Call us: +86-137-2353-4866

A force sensing resistor strip checks how much force is put on it. It is like a mat that feels pressure when you step on it. But this strip is much thinner and more exact. The SOUSHINE FSR 408 is a well-known force sensing resistor. Its resistance changes when you press it. This makes it good for touch controls in electronics.

- The world market for force sensing resistor strips may reach about $400 million by 2025.

- The market should grow by 10% each year, and it may rise to 11% from 2025 to 2032.

Table of Contents

Key Takeaways

- Force sensing resistor strips change how much resistance they have when you press them. This helps devices feel touch and measure force well.

- The SOUSHINE FSR 408 is a top pick because it is thin and strong. It can last through up to 10 million presses.

- These sensors are useful and work in many things, like cars, medical tools, and wearable tech.

- Engineers can add force sensing resistors to projects with easy circuits. This makes them good for both hobbyists and experts.

- Force sensing resistors do not cost much and work well. Many people choose them for electronic designs.

Force Sensing Resistor Strip Basics

What Is a Force Sensing Resistor Strip

A force sensing resistor strip is a sensor that changes how much electricity it lets through when you push on it. Engineers call these sensors force sensing resistors, or FSRs. The strip has a bendy base with two parts of a special circuit. A spacer keeps this base apart from another layer that has conductive ink on it. When you press the strip, the conductive layer touches the circuit. This lets electricity move through. The harder you press, the more electricity can flow.

A force sensing resistor strip connects touch to electronics. It helps devices know when and how hard you press.

The main parts of force sensing resistors are:

- Flexible base

- Special circuit

- Spacer

- Conductive ink

Manufacturers put solder tabs on the flexible base. These tabs touch the semi-conductive material. This is needed for the sensor to work.

Force sensing resistor strips come in different thicknesses and weights. The table below shows some common sizes:

| Item Description | Thickness | Weight |

|---|---|---|

| 24″ × 0.4″ Strip | 0.02 in | 5 g |

| Round Force-Sensitive Resistor (FSR) | 0.56 mm | 0.9 g |

Main Purpose

Force sensing resistors are important in electronics. They help devices feel force and pressure. You can find these sensors in many areas, like gadgets, robots, and medical tools. Force sensing resistor technology lets devices sense touch, check pressure, and make controls better.

| Role of Force Sensing Resistor Strips | Description |

|---|---|

| Detecting Applied Forces | They notice changes in resistance when you press them. This is useful in smart clothes and devices. |

| Integration with Textiles | Engineers put them in wearable electronics to sense touch and pressure. |

| Dynamic Range and Stability | The sensors have good range and work the same way each time. This helps devices work well. |

Force sensing resistors can be used alone or in groups. This helps devices see where pressure is on a surface and makes them easier to use.

SOUSHINE FSR 408 is a top example of a force sensing resistor strip. The sensor uses polymer thick film technology and can measure forces from 0.1 N to 10 N. It is very thin, only 0.40 mm, so it fits in many devices. SOUSHINE FSR 408 is strong and can handle up to 10 million presses. The sensor works in many places, like cars, hospitals, and robots.

| Feature | SOUSHINE’s FSRs | Other Piezoresistive Sensors |

|---|---|---|

| Customizable Shapes and Sizes | Yes | Limited |

| Durability and Reliability | High | Varies |

| Low Power Consumption | Yes | Often higher |

| Ease of Integration | Simple electrical interface | May require complex setup |

Researchers and engineers like force sensing resistor strips because they are easy to use and work well. Studies show that force sensing resistors help robot hands and biomechanical devices measure force and control movement.

Force sensing resistor strips help devices react to touch and pressure. They make technology easier to use and more dependable.

How Force Measurement Works

Principle of Force Sensing Resistor

Force sensing resistors use piezoresistive technology to sense force. The piezoresistive effect happens when a material changes resistance as it bends or stretches. This effect helps us measure force, pressure, or stress by watching resistance changes. Many force sensing resistors use carbon-based ink or semiconductors for this.

A force sensing resistor strip has a simple design. The table below lists its main parts and what they do:

| Component | Description |

|---|---|

| Layers | Two layers made from flexible polymer |

| Conductive Material | Carbon-based ink and special electrodes |

| Function | Resistance changes when you press on it |

When you press the strip, the layers touch each other. The conductive material lets more electricity move through. If you press harder, resistance gets lower. This change helps the sensor measure force.

