Call us: +86-137-2353-4866

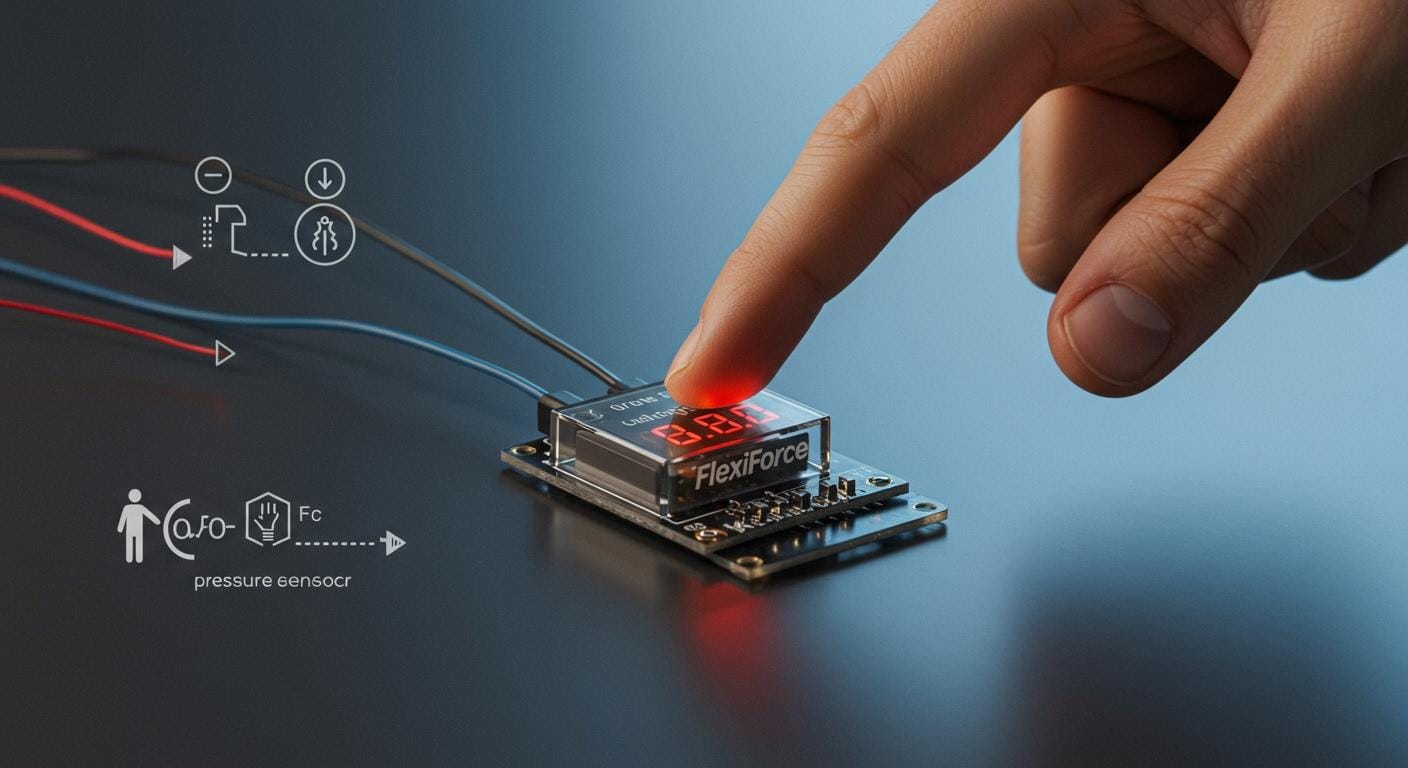

A flexiforce pressure sensor checks force between two surfaces. It does this by changing its resistance. SOUSHINE is a top company in force sensing technology. Their sensors are only 0.203 mm thick. These sensors are flexible and light. This makes them simple to use in many designs.

The global force sensor market may reach US$3.9 billion by 2032. It is growing at a steady rate of 5.5% each year.

| Characteristic | Specification |

|---|---|

| Type | Variable resistor |

| Sensing area diameter | ø3.8mm |

| Dimensions | 38.1mm x 7.6mm x 0.203mm |

A flexiforce pressure sensor gives real-time force sensing. Many industries use it.

