chemicals. Sealing with gaskets and O-rings stops water from getting inside sensor cases. Using non-corrosive materials, like stainless steel and special plastics, helps sensors last longer in wet places. Cleaning and checking sensors often can stop rust and make sure they work right. SOUSHINE’s Force Sensing Resistors are made to work well in wet places. This makes them good for medical and industrial uses.

Force sensors: challenges in wet environments

Force sensors have problems in wet places. Water, humidity, and electrical noise can hurt how sensors work. Engineers need to know these dangers to pick the best sensor for each job.

Water ingress

Water ingress happens when moisture gets inside the sensor. This can happen to force sensors, strain sensors, and fluidic soft sensors.

Component effects

- Water can rust inside parts, which makes them break and stop working.

- Moisture can cause short circuits, which mess up the signals sensors need.

- Some sensors, like piezoresistive sensors, last longer in humid air. Capacitive sensors can handle pressure for a short time but still have trouble with water.

Corrosion risks

- Rust makes sensor parts and connections weaker.

- Over time, rust can break sensors and make them fail.

- High humidity makes rust more likely, especially in sensors with metal showing.

Electrical issues

Wet places cause many electrical problems for force sensors. These problems can make sensors wrong or stop working.

Short circuits

| Issue | Description |

|---|---|

| Moisture ingress | Makes rust and shorts, which cause wrong readings or total failure. |

| Connector and cable failure | Wet air can break connectors and cables, hurting sensor work. |

| Electrical noise | Can mess up signals, so measurements are not reliable. |

- Wetness for a long time can rust inside wires.

- Water can make paths that connect parts and cause shorts.

- Shorts often make sensors give wrong numbers or shut down.

Signal loss

High humidity can make water drops inside the sensor. These drops can short wires or rust parts. After a while, sensors work worse. Sensors may start to drift, so numbers are less true because of moisture. Water vapor can also add noise, making sensor data hard to read. These problems happen to force sensors, strain sensors, and other types.

Note: IP ratings help people pick sensors with the right protection. Higher IP ratings mean sensors are better at stopping water and dust. Picking sensors with good IP ratings lowers the chance of water getting in and causing problems.

Solutions for wet conditions

Protective coatings

Waterproof types

Engineers put special coatings on force sensors to keep out water. Parylene coatings make a tough shield against chemicals and germs. Makers use vapor to cover the whole sensor with this coating. Parylene C stops water and bad gases, so it works well in wet places. Antifouling coatings help marine sensors last longer by stopping things from sticking. Polyethylene glycol coatings make a layer that keeps away living things, so sensors last longer. SLIPS surfaces work well in still water and help sensors stay clean.

Sealing methods

Sealing keeps water from getting into sensors. Makers use gaskets, O-rings, and glue seals to close up sensor cases. These seals block water from touching important parts. Engineers test seals with pressure and water to make sure they work. Good sealing helps strain sensors and fluidic soft sensors stay correct in wet places.

Materials and enclosures

Non-corrosive options

Sensor cases protect inside parts from water and rust. Stainless steel does not rust and is good for factories and hospitals. Aluminum is strong and light, so it is used in cars and gadgets. Plastics like PEEK, PVC, and nylon do not react with chemicals and cost less. Brass is easy to shape and carries electricity well for pipes and air systems. Titanium is strong and does not rust, so it is used in the sea and in medicine.

| Material | Key Properties | Applications |

|---|---|---|

| Stainless Steel | High strength, corrosion resistance | Industrial, food and beverage, medical |

| Aluminum | Lightweight, thermal conductivity | Automotive, aerospace, consumer electronics |

| Plastics | Chemical resistance, lightweight, cost-effective | Automotive, industrial, consumer electronics |

| Brass | Corrosion resistance, machinability | Plumbing, HVAC systems |

| Titanium | Strength-to-weight ratio, corrosion resistance | Marine, medical, aerospace |

IP ratings

IP ratings show how well sensors block water and dust. Higher numbers mean better protection. IP68 sensors can stay underwater for a long time and not break. Engineers pick sensors with high IP ratings for wet and rough places. This helps force sensors and strain sensors work well where there is water and damp air.

