Call us: +86-137-2353-4866

A load cell uses mechanical force to make a signal. A force sensing resistor measures compressive force right away. These differences are important when picking a sensor for a job. Load cells are very accurate. Force sensing resistors are flexible and work well in custom designs. New market data shows load cells are used most in factories. Force sensing resistors are growing fast in consumer electronics. How sensors measure, how accurate they are, cost, durability, and uses help choose the best sensor for a project.

Table of Contents

Key Takeaways

- Load cells use strain gauges to measure force very well. They are great for jobs that need exact results.

- Force sensing resistors (FSRs) are bendable and light. They can fit into tiny or curved places.

- Load cells are used in factories for weighing things and checking quality. FSRs are used a lot in gadgets and robots.

- Price matters a lot. Load cells cost more but last longer and work well. FSRs cost less and are simple to add to designs.

- Load cells need to be set up right to give good results. FSRs need gentle care so they do not give wrong results from things around them.

- Each sensor is good for different things. Load cells are best for measuring things that do not move. FSRs work better for things that move or need touch.

- Engineers should think about what their project needs. They should look at how exact, big, or costly the sensors are before picking one.

- SOUSHINE can make special load cells and FSRs for many jobs. They help different industries with their needs.

Load Cell Overview

Definition

A load cell is a tool that measures force. It turns mechanical energy into an electrical signal. Many industries use load cells to check weight or force. The table below shows how top companies explain what a load cell is.

| Source | Definition |

|---|---|

| Leading Load Cell Manufacturers | A load cell is a transducer which converts mechanical energy (tensile and compressive forces) into electrical signals. |

| Loadstar Sensors | A load cell is a sensor or a transducer that converts a load or force acting on it into an electronic signal. This electronic signal can be a voltage change, current change or frequency change depending on the type of load cell and circuitry used. |

Working Principle

Strain Gauge

Most load cells use strain gauge technology. A strain gauge is a thin wire or foil stuck to metal. When force pushes or pulls the load cell, the metal bends. The strain gauge stretches or squeezes with the metal. This changes the electrical resistance in the strain gauge. The load cell uses a Wheatstone bridge circuit to check this change. The circuit sends a voltage signal that matches the force. The load cell goes back to its normal shape after the force stops. This lets the load cell measure force again and again.

- Load cells use strain gauge technology to find force by checking changes in electrical resistance.

- The Wheatstone bridge circuit helps check these resistance changes and gives a voltage output.

- Elastic deformation lets the load cell go back to its normal shape after each use.

- Calibration checks if the load cell is accurate by comparing its output to known weights.

- Temperature compensation keeps the readings right when the temperature changes.

Types

There are different types of load cells. Each type works for different jobs. The main types are:

- Compression load cells: Measure force when something pushes down.

- Tension load cells: Measure force when something pulls.

- Shear beam load cells: Measure force from side-to-side movement.

- Bending beam load cells: Measure force by bending.

- Single-point load cells: Used in small scales and balances.

Advantages

Load cells have many good points for measuring force. The table below compares load cells to other force sensors.

| Advantage | Load Cells | Other Force Sensors |

|---|---|---|

| Accuracy | High precision in steady weight measurements | Better for dynamic force changes |

| Durability | Enhanced with new materials and designs | Varies by type |

| Response Time | Faster data analysis with advancements | Slower in some cases |

| Application Versatility | Used in many industries | Limited to specific applications |

- Load cells give results that are accurate and repeatable.

- Many industries use load cell technology for weighing, automation, and safety.

- Load cells work well in tough environments.

- The design of load cells lets them respond fast and fit easily into systems.

Load cell technology helps in manufacturing, healthcare, and civil engineering. Examples of load cell uses are weighing systems, structural monitoring, and safety devices. Load cells are still very important in modern measurement systems.