The piezoresistive effect makes force sensing resistors good for measuring force in many devices.

How Resistance Changes with Force

A force sensing resistor works like a resistor that can change. When you push on it, resistance goes down. When you stop pressing, resistance goes back up. This change is important for measuring force.

Force sensing resistors use a special polymer that conducts electricity. This material changes resistance clearly when pressed. Devices use this to measure how much force is on one spot.

To measure force, engineers use a voltage divider circuit. They connect the force sensing resistor to a fixed resistor. This setup makes a spot where voltage changes with force. An Arduino can read this voltage with its analog-to-digital converter. A common setup uses a 10kΩ resistor with the sensor. The Arduino checks the voltage at the middle point to measure force.

- Steps to connect a force sensing resistor to an Arduino:

- Connect one end of the sensor to a power source.

- Connect the other end to a fixed resistor, then to ground.

- Connect the middle point to the Arduino’s analog input.

- The Arduino reads the voltage and figures out the force.

The SOUSHINE FSR 408 is known for being sensitive and having a wide range. It can sense forces from 0.2N to 20N. This makes it useful for many jobs. The sensor reacts fast and gives the same results each time. Engineers use it in projects that need to measure force well, like robots, medical tools, and smart gadgets.

Force sensing resistor technology gives devices an easy way to measure force. The SOUSHINE FSR 408 is a reliable and sensitive choice for many uses.

Force-Sensitive Features & Uses

Key Benefits

Force sensing resistors have many good points for making products. These sensors come in shapes like squares, circles, and strips. They are small, thin, and light, so they fit in lots of devices. Designers can pick different terminals, like bare, solder tab, or connector types. Each sensor can take up to 5 kilograms of force. They use very little power and work well almost anywhere. They still work if they get wet or near strong magnets.

| Feature/Benefit | Description |

|---|---|

| Design Options | Square, circle, and strip designs |

| Terminal Options | Bare, solder tab, and connector |

| Force Capacity | Handles up to 5 KG of force |

| Size and Weight | Small, thin, and lightweight |

| Environmental Resistance | Immune to EMI and water events |

| Power Consumption | Low power usage |

| False Touch Rejection | Rejects false touches |

| Cost-Effectiveness | Economical for many uses |

| Durability | Over 10 million activations |

| Dynamic Resistance | Resistance drops as force increases |

Force sensing resistors can give feedback without a click or bump. This helps make touch controls better for users. They can show where force is on a surface. This is helpful for robots and smart gadgets.

