Call us: +86-137-2353-4866

A force probe checks physical force in many careful jobs. Force probe physics is very important in jobs that need good force sensing. New studies show that both technical details and calibration ways change how correct the measurements are. The world market for high precision force sensors was about 2,007.3 million USD in 2024. It will likely get bigger because more machines and needs in healthcare and cars are growing. SOUSHINE has a force sensing resistor that gives strong and changeable answers for these needs.

Table of Contents

Key Takeaways

Force probes help measure force very accurately. This is important in fields like healthcare and cars. SOUSHINE FSRs are very sensitive. They can sense forces from 10 grams up to 1000 grams. This makes them useful for many different jobs. It is important to check force probes often to keep them correct. Engineers should plan checks based on how much and where they use them. Knowing about different force probes, like resistance-based and piezoelectric, helps pick the best one for each job. Writing down how you check and fix probes is important. It helps track changes and find problems later. Things like temperature and humidity can change force readings. Keeping these things steady is very important. Engineers should check force probes in more than one way. They should use repeatability and cross-validation to make sure readings are right. SOUSHINE gives help and tools to engineers. This helps them choose and check force sensing resistors.

Force Probe Physics

Principles

Resistance-Based Sensing

Force probe physics tells us how sensors find force. Many force probes use resistance-based sensing. When something stretches or gets squeezed, its resistance changes. Strain gauges work like this. They have a thin wire or film. If you bend or stretch the wire, the resistance changes. The sensor notices this and figures out the force. Young’s Modulus helps connect how much something bends to the force. This way gives steady and repeatable results.

Mechanical and Piezoelectric Types

Different force probes use special ways to sense force. The table below shows how resistance-based and piezoelectric probes work and what makes them different.

| Type of Probe | Sensing Mechanism | Performance Characteristics |

|---|---|---|

| Piezoresistive | Resistance changes when force is applied | Sensitivity can be higher by changing conductivity; sensitivity might drop over time because modulus goes up and hysteresis happens. |

| Piezoelectric | Pressure causes polarization and charge to build up | High piezoelectric coefficients come from certain ceramics; polymers make them flexible for 3D detection. |

Mechanical force probes use springs or levers. These parts move when force pushes on them. Other sensors measure this movement. Piezoelectric probes use special materials. When you press them, they make an electric charge. This charge shows how much force is there. Each type works best for different jobs in force probe physics.

