Call us: +86-137-2353-4866

Think about a doctor who wants to see how hard a patient can squeeze with their hand. A force probe helps the doctor do this. This tool shows how much force a person uses on something. Force sensing is very important in science and industry because it gives correct information. People use a force sensing resistor when they need fast and trustworthy results.

Table of Contents

Key Takeaways

A force probe checks force by turning pressure into an electric signal. Force probes are important tools in science and industry. They help test materials and keep things safe. Calibration is very important for correct force readings. Always follow the right steps to avoid mistakes. There are many types of force probes for different jobs. Some measure small forces, and others check heavy weights. Force probes use different technologies like strain gauges or capacitance sensors. It is important to understand the data from force probes. Look for steady results and compare them to standards. Force probes are not the same as Force Sensing Resistors (FSRs). They have different designs and uses. Pick the one that fits your needs. Using the right force tool can make products and experiments safer and better.

Force Probe Overview

What Is a Force Probe

A force probe is a tool that measures force. It changes mechanical force into an electrical signal. Scientists and engineers use it to test things. They also use it to check how strong materials are. The device can measure force, torque, or pressure. Most force probes have a sensor with a spring. The sensor bends when you put weight on it. This bending helps the probe know how much force is used.

Tip: Force probes are also called load cells or force transducers. They can measure load, weight, tension, compression, or pressure.

The most common types of force probes are:

- Tools for testing materials

- Devices for checking structures

- Instruments for quality control

A force probe often works with other machines. This helps it give correct results. Some models use quartz crystal resonators for tests. Others are waterproof and can test things in liquids.

| Characteristic | Description |

|---|---|

| Measurement Range | Can be used for many different tests. |

| Waterproof Features | Good for testing things in liquids. |

| Integration | Works with other systems for better results. |

| Configuration | Has a flat design for easy viewing during tests. |

| Core Components | Has a cantilever, diode laser, and photodetector. |

| Application | Used for mechanical tests on living samples in solutions. |

Core Functions

Force probes do many important jobs in science and industry. They help measure how much force is put on objects. In labs, force probes test how strong things are. They also watch for changes in materials. Engineers use them to check if machines and buildings are safe.

- Measure force on small plates with sensitive cantilevers

- Find force directions in electric propulsion systems

- Allow detailed measurements for both ionic and neutral particles

Force probes also help check electric propulsion systems. They let scientists see how much force a thruster makes. This helps make engines safer and better.

Different force probes have different sensitivity and accuracy. Atomic force microscopy uses stiff transducers for tiny measurements. Optical tweezers use softer probes for gentle force checks. Biomembrane force probes balance sensitivity and detail for single-molecule studies. Each type is best for certain jobs and situations.

How Force Probes Work

Working Principle

A force probe checks force by changing it into electricity. Most use a strain gauge to do this job. The strain gauge sticks to a metal part inside the force transducer. When you push or pull, the strain gauge gets longer or shorter. This makes its electrical resistance go up or down. A Wheatstone bridge circuit finds this change in resistance. It then makes a voltage signal. This signal tells how much force is there.

Some force probes use capacitance-based sensing instead. These have two plates with a space between them. When force pushes the plates, the space gets smaller. This changes the electrical capacitance. The probe measures this and turns it into a signal. Capacitance-based force probes are good for soft robotics and prosthetics. They also help with health monitoring. Studies show these sensors can find small forces very well. For example, a sensor array using this method got an R2 value of 0.9996 and an RMSE of 0.0446 in the 1 to 3 newton range.

| Aspect | Details |

|---|---|

| Study Title | Real-Time Detection and Localization of Force on a Capacitive Elastomeric Sensor Array Using Image Processing and Machine Learning Techniques |

| Key Technologies | Capacitive sensor array, image processing, machine learning |

| Performance Metrics | R2=0.9996, RMSE=0.0446 |

| Force Range | 1 to 3 N |

| Applications | Prosthetics, wearable health monitoring, soft robotics |

| Methodology | Custom-fabricated sensor array, real-time localization, machine learning models for force estimation |

Main Components

A force probe has a few main parts. Each part helps measure force and send out a signal.