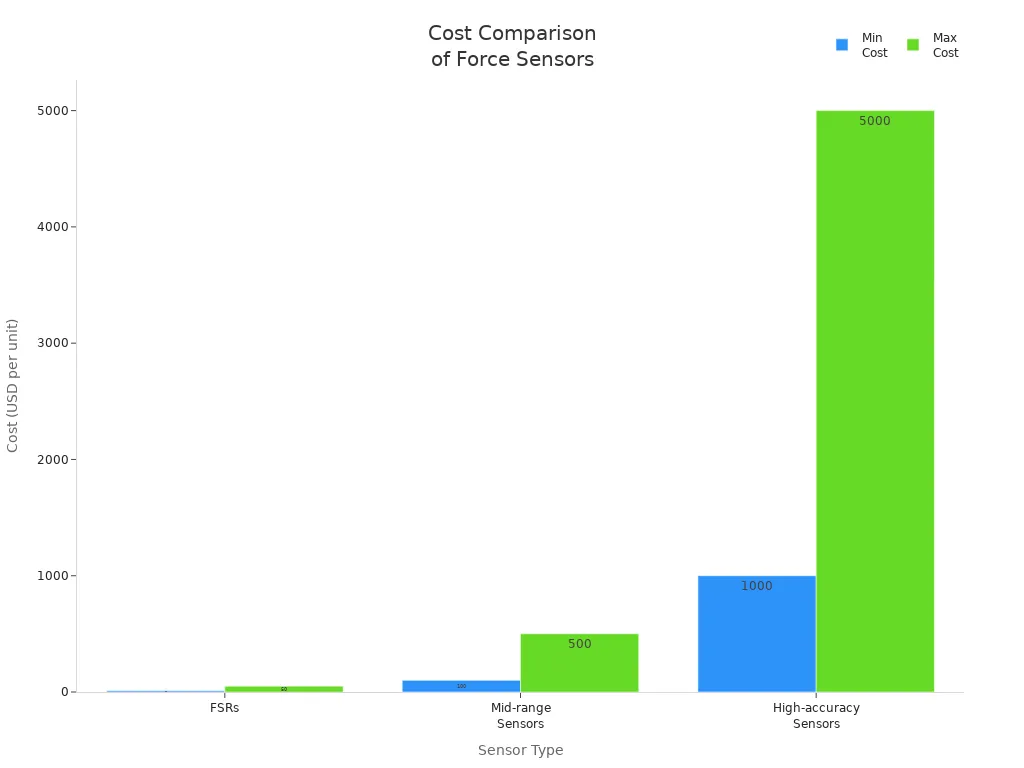

Force sensing resistor strips cost less than other sensors. The chart below shows how prices compare:

Common Applications

Force sensing resistor technology is used in many fields. In cars, these sensors check how hard you grip the steering wheel. They help with touch panels and seat sensors. They also help with cruise control and moving mirrors.

In hospitals, force sensing resistors watch how patients move and feel in smart beds. They check vital signs and warn nurses about too much pressure. Disposable sensors help stop germs from spreading.

| Application | Description |

|---|---|

| Patient Monitoring | Tracks patient condition and alerts staff |

| Smart Beds | Monitors movement and comfort |

| Real-time Monitoring | Gives instant feedback in medical devices |

| Error Prevention | Warns staff about high pressure |

| Health Monitoring | Sends data to healthcare professionals |

| Infection Control | Uses disposable sensors to prevent cross-infection |

Robots use force-sensitive sensors in their fingers and to check parts. Wearable gadgets use them to sense touch and pressure.

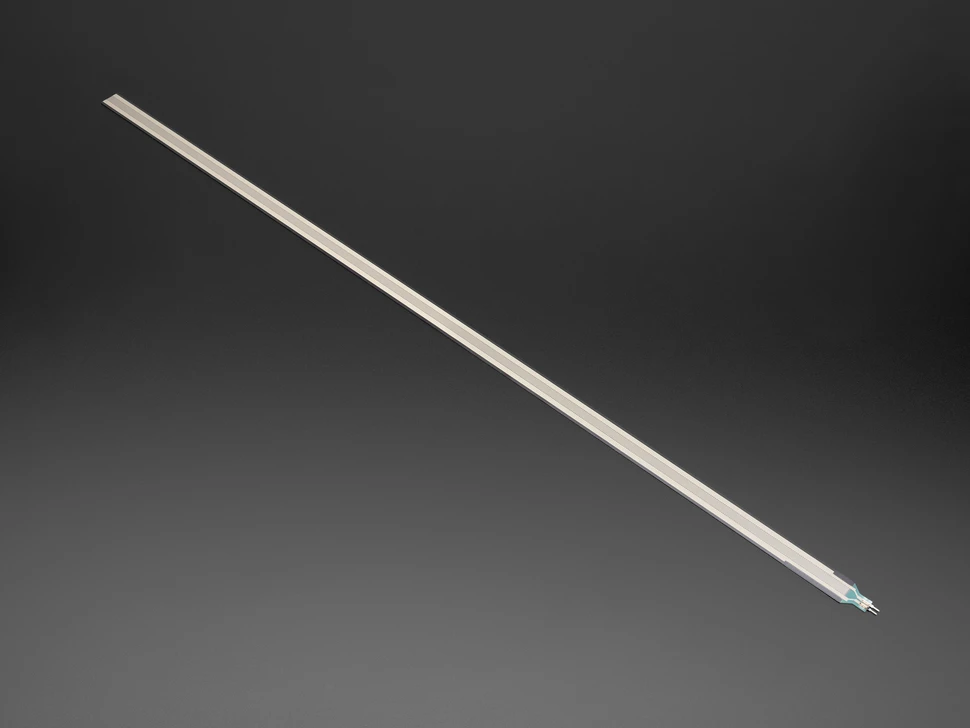

The SOUSHINE FSR 408 force sensing resistor strip is strong and made with polymer thick film. It comes in many lengths, from 50mm to 610mm, so it fits lots of jobs. This sensor works great in cars, hospitals, and robots. It lasts a long time and is very sensitive. Engineers like it because it is reliable for force sensing.

Force sensing resistors help products react to touch and pressure. They make devices safer, smarter, and more fun to use.