Sensor design

Submersion adaptations

Sensor changes help them work underwater. Multi-directional force sensors have waterproof parts to get IP68 ratings. These sensors still work after being underwater for days. Engineers test sensors at different depths to make sure they are stable. Good design keeps water out and lets sensors work in water jobs.

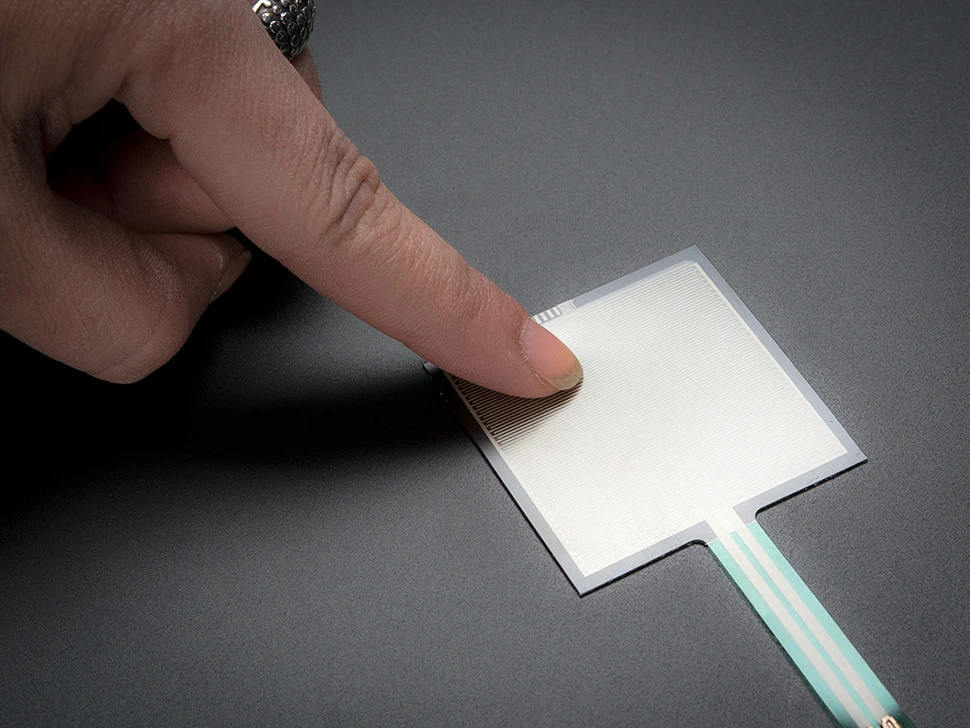

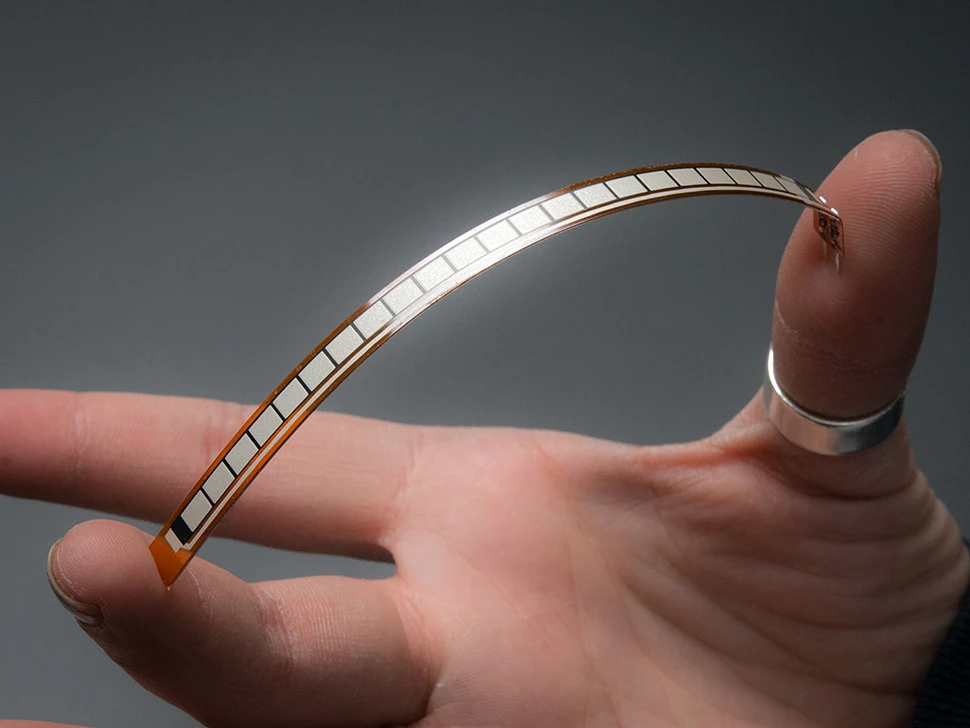

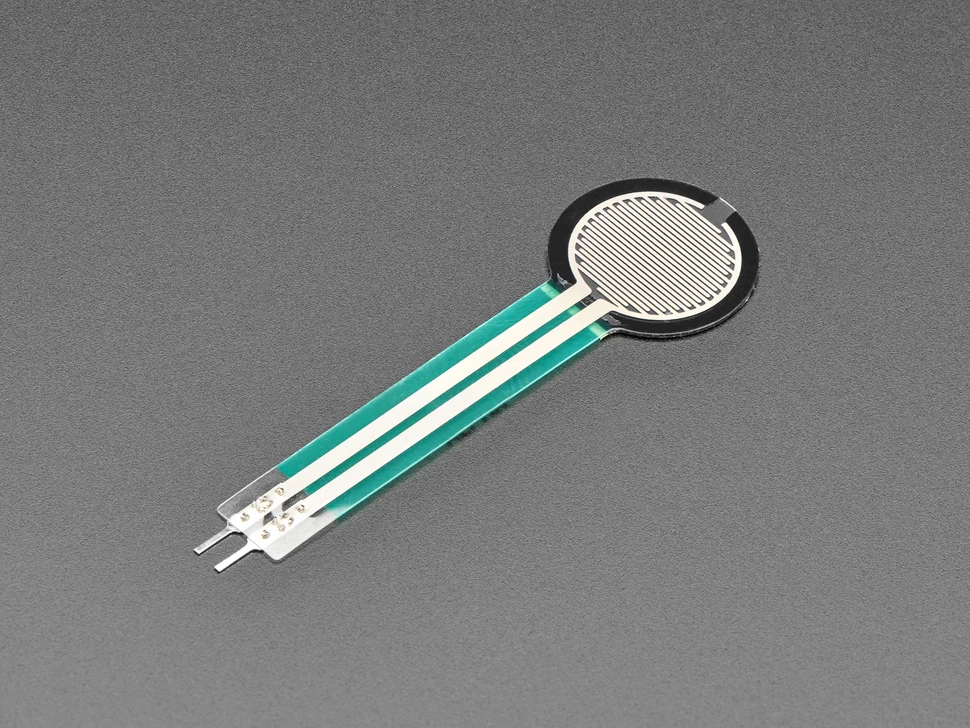

SOUSHINE’s Force Sensing Resistors use a bendy base and special material. This design helps them work in wet places and underwater. SOUSHINE makes FSRs in many shapes and sizes for different wet uses.

Humidity resilience

Sensors have problems in humid air. Superhydrophobic sensors stop water from sticking and keep working well. Materials like MXene-sodium alginate sponges make a wall that blocks water vapor. These things help strain sensors work in very damp air. Water can cause drops and ice, which can hurt sensors. Engineers pick materials and designs that fight humidity and keep sensors working right.

Tip: Picking sensors with waterproof coatings, strong seals, and cases that do not rust helps them last longer in wet places.

Force sensors: applications

Medical devices

Monitoring

Medical devices use force sensors to watch things closely in wet places. These sensors check fluid levels in pumps and dialysis machines. They also help doctors during surgery by giving quick feedback. In physical therapy, strain sensors measure how hard patients push. Orthopedic devices use force sensors to check pressure on joints and bones. MRI machines use sensors to watch patient movement.

| Application Type | Description | Water Resistance Requirement |

|---|---|---|

| Fluid Monitoring | Watches fluid levels in medical devices. | Yes |

| Dialysis Machines | Measures fluid removal very accurately. | Yes |

| Endoscopic Surgery | Gives feedback during small surgeries. | Yes |

| Physical Therapy Equipment | Measures force during rehab exercises. | Yes |

| Orthopaedics | Checks force in orthopedic devices. | Yes |

| MRI Devices | Uses sensors to watch patients during scans. | Yes |

These jobs need sensors that can handle water and cleaning. Flexible designs make it easy to fit sensors in different devices. Custom sensors help meet special water resistance needs.