Sensing Element

The sensing element is the most important part. It reacts when you put force on it. The strain gauge is the most common sensing element. It changes resistance when stretched or squeezed. Some probes use a tuning fork design. This changes how sensitive and accurate the probe is. The material’s Young’s modulus affects how stiff and sensitive it is. The shape of the probe tip can change how much force it can sense. Things like temperature and humidity can also affect how well it works.

| Factor | Impact on Performance |

|---|---|

| Tuning Fork Probe Design | Changes sensitivity and resolution |

| Young’s Modulus | Affects stiffness and sensitivity |

| Quality Factor (Q factor) | Higher Q means better sensitivity and less noise |

| Environmental Conditions | Temperature and humidity can change performance |

| Probe Tip Geometry | Larger tips increase force range and sensitivity |

| Electrostatic Force | Important in shear-force measurements |

| Capillary Force | Can affect accuracy in humid conditions |

Electronics

The electronics handle the signal from the sensing element. The Wheatstone bridge circuit is very important. It checks for small resistance changes in the strain gauge. The electronics turn this into a voltage signal. This signal matches the force used. Good electronics help the probe give steady and correct readings.

| Component | Role in Force Measurement |

|---|---|

| Strain Gauge | Changes resistance when force is applied |

| Wheatstone Bridge | Measures resistance change and creates voltage output |

Output

The output is the last signal from the force probe. This signal can go to a screen, computer, or other device. The output shows how much force was measured. Some force transducers give analog signals. Others give digital signals. The output lets people see and save the force data for tests or checks.

Note: All parts of the force probe must work together to give correct and steady force measurements.

Measuring Force

Measurement Process

A force probe helps people measure force in a careful way. First, someone pushes or pulls on the probe. The sensing part inside feels this force. The electronics change this into an electric signal. The probe then shows the number to the user.

To test force, you must follow steps. Start by setting up the force probe and connecting it. Next, you need to calibrate it for correct results. This means using weights or known forces. After calibration, push or pull on the object. The probe measures the force and sends the data to a computer or screen.

Many jobs use force testing to check safety and quality. For example, tensile testing checks how much force breaks a material. Every time, the steps must be the same for good results.

Some things can make force measurements wrong. Users should watch out for these problems:

- Pin size matters with tension links. The wrong pin can cause mistakes.

- Loading the shoulder is better than thread loading.

- How you bolt or tighten parts can change the reading.

- The top adapter should be hard and flat. If not, errors can happen.

- Not following rules like ASTM E74 can cause calibration issues.

If you follow the right steps and rules, you can lower mistakes and get better results from force testing.

Data Interpretation

After you get the numbers, you need to understand them. The force probe gives raw data, but you must know what it means. People often check the numbers against what they expect or against standards.

Looking at force data means checking for mistakes or odd things. Topography artifacts can make the numbers less clear. These can affect electric, magnetic, heat, mechanical, or light signals. Users must spot these problems when looking at the data.

Scientists sometimes use fake data to see how the probe and sample work together. This helps them learn how the test works and how the shape of things changes the results. Math tools help people look at data that does not show shape. These tools make pictures that can be checked against real tests.

A normal way to look at data is:

- Check if the numbers are steady.

- Look for strange patterns or mistakes.

- Compare the results to standards or old tests.

- Use math to study hard-to-see details.

- Write down what you find in a clear way.

Note: Careful data checks help make sure force testing gives good and helpful information.

Molecular Force Probe

Applications in Molecular Science

A molecular force probe helps scientists look at tiny forces. It lets them see how molecules push or pull each other. Scientists use it to learn about single molecules. They want to know how strong and how they act. In labs, people use single-molecule force spectroscopy for this. This method gives clear numbers about molecule interactions.