Disadvantages

Load cells are used in many jobs to measure force and weight. But they also have some problems. The table below lists the main problems with load cells.

| Disadvantage | Description |

|---|---|

| High-temperature sensitivity | Load cells are sensitive to temperature changes, making them unsuitable for static conditions. |

| Poor overload capacity | Load cells may not handle overload situations effectively. |

| Sensitivity to off-center loading | Load cells can be highly sensitive to loads applied off-center, affecting accuracy. |

| Physical weight | Larger load cells can be heavy, complicating their use as field standards. |

Load cells might not be correct if it gets too hot or cold. Some load cells do not work well if the force is not in the middle. Big load cells are heavy and hard to move. If you put too much weight on a load cell, it can break or stop working. Because of these problems, people must pick the right load cell for each job.

Applications

Load cells are used in many areas. They help people check force and weight in different ways.

Industrial

Factories use load cells in many machines. Load cells help with weighing and checking quality. In factories, load cells make sure products are made right. Many factories use load cells to control how much stuff goes into a product. This helps save money and stop waste. Shear beam and bending beam load cells are used a lot in factories because they are very exact.

Medical

Hospitals and clinics use load cells in medical tools. Load cells help doctors and nurses check a patient’s weight. Some machines use load cells to watch weight changes over time. Load cells also help make sure medical tools work right. In therapy, load cells measure how much force a patient uses.

SOUSHINE Products

SOUSHINE makes many kinds of load cells for different jobs. Their load cells are used in factories and hospitals. SOUSHINE load cells are correct and last a long time. The company makes load cells that are easy to use and strong. SOUSHINE also helps customers choose the best load cell for their needs. Many people trust SOUSHINE load cells for their work.

Note: Load cells are very important in many jobs. Picking the right load cell helps keep things safe and good.

Force Sensing Resistor (FSR) Overview

Definition

A force sensing resistor is a tool that checks force on a surface. It can sense both steady and moving forces by changing its resistance. Many companies use these sensors to find pressure or touch. Books and articles say force sensing resistors work by changing resistance when force is added. These sensors are found in robot hands and in body science. People often wonder what is force sensor, and force sensing resistors show this by linking force to resistance changes.

Working Principle

Resistive Technology

Force sensors use piezoresistive technology to work. When you press on the sensor, its resistance goes down. If there is no force, the resistance is high. As you push harder, the resistance gets lower. This lets the sensor measure many different pressures. Calibration uses weights to match resistance to force. Many people ask what is force sensor, and piezoresistive technology makes it easy to understand. The table below explains how force sensing resistors work.

| Aspect | Description |

|---|---|

| Working Principle | Resistance drops as force increases. |

| Resistance | High when unloaded, low when loaded. |

| Calibration | Uses known loads to match resistance to force. |

| Construction | Semi-conductive material between two substrates. |

| Applications | Used in human-machine interfaces, robotics, medical devices, electronics. |

