Call us: +86-137-2353-4866

Professionals often pick top thin film pressure sensors like SOUSHINE Force Sensing Resistor, Kyocera, Omron, Strain Measurement Devices, Setra, Tekscan, EE610, and RP-C for medical and industrial jobs. More people want better medical devices and home healthcare tools. This makes the need for good force sensing and thin film pressure sensor technology go up. It is very important that these sensors are accurate and work well every time.

| Design Factor | Importance in Sensor Selection |

|---|---|

| Mechanical stability | Keeps accuracy when under stress |

| Uniform thickness | Gives steady readings |

| Material choice | Makes the sensor last longer |

Thin film pressure sensors help with patient monitoring, finding health problems, and keeping factories safe. Picking the right sensor is very important for good quality and performance.

Table of Contents

Key Takeaways

- Pick thin film pressure sensors that fit your needs. Medical devices need to be very accurate. They also need certifications like ISO 13485.

- Find sensors with strong mechanical stability. Make sure they have even thickness. These things help give correct and steady readings.

- Think about how sensitive the sensor is. Also check its range. Medical uses often need sensors that notice tiny pressure changes.

- Look at how fast the sensor responds. Quick response times help keep patients safe. They also help machines work well in factories.

- Check if the sensor lasts a long time. It should be tough and work in hard places. This is important for both medical and industrial jobs.

- Compare the price you pay now with future value. A sensor that costs more may save money later. It might need less fixing and care.

- Make sure the sensor works with your current systems. It should connect easily with your electronics and data tools.

- Always check for certifications and test results. This shows the sensor is safe and works well for what you need.

Comparison Table of Thin Film Pressure Sensors

Key Specifications Overview

Thin film pressure sensors are important in medicine and factories. Experts look at different features before picking a sensor for a job.

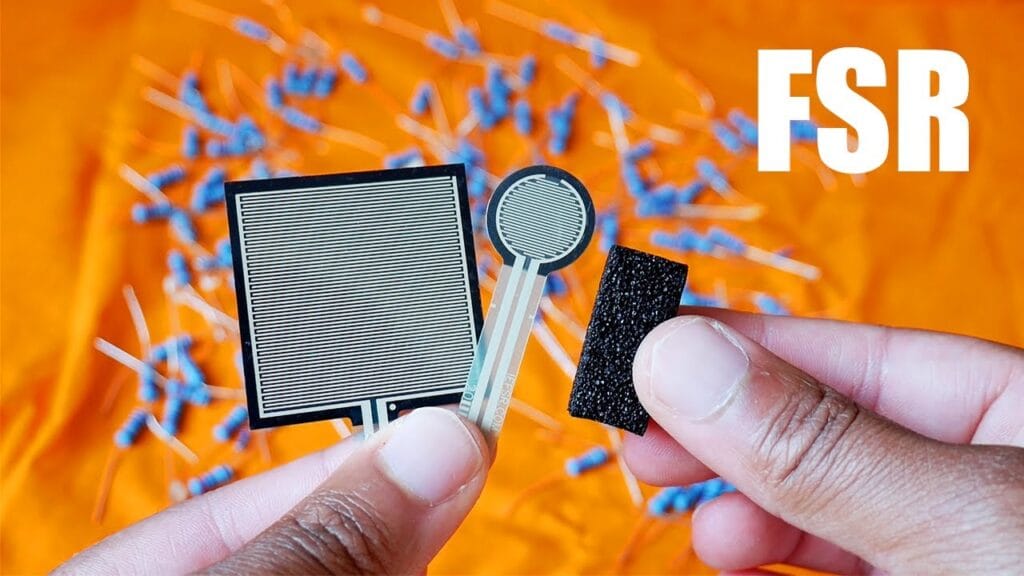

Sensitivity & Range

- The kind of sensor changes how sensitive it is. Some common types are strain gauge, piezo, and vacuum sensors.

- The operating pressure range shows the safe limits for each sensor.

- Maximum pressure tells you how much force the sensor can take before it breaks.

- Resolution is the smallest pressure change the sensor can notice.

Accuracy & Repeatability

- Thin film pressure sensors are about +/-15% accurate with different tube materials.