Researchers use a molecular force probe in many ways:

- Measurement of intercellular mechanical forces: Scientists use probes like the membrane DNA tension probe. They check how much force cells use at their meeting points.

- Quantification of collective cell behaviors: The DNAMeter helps measure force between cells. It works when cells move or do things together.

- Molecular tension imaging: The FLIM-MDTP lets scientists see force between many ligand–receptor pairs. It does this all at once.

- Investigation of forces during wound healing: The MTFM method shows force and energy. It helps when cells move together to heal wounds.

Single-molecule force spectroscopy uses a molecular force probe. It pulls on one molecule at a time. This helps scientists find out how strong a bond is. They can see when a bond breaks or a molecule unfolds. This helps with drug design and learning about diseases.

A molecular force probe also helps study proteins, DNA, and other molecules. Scientists test how much force opens or closes a protein. They also see how DNA strands come apart. These tests give clues about how life works at a tiny scale.

| Application Area | What Scientists Learn |

|---|---|

| Cell Junctions | How much force cells use to stay together |

| Collective Cell Movement | How cells share force as they move |

| Ligand–Receptor Interactions | How strong the bonds are between molecules |

| Wound Healing | How much force cells use to repair tissue |

| Protein and DNA Studies | How molecules change under force |

Note: Molecular force probes and single-molecule force spectroscopy help scientists see and measure very small forces.

Molecular force probes have changed how scientists study biology and chemistry. These tools give direct force measurements at the molecular level. They help answer questions about cells, molecules, and how life reacts to stress.

Force Probe vs FSR

Appearance

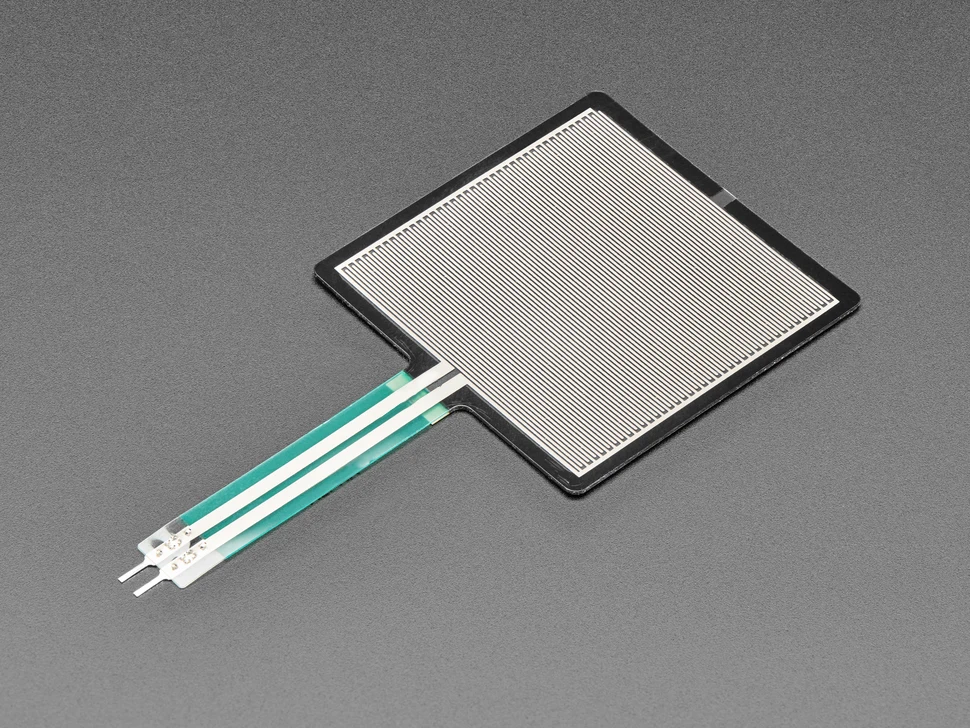

Force probes and Force Sensing Resistors (FSRs) do not look the same. A force probe usually has a hard body made of metal or plastic. You might see a sensor, spring, or cantilever on it. Some force probes have a flat end or a small tip for touching things. Wires or connectors come out of the probe to send data.