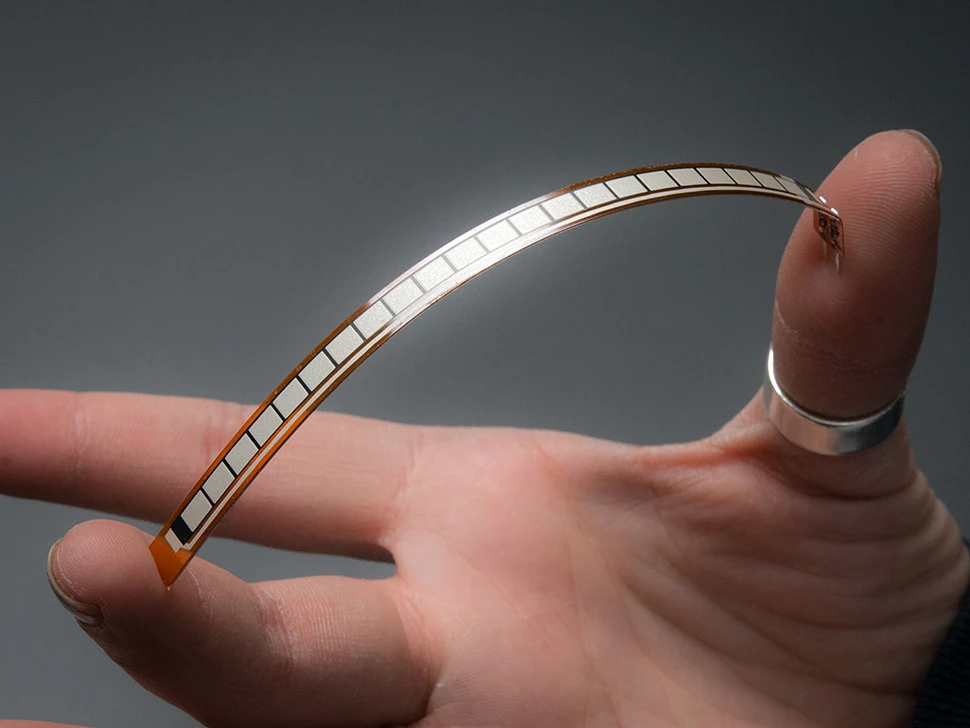

Construction

Manufacturers make force sensors with a special layer between two soft sheets. The sensor can use shunt mode or thru mode. The piezoresistive part is made of ink between the sheets. When you press the sensor, the ink particles get closer. This makes the resistance go down. Signal conditioning uses extra electronics to read the changes. Most systems use a voltage divider to turn resistance into a signal. Calibration changes resistance into force values. This helps force sensors give correct readings in many uses.

Advantages

Force sensors have many good points over other sensors. Many gadgets, fake limbs, game controllers, and smart clothes use force sensors. These sensors are cheap, bendy, and light. They change resistance when you press them, so they are good when you care about changes, not exact numbers. Force sensors are easy to add to projects and react fast to force. They are simple, two-ended devices that lower resistance when pressed. Companies sell force sensors for low prices, and they are easy to use in many things.

- Force sensors fit in small places and work in many designs.

- They react quickly to touch and pressure.

- Many companies use force sensors because they are simple to set up and fix.

- Their bendy shape lets designers make many sizes and shapes.

- Force sensors help answer what is force sensor by showing how easy and useful they are.

Disadvantages

Force sensors have many good points, but they also have problems. Experts say there are a few main issues:

- Sometimes, force sensors are not very accurate. The numbers can change or be wrong. Things like heat or dust can make readings off.

- Some older force sensors cannot measure all force sizes. They might miss very small or very big forces.

- Force sensors can break or wear out. Problems like hysteresis, crosstalk, and noise make them work less well, especially in rough places.

- Some force sensors are slow to react. This can be a problem if you need fast results.

- It can be hard to add force sensors to big systems. This can make projects take longer.

Engineers and designers need to think about these problems when picking force sensors for their work.

Applications

Force sensors are important in many jobs. The table below shows where force sensors help.

| Application Area | Industry Impact |

|---|---|

| Automotive | Makes cars safer and easier to use. Needed for new cars, even self-driving ones. |

| Healthcare | Helps doctors watch patients and do tests. Makes care better. |

| Consumer Electronics | Lets people use touch screens and smart watches easily. |

| Industrial | Helps factories work better and faster. |

| Robotics | Lets robots feel and hold things. Makes robots safer and smarter. |

| Others | Used in planes, the army, and science labs where exact force is needed. |

Automotive

Car makers use force sensors to make cars safer and more comfy. These sensors help airbags and seat belts work right. They also help with touch screens in cars. Self-driving cars use force sensors to feel pressure and change things fast.

Healthcare

Doctors use force sensors to watch patients’ health. These sensors help check heartbeats and other signs. Some online doctor tools use force sensors to see how hard a patient presses. Therapy machines use force sensors to track how strong a patient is.

Robotics

Robots need force sensors to feel things. Robots use these sensors to touch and grab stuff. Force sensors help robots move the right way and not break things. This makes robots safer and more careful.

Consumer Electronics

Phones and tablets use force sensors for touch controls. Smart watches use them to count steps and track movement. Game controllers and smart home gadgets use force sensors to work better.