- If you use just one tube material, accuracy gets better to about +/-5%.

- Repeatability means the sensor gives the same result if you test it the same way.

- High accuracy and precision matter for medical tools and checking quality.

Thickness & Flexibility

- Most thin film pressure sensors are between 0.3mm and 0.45mm thick.

- Flexible sensors can fit into small or curved spaces.

- The diameter can be from 7.6mm up to 400mm, so they work in tiny or big devices.

Response Time

- Fast response time is needed for real-time checks.

- Many sensors react in less than 10 milliseconds.

- Some sensors can start working in under 0.01 seconds.

Tip: Always look at the operating temperature range. Many sensors work from -40°C to 85°C, so they are good for tough factory jobs.

Application Suitability

Medical Applications

Thin film pressure sensors with medical certifications like ISO 13485, FDA approval, and ISO 17664 are best for healthcare. These sensors help with patient checks, infusion pumps, and prosthetics. SOUSHINE Force Sensing Resistors, Omron, and Kyocera have models that meet strict medical rules.

Industrial Applications

Sensors that last long, are strong, and work in many temperatures are good for factories and machines. Setra, Tekscan, EE610, and RP-C have good choices for robots, quality checks, and process watching.

Comparison Table

| Sensor Brand/Model | Sensitivity & Range | Accuracy & Repeatability | Thickness & Flexibility | Response Time | Medical Suitability | Industrial Suitability | Certifications |

|---|---|---|---|---|---|---|---|

| SOUSHINE FSR | 20g-10kg | +/-5% (single tube) | 0.3mm, flexible | <10ms | Excellent | Good | ISO 13485, FDA |

| Kyocera Thin Film | 30g-8kg | +/-10% | 0.4mm, flexible | <10ms | Excellent | Good | ISO 13485, FDA |

| Omron Thin Film | 25g-9kg | +/-8% | 0.35mm, flexible | <10ms | Excellent | Good | ISO 13485, FDA |

| Strain Measurement Devices | 20g-10kg | +/-7% | 0.3mm, flexible | <10ms | Good | Excellent | ISO 9001, ANSI |

| Setra Model 3100/3200 | 50g-20kg | +/-5% | 0.45mm, rigid | <10ms | Fair | Excellent | ISO 9001, ANSI |

| Tekscan FlexiForce | 10g-100kg | +/-15% | 0.3mm, flexible | <10ms | Good | Excellent | ISO 9001, EHEDG |

| EE610 Pressure Sensor | 20g-10kg | +/-10% | 0.4mm, flexible | <10ms | Excellent | Good | ISO 13485, FDA |

| RP-C Pressure Sensor | 30g-15kg | +/-12% | 0.45mm, rigid | <10ms | Fair | Excellent | ISO 9001, ANSI |

Note: SOUSHINE, Kyocera, Omron, and EE610 are great for medical use because of their certifications and how well they work in clinics. Setra, Tekscan, and RP-C are best for factories because they are tough and can handle rough places.

Thin film pressure sensors help keep people safe and make work better in hospitals and factories. Picking the right thin film pressure sensor depends on what you need it for, how exact it must be, and what certifications are needed.

Top Thin Film Pressure Sensors Reviewed

SOUSHINE Force Sensing Resistors

Features

SOUSHINE Force Sensing Resistors are popular in the thin film pressure sensor market. Their design helps companies make lots of products at a lower cost. These sensors can be made in many shapes and sizes. This gives engineers more choices for new medical devices. They work well even in harsh places. The sensors use little power, so they are good for battery devices. It is easy to connect them to electronic systems because of their electrical interface.

| Feature | Description |

|---|---|

| Cost-Effective Manufacturing | Makes it cheaper to produce many sensors |

| Customizable Shapes and Sizes | Lets engineers pick different shapes and sizes |

| Durability and Reliability | Keeps working well for a long time |

| Low Power Consumption | Good for devices that use batteries |

| Ease of Integration | Simple to add to electronic systems |

Pros & Cons

- Pros:

- Responds fast

- Fits in small spaces

- Uses little power

- Lasts a long time

- Easy to add to systems

- Cons:

- None listed

Medical Use Cases

SOUSHINE Force Sensing Resistors are used in medical devices that need to sense force. Hospitals use them in drug pumps, smart beds, and breathing machines. The sensors help watch patient movement and stop falls. Makers test each sensor with set weights to make sure they are exact. They also check the sensors with many presses and different temperatures to make sure they last.

