Call us: +86-137-2353-4866

Choosing force sensing resistors matters for both force sensitive resistor price and how well they perform. Many people opt for popular brands like SOUSHINE, Interlink, FlexiForce, Tekscan, and Ezweiji. These brands offer various benefits tailored to different projects. The price of a force sensitive resistor can vary based on its features, durability, and the brand’s reputation. As force sensing technology continues to advance, users seek sensors they can trust from reputable companies. The worldwide market for force sensing resistors is experiencing rapid growth:

- The market is projected to be worth about $36 million in 2024 and could reach $87.7 million by 2031.

- Some reports indicate the market might expand from $800 million in 2023 to $1.5 billion by 2032.

Force sensing resistors are utilized across numerous fields. Understanding force sensing technology helps buyers select options that best fit their needs and budgets.

Table of Contents

Key Takeaways

Picking the right force sensing resistor is very important. You need to balance cost and how well it works. Popular brands like SOUSHINE, Interlink, FlexiForce, Tekscan, and Ezweiji have special features for different projects. SOUSHINE FSRs do not cost much and can be changed to fit your needs. This makes them good for many uses. Interlink sensors are very sensitive and work well. They are great for tough projects. FlexiForce sensors are light and simple to use. They are best for jobs that do not need to be very exact. Tekscan has sensors that are very accurate for research and medical jobs. Ezweiji has cheap choices for students and people who build things for fun. When you pick a force sensing resistor, think about how long it will last, how sensitive it is, and how easy it is to use. Try the sensor in your real project setup. This helps you get correct results and better project success.

Top Force Sensing Resistors

SOUSHINE FSRs

SOUSHINE is a well-known force sensor maker. Their force sensing resistors have a special design. This design helps them sense small forces very well. When you press on them, their resistance changes. This makes them helpful in many areas. Medical devices use these sensors in tight spots. Factories use them to keep machines safe and working well. Touchpads and game controllers use them to make things easier for people.

The table below shows how SOUSHINE force sensing resistors compare to other sensors:

| Feature | Force Sensing Resistors (FSRs) | Other Sensors (Load Cells, Strain Gauges) |

|---|---|---|

| Output Type | Non-linear resistance change | Linear resistance change |

| Accuracy | Moderate | High |

| Complexity | Low | High |

| Durability | Moderate | High |

| Application | Tactile interfaces, wearables, medical devices | Structural analysis, precision measurement |

| Cost | Low | Higher |

| Environmental Stability | Moderate | Excellent |

SOUSHINE makes force sensing resistors in many shapes and sizes. This helps engineers use them in different projects. The company gives good help and fair prices. Many other companies do not let you change the sensors as much.

Interlink Models

Interlink is a famous force sensor company. Their force sensing resistors are very sensitive and last a long time. Many engineers pick Interlink for projects that need to work well. These sensors are simple to use and not expensive. Some big projects may need calibration, but most people find them easy to use.

| Aspect | Description |

|---|---|

| Sensitivity | High sensitivity, suitable for various projects |

| Longevity | Long life, reliable in the industry |

| Calibration | May require calibration in larger setups |

| User Experience | Affordable and easy to use |

Interlink force sensing resistors are used in robots, electronics, and cars. People trust them because they work well and last long.