SOUSHINE FSRs

SOUSHINE makes force sensors for many jobs. Their sensors are used in cars, hospitals, robots, and gadgets. SOUSHINE sensors can be made special for each job and last a long time. They use little power, so they save energy. SOUSHINE helps customers from start to finish. Many companies pick SOUSHINE because their sensors work well in tough jobs.

Force sensors are changing many fields today. These uses show why force sensors matter in new technology. Engineers look for force sensor examples when starting new ideas.

Key Differences

Measurement Principles

Load cells and force sensors measure force in different ways. Load cells use strain measurement to check force. When a load cell gets force, it bends a little. This bending changes the resistance inside the strain gauge. The change makes an electrical signal. Engineers use this signal to know the force amount. Force sensors use other methods to measure force. Some use piezoelectric or capacitive ways. These ways help force sensors measure fast-moving forces. The table below shows how each device measures force.

| Device Type | Measurement Principle | Key Characteristics |

|---|---|---|

| Load Cell | Strain measurement | High accuracy and reliability, ideal for static loads. |

| Force Sensor | Various technologies (piezoelectric, capacitive) | More dynamic measurements, prioritizes speed and versatility. |

People often want to know what a load cell is. A load cell checks force by looking at changes in strain. Force sensors use other ways to measure force. These differences help engineers pick the best device for each job.

Accuracy

Accuracy is important in many projects. Load cells give very exact and steady results. They are good for jobs that need careful and steady checks. Force sensors can also be accurate. New studies show sensors like Flexiforce A201-1 and Interlink FSR-402 work well. Their output voltage matches the force put on them. This means force sensors can give good results for many uses.

- Load cells give steady and exact measurements.

- Force sensors give good readings for quick and touch jobs.

- Both devices show a clear link between force and signal.

These accuracy differences help people choose the right sensor. Load cells are best for weighing and steady force checks. Force sensors are better for fast and flexible jobs.