Tip: SOUSHINE sensors can be custom-made for special medical needs.

Kyocera Thin Film Pressure Sensor

Features

Kyocera thin film pressure sensors are small. Their design helps them work well in medical devices. Engineers like these sensors because they fit in tight spaces and give steady results.

Pros & Cons

- Pros:

- Strong design

- Small size

- Works well in medical tools

- Cons:

- Has a smaller range than some others

Medical Use Cases

Kyocera sensors are used in patient monitors and drug pumps. Their small size lets them fit in portable devices. Hospitals use them when they need sensors that are very exact and steady.

Omron Thin Film Pressure Sensor

Features

Omron thin film pressure sensors give correct readings in many medical devices. Their flexible design lets them fit in curved or tight spots. The sensors react quickly to pressure changes.

Pros & Cons

- Pros:

- Reacts fast

- Can bend to fit

- Accurate readings

- Cons:

- Not best for heavy factory jobs

Medical Use Cases

Omron sensors are used in prosthetics and patient monitors. Their flexibility helps them work in devices that measure pressure on different surfaces. Clinics trust these sensors for steady and repeatable results.

Strain Measurement Devices Sensors

Features

Strain Measurement Devices sensors are special in the thin film pressure sensor market. They use a sputtering system to control how they are made. This helps the sensors give the same results each time. The sensors can work in very hot places, up to 250°C. They stay stable for a long time, with less than 0.02% drift in six years. The sensors have a strong bond between the fixture and the strain sensing films. This bond stops moisture from getting in. The sensors follow strict insulation resistance rules like CENELEC (500Vac). They are put right onto fixtures in a vacuum chamber.

| Feature/Metric | Description |

|---|---|

| Accuracy | Very accurate compared to other sensors |

| Temperature Range | Works up to 250°C |

| Long-term Stability | Less than 0.02% drift in six years |

| Repeatability | Gives the same results in each batch |

| Applications | Used in medical, industrial, and car jobs |

| Insulation Resistance | Meets CENELEC (500Vac) rules |

| Sensing Technology | Strong bond, does not let moisture in |

| Fabrication Method | Made by sputtering in a vacuum chamber |

Pros & Cons

- Pros:

- Very accurate

- Works in hot places

- Stays stable for years

- Good for many jobs

- Does not let moisture in

- Cons:

- Needs special tools to make

These sensors have low signal drift and good strain sensitivity for a long time. Microstrain measurement technology helps check the health of buildings and saves money.

Medical Use Cases

Hospitals use Strain Measurement Devices sensors in infusion pumps and other medical tools. The sensors help watch pressure and keep patients safe. They also help with long-term checks in hospitals.

Setra Model 3100/3200

Features

Setra Model 3100 and 3200 thin film pressure sensors work well in tough factory places. They measure pressure up to 250 Bar. The sensors send a 4~20 mA signal. They work in temperatures from -40 to 257°F. The case has an IP 67 rating, so it keeps out dust and water. The sensors are made with stainless steel parts. The 3200 Series has a thicker diaphragm and a pressure restrictor for pressure spikes.

| Specification | Details |

|---|---|

| Measuring Range | 0-250 Bar |

| Signal Output | 4~20 mA |

| Temperature Range | -40 to 257°F |

| Enclosure Rating | IP 67 |

| Approvals | CURUS, RoHS Compliant |

| Weight | 200 g |

- CURUS

- RoHS Compliant

Pros & Cons

- Pros:

- Handles high pressure

- Works in hot and cold places

- Stainless steel parts

- Keeps out dust and water

- Reliable in hard jobs

- Cons:

- Heavier than some other sensors

Industrial Use Cases

Factories use Setra Model 3100/3200 sensors for process control and automation. The sensors help watch pressure in machines and pipes. They work well in places with very hot or cold temperatures or pressure spikes.