FlexiForce Series

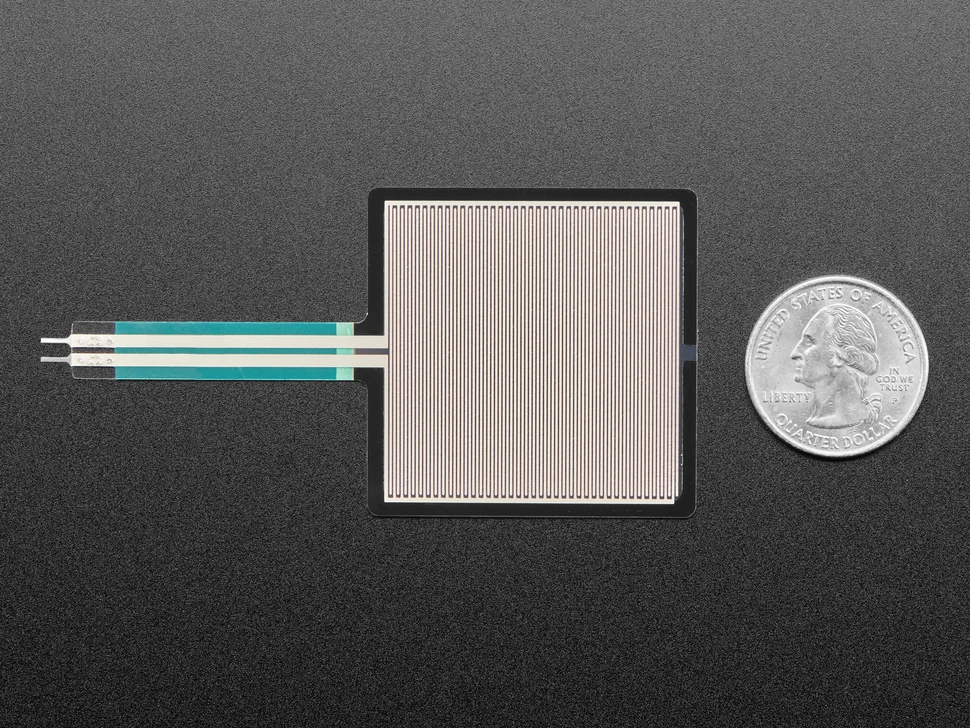

FlexiForce sensors are made by Tekscan. They are thin and light force sensing resistors. These sensors fit in small places and can measure many different forces. FlexiForce sensors do not cost much and are easy to set up. They are good for jobs that do not need perfect accuracy.

| Feature | Description |

|---|---|

| Flexibility | Thin and light, fits in small spaces |

| Low Cost | Affordable for many projects |

| Ease of Integration | Simple to set up |

| Wide Dynamic Range | Measures a broad range of forces |

| Moderate Precision | Good for applications not needing high precision |

| Customization | Available in many shapes, sizes, and connection methods |

FlexiForce sensors come in many shapes and sizes. They also have different ways to connect. This makes them a good choice for many engineers and designers.

Tekscan and Ezweiji

Tekscan and Ezweiji are both important in force sensing resistors. Tekscan is known for new sensor technology. Ezweiji is popular because its products are cheap and dependable. Both brands make force sensing resistors for many jobs.

Tekscan makes many types of force sensing resistors. These sensors help engineers measure force in different ways. They are used in medical devices, robots, and electronics. You can also find them in labs and for testing products. Tekscan sensors give results that are correct and can be repeated. Many engineers pick Tekscan when they need good data.

Ezweiji makes force sensing resistors that are simple and not expensive. Many students and hobbyists use Ezweiji for their projects. The company sells sensors in many shapes and sizes. Ezweiji sensors work well in easy circuits and learning kits. Some factories use them when only basic force checks are needed.

Note: Tekscan and Ezweiji both give help and guides. This makes it easier to use their force sensing resistors the right way.

The table below shows how Tekscan and Ezweiji compare:

| Brand | Main Strengths | Typical Applications | Price Range |

|---|---|---|---|

| Tekscan | High accuracy, variety | Medical, robotics, research | Mid to high |

| Ezweiji | Low cost, simplicity | Education, DIY, light industry | Low |

Engineers often use Tekscan when they need to measure force very closely. These sensors can notice small changes in pressure. They also last a long time. Ezweiji is good for people who want something easy and cheap. These sensors are best for simple projects.

Both brands keep making their force sensing resistors better. They listen to what users say and make changes. This helps them stay important as more people use these sensors. When picking Tekscan or Ezweiji, think about how exact you need to be, how much money you have, and how hard your project is.

Force sensing resistors from Tekscan and Ezweiji give people many choices. If you need something very exact or just want to save money, these brands have options. Their products help people use force sensing resistors in new and fun ways.