Comparing Force Sensing Resistors

Limitations

Force sensing resistors have many good uses, but they also have limits. These sensors can give different readings if the temperature goes up or down. If you bend the sensor, it may not work the same. Each sensor might need its own setup, especially on soft things like skin or cloth. The way a force sensing resistor reacts can change with time or if it gets wet.

- When the temperature changes, the sensor’s current changes too.

- If you bend the sensor, the reading will be different.

- Soft things under the sensor can make it less exact.

- The sensor does not always react the same as you press harder.

- Sensors made together may not all work the same.

| Factor | Impact on FSR Performance |

|---|---|

| Temperature | Sensor readings can change |

| Curvature | Output and setup can change |

| Tissue Compliance | Each sensor needs its own setup |

| Non-linearity | Response can change with time or weather |

How long a force sensing resistor lasts depends on what it is made of. Some sensors can last longer than others. FlexiForce sensors can take lots of presses before they break.

Other Force Sensors

Engineers look at force sensing resistors and other sensors to see which is best. Each sensor works better for some jobs.

| Feature | Force Sensing Resistors | Capacitive Force Sensors |

|---|---|---|

| Measurement Method | Resistance changes | Capacitance changes |

| Precision | Not as high | Higher |

| Environmental Sensitivity | Not as much | More |

| Force Range | Wider | Smaller |

| Cost | Lower | Higher |

| Applications | Buttons, robots, medical tools | Touch screens, robots, medical |

Piezoelectric sensors are good for quick changes and shaking. Force sensing resistors are better for steady force. Piezoelectric sensors are used when you need fast and exact results. Force sensing resistors are used in cars, hospitals, robots, and factories.

| Sensor Type | Sensitivity | Application Examples |

|---|---|---|

| Piezoelectric | Best for quick changes and shaking | Fast, exact measurements |

| Force Sensing Resistor | Good for steady force | Cars, hospitals, robots, planes |

When picking a sensor, engineers think about how tough it is, where it will be used, how big it is, if it gives the same results, how sensitive it is, and how much it costs.

| Factor | Description |

|---|---|

| Durability | FSRs can take rough use better than load cells |

| Environment | Temperature and wetness can change how it works |

| Form Factor | Thin, bendy sensors fit in small places |

| Repeatability | Getting the same results is important |

| Sensitivity | Must match the force you want to measure |

| Cost | Pick what fits your project and money |

A force sensing resistor strip is an easy way to measure force. Other sensors may be more exact or faster, but force sensing resistors are liked because they are flexible and cheap.

Force sensing resistor strips change how much resistance they have when you press them. Here are some important things to know:

- If you do not press, the resistance is high. When you press, the resistance goes down.

- The resistance changes in a way that is almost straight, so it is simple to measure force.

- There are two main types: Shunt Mode and Thru Mode.

- You need to use weights you know to set it up right.

- Other electronics are needed to read what the sensor says.

The SOUSHINE FSR 408 is special because it bends easily and works well for a long time:

| Feature | Description |

|---|---|

| Customizable Shapes and Sizes | It can fit lots of different designs. |

| Durability and Reliability | It keeps working for a long time. |

| Low Power Consumption | It does not use much energy. |

| Ease of Integration | It is easy to add to your projects. |

A lot of hobbyists and engineers use FSRs to make pressure switches or to measure force with Arduino. Force sensing technology helps make devices safer and smarter. Try using a force sensing resistor in your next project and see what you can make!

FAQ

What does a force sensing resistor strip do?

A force sensing resistor strip checks how hard you press on it. When you push on the strip, its resistance changes. Devices use this change to know if you touched or pressed it.

How does the SOUSHINE FSR 408 connect to electronics?

You connect the SOUSHINE FSR 408 to a circuit with solder tabs. The sensor works with microcontrollers such as Arduino. A voltage divider circuit helps the device read force.

Can the FSR 408 strip be cut to size?

Yes, you can cut the FSR 408 strip to make it shorter. This lets the sensor fit into different projects or small spaces.

Where do engineers use force sensing resistor strips?

Engineers put these strips in cars, robots, wearables, and medical devices. The strips help measure grip, check pressure, and sense touch.

How long does the SOUSHINE FSR 408 last?

The SOUSHINE FSR 408 can take up to 10 million presses. This makes it a strong choice for projects that need lots of uses.