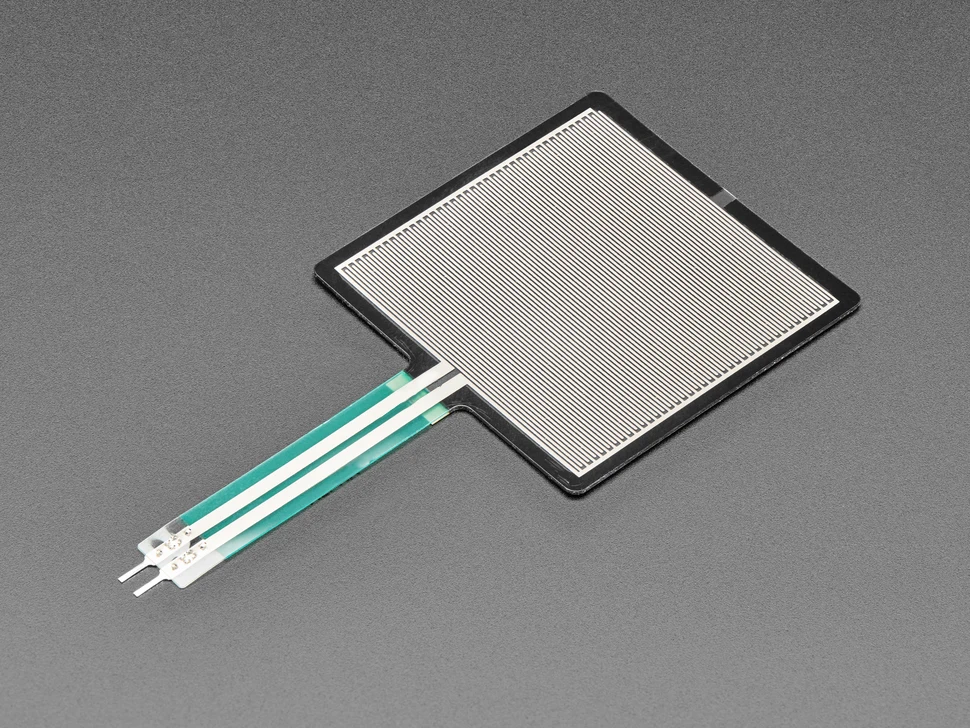

Tekscan FlexiForce Series

Features

Tekscan FlexiForce Series sensors are flexible and measure a wide range of forces. They measure from 10 grams to 100 kilograms. The sensors are thin, only about 0.3mm thick. They react fast to changes in force. The sensors work in many factory jobs, like robotics and quality control.

| Feature | Description |

|---|---|

| Measuring Range | 10g to 100kg |

| Thickness | 0.3mm |

| Response Time | Less than 10 milliseconds |

| Flexibility | Fits curved or tight spaces |

| Application Areas | Robotics, quality control, automation |

Pros & Cons

- Pros:

- Measures many different forces

- Thin and bends easily

- Reacts quickly

- Fits in many devices

- Cons:

- Not as accurate as some other sensors

Industrial Use Cases

Tekscan FlexiForce sensors help in robots, quality checks, and automation. The sensors fit into small or curved spaces. They give real-time feedback in factories and robot systems.

EE610 Pressure Sensor

Features

The EE610 Pressure Sensor works in hospitals and clean rooms. It measures small changes in pressure. The sensor has a thin film part inside. This part helps it give steady results for a long time. The EE610 is small and fits in tiny devices. It can send out both digital and analog signals. This means it can work with many types of monitors.

| Feature | Description |

|---|---|

| Measurement Range | 0–1000 Pa |

| Output Options | Analog (0–10V), Digital (Modbus) |

| Accuracy | ±0.5% of full scale |

| Response Time | <10 milliseconds |

| Size | Compact, easy to install |

| Certifications | ISO 13485, FDA |

Note: The EE610 sensor has a thin film part. This helps it stay steady in places that need clean air.

Pros & Cons

- Pros:

- Measures very small pressure

- Gives quick and steady results

- Works with many signal types

- Fits in tight spaces

- Passes medical and clean room tests

- Cons:

- Not made for high pressure jobs

Medical & Clean Room Use

Hospitals use the EE610 in breathing machines and patient monitors. It checks air flow and pressure in these tools. Clean rooms use the EE610 to watch air pressure. This helps keep out dust and germs. The sensor reacts fast, so staff can act quickly. Its small size lets it fit in hard-to-reach places. The EE610 follows strict rules for medical and clean rooms.