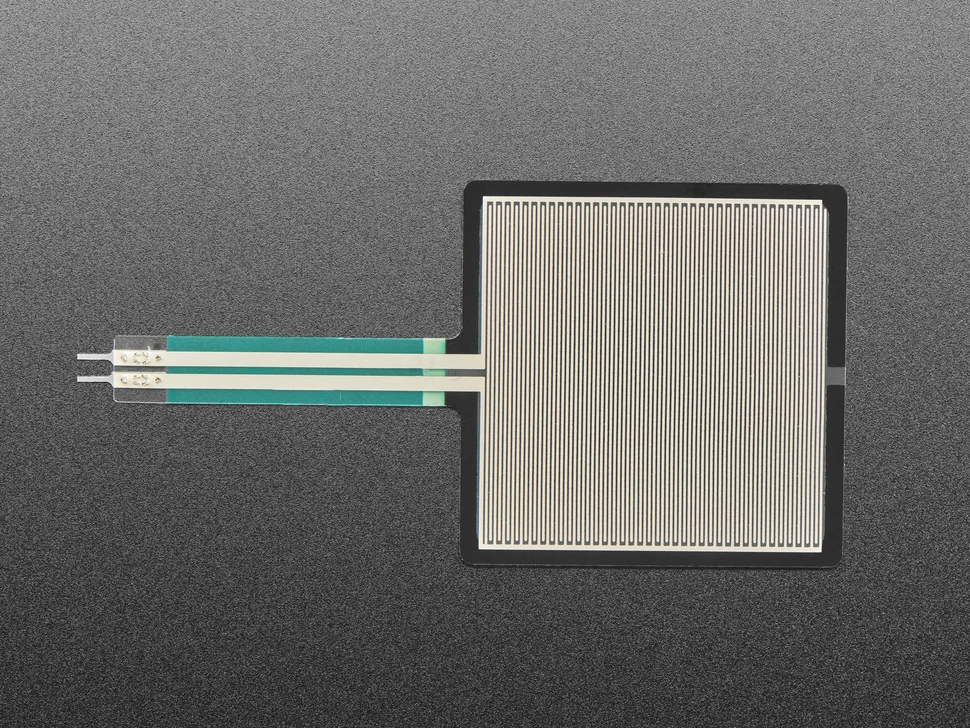

SOUSHINE FSRs

Construction

SOUSHINE makes Force Sensing Resistors (FSRs) with advanced materials. The table below lists the main parts and what they do.

| Material Type | Characteristics |

|---|---|

| Flexible Polymer Sheets | Very thin, light, bendable, and strong |

| Conductive Materials | Needed for resistance change when pressed |

| Resistive Materials | Works together with conductive materials |

FSRs have two main designs. In shunt mode, two polymer sheets with a gap get pressed together. This lowers resistance. In thru mode, a polyester film with electrodes gets squeezed. This also lowers resistance. These designs help SOUSHINE FSRs react fast and last longer. The mix of bendable sheets and special coatings makes them tough and flexible.

Applications

Force probe physics helps many industries. SOUSHINE FSRs are used in medical, automotive, industrial, consumer electronics, and robotics. The table below shows common uses.

| Industry | Application Description |

|---|---|

| Medical | Used in drug-delivery devices for safe and steady medicine use. |

| Automotive | Sensors check door seal pressure, airbags change force for people, and watch battery pack pressure. |

| Industrial | Used in food packaging machines to make sure seals are good and in assembly lines to check force. |

| Consumer Electronics | Put in touchpads, game controllers, and electronic drum kits for better user experience. |

| Robotics | Used in robot grippers to watch grip force and in wearable robots to track joint movement. |

SOUSHINE FSRs are special in force probe physics. They are very accurate, tough, and easy to use. The table below compares SOUSHINE FSRs to other brands.

| Feature | SOUSHINE’s FSRs | Competitors’ FSRs |

|---|---|---|

| Accuracy | Better | Changes |

| Durability | Strong | Not as strong |

| Customization | Many choices | Few choices |

| Low Power Consumption | Yes | Changes |

| Ease of Integration | Easy | Hard |

SOUSHINE FSRs come in many shapes and sizes. They use little power and work well in hard places. Their design helps engineers and researchers get good force measurements. Force probe physics helps people pick the right sensor for each job.

Tip: SOUSHINE gives technical help for design and setup. Their team helps users choose FSRs for their projects.