Table of Contents

Key Takeaways

- FlexiForce pressure sensors work by changing resistance when pressed. This helps collect data right away.

- SOUSHINE’s FlexiForce sensors are very thin at 0.203 mm. They are flexible and fit in small or tight spaces. They also fit between moving parts.

- These sensors are used in many fields like medical, robotics, and electronics. They are light and strong, so they last a long time.

- FlexiForce sensors can work in high heat, up to 400°F (about 204°C). This makes them good for tough places.

- You can choose different shapes, sizes, and force ranges. This helps meet the needs of your project.

- The sensors are simple to use with microcontrollers like Arduino and Raspberry Pi. This makes them easy for engineers and hobbyists to use.

- FlexiForce sensors do not cost much and work well. They do not use a lot of power, so they are great for battery devices.

- SOUSHINE helps with design and setup. They help users get the best results from their FlexiForce sensors.

FlexiForce Pressure Sensor

What It Is

SOUSHINE makes FlexiForce Load/Force Sensors and Systems. These sensors measure force between two surfaces. Each sensor is thin and flexible. The thickness is only 0.203 mm. This small size lets it fit in tight spaces. It can also go between moving parts. The sensor bends but does not break. It works well in many products.

The flexiforce pressure sensor changes its electrical resistance when pressed. This helps engineers and researchers see force data right away. Many people use these sensors for testing, design, and quality checks.

SOUSHINE makes all FlexiForce sensors in their own factory. This lets them check quality and ship sensors quickly.

The table below shows how FlexiForce sensors are thinner than other types:

| Sensor Type | Thickness (mm) | Advantages |

|---|---|---|

| FlexiForce A301 | 0.203 | Very thin, flexible, fits in small spaces |

| Other Force Sensors | >0.203 | Thicker, not good for small places |

SOUSHINE gives a flexiforce quick start example for beginners. This helps engineers and students learn to use the sensor in easy projects.

Main Types

SOUSHINE has different models of the flexiforce pressure sensor. Each model measures a different force range. The table below lists the main product lines and their details:

| Sensor Model | Max Force (High Gain) | Max Force (Low Gain) | Sensor Thickness | Temperature Range (Low) | Temperature Range (High) |

|---|---|---|---|---|---|

| B201 – L | 4.4 N (0 – 1 lb) | 111 N (0 – 25 lb) | 0.203 mm (0.008 in.) | -40 F | 140 F |

| B201 – M | 111 N (0 – 25 lb) | 667 N (0 – 150 lb) | 0.203 mm (0.008 in.) | -40 F | 140 F |

| B201 – H | 667 N (0 – 150 lb) | 4448 N (1 – 1000 lb) | 0.203 mm (0.008 in.) | -40 F | 140 F |

There are two main types of FlexiForce sensors:

- Standard FlexiForce Sensors: These use very thin, flexible printed circuits. They have a pressure-sensitive layer between two flexible pieces. The resistance goes down when you press on them. This type gives a steady and more even output.

- Shunt Mode Sensors: These have two layers with a gap of air. Special ink connects the traces when pressed. This type is less even and the voltage can change over time.

The table below compares these two types:

| Feature | FlexiForce Sensors | Shunt Mode Sensors |

|---|---|---|

| Construction | Very thin, flexible printed circuits with two layers | Thick-film devices with two layers and an air gap |

| Sensing Mechanism | Conductive polymer on layers with a pressure-sensitive part | Special ink connects traces when pressed |

| Resistance Behavior | High resistance when not pressed, drops when pressed | Acts the same, but less even response |

| Performance | More even results in tests, steady voltage | Not as even, voltage drops over time |

SOUSHINE can make each flexiforce pressure sensor special for your needs. They can change the shape, size, or how it connects. Their engineers help with both mechanical and electrical setup. SOUSHINE tests every sensor in their certified lab. This makes sure each sensor is high quality and works well.

Tip: Custom sensors can be as small as 1.86 mm or as big as 402.59 mm. They can also work in hot places up to 204°C.