RP-C Pressure Sensor

Features

The RP-C Pressure Sensor is used in many factories. It measures medium and high pressure. The sensor has a strong thin film build. This makes it work well in rough places. The RP-C can handle hot and cold temperatures. It sends out analog signals, so it is easy to add to machines.

| Feature | Description |

|---|---|

| Measurement Range | 0–15 kg |

| Output Type | Analog |

| Accuracy | ±12% of full scale |

| Structure | Rigid thin film |

| Temperature Range | -40°C to 85°C |

| Certifications | ISO 9001, ANSI |

Tip: The RP-C sensor works great where there are lots of shakes or big temperature changes.

Pros & Cons

- Pros:

- Handles medium and high pressure

- Works in rough places

- Easy to hook up to machines

- Reliable in hot and cold weather

- Cons:

- Not as bendy as some other sensors

Industrial Use Cases

Factories use the RP-C sensor for robots and machine control. It checks pressure in pipes and tanks. This helps keep machines safe. The RP-C also works in robots and big machines. Its hard build keeps it safe from bumps and shakes. Engineers choose the RP-C when they need a sensor that lasts in tough jobs.

How to Choose Thin Film Pressure Sensors

Application Needs

Medical Device Requirements

Medical devices need sensors that follow strict rules. Hospitals use sensors in monitors, pumps, and smart beds. These sensors must give steady and correct readings. They should fit in small spaces and use little power. Hospitals want sensors that pass ISO 13485 and FDA checks. Medical sensors must work well after many uses. Some tools, like prosthetics, need sensors that bend and fit different shapes.

Tip: Medical teams should see if the sensor can be cleaned and sterilized.

Industrial Demands

Factories and machines need sensors that last for years. Industrial sensors must work with dust, heat, or vibration. Factories use sensors in robots, quality checks, and control jobs. These sensors must handle high pressure and quick changes. Some jobs need sensors for hot and cold weather. Factories pick sensors that meet ISO 9001 or ANSI standards.

Performance Factors

Sensitivity & Range

Sensitivity means how well a sensor notices small force changes. Range tells how much force the sensor can measure. Medical devices need high sensitivity for small pressure changes. Industrial jobs may need a wide range for light and heavy forces. Users should match the sensor’s range to the job. For example, a smart bed needs to sense small shifts. A robot arm may need to handle heavy loads.

Response Time

Response time means how fast the sensor reacts. Medical devices need quick response to keep patients safe. For example, a breathing machine sensor must react in milliseconds. In factories, fast response helps machines work better and safer. Users should check the sensor’s response time in the product sheet.

Durability & Longevity

Clinical Environments

Sensors in hospitals get used many times each day. They must keep working after many presses and cleaning. Some sensors need to resist moisture and cleaning chemicals. Hospitals pick sensors that last long and stay accurate.

Industrial Environments

Factories can be tough on sensors. Machines may shake or get hot. Sensors must work with dust, oil, or strong cleaning. Many factories pick sensors with strong cases and seals. These sensors must last for years and keep their accuracy.

Note: Always check the sensor’s test results for durability before you choose.

Cost & Value

Upfront vs. Long-Term Costs

Cost is important when picking a thin film pressure sensor. Many people look at the price first. The cheapest sensor is not always the best deal. Some sensors cost more at first but last longer. These sensors do not break as much and need fewer fixes. This can help save money over time.

- Upfront Costs:

This means the price of the sensor and putting it in. Some sensors need special tools or extra parts. This can make the starting price higher. - Long-Term Costs:

These are for repairs, new parts, and lost work time. Sensors that break a lot can stop work or cause trouble in hospitals. Sensors that work well may cost more at first but save money later.

Tip: Buyers should look at both the starting price and the cost to keep the sensor working. A sensor that costs more at first may save money later.