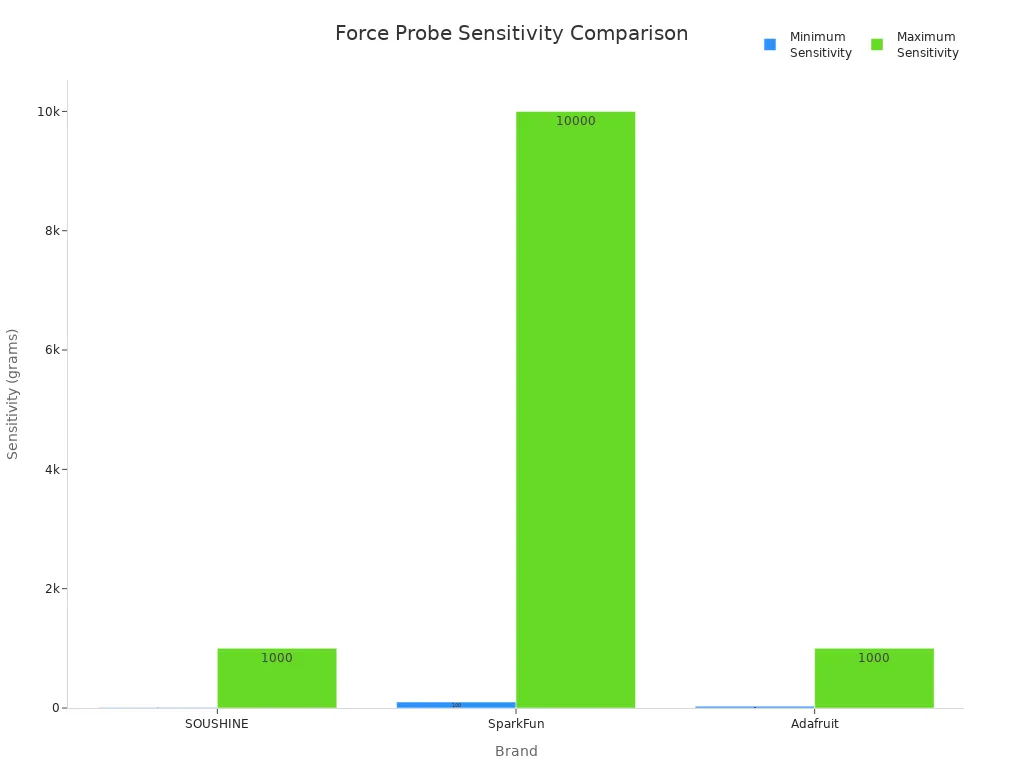

Technical Specifications

Sensitivity

Sensitivity means how well a force probe finds small force changes. If a sensor has high sensitivity, it can notice tiny forces. This is important in medical devices and robotics. Small changes can make a big difference in these jobs. SOUSHINE FSRs can sense forces from 10 grams to 1000 grams. This range works for light touches and heavier presses. The table below shows how SOUSHINE FSRs compare to other brands.

| Brand | Sensitivity Range |

|---|---|

| SOUSHINE | 10g–1000g |

| Interlink | Few grams–kg |

| Tekscan | Wide (g–kg) |

| SparkFun | 0.1kg–10kg |

| Adafruit | 30g–1000g |

| Flexiforce | Wide (g–kg) |

| Sensitronics | Customizable |

SOUSHINE FSRs are as sensitive or more sensitive than other brands. This helps engineers pick the best sensor for their work.

Range

Range shows how much force a probe can measure. A bigger range lets the sensor work in more places. SOUSHINE FSRs can measure soft touches and strong presses. This makes them good for cars and factories. When people choose a force probe, they look at the range. They want to make sure the sensor fits the job. If the range is too small, strong forces might not get measured. If the range is big, the sensor can measure both small and large forces. SOUSHINE has different models for many force ranges.

Resolution

Resolution is the smallest force change a sensor can find. High resolution helps the sensor notice tiny changes. This is important for careful jobs. In medical devices, small force changes can keep patients safe. In robotics, high resolution helps robots hold things gently. Here are reasons why resolution matters:

- Resolution shows the smallest force change a sensor can find.

- Higher resolution means more exact measurements for careful jobs.

- Good calibration helps the sensor give true results.

- Resolution helps find small force changes, which is important for careful work.

SOUSHINE FSRs have strong resolution. This helps people get results they can trust. Engineers and researchers use SOUSHINE FSRs when they need good accuracy.

Tip: People should check sensitivity, range, and resolution before picking a force probe. SOUSHINE gives help to users so they can choose the best sensor for their project.

Linearity

Linearity shows if a force probe gives a straight answer when force changes. If the sensor has good linearity, the output matches the force all the way. Engineers use linearity to see if the sensor works well for different forces.

Manufacturers check linearity by comparing the sensor’s output to a straight line. They test many points across the sensor’s range. Each point is the average of three tests. Data points are often marked at every 20% of the sensor’s range. If the output stays close to the line, the sensor has high linearity.

Linearity is shown as a percent of the full output. For example, if a sensor has 2% linearity, the output does not change more than 2% from the line. This helps users know how much error there might be.