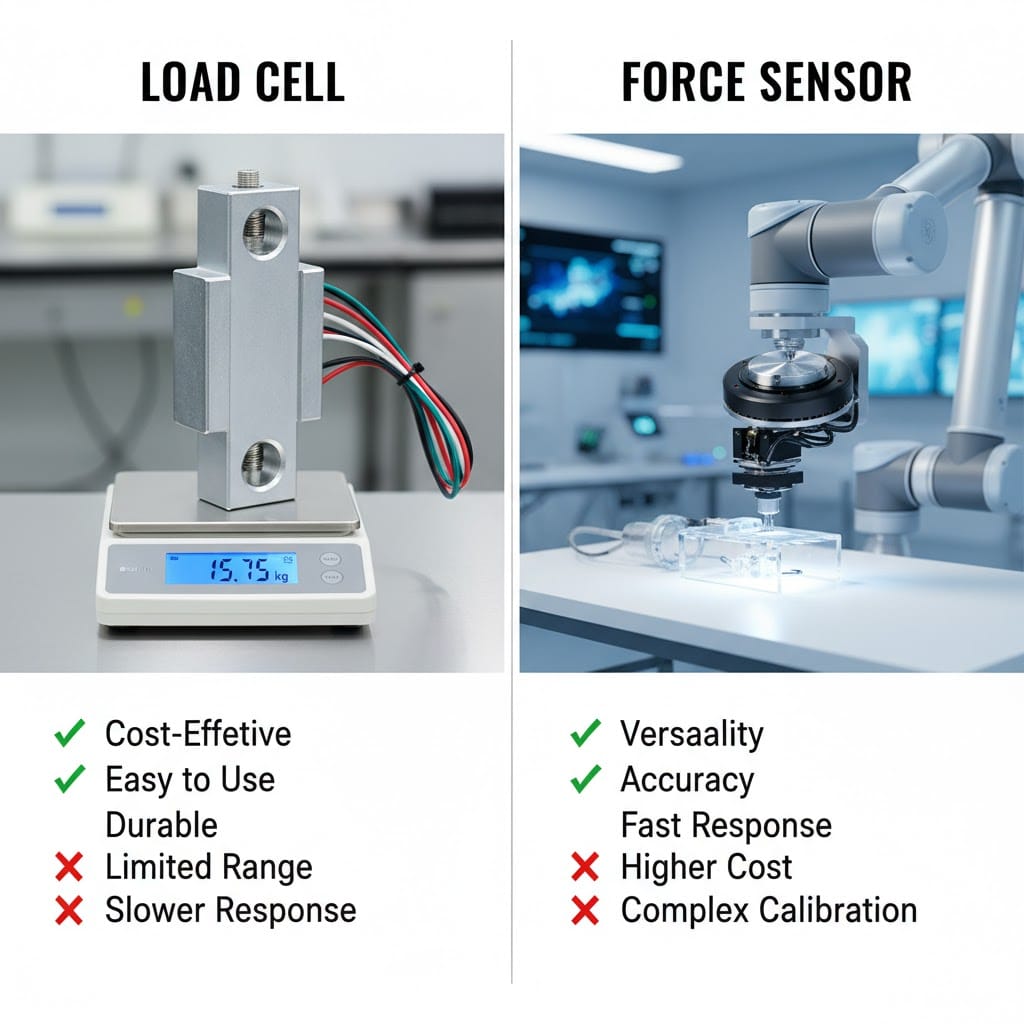

Cost

Cost is important when picking a sensor. Force sensors usually cost less. Their price changes with how sensitive they are and what features they have. Load cells cost more money. They last longer and work better. Many factories use load cells because they need strong and exact tools. Force sensors are good for products and projects that need to save money.

The cost differences help buyers choose the right sensor. Load cells are good for jobs that need strong and exact tools. Force sensors are better for designs that need to be cheap and flexible.

Durability

Load cells and force sensing resistors are not the same in durability. Load cells have metal parts and strain gauges inside. These sensors work well in tough places like factories. Many factories use load cells because they last a long time. Load cells can handle shock and shaking. They keep working even after being used many times.

Force sensing resistors, such as SOUSHINE FSRs, use bendy materials. These sensors can bend and twist without breaking. Designers put FSRs in things that need to move or change shape. FSRs work well in things that get touched or pressed a lot. Their build lets them keep working after lots of use. FSRs also do not wear out fast from daily use.

Note: Both sensors work well but in different ways. Load cells are good for rough, fixed places. FSRs are better for bendy and easy-to-carry designs.

Size

Size is important when picking a sensor. Load cells are usually bigger and heavier. Their metal bodies and parts take up more room. Most load cells need to be put in one spot on a machine. This makes them hard to use in small or portable things.

Force sensing resistors are thin and light. SOUSHINE FSRs come in many shapes and sizes. Designers use FSRs where there is not much space. FSRs fit inside slim gadgets, wearables, and tiny robots. Their bendy shape lets them wrap around things or fit in special spots.

- Load cells: Big, heavy, need to stay in one place.

- FSRs: Thin, light, bendy, fit in small or curved spots.

Use Cases

Load cells and force sensing resistors help many jobs. Each sensor works best for certain tasks. The table below shows where each sensor is used.

| Industry/Application | Description |

|---|---|

| Medical Devices and Equipment | Measures force in tools like syringes and pumps. Makes treatments safe. |

| Pharmaceutical Manufacturing | Checks force in tablet making. Keeps quality high. |

| Microelectronics and Semiconductor | Controls force in chip and wafer handling. |

| Materials Testing | Tests how strong things are by pulling or pushing. |

| Aerospace and Aviation Testing | Measures force in plane and spacecraft parts. |

| Dental Equipment | Checks force during dental work. |

| Robotics and Automation | Controls robot grip and movement. |

| Biomechanics and Rehabilitation | Measures body force when moving. |

| Product Development | Tests force in new tools and electronics. |

| Educational Laboratories | Teaches force measurement in science labs. |

| Small-Scale Manufacturing | Controls force in jewelry and small parts. |

| Custom Machinery | Adds force sensing to special machines. |

| Packaging and Testing of Miniature Components | Tests and packs tiny electronic parts. |

Many industries use load cells to make things safer and more exact. Factories use them to weigh things and run machines. Farms use load cells for planting and picking crops. Trucks use load cells to check weight and balance loads.