SOUSHINE’s FSRs are thin and can bend easily. The FSR looks like a flat sheet. It has a bendable base and a layer that carries electricity. The FSR can bend and fit into small places. You can cut or shape the FSR to fit different products. The FSR does not have a spring or cantilever.

| Feature | Force Probe | SOUSHINE FSR |

|---|---|---|

| Body | Rigid, solid | Thin, flexible |

| Sensor Type | Spring, cantilever | Conductive film |

| Shape | Fixed | Customizable |

| Size | Bulky or compact | Ultra-thin |

Function

A force probe checks force by turning movement into electricity. It uses a strain gauge or something like it. When you push on the probe, it bends or stretches. The sensor feels this and sends a signal to the electronics. The probe shows a number that matches the force.

SOUSHINE’s FSR works in another way. The FSR changes its resistance when you press it. If you push harder, the resistance gets lower. The FSR sends this change to a circuit, which reads the number. The FSR can feel both soft and hard presses. It is good for measuring force all the time.

Note: Both tools measure force, but they use different ways and materials.

Application Scenarios

People use force probes in labs and factories. They test things, check machines, and measure weight. Engineers use force probes to make sure things are safe and work well. Force probes help with research, product tests, and machine studies.

SOUSHINE’s FSRs are used in many fields. In cars, FSRs help with seat sensors and safety. In hospitals, FSRs watch how patients move and check pressure. Robots use FSRs to feel touch. Phones and gadgets use FSRs for buttons and controls. FSRs also go in smart tools and things you can wear.

- Force probes: best for lab tests, heavy loads, and work that needs to be exact.

- SOUSHINE FSRs: best for bendy designs, touch sensing, and small devices.

Tip: Pick a force probe if you need high accuracy and big force ranges. Pick an FSR if you want something thin, bendy, and easy to shape.

Pros and Cons

When picking between a force probe and a Force Sensing Resistor (FSR), people should think about what each one does well and where it falls short. Both can measure force, but they are better for different jobs and places.

A force probe is very accurate. It is great for labs and factories that need exact numbers. The body is hard and the sensor is very sensitive. This makes it good for measuring heavy things. Force probes are strong and last a long time. But they can be big and heavy. They might not fit in small or bendy spaces. Force probes usually cost more than FSRs. Setting them up can take longer and may need special tools.

SOUSHINE’s FSRs have other good points. These sensors are thin and can bend. You can cut or shape them for many products. FSRs are good for things that need to bend or fit in tight spots. They cost less than most force probes. People find them easy to use in new designs. FSRs do not use much power, so they are good for battery devices. They work in cars, hospitals, and robots.

But FSRs are not as exact as force probes. Their numbers can change if it gets hot or cold. You must set them up right to get steady numbers. FSRs are not the best for jobs that need very high accuracy or must measure big forces.

The table below makes it easy to compare:

| Feature | SOUSHINE FSRs | Traditional Force Probes |

|---|---|---|

| Cost | Low | High |

| Flexibility | High (can bend and shape) | Low (rigid structure) |

| Integration | Easy to add to products | More complex setup |

| Precision | Moderate | High |

| Suitability for Thin Designs | Excellent | Limited |

| Durability | Good for most uses | Excellent |

| Sensitivity to Temperature | Can be affected | Usually stable |

| Power Consumption | Low | Varies |

Tip: SOUSHINE FSRs are best for things that need a thin, bendy sensor. Force probes are better for jobs that need to be very exact and can use a hard device.

Force Measurement Devices

Choosing Devices

People use different force measurement devices in science and industry. Each device does a special job. Some common force measurement devices are:

- Force sensors help robots and medical tools feel touch.