FlexiForce sensors are used in many industries. Their thin size, bendy shape, and custom options make them a great choice for measuring force.

Force Sensing Resistor Technology

How It Works

A force sensing resistor checks force by changing resistance. When you press the sensor, resistance goes down. This lets the sensor show how much force is there. FlexiForce sensors use this idea to give force data right away.

A force sensing resistor works as a variable resistor in a circuit. It has high resistance when no force is on it. When you push on it, resistance drops from megaohms to kiloohms. Conductance, which is the opposite of resistance, goes up as force goes up. This change stays steady within the sensor’s range. Engineers use this steady change to get good force readings.

A force sensing resistor uses piezoresistive technology. It senses force by changing resistance.

The table below shows how a force sensing resistor works:

| Feature | Description |

|---|---|

| Construction | Flexible printed circuits use polyester film for the outside. |

| Operation | Uses piezoresistive technology to measure force by changing resistance. |

| Resistance Characteristics | High resistance (Megaohms) when not pressed, drops to Kiloohms when pressed. |

| Conductance Relationship | Conductance and force go up together in a straight line within the sensor’s range. |

A force sensing resistor can connect to simple circuits. Other circuits can turn resistance changes into voltage. This makes it easy to read force with a microcontroller or display.

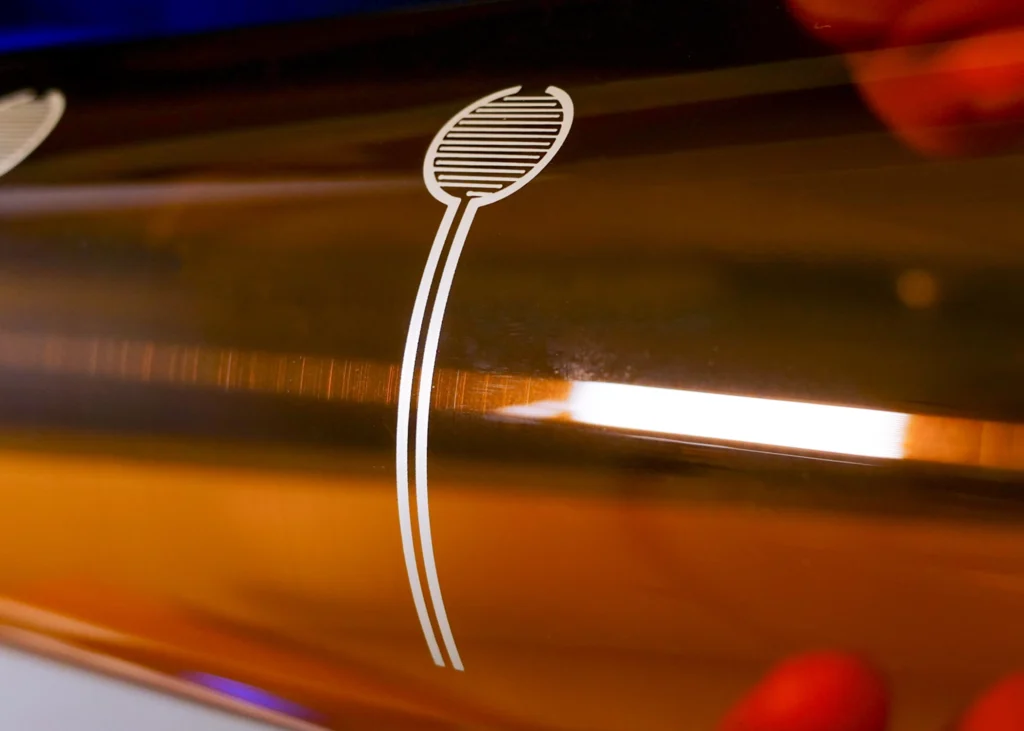

Sensor Construction

Materials

A force sensing resistor has several layers. The main parts are:

- Two flexible polyester sheets make the outside.

- Printed silver ink forms the paths for electricity.

- A soft polymer layer sits between the conductive layers.