The table below shows how manufacturers talk about linearity in technical specs:

| Parameter | Description |

|---|---|

| Measuring range | Linearity over the whole measurement range |

| Clamping shaft diameter | Set at the factory |

| Operating temperature range | Best range for good performance |

| Electrical Data | Details about power and connections |

Calibration follows set rules. If the tested points do not match the specs, the unit fails calibration. This makes careful measurement and following rules very important.

SOUSHINE FSRs have strong linearity across their range. Their design keeps sensitivity changes low when force goes up. This means users can trust the readings for both light and heavy forces. SOUSHINE’s support team helps users set up calibration to meet linearity standards.

Tip: Always check the linearity percent in the datasheet before picking a force probe for your project.

How Linearity Is Quantified:

- Linearity is a number that shows how sensitivity changes with force.

- It is found by dividing the difference from the line by the full value.

- Manufacturers show linearity as a percent of the full output.

Response Time

Response time means how fast a force probe reacts when force is added or taken away. Fast response time lets sensors track quick force changes. This is important in robotics, medical devices, and electronics.

SOUSHINE FSRs have short response times. Their bendable materials and smart design help them react fast to touch or pressure. This makes them good for jobs where speed matters, like robot hands or touchpads.

Engineers look at response time when picking a sensor for fast systems. A slow sensor might miss quick force changes. A fast sensor gives real-time feedback, which helps machines work better.

Things that affect response time include:

- Material type

- Sensor thickness

- Electrical circuit design

The table below lists common response time ranges for force probes:

| Sensor Type | Typical Response Time |

|---|---|

| SOUSHINE FSRs | <1 millisecond |

| Piezoelectric | <1 millisecond |

| Mechanical | 10–100 milliseconds |

SOUSHINE FSRs respond in less than one millisecond. This speed helps users get good data for fast events.

Note: Always match the sensor’s response time to your project’s needs. Fast response time helps keep systems safe and working well.

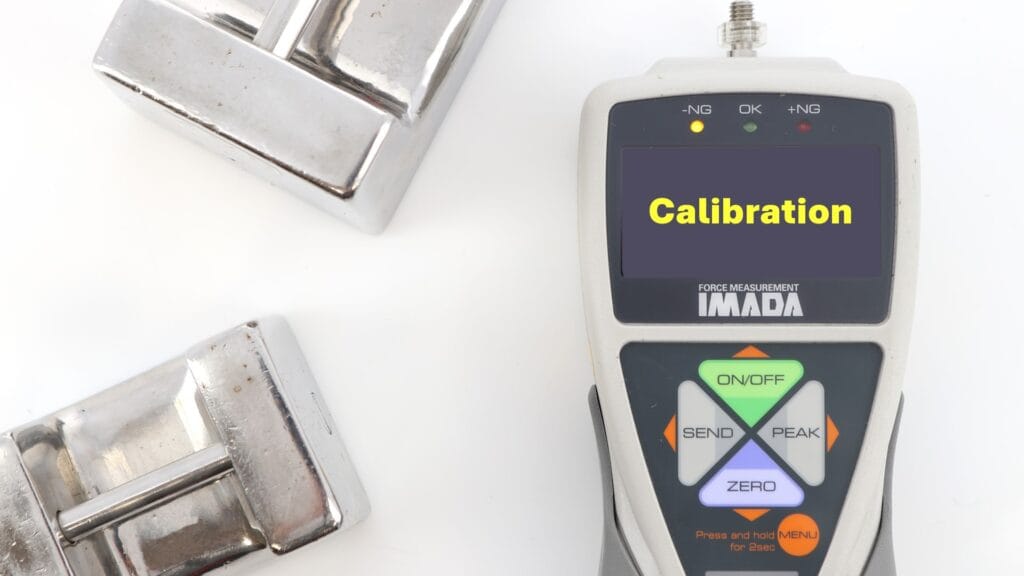

Force Calibration

Force calibration helps people get correct readings from force probes. This process makes sure force measuring tools work well in many jobs. Engineers use force calibration to check if sensors show the right numbers. They follow steps to keep results true.