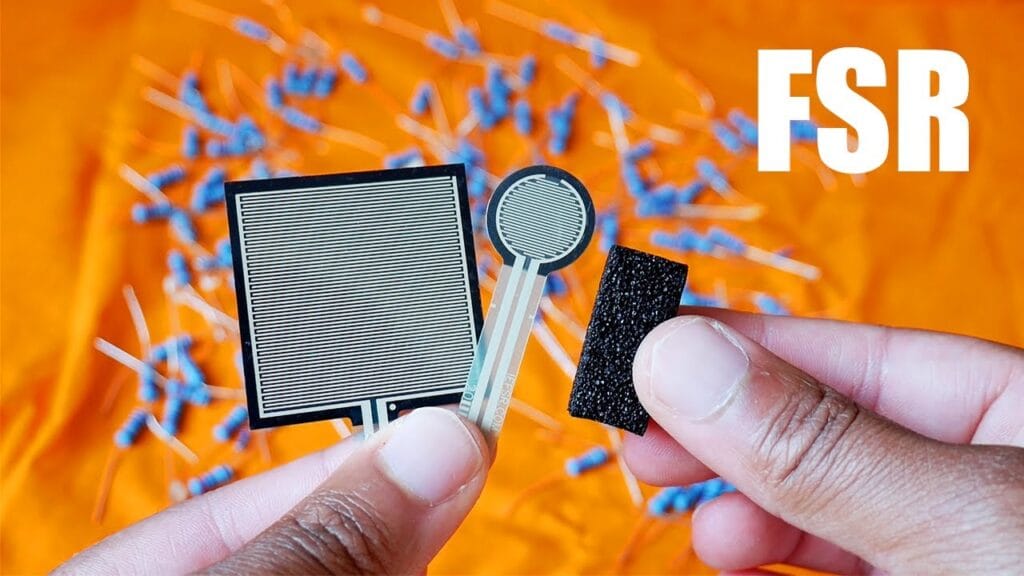

How Force Sensing Resistors Work

Operating Principle

Force sensing resistors work using a simple idea. When you press the sensor, its resistance goes down. This happens because of the piezoresistive effect. The sensor has a special material that changes with force. If you push harder, the resistance gets lower. This lets the sensor tell how much pressure is used.

The table below shows how this idea changes how the sensor works:

| Evidence Type | Description |

|---|---|

| Operating Principle | The piezoresistive effect where resistance decreases with applied force. |

| Performance Factors | Non-linear response, calibration needs, temperature effects, and hysteresis. |

| Contact Resistance | Changes due to stress, affecting current conduction and effective area. |

Force sensing resistors do not react the same to every push. They have non-linear sensitivity. People often need to calibrate them for better results. Heat and using the sensor many times can change how it works. These things make force sensitivity important for many projects.

Key Features

Force sensing resistors are different from other sensors. They are flexible and fit into many designs. The table below shows how force sensors and pressure sensors are not the same:

| Feature | Force Sensors | Pressure Sensors |

|---|---|---|

| Main Structure | Solid block, beam, or disc | Thin diaphragm |

| Measurement Focus | Total force or torque | Force per unit area (pressure) |

| Signal Output | Direct force readings, often multi-axis | Pressure readings, single or differential |

| Material Selection | Metals for strength and durability | Metals, ceramics, silicon for flexibility |

| Integration | Robotics, industrial machines | Pipelines, HVAC, medical devices |

Force sensing resistors give direct force readings. Their sensitivity helps in many uses. They work well in robots, medical tools, and electronics. Their bendy design and low price make them a top pick in force sensor technology.

Common Uses

Many industries use force sensing resistors for lots of jobs. Some common uses are:

- Medical industry: Finding patient falls and checking pressure spots in health devices.

- Robotics and prosthetics: Measuring grip strength and helping robots hold things safely.

- Automotive: Checking if someone is in a seat, finding crashes, and replacing dashboard buttons.

- Agriculture: Knowing the best time for cattle insemination.

- Consumer electronics: Making touch screens for phones and tablets.

- Gaming and virtual reality: Sensing finger pressure for fun experiences.

- Touch and pressure-sensitive user interfaces: Making devices easier to use.

Force sensing resistors are important in these jobs. Their high sensitivity helps measure force well. Engineers use force sensor technology to make things safer and more comfortable. The many uses show how important these sensors are today.

Force Sensitive Resistor Price Comparison

Price Ranges by Brand

Force sensitive resistor price is different for each brand. Some brands try to keep prices low. Other brands add more features for force measurement. The table below shows what you might pay for each brand:

| Brand | Price Range (USD per unit) | Main Focus |

|---|---|---|

| SOUSHINE | $2 – $10 | Customization, durability |

| Interlink | $3 – $12 | Sensitivity, reliability |

| FlexiForce | $5 – $18 | Thin design, flexibility |

| Tekscan | $8 – $25 | High accuracy, research |

| Ezweiji | $1 – $5 | Low cost, basic use |

SOUSHINE gives many choices for force measurement at a good price. Interlink sensors cost a little more because they are reliable. FlexiForce sensors get more expensive with special shapes or features. Tekscan sensors cost the most because they are for research and medical jobs. Ezweiji keeps prices low for students and people who like to build things.

Factors Affecting Price

Many things can change force sensitive resistor price. Brands use different materials and designs for force measurement. Some sensors last longer because they use strong parts. Other sensors are cheaper but may not last as long. If you want a special shape or size, it will cost more.

Sensors that last longer and work in hard places usually cost more. Making sensors in special shapes or sizes also makes them more expensive.