The table below lists the main components:

| Component | Description |

|---|---|

| Sensing Area | The spot where pressure is put, making the polymer layer squeeze. |

| Polymer Layer | Soft layer that changes conductance when pressed. |

| Conductive Layers | Two layers of silver ink help measure resistance changes. |

A force sensing resistor stays thin and light because of these materials. The sensor can bend and fit in small spaces. The flexiforce pressure sensor uses this build to measure force between surfaces.

Variable Resistance Principle

The variable resistance principle is the main idea of force sensing resistor technology. When there is no force, the sensor has very high resistance. As force goes up, the polymer layer gets squeezed. This lets more current move between the conductive layers. Resistance drops because of this.

- A force sensing resistor starts with resistance in the megaohm range.

- When you press it, resistance drops to the kiloohm range or lower.

- The resistance change is steady and follows a straight pattern in the sensor’s range.

A force sensing resistor can be set up for accuracy. SOUSHINE uses a three-point calibration process. This process changes how sensitive the circuit is. Engineers can use different op-amp circuits to set the output. Adjustable parts help set the output to 80-90% of full scale at max force. This method gives FlexiForce sensors a linearity of ±3%. The sensor can then give results that are reliable and repeatable.

A force sensing resistor can be made in many shapes and sizes. SOUSHINE offers custom choices for different needs. The sensor can work in many places and can be used in many products.

Tip: A force sensing resistor can be put inside OEM devices or used in research labs for accurate force measurement.

A force sensing resistor gives engineers an easy way to measure force. The technology makes it a popular choice for many industries.

Force Resistive Sensor Features

Key Benefits

FlexiForce sensors have many good features. They are thin and light. Engineers can put them in small spaces or on moving things. These sensors do not use much power, so they are good for battery devices. FlexiForce sensors also measure force very well.

The table below shows how FlexiForce sensors are different from other types:

| Feature | FlexiForce Sensors | Other Technologies |

|---|---|---|

| Flexibility | Yes | No |

| Cost | Low | High |

| Ease of Integration | High | Variable |

| Dynamic Range | Wide | Limited |

| Precision Requirement | Moderate | High |

FlexiForce sensors work in many places. Some can handle heat up to 400°F (about 200°C). This makes them good for hot spots. The sensors react fast when you press them, so you get feedback right away.

Note: FlexiForce sensors help people measure force in many products.

Customization

SOUSHINE lets people order special force resistive sensors. You can ask for a sensor in a certain shape or size. This helps if your project needs a sensor that fits just right. SOUSHINE can also change how the sensor connects or where it senses.

- SOUSHINE lets you pick the size and shape you want.

- Custom sensors take more time to make, but they fit your project.

- SOUSHINE gives advice to help you pick and set up the sensor.

SOUSHINE’s team helps customers from start to finish. They answer questions about design and setup. This help makes sure you get the best from your sensor.

Durability

FlexiForce sensors are strong. Thin polyester layers keep the sensor safe from harm. The sensors keep working after many uses. They can take lots of pressing and bending. Some models work in hot places, up to 400°F. This makes them good for hard jobs.

FlexiForce sensors do not break down easily. The materials help the sensor last a long time. People can use these sensors for short tests or for a long time.

Tip: FlexiForce sensors are great for medical, industrial, and home products because they last.

The flexiforce pressure sensor is special because it is thin, bends, and measures force between surfaces. SOUSHINE’s custom orders and technical help make these sensors a smart pick for many projects.