Compatibility & Integration

Electronics & Data Systems

Sensors must work with the devices already in use. Some sensors use analog signals and some use digital signals. The best choice depends on the system you have.

| Signal Type | Common Use | Example Devices |

|---|---|---|

| Analog | Simple systems | Basic monitors, pumps |

| Digital | Advanced systems | Smart beds, robots |

Engineers check if the sensor matches the power and data system. Some sensors need special software or connectors. Others work with many types of equipment. Easy setup saves time and money.

Note: Always check the sensor’s datasheet for details about voltage, current, and data output.

Certifications & Standards

Medical-Grade Certifications

Medical sensors must follow strict rules. These rules help keep patients safe. Common certifications are:

- ISO 13485:

This means the sensor meets medical device rules. - FDA Approval:

This means the sensor is safe to use in the United States. - ISO 17664:

This covers cleaning and sterilizing the sensor.

Hospitals and clinics look for these marks before buying sensors.

Industrial Standards

Factories need sensors that follow different rules. These rules help keep workers and machines safe.

- ISO 9001:

This means the sensor comes from a company with good quality checks. - ANSI:

This means the sensor meets American safety and performance rules. - EHEDG:

This is important for sensors used in food or clean places.

Tip: Always match the sensor’s certifications to the job. Medical jobs need medical-grade marks. Factories need industrial standards.

Real-World Applications of Thin Film Pressure Sensors

Thin film pressure sensors are used in many areas. They help people check health, run machines, and make new tech better. These sensors work in hospitals and factories.

Medical Devices

Patient Monitoring

Hospitals use thin film pressure sensors to watch patients. Nurses can tell if someone gets out of bed or a chair. This helps stop falls. The sensors also help doctors check breathing and heartbeats. They give quick data, so staff can act fast.

Infusion Pumps

Infusion pumps use thin film pressure sensors to control medicine flow. The sensors check the tube’s pressure. If the pressure changes, the pump can stop or warn a nurse. This keeps patients safe and gives the right medicine amount.

Prosthetics

Engineers put thin film pressure sensors in fake arms and legs. The sensors measure force when someone walks or grabs things. This feedback helps people move their limb better. It also helps doctors make the fit and use better.

Industrial Automation

Robotics

Robots use thin film pressure sensors to feel touch and force. The sensors help robots pick up things without breaking them. They also help robots move safely near people and machines. Engineers use these sensors to make robots safer and smarter.

Quality Control

Factories use thin film pressure sensors to check products as they are made. The sensors measure pressure in machines and on items. If something is wrong, the system can stop or tell a worker. This keeps quality high and cuts down on waste.