The table below lists the main things that change the price of force sensing resistors:

| Factor | Description |

|---|---|

| Durability | The sensor must handle repeated force and rough use. |

| Environment | The sensor should resist dust, moisture, and dirt, functioning in various conditions. |

| Form Factor | The size and shape must fit the device, with thin and flexible sensors suitable for small spaces. |

| Repeatability | The sensor should provide consistent results for the same force applied. |

| Sensitivity | The sensor must accurately detect the required range of force for its application. |

| Cost | The sensor should align with project budgets while meeting performance needs. |

Engineers can pick the right sensor for their project by choosing options. This can make the force sensitive resistor price go up. Durability is important too. Sensors that last longer in tough places need better parts, which costs more. SOUSHINE gives lots of choices for force measurement. This helps people find the best mix of price and how well it works.

Price-Performance Ratio

The price-performance ratio shows if a sensor is worth the money. A sensor with a low force sensitive resistor price but bad performance is not helpful. A sensor that costs more but works better and lasts longer can save money later.

Buyers should see how well a sensor works for their needs. They should check if the sensor measures force well, lasts a long time, and fits their budget. Some brands, like SOUSHINE, give good performance for a fair price. Others, like Tekscan, focus on top performance for special jobs, so their force sensitive resistor price is higher.

Tip: Always pick a sensor that matches what your project needs. Paying more for better force measurement can help you later.

A good price-performance ratio means the sensor works well for its price. This helps engineers and students choose the best sensor for their projects. They can look at different brands, compare the force sensitive resistor price, and pick the one that fits their budget and works well.

Performance Analysis

Sensitivity and Accuracy

Force sensing resistors are used to measure force in many projects. Sensitivity means how well the sensor can notice small changes in force. Accuracy means how close the sensor’s reading is to the real force. Top brands make sensors that give steady readings with light touches and many force levels. The table below shows some common numbers for these sensors:

| Specification | Value |

|---|---|

| Resistance (no load) | Over 1 MΩ |

| Resistance (20 g) | 50 kΩ |

| Resistance (max load) | About 200 Ω |

| Force Accuracy | Between 5% and 25% |

| Resolution | Better than 0.5% of full range |

| Sensitivity | Reacts to light taps |

Most force sensing resistors are sensitive and can feel small touches. The accuracy can be different depending on the brand and how you use the sensor. Some sensors can be off by as much as 25%, but others are closer to 5%. Precision is important when engineers need exact results. Sensors with high precision are used in medical and research work. Things like temperature and bending the sensor can change how accurate it is. Calibrating the sensor where it will be used helps make it more accurate and precise.

Durability and Lifespan

Durability means how long a sensor keeps working after being used many times. Lifespan is how many times you can use the sensor before it stops working well. Brands test their sensors to see how strong they are. The table below shows what happens to force sensing resistors after lots of use:

| Evidence Description | Impact on Durability |

|---|---|

| Sensitivity loss from repeated use | Durability goes down with lots of use |

| Creep and less sensitivity | Stress makes the sensor work worse over time |

| Lower pressure output in tests | Fast sensitivity loss shortens lifespan |

| Non-linear sensitivity loss | Stress makes readings less correct |

Pressing or bending the sensor again and again can make it less sensitive and less accurate. Some sensors lose their precision after many uses. Brands try to make sensors last longer by using better materials and designs. People should check how many times a sensor can be used before picking one for their project.

Circuit Design Impact

How you design the circuit is important for how well a force sensing resistor works. A good circuit can help stop problems like drift, non-linearity, and hysteresis. These problems can make the sensor less accurate and less precise. Engineers use special circuits to get better signals from the sensor. For example, using both voltage and capacitance readings can make the sensor more accurate. Careful design helps the sensor give steady and repeatable results. This makes the system work better for a long time.

Tip: Always test the sensor in the same setup as your final project. This helps keep the sensor accurate and precise.

A good circuit helps the sensor reach its best accuracy and precision. This matters for projects in healthcare, robotics, and research. Engineers should pay attention to both the sensor and the circuit to get the best results.

Choosing Force Sensing Resistors

Selection Criteria

Picking the right force sensing resistor means looking at a few key things. Engineers check the sensor’s resistance range and how tough it is. They also see if it fits well in their circuit. The resistor must match the force range for the project. For example, when using a static resistor with an FSR, engineers look at the highest and lowest resistance. This helps stop the readings from being too high or too low. A static resistor of about 3kΩ or 3.3kΩ works for a force range of 0.1-10kg. The fixed resistor and FSR make a voltage divider. This setup helps measure changes in force. When you do not press the FSR, it acts like an open switch because its resistance is high.