Sterilization

Sterilization is very important in hospitals. Devices often get hot or face strong chemicals. Some ways to clean, like autoclaving, can make materials crack or lose stretch. This can make strain sensors not last as long. Other ways, like ethylene oxide or low-pressure gas plasma, are gentler on sensor materials. Picking the right cleaning method helps sensors work well and last longer.

Industrial automation

Food processing

Food factories use force sensors in wet and washdown areas. These sensors must handle lots of cleaning with water and chemicals. Most places pick sensors with IP67, IP68, or IP69K ratings. IP67 sensors keep out dust and short water dips. IP68 sensors work underwater for a long time. IP69K sensors can take strong, hot water sprays.

- Food sensors often use stainless steel to last longer.

- Sealed sensors stop water from getting inside.

- Conveyors and mixers use these sensors to measure force exactly.

Chemical environments

Factories with chemicals need sensors that do not rust. Stainless steel and special plastics protect sensors from harsh stuff. These materials help sensors keep working after many cleanings. Strain sensors in these places must give true data and last through lots of cleaning.

Marine and outdoor

Navigation

Marine places have special problems. Saltwater makes things rust, and sensors must work at different depths. Navigation systems use sensors that do not rust and can handle pressure changes. These sensors help guide ships and watch equipment on board.

| Challenge | Description |

|---|---|

| Corrosion | Sensors must not rust in saltwater. |

| Pressure at Various Depths | Sensors need to work under changing water pressure. |

| Harsh Conditions | Sensors must survive tough weather and marine places. |

| Reliable Communication Systems | Sensors must send data in hard conditions. |

Leak detection

Outdoor and marine systems use sensors to find leaks in pipes and tanks. These sensors must work in wet, salty, or damp places. Good leak detection keeps equipment safe and stops harm to nature. Force sensors and strain sensors both help in these safety systems.

Tip: Picking the best sensor material and protection helps sensors last longer in wet and tough places.

SOUSHINE FSRs

Product features

SOUSHINE makes force sensors for wet places. Their Force Sensing Resistors have a bendy base and a special material. This mix lets the sensors measure force and pressure very well. The sensors react fast when force changes. They work in water, damp air, or with cleaning chemicals.

SOUSHINE lets engineers pick shapes and sizes for wearables. The sensors fit in tight spots and on curved things. This helps in health and sports wearables. The sensors do not rust and keep working after many cleanings.

SOUSHINE uses strong seals and coatings on their sensors. These keep out water and dust. The sensors have high IP ratings like IP68. This means they can stay underwater for a long time. The sensors also handle heat changes and rough use.

Tip: SOUSHINE’s force sensors help wearables work in wet places like hospitals, gyms, and outside.

Industry examples

SOUSHINE’s sensors are used in many jobs. In healthcare, wearables use these sensors to track movement and check pressure. Hospitals clean devices a lot, so the sensors must survive water and chemicals. SOUSHINE’s sensors keep working after many cleanings.

In sports, wearables use the sensors to measure force in training. Athletes wear them to track steps, jumps, and hits. The sensors give quick feedback. Coaches use this data to help athletes get better.

Factories use SOUSHINE’s strain sensors in machines. Machines need sensors that work in wet and dirty places. The sensors measure force in robot arms and belts. Food plants use them to check pressure during cleaning.

Marine engineers use SOUSHINE’s sensors for ships and leak checks. Ships and underwater robots need sensors that resist saltwater. The sensors help find leaks in pipes and tanks.

| Industry | Application | Benefit in Wet Environments |

|---|---|---|

| Healthcare | Wearable devices, monitoring | Survive cleaning and sterilization |

| Sports | Wearable devices, training | Work during sweat and rain |

| Industrial | Automation, strain sensors | Resist water and chemicals |

| Marine | Navigation, leak detection | Handle saltwater and pressure |

SOUSHINE’s force sensors help wearables in many areas. Their design and materials help them last longer in wet places.

Choosing force sensors for wet use

Picking force sensors for wet places needs careful thought. Engineers want sensors that can handle water, dust, and heat changes. These things help sensors work well when there is moisture or dirt.