Force sensing resistors are in many new devices. Car makers put FSRs in seats and dashboards. Hospitals use FSRs in patient monitors and therapy tools. Robot teams use FSRs to help robots feel touch. Smartwatches and game controllers use FSRs for touch controls.

- Load cells: Best for tough, fixed, and very exact jobs.

- FSRs: Best for easy-to-carry, bendy, and touch jobs.

Load Cell vs Force Sensor

Comparison Table

The table below shows how load cells and force sensors are different. Each feature helps people pick the right sensor for their needs.

| Feature | Load Cells | Force Sensing Resistors (FSRs) |

|---|---|---|

| Sensitivity | Lower sensitivity to small forces | Higher sensitivity to small forces |

| Accuracy | High accuracy and reliability | Needs careful reading of results |

| Cost | Higher cost | Lower cost |

| Linearity | High linearity and repeatability | Less linearity |

| Flexibility | Rigid, fixed shape | Thin, flexible, fits many shapes |

| Calibration | Needs calibration for best results | Needs error checks for best results |

| Application Examples | Weighing scales, industrial machines | Touch buttons, grip strength, prosthetics |

| Precision | High precision, repeatable | Less precise, repeatability can vary |

Pros and Cons

When you compare load cells and force sensors, each has good and bad points. People should think about these before picking one.

- Load cells:

- Give steady results every time.

- Work well in big machines and weighing tools.

- Cost more than force sensors.

- Need calibration to work their best.

- Stay stiff and do not bend.

- Force sensors:

- Notice small changes in force.

- Fit into thin or curved places.

- Cost less and use less energy.

- Need careful reading to avoid mistakes.

- Sometimes do not give the same result each time.

Note: FSRs are not good for exact measurements unless you check for errors. Mistakes can be as much as ±15%. Always follow error rules for each job.

Suitability

Picking load cells or force sensors depends on what you need. Load cells are best when you need high accuracy and steady results. Factories use load cells in weighing tools and big machines. These sensors handle strong forces and give steady numbers.

Force sensors are better for designs that need to bend or save money. Many engineers use force sensors in touch buttons, grip tools, and fake limbs. These sensors work well in tight spaces or places that need to bend.

- Load cells: Best for weighing, big machines, and jobs needing high accuracy.

- Force sensors: Best for touch controls, bendy designs, and jobs where price matters.

Engineers compare load cells and force sensors before starting work. They look at size, price, and how exact the sensor needs to be. This helps them choose the right sensor for their project.

Differences Between Load Cells and Force Sensors

Operational Principles

Load cells and force sensors work in different ways. A load cell uses a strain gauge to check force. When you push on it, the strain gauge changes resistance. This makes an electrical signal. Engineers use this signal to know the force amount. A force sensor, like a force sensing resistor, works with piezoresistivity. When you press it, the resistance goes down. Conductive particles move closer together. This change helps measure the force.

The table below shows how each part works:

| Component | Operational Principle |

|---|---|

| Force Sensing Resistors | Work by piezoresistivity; resistance drops when force is added because particles get closer. |

| Load Cells | Turn mechanical force into an electrical signal using strain gauges that change resistance when bent. |

These differences change how each sensor performs. Load cells give steady results every time. Force sensors react fast to touch and pressure. Designers pick the sensor that fits the job best.

Application Scenarios

Engineers use these differences to choose the right sensor. Load cells are good when you need exact numbers. Factories use load cells to weigh things. Scientists use them to test materials. Force sensors fit in small places and bend easily. Many gadgets use force sensors for touch controls.