Applications

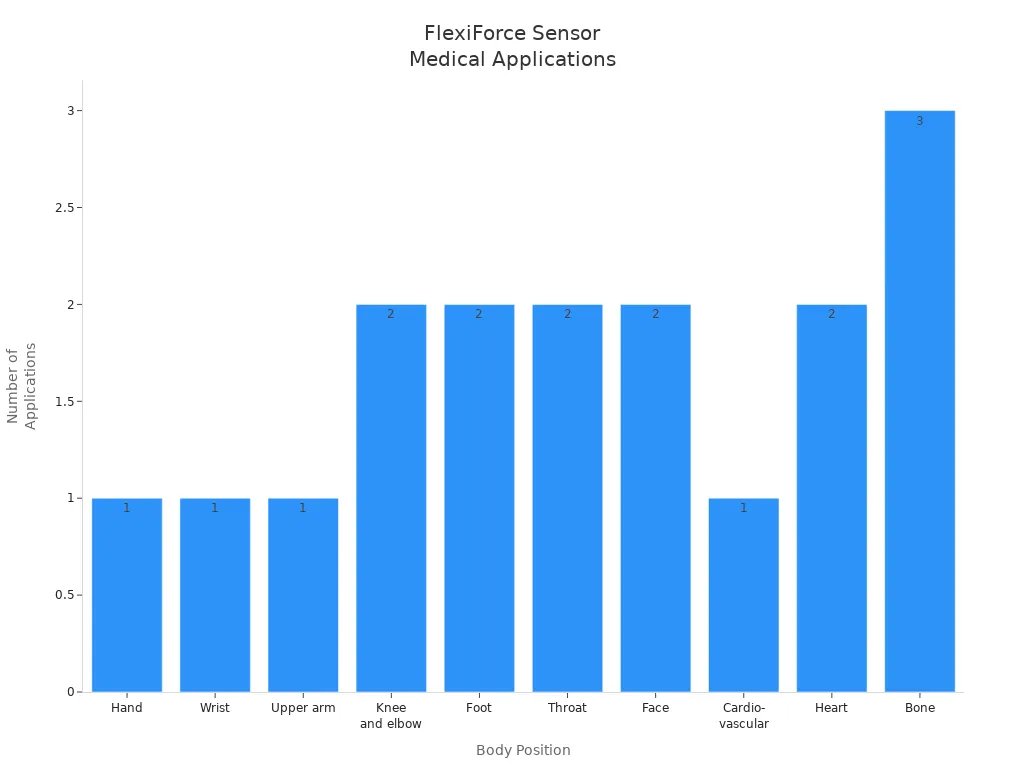

Medical

FlexiForce sensors are important in medical devices. They help doctors and scientists watch force and pressure on the body. These sensors fit inside health monitors you can wear. They also go in rehab tools and test equipment. The table below lists some ways they are used in medicine:

| Position of Human Body | Measured Parameter | Possible Applications in Health Monitoring |

| Hand | Motion | Watching hand healing |

| Wrist | Pulse | Checking for heart problems |

| Upper arm | Blood pressure | Treating high blood pressure |

| Knee and elbow | Strain distribution | Helping after surgery; Checking movement |

| Foot | Pressure distribution | Studying how people walk and train |

| Throat | Sound vibration | Voice checks; finding vocal cord problems |

| Face | Muscle movement | Reading faces; Finding facial nerve issues |

| Cardiovascular | ECG | Stopping and treating heart disease |

| Heart | Heart rhythm | Fixing heartbeats and arrhythmia |

| Bone | Pressure | Helping bones heal; fixing nerves and cells |

Doctors use these sensors to check blood pressure and heartbeats. They also measure how muscles move. Therapists use them to watch patients heal after surgery. Sports coaches use them to study walking and help athletes get better. The sensors help with voice checks and finding face muscle problems.

Robotics

Robotics engineers use FlexiForce sensors to help robots work better. These sensors measure force where robots grab things. This helps robots hold objects gently. The table below shows how the sensors help robots:

| Feature | Description |

| Sensor Type | FlexiForce A201 |

| Function | Measures force at the robot’s grip |

| Mechanism | Uses a voltage divider to sense changes |

| Sensitivity | Can feel very small forces, like 0.108N |

| Output | Sends digital signals to a computer |

Robots use these sensors in many ways:

- FlexiForce sensors are put in surgery tools. Surgeons can feel how hard they press.

- The sensors help make surgery safer and more exact.

- Engineers put thin sensors in robot hands. The sensors measure force and send signals for better control.

- The Neo interface uses FlexiForce sensors for touch feedback.

- A sensor in a robot hand checks force.

- The system turns force into signals, helping doctors use tools better.

These sensors help robots measure force very well. They let robots do careful jobs and keep people safe.

Industrial

Factories and labs use FlexiForce sensors to watch machines and products. The sensors check pressure between moving parts to stop damage. Workers use them on assembly lines to measure force when pressing or cutting.

Engineers use pressure mapping to see how force spreads on surfaces. This helps them make safer and better machines. The sensors also fit in automatic systems for checking quality.