Calibration Process

Preparation

Engineers start by getting the workspace ready. They clean the probe and the test platform. They check that the force measurement device is set up. The reference standard must be in good shape. The team sets up the probe and connects it to the load cell. They make sure all tools work.

Zeroing

Zero position calibration is an important step. The engineer attaches the probe to the load cell. They move the arm down until the probe touches the test platform. The system sets this spot as zero. Zero position calibration helps remove starting errors. Engineers repeat zero position calibration three times to check the setup.

Applying Known Forces

The next step uses reference standard weights. The engineer puts known forces on the probe. They use weights or machines that push with a set force. The probe measures each force. The team checks if the probe matches the reference standard. This step helps find sensor errors.

Data Recording

Engineers write down all measurements during force calibration. They record the force used and the sensor reading. They compare these numbers to the reference standard. The team looks for differences. If the probe passes tests, it is ready to use. If not, they fix the probe and try again.

Tip: Always write down each step in force calibration. Good records help with future checks and traceability.

International Standards

Force calibration follows rules from international standards. These standards help people get the same results everywhere. Two main standards guide force calibration: ISO 376 and ASTM E74. Each standard has a different focus.

| Standard | Calibration Focus | Key Differences |

|---|---|---|

| ISO 376 | Specific methods | Focuses on specific calibration methods. |

| ASTM E74 | General methods | Based on measurement uncertainty and categories. |

| Class AA | Reference force | Used for secondary standard reference dynamometers. |

| Class A | Verification | Used for verifying testing machines. |

Many labs use ASTM E74 for force calibration. Morehouse has used this standard since 1974. ISO 376 calibrations started in the early 2000s. These standards are not the same. Each one helps with traceability and keeps measurements correct.

Environmental Factors

Environmental factors can change force calibration results. Temperature is the most important factor. If the room gets hot or cold, probe materials can expand or shrink. This change affects measurements. Humidity also matters. High humidity can cause electrical leaks or rust. These problems can make measurements wrong.

Thermal equilibrium helps keep force calibration accurate. The probe and the reference standard must be at the same temperature. If they are not, errors can happen. Engineers wait until everything reaches thermal equilibrium before starting force calibration.

- Temperature changes can affect force calibration accuracy.

- Humidity can cause problems with electrical parts.

- Thermal equilibrium keeps measurements steady.

Note: Regular force calibration helps sensors work well. Engineers should check probes every year in general manufacturing. In tough places, they may need to calibrate every six months. For safety jobs, quarterly calibration gives the best results.

| Calibration Frequency | Recommended For | Description |

|---|---|---|

| Annual | General manufacturing, quality control | Most common interval, balancing cost and reliability. |

| Semi-Annual | High-use instruments, harsh environments | Ensures optimal performance in demanding conditions. |

| Quarterly | Critical safety applications, regulated environments | Provides the highest level of measurement assurance. |

Force calibration is important for industrial force measurement. It helps engineers trust their readings and keep machines safe. Regular calibration and careful control of environmental factors make sure force measuring tools stay accurate. Using a reference standard and following international rules gives good traceability. Engineers use force check steps to confirm probes work well after calibration.

Force Verification

Methods

Repeatability

Repeatability testing checks if a force probe gives the same result every time. Engineers use this test to see if the sensor works well in different jobs. They measure the same force again and again under the same conditions. They write down all the results. If the numbers are close together, the probe has good repeatability. This helps make force verification better and keeps errors low.

| Aspect | Description |

|---|---|

| Definition | Repeatability is a type ‘A’ uncertainty, shown by variance. |

| Measurement Conditions | Engineers measure the same thing under the same conditions. |

| Impact on Accuracy | Repeatability helps find and fix errors, making measurements better. |

Repeatability is important in many areas. For example, in coordinate measuring machines, the trigger probe’s job affects how correct the measurement is. In CNC machine tools, repeatability changes how good the products are.

| Application | Importance |

|---|---|

| Coordinate Measuring Machines | Trigger probe performance changes measurement accuracy. |

| CNC Machine Tools | Repeatability changes the quality of finished products. |

Cross-Validation

Cross-validation uses two or more ways to check the same force. Engineers compare results from different probes or systems. If the numbers match, the sensor is accurate. This method helps find mistakes and makes force verification stronger. Cross-validation also helps with regular checks and keeps sensors working well.