The table below lists some ways sensors are used:

| Application Scenario | Description |

|---|---|

| Haiphong Municipality Water Levels | Checks water levels in real time with underwater sensors. |

| Dynamic Mooring Rope Testing | Load cells watch pulling force in marine test rigs. |

| Towing Force on Tractors | Pancake load cells measure how tractors pull and use fuel. |

| Ice Sheet Change Prediction | Load cells help track ice flow for climate studies. |

| On-Orbit Testing | Small load cells test strength in space. |

| Support for British Swimmers | Load cells check swimming force in sports studies. |

| Tidal Turbine Testing | Dual-axis sensors measure push and twist in energy research. |

| Regenerative Fatigue Testing | Load cells help test tidal energy machines for wear. |

Engineers also use load cells in robot arms. Clamps and fixtures use small load cells for grip. Medical tools use load cells for feedback. Prosthetic devices use load cells for control. Drones use load cells to manage weight. Testing uses load cells for grip checks. Farms use load cells to check if crops are ready.

Force sensors are in touch screens, smart watches, and robot hands. Designers put force sensors where space is tight. These sensors help robots feel things. Force sensors also help doctors watch patients.

These differences help engineers and designers pick the right sensor. Each sensor works best for certain jobs. The right choice keeps things safe and working well.

How to Choose

Factors

Picking the right sensor needs you to think about a few things. Engineers and designers ask what is a load cell and how it is different from other force sensors. These points help you decide:

- The job tells you which sensor to use. Some jobs need high accuracy. Other jobs need sensors that bend or fit in small places.

- Money matters when picking sensors. Big projects need cheaper sensors. Load cells cost more. Force sensors are better if you need to save money.

- Where you use the sensor is important. Load cells can break in very hot or cold places. Force sensors like FSRs work well in tough spots. They do not get ruined by dust or water.

- Space is a big deal. Load cells are big and heavy. They work best in one spot. Force sensors are thin and bendy. They fit in small devices.

- Sensors should work the same every time. This is important when making lots of parts.

Requirements

Engineers must know what the sensor will measure. Some jobs need exact force numbers. Other jobs need sensors that bend or fit in tight spaces. The thing being measured also helps you pick the sensor.

Budget

How much money you have changes your choice. Load cells cost more because they are very exact and last longer. Force sensors cost less. They are good for jobs that do not need perfect numbers.

Environment

Where you use the sensor matters a lot. Factories can be hot, dusty, or wet. Load cells can break in these places. Force sensors, like FSRs, do not break easily. They last longer in rough places.

Selection Guide

Steps

Experts say you should follow steps to pick the best sensor:

- Find out what you want to measure. Pick the sensor that fits the job.

- Check how far the sensor needs to work. Make sure it can get the data you need.

- Think about what matters most: speed, accuracy, cost, or repeatability.

Tip: Always pick the sensor that fits the real job, not just what the specs say.

Examples

Engineers use different sensors for different jobs. Here are some examples:

- Robots use force sensors to check grip. These sensors are small and light. Robots can measure grip without getting heavy.

- Robots use force sensors to keep parts in place. This helps control quality.

- Factories use force sensors to check for bumps in packaging. These sensors help stop damage to fragile things.

- Car tests use load cells to measure force and torque. These sensors give exact numbers for safety checks.

- Factories use load cells to watch force in machines. This helps keep products good.

- Engineers use load cells to test how strong materials are. This helps them learn about new materials.

You should pick load cells or force sensors based on the job, money, and place. Each sensor is best for certain tasks.

Mistakes and Best Practices

Common Errors

Many people make mistakes with load cells and Force Sensing Resistors. These mistakes can give wrong results or break the sensor. Here are some common errors:

- Installation Issues: Sometimes, people do not line up the sensor right. They may use the wrong parts to mount it. This can make the sensor weak.

- Temperature Effects: Some sensors do not fix for temperature changes. If not, the signal can drift or shift.

- Signal Instability: Bad wires or poor grounding can make signals jump around. Noise from electricity can also cause problems.

- Non-linearity and Hysteresis: Old or broken parts can cause these issues. Things touching the sensor can also make it worse.

- Environmental Contaminants: Dust and chemicals can hurt sensors. Using the wrong case can make damage worse.

- Moisture Ingress: Water can get inside if the sensor is not made for wet places. Broken seals let water in too.

- Cable Failures: Worn out cables or loose plugs can mess up signals.