FlexiForce sensors work in hot places. They help test materials and watch big machines. Research teams use the ELF System from SOUSHINE for deep study in labs. The system gives good data for making and testing products.

FlexiForce sensors help with many factory jobs. They keep machines working well and make products better.

Consumer Electronics

FlexiForce sensors are important in many electronics people use. These sensors help gadgets react to touch and pressure. Companies use them to make products easier for people.

Smartphones and tablets have FlexiForce sensors under screens or buttons. When you press, the sensor checks how hard you push. The device can do different things based on your touch. A soft tap might open an app. A hard press could show more choices.

Wearable devices like fitness trackers and smartwatches use these sensors too. They check how tight a band is on your wrist. Some track steps or exercise by feeling pressure changes. FlexiForce sensors help these gadgets give correct feedback.

Game controllers use FlexiForce sensors under buttons or triggers. Players press harder or softer to change speed or power. This makes games feel more real and fun.

Tip: FlexiForce sensors make touchpads and keyboards more sensitive. This gives users better control and faster actions.

The table below lists ways FlexiForce sensors are used in electronics:

| Device Type | Sensor Function | User Benefit |

|---|---|---|

| Smartphone | Touch/force detection | More control |

| Smartwatch | Band fit, activity sense | Better tracking |

| Game Controller | Pressure on triggers | Realistic gameplay |

| Laptop | Touchpad feedback | Smooth navigation |

| E-reader | Page turn pressure sense | Easy page turning |

SOUSHINE lets device makers pick custom FlexiForce sensors. Engineers choose the size, shape, and force range they need. This helps the sensor fit in small spots inside gadgets. SOUSHINE’s team helps with design and testing.

The ELF System from SOUSHINE helps test sensors in new products. It gives live data and helps make devices work better.

FlexiForce sensors use very little power. Devices can last longer on one charge. The sensors also work after many presses and touches. This makes them great for things people use every day.

Consumer electronics need sensors that are thin, light, and strong. FlexiForce sensors are perfect for these needs. They help make gadgets smarter and easier to use.

Integration

Hardware Needs

FlexiForce pressure sensors are easy to connect to electronics. Most people use a simple circuit to start. The sensor works like a variable resistor. When you press it, the resistance changes. You can measure this with a voltage divider circuit. Microcontrollers like Arduino, Raspberry Pi, and STM32 can read these signals.

Engineers usually need these parts:

- FlexiForce sensor

- Resistor for the voltage divider

- Microcontroller such as Arduino or Raspberry Pi

- Analog-to-digital converter if needed

- Wires and connectors

The table below lists the main hardware:

| Component | Function |

|---|---|

| FlexiForce Sensor | Senses force and changes resistance |

| Resistor | Works with the sensor in the circuit |

| Microcontroller | Reads the voltage and handles data |

| ADC | Turns analog signals into digital ones |

| Connectors | Connects the sensor to the circuit |

FlexiForce sensors are thin and bendy. They fit in many products and tight spaces. Engineers put them in both small gadgets and big machines. These sensors work well in custom projects and OEM devices.

If you work with the FlexiForce team on a project, you save time and money. The team helps you at every step. They ask good questions and make sure your project works well.

Software Needs

Software helps you collect and study data from FlexiForce sensors. Most programs show force changes right away. You can save the data in ASCII format for other uses.

Important software features are:

- Real-time data so you see changes as they happen

- Easy calibration steps

- Multi-point calibration for better results

- Load taring to set the zero point

- Sensitivity settings to match your needs

- Internal load triggers for simple measuring

- Movie recording to save and watch data later

- Good signals even if the computer is far away

The table below shows key software features:

| Feature | Description |

|---|---|

| Real-time data capture | Shows force changes right away |

| Calibration | Keeps readings correct |

| Movie recording | Lets you save and review data |

| Multi-point calibration | Makes readings better across all forces |

| Load taring | Sets the starting point for accuracy |

| Sensitivity adjustment | Matches the sensor to your project |

| ASCII output | Lets you export data for study |

Some software uses AI or machine learning to help with data. Cloud tools let you check your data from anywhere.