Emerging Trends

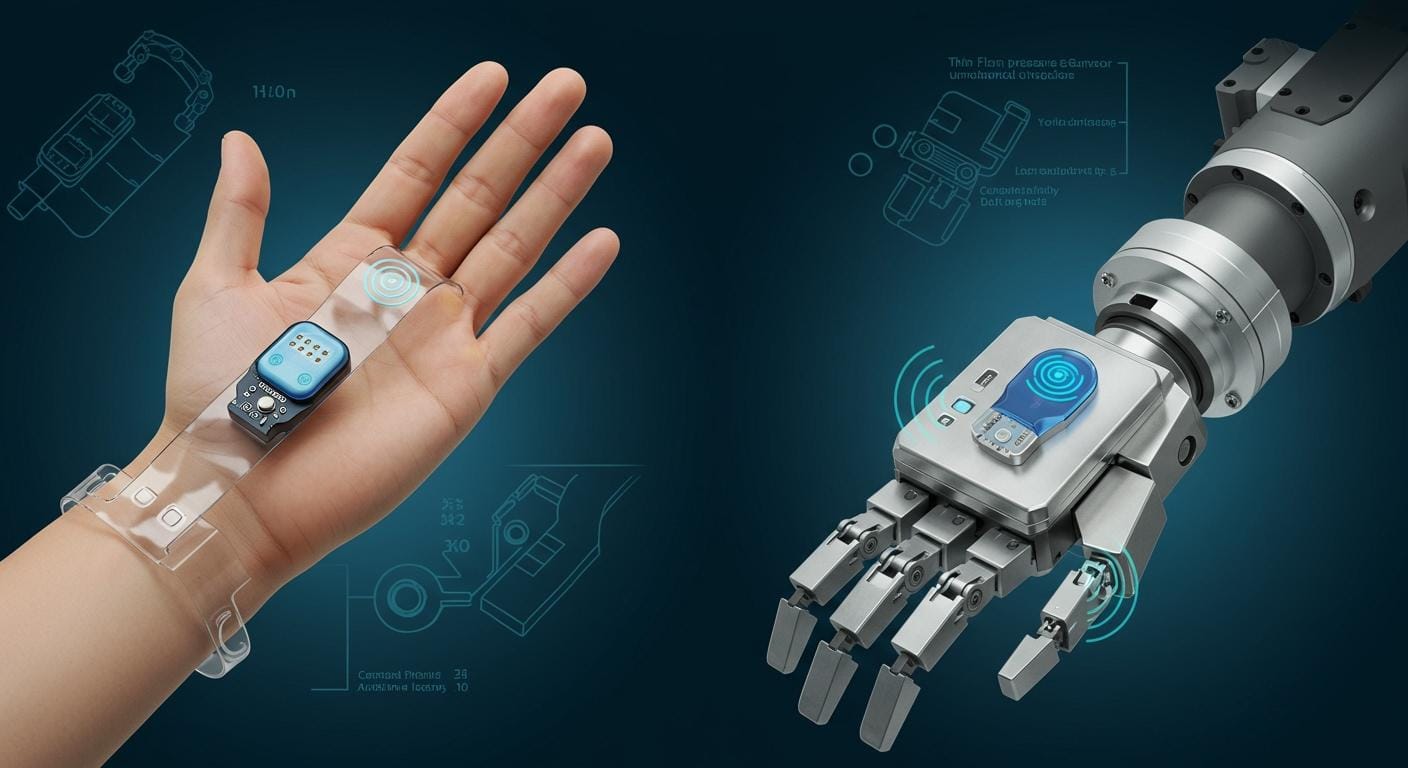

Flexible & Wearable Sensors

Thin film pressure sensors are now in bendy and wearable tech. People wear these sensors on skin or clothes. The sensors track moves, pressure, and health info. This helps athletes, patients, and workers stay safe and healthy.

IoT Integration

Many companies link thin film pressure sensors to the Internet of Things (IoT). The sensors send data to computers or phones. This lets people watch and control things from far away. For example, a smart bed in a hospital can tell staff if a patient moves. In factories, bosses can check machines from other places.

Note: Thin film pressure sensors help make things safer, better, and more comfortable. Their use in hospitals and factories keeps growing as tech gets better.

Thin film pressure sensors make hospitals and factories safer and better. SOUSHINE Force Sensing Resistors are great for medical tools. Setra and Tekscan work well in factories. Kyocera and Omron are good choices for clinics. People should look at the comparison table to find what they need. Asking for samples or talking to makers helps people pick the right sensor.

Tip: Always check the certifications and test results before you decide.

FAQ

What is a thin film pressure sensor?

A thin film pressure sensor checks force or pressure with a thin layer. Engineers use these sensors in medical tools and machines. They give fast and correct results.

How do thin film pressure sensors work?

Thin film pressure sensors change their electrical resistance when pressed. Devices read this change and show the pressure amount. This helps control and watch many systems.

Where are thin film pressure sensors used?

Hospitals use these sensors in patient monitors, infusion pumps, and prosthetics. Factories use them in robots, quality checks, and automation.

What certifications should medical sensors have?

Medical sensors should have ISO 13485 and FDA approval. These show the sensor is safe and good for healthcare.

How long do thin film pressure sensors last?

Thin film pressure sensors can work for years if used right. Testing often and cleaning them helps them last in hospitals and factories.

Can thin film pressure sensors fit in small devices?

Yes. Many thin film pressure sensors are thinner than 0.5mm. Engineers put them in small or curved spots in medical tools or machines.

What is the difference between analog and digital output?

Analog output gives a smooth signal. Digital output sends data in steps. Simple systems use analog, and advanced ones use digital.

Do thin film pressure sensors need special care?

Cleaning and careful use help sensors last longer. Hospitals and factories should follow the maker’s instructions for best results.