- Overload and Shock Loading: Too much force can break the sensor.

- Misalignment: If you install it wrong, it can twist or get side force.

Tip: Check sensors often and install them right to stop most mistakes.

Mistakes in making sensors can also cause problems. Bad materials, glue, or soldering can make sensors fail. Checking and setting sensors during making helps keep them correct.

Installation Tips

Putting sensors in the right way helps them work better and last longer. Here are some easy tips:

- Line up the load with the right direction. This stops errors.

- Watch out for shaking and heat changes. These can change what you read.

- Make sure wires and grounding are good. This keeps signals clear.

- Control heat and water. Use sensors made for the place.

- Pick a sensor that can handle the force. Do not use too much weight.

Here is a table to show these tips:

| Installation Step | Why It Matters |

|---|---|

| Align load correctly | Stops wrong readings |

| Control environment | Keeps results steady |

| Check cables and grounding | Stops signal trouble |

| Select right capacity | Stops damage from too much force |

Performance Optimization

Making sensors work their best starts with smart design. The shape and size of a load cell change how well it works. Engineers use computer tools to make sensors small and strong. They pick materials that last in tough places.

Checking sensors often keeps them working right. Look for damage or wear to keep them good. Covers help protect sensors from dust and chemicals.

Note: Smart design, careful setup, and regular checks help sensors give good results.

Future Trends

Load Cell Innovations

Engineers keep making load cells better. They use new materials to make sensors stronger and lighter. MEMS-based silicon sensors can find very small force changes. These sensors work in many places. Companies use eco-friendly materials to help the planet. Factories want sensors that last longer and cost less. Many new load cells can connect to smart devices. This lets workers see problems right away and fix them fast.

FSR Advances

Force sensors are now thinner and more bendy. Makers use better materials so they last longer. These sensors are cheaper to make. Many new force sensors work with AI and IoT systems. This helps collect data fast and makes smart choices. Some companies use green ways to make these sensors. More people want smaller and bendy sensors. Many gadgets need sensors that fit in tiny spaces.

- Thinner and more bendy sensors

- Cheaper to make

- Last longer

- Real-time data with AI and IoT

- Use of eco-friendly materials

Emerging Uses

Many jobs now use new sensors in cool ways. Hospitals use sensors to watch how patients move and feel pressure. Robots use sensors to help them feel touch. Phones and tablets use sensors for better controls. Factories use sensors to watch machines and keep workers safe. Cars use sensors to help drivers stay safe. Smart homes use sensors to control lights and other things.

Sensors are now very important in smart gadgets and connected systems. Their small size and bendy shape let people use them in many new ways.

Load cell and force sensors work in different ways. Load cells measure force with high accuracy. Force sensors fit into small spaces and respond quickly. People should choose a sensor based on project needs. SOUSHINE offers products for many uses. Readers can contact SOUSHINE experts for help. Start your project with the right sensor today.

FAQ

What is the main difference between a load cell and a force sensing resistor?

A load cell checks force with strain gauges. A force sensing resistor changes resistance when you press it. Each sensor is best for certain jobs.

Can force sensing resistors measure very small forces?

Force sensing resistors can find tiny forces. They react fast to gentle touches. Designers put them in devices that need touch sensing.

Where do engineers use load cells most often?

Engineers use load cells in factories. They check weight in machines and scales. Many industries trust load cells for exact results.

Are SOUSHINE FSRs customizable for different shapes?

SOUSHINE FSRs come in lots of shapes and sizes. The company makes special designs for unique projects. This helps sensors fit into different products.

How long do force sensing resistors last in daily use?

Force sensing resistors last a long time with daily use. Their bendy design helps stop wear. Many products use them for pressing and touching over and over.

Do load cells need calibration before use?

Load cells need calibration to work right. Engineers test them with known weights. Calibration helps make sure every reading is correct.

What industries use SOUSHINE force sensing resistors?

SOUSHINE force sensing resistors are used in cars, hospitals, robots, and electronics. Many companies pick them for safety, monitoring, and controls.