- Dynamometers check torque and force in machines.

- Strain gauges show how much a material stretches.

- Hydraulic and pneumatic load cells handle heavy loads.

- Piezoelectric force transducers track quick force changes.

- Force plates measure ground force in sports and health.

When picking a force measurement device, people think about a few things. The table below shows what to look for:

| Criteria | Description |

|---|---|

| Cost | Choose a device that matches your budget and needs. |

| Environment | Some devices, like FSRs, work better in tough places. |

| Form Factor | FSRs are thin and fit into small spaces. |

| Repeatability | Devices should give the same results every time. |

| Sensitivity | Some devices notice small force changes better than others. |

A load cell is very accurate and good for big forces. An FSR fits in small, bendy designs. SOUSHINE FSRs last a long time, use little power, and fit many shapes. These devices work well in both small and big products.

When to Use Each

People choose force measurement devices based on the job they need to do. A load cell is best for heavy loads and when you need high accuracy. FSRs are good when space is tight or the device must bend. SOUSHINE FSRs work well in many real-life uses.

The table below shows how cost and durability compare:

| Feature | Load Cells | FSRs |

|---|---|---|

| Cost | Higher because they are very exact | Cheaper and more flexible |

| Durability | Very strong and stable | Good for low-cost uses |

SOUSHINE FSRs have extra good points. They last through many uses and use little power. They work well in battery-powered devices. People use them in phones, games, and smart homes. Users say SOUSHINE FSRs make smartwatches more sensitive and game controllers more fun. Touch switches and remotes work well with these sensors. Most people find SOUSHINE FSRs are accurate within ±10%, which is good for most jobs.

The table below shows where SOUSHINE FSRs work best:

| Advantage | Description |

|---|---|

| Durability | SOUSHINE FSRs keep working after lots of use. |

| Power Consumption | They use little energy, so they are good for batteries. |

| Flexibility | They fit in both small and big devices. |

Tip: Pick a load cell for heavy jobs and high accuracy. Choose SOUSHINE FSRs for flexible, cheap, and battery-friendly designs.

Force measurement devices help people test, build, and use products safely. The right device makes work easier and results better.

A force probe checks force by changing movement into electric signals. It has a sensing part, electronics, and an output to show the force. New types include dual and glowing biomembrane probes and small lab-on-a-chip tools. Picking the right device helps you get correct and steady results. Many businesses now use bendy sensors for safety and control. When picking a force measurement tool, people should think about how exact it is, how to set it up, if it will last, and ask experts for help.

- More people want small, bendy, and cheap sensors.

- FSRs help game controllers and robot arms feel force better.

SOUSHINE FSRs give smart, flexible choices for many uses.

FAQ

What is a force probe used for?

A force probe helps measure force in science and factories. People use it to test things, check machines, and see how objects handle pressure.

How does a Force Sensing Resistor (FSR) work?

An FSR changes its resistance when you press on it. The device checks this change and shows how much force is there.

Can SOUSHINE FSRs fit into small devices?

SOUSHINE FSRs are thin and can bend easily. They fit in tight spots and work well in small things like smartwatches and medical tools.

What is the difference between a force probe and an FSR?

A force probe uses a hard sensor for very exact force checks. An FSR has a bendy film and works best in things that need to bend or change shape.

Are force probes accurate for heavy loads?

Force probes give exact numbers for big forces. Engineers use them in labs and factories to measure heavy things and keep work safe.

Where do people use SOUSHINE FSRs?

People use SOUSHINE FSRs in cars, hospitals, robots, and electronics. These sensors help with touch buttons, patient checks, and safety systems.

How do you read data from a force probe?

The force probe sends a signal to a screen or computer. The user sees the force number and can save it for later.

Do force probes and FSRs need calibration?

Both tools need calibration before you use them. Calibration makes sure the numbers stay right and steady during tests or daily use.