Key features

Materials

Sensors for wet places have sealed force sensing parts. This keeps out water, dust, and dirt. Stainless steel and special plastics stop rust and protect inside parts. Flexible bases let sensors fit in small spaces and on curved things. Some sensors have coatings that block water and chemicals. These materials help sensors last longer and keep working after many cleanings.

- Sealed force sensing parts keep out water and dirt.

- Stainless steel and plastics stop rust and chemicals.

- Flexible bases fit many shapes and surfaces.

- Coatings add more protection from water.

Strain sensors use strong materials for wet and humid air. These choices help sensors stay safe and work well in tough places.

Certifications

Certifications show how sensors handle wet places. The IP rating is very important. It tells how much a sensor can block water and solid things. Higher IP ratings mean better protection from moisture.

| Aspect | Description |

|---|---|

| IP Rating | Shows protection from water and solid things |

| First Digit | Tells how well it blocks solid objects |

| Second Digit | Tells how well it blocks water |

| Application Requirements | Depends on where and how the sensor is used |

Sensors with IP ratings of 60 or more work well in wet places. The first number shows how well it blocks dust. The second number shows how well it blocks water. Engineers pick sensors with high IP ratings for places with lots of moisture.

Tip: Always check the IP rating before you pick a sensor for wet places. Higher ratings mean better protection.

Maintenance tips

Cleaning

Cleaning sensors often helps them last longer in wet places. Use soft cloths and gentle cleaners to wipe off dirt and water. Do not use strong chemicals that can hurt the sensor’s surface. Dry the sensor after cleaning so water does not get inside. Cleaning helps sensors work well and stops rust.

- Wipe sensors with a soft cloth.

- Use gentle cleaners for safe cleaning.

- Dry sensors after each cleaning.

Inspection

Checking sensors often finds problems early. Look for cracks, loose seals, or rust. Check cables and connectors for damage. Change broken parts right away. Checking sensors helps them stay safe and work well.

- Look for cracks and rust on sensors.

- Check seals and connectors.

- Change worn or broken parts.

Note: Good cleaning and checking help sensors work well in wet places and last longer.

Force sensors can keep working well in wet places if they are made and cared for the right way. SOUSHINE FSRs have waterproof covers and tight seals that stop water from getting in. People should keep sensors in dry spots and look for any damage. New sensor technology makes sensors more waterproof and lets them work together for better results in water sports and factories.

| Environmental Factor | Impact on Performance |

|---|---|

| Temperature (55 °C) | Changes how sensor layers act |

| Humidity (90% RH) | Makes readings different |

In the future, new ideas will help sensors get even stronger and more accurate in wet places.

FAQ

Can force sensors work in wet environments?

Engineers make force sensors to work in wet places. They pick materials that keep water out and stop damage. Sensors can have trouble when liquid that carries electricity gets inside. This liquid can mess up readings and cause shorts.

What is the main risk for force sensors in wet places?

The biggest danger is liquid that carries electricity. It can get into sensor parts and change how electricity moves. This can make sensors give wrong numbers or stop working. Engineers use seals and coatings to keep this liquid out.

How do manufacturers protect sensors from conductive liquid?

Makers put waterproof coatings and strong seals on sensors. These things stop the liquid from touching important parts. Engineers also pick materials that do not rust and block the liquid.

Why does conductive liquid affect sensor performance?

Liquid that carries electricity changes how current moves in the sensor. It can make new paths for electricity, which causes signal loss or shorts. Sensors need good protection to keep this liquid away from key spots.

Can SOUSHINE FSRs handle conductive liquid exposure?

SOUSHINE FSRs have a bendy base and special materials. These help stop the liquid from getting in. The sensors keep working in wet places, even when cleaned or used with this liquid.

What maintenance helps sensors resist conductive liquid?

Cleaning and checking sensors often helps them fight this liquid. Engineers look for cracks or loose seals. They dry sensors after cleaning to get rid of any leftover liquid.

Are there certifications for sensors exposed to conductive liquid?

Sensors often have IP ratings. These ratings show how well sensors keep out liquid and dust. Higher IP numbers mean better protection in wet places.

Where do engineers use sensors that face conductive liquid?

Engineers use sensors in medical tools, food plants, ships, and outdoor gear. These places often have liquid that can touch sensors. Good design and the right materials help sensors last longer.