Engineers also think about how well the sensor handles lots of use. They want sensors that last in hot or shaky places. It is important that the sensor works well with other parts. The sensor should fit into the system without problems.

Key selection criteria include:

- Resistance range and matching static resistor

- Durability under repeated force and harsh conditions

- Ease of integration into existing circuits

- Sensitivity to the required force range

- Consistent performance over time

Application Fit

Force sensing resistors are used in many fields. Engineers put them in robots, healthcare tools, and cars. In robots, these sensors help feel touch and pressure. Robots can hold breakable things and put parts together right. In healthcare, force sensing resistors watch how patients move in beds and chairs. They also check force during therapy. Cars use these sensors to see if someone is sitting and to measure force on pedals and buttons.

The table below shows how force sensing resistors fit different applications:

| Application | Sensor Role | Benefit |

|---|---|---|

| Robotics | Senses touch and pressure | Handles objects safely |

| Healthcare | Monitors movement and force | Improves patient care |

| Automotive | Detects seat occupancy, measures pedal force | Enhances safety and control |

| Consumer Devices | Adds touch sensitivity | Improves user experience |

| Industrial | Monitors machine pressure | Increases reliability |

| Education | Teaches sensor technology | Supports learning |

| Gaming | Senses finger pressure | Creates interactive controls |

Engineers pick the sensor by checking the force range, size, and how it connects. They choose sensors that fit the space and do what the project needs.

Tips for Best Value

Engineers want good value when picking force sensing resistors. They look for sensors that are not too expensive but work well. Checking the warranty and support can help avoid trouble later. Good support makes fixing problems easier during setup or use.

Some problems are bad accuracy, small range, weak build, and hard setup. If the sensor does not work the same every time, the data can be wrong. Old sensors may not measure both light and strong forces well. Sensors can break if there is too much force, heat, or shaking. Hard setups can slow down the project.

Tips for getting the best value:

- Review warranty and support options before buying

- Test the sensor in the actual application setup

- Avoid sensors with known accuracy or durability problems

- Choose sensors with clear documentation and guides

- Match the sensor’s force range to the application’s needs

- Consider customization for unique applications

- Ask for feedback from other users in similar applications

Tip: Engineers should always test the sensor in the final circuit to ensure accurate readings.

Picking the right force sensing resistor helps projects work better and cost less. Engineers who follow these steps find sensors that work well in many jobs.

SOUSHINE FSRs are accurate and can be changed for your needs. They do not cost too much. Interlink and FlexiForce are good choices too. The table below shows what people like and dislike:

| Model | Advantages | Disadvantages |

|---|---|---|

| Interlink FSR | Many shapes, low price, strong build | Not all units are the same, resistance can change, slow to react |

| FlexiForce | Accurate, gives same results often | Costs more, breaks easily |

Buyers should do these things:

- Talk to engineers to make sure it fits the job.

- Share project goals with the design team.

- Look at custom sensor choices.

Specs tell you how accurate a sensor is, but real use can be different. How you set up and where you use the sensor matters. FSRs are good for finding pressure and saving money. People should read the guides and try the sensors before picking one.

FAQ

What is a force sensing resistor?

A force sensing resistor is a sensor that changes resistance when pressed. People use it in electronics to measure force or pressure. Many electronic devices use these sensors to find touch or weight.

Where do people use force sensing resistors in electronics?

People put force sensing resistors in things like game controllers, touchpads, and smart gadgets. These sensors help devices react to touch or pressure. Robotics and medical electronics also use them a lot.

How do force sensing resistors help in robotics and electronics?

Force sensing resistors let robots and electronics feel touch or pressure. Robots use them to hold things without breaking them. Electronics use these sensors to make devices easier for people to use.

Can students use force sensing resistors in electronics projects?

Students can use force sensing resistors in their projects. These sensors are simple to connect and work in easy circuits. Many school kits have them for learning about sensors and measuring force.

What is the price range for force sensing resistors in electronics?

Force sensing resistors cost between $1 and $25 each. The price changes with brand, size, and features. Many stores sell them for both hobby and professional projects.

How do you connect a force sensing resistor to electronics?

To connect a force sensing resistor, use a voltage divider circuit. Attach one end to power and the other to a resistor. This setup lets devices measure resistance changes when you press the sensor.

Why do electronics engineers choose force sensing resistors?

Engineers pick force sensing resistors because they are simple and cheap. These sensors fit many designs and measure force without hard parts. Many electronics projects need this type of sensor.

Are force sensing resistors reliable for electronics applications?

Force sensing resistors work well in many electronics jobs. They are good for devices that need to sense touch or pressure. Designers trust them because they are easy to use and work the same each time.