FlexiForce sensors work with many kinds of data software. You can pick the program that fits your project. The design makes it simple to add these sensors to new or old systems.

Selection Tips

Choosing the Right Sensor

Picking the right FlexiForce sensor helps you get good results. You should think about a few important things before you choose. The table below shows what to look for:

| Criteria | Description |

|---|---|

| Output Signal Compatibility | See if the sensor gives analog or digital signals. This changes how you read the data. |

| Size & Mounting | The sensor’s size matters for fitting in your device. Good mounting keeps it steady and correct. |

| Energy & Voltage Requirements | Make sure the sensor works with your power supply. This helps it work right. |

| Resolution & Range | High resolution shows more detail. The range must cover all the forces you want to check. |

| Response Speed | Fast response is good for safety and quick actions. |

You can make the sensor work better by following some tips:

- Use load concentrators to spread force out.

- Try to lower shear force to keep the sensor sensitive.

- Pick the best way to mount the sensor for steady results.

Some mistakes can make the sensor give wrong results. Sometimes, people see changes and think the sensor is broken. But outside things often cause these changes. Always use the same offloading method to lower errors. The surface material you pick also matters. Changes in temperature and humidity can change readings, so keep these steady during tests.

SOUSHINE Options

SOUSHINE has both standard and custom FlexiForce sensors. Standard sensors are good for most projects. They cost less and are easy to use in many devices. Custom sensors let you pick the shape, size, and force range. This helps if your project needs something special.

The table below compares standard and custom SOUSHINE sensors:

| Feature | Description |

|---|---|

| Cost-Effective Manufacturing | Makes it cheaper to make lots of sensors |

| Customizable Shapes and Sizes | Lets you pick different shapes and sizes |

| Durability and Reliability | Keeps working well for a long time |

| Low Power Consumption | Good for battery-powered devices |

| Ease of Integration | Easy to add to electronic systems |

SOUSHINE’s team helps you pick the best sensor. They give advice on design and setup. This help lets you get the most from your sensor system. Both standard and custom sensors work well and last a long time.

Tip: Custom sensors are great for special projects with unique shapes or force needs. For most jobs, standard sensors work well and save money.

A FlexiForce sensor checks force by changing resistance. SOUSHINE makes sensors for many different jobs. Their sensors are easy and quick to set up. The table below shows what SOUSHINE does well:

| Advantage | Description |

|---|---|

| Industry Applications | Used in healthcare, robotics, and automation |

| Competitive Pricing | Saves money when you buy a lot |

| Seamless Integration | Connects easily to electronic devices |

| Product Features | Very sensitive, fast, and comes in many sizes |

| Rapid Prototyping | Helps test and build things faster |

Engineers get help with putting the sensor in place. They also learn how to use the sensor and add force. SOUSHINE gives guides, videos, and papers for every step. In the future, sensors may use better materials and AI for data. There will be new ways to use them in healthcare and wearable devices.

FAQ

How thin is a FlexiForce pressure sensor?

A FlexiForce pressure sensor is only 0.203 mm thick. This makes it easy to fit between tight spaces or moving parts.

Can FlexiForce sensors measure high temperatures?

FlexiForce sensors can work in places as hot as 400°F (about 204°C). This means they are good for use in hot factories or medical tools.

What devices can use FlexiForce sensors?

Engineers put FlexiForce sensors in medical tools, robots, electronics, and machines. Their flexible shape lets them fit into many different products.

How does a FlexiForce sensor send data?

The sensor’s resistance changes when you press it. A microcontroller reads this and turns it into force data. Most systems use a voltage divider to do this.

Are FlexiForce sensors customizable?

SOUSHINE lets you pick custom shapes, sizes, and force ranges. Their team helps people design sensors for special projects or unique devices.

What is the typical force range for FlexiForce sensors?

FlexiForce sensors can measure less than 1 pound up to 1000 pounds. You can choose the model that fits your needs.

Do FlexiForce sensors need much power?

FlexiForce sensors use very little power. Battery-powered devices can last longer with these sensors.

How does SOUSHINE support customers?

SOUSHINE gives help with technical questions, design, and calibration. Their team helps with both standard and custom sensor orders.