Tip: Engineers should use both repeatability and cross-validation to make sure force probes give good results.

Unit Conventions

Newtons

The newton is the main unit for force in science and engineering. One newton is the force needed to speed up one kilogram by one meter per second squared. Engineers use newtons for force verification because it follows the International System of Units (SI).

Grams-Force

Grams-force is the force made by one gram under normal gravity. This unit is used for small things. Engineers use grams-force when working with light objects or gentle sensors.

Pounds-Force

Pounds-force is used in the United States and some other places. One pound-force is the force needed to speed up one pound at 32.174049 feet per second squared. Engineers often change between newtons and pounds-force for different jobs.

| Unit | Definition | Conversion Factor to Other Units |

|---|---|---|

| Newton (N) | The SI unit of force, equal to the force needed to speed up 1 kg at 1 m/s². | 1 N = 0.224809 lbf |

| Pound-force (lbf) | The force needed to speed up 1 lb at 32.174049 ft/s². | 1 lbf = 4.44822 N |

| Gram-force (gf) | The force made by 1 gram under normal gravity (9.80665 m/s²). | 1 gf = 0.00980665 N |

To change newtons to pounds-force, multiply the newtons by 0.224809. For example, 5 newtons is 1.124045 pounds-force.

Note: Using standard units like newtons, grams-force, and pounds-force helps engineers compare results and keep measurements clear. Standard units help with force verification and make it easier for teams to talk about their work.

Calibration Best Practices

Routine Schedules

Routine schedules help force probes stay accurate. Engineers set times for calibration and testing. Teams pick yearly, twice a year, or every three months. They choose based on how much sensors are used and where they work. Busy factories test every three months to find problems early. Labs may only need yearly tests. Each schedule should fit the equipment and risks. Teams write down dates for each test and calibration. This helps them plan and not miss checks. SOUSHINE says routine testing is important for Force Sensing Resistors to get good results.

Tip: Teams should look at their schedules every year. They can change them if equipment use or the environment changes.

Documentation

Good documentation helps keep calibration and testing easy to track. Each record needs important details about the equipment and process. The table below shows what teams should write for every calibration and test.

| Essential Documentation Practices | Description |

|---|---|

| Identification of Equipment | Serial number, model, and more |

| Calibration Dates | Date of calibration and next date |

| Calibration Procedure | Steps used for calibration |

| Calibration Results | Results before and after changes |

| Technician Signature | Signature or proof from the technician |

| Reference Standards | Standards used for calibration |

Teams keep these records safe. They use them to check old tests and calibrations. If something goes wrong, engineers look at the records to find out why. Good records help with audits and quality checks. SOUSHINE gives guides and training to help teams keep good records.

Handling

Proper handling keeps force probes working well. Engineers follow easy steps to stop damage and keep accuracy.

- Force torque sensors in robots measure arm forces. This helps with gentle handling.

- Strain gauge sensors in robot grippers change grip strength. This protects fragile parts during tests.

- Force sensors find collisions and start safety actions. This keeps robots and equipment safe.

- Collaborative robots use these sensors for safety near people, especially during tests.

Teams store sensors in clean, dry places. They do not drop or bend the probes. During tests, they look for damage or wear. SOUSHINE gives help and fast support for handling questions. Their warranty and support help users fix problems quickly.

Note: Careful handling during tests and daily use makes force probes last longer and keeps results correct.

Troubleshooting

Troubleshooting helps engineers fix calibration problems with force probes. If a sensor gives strange readings, engineers follow steps to find and fix the problem. First, they check the sensor and its surroundings carefully.

Common Troubleshooting Steps:

- Look at the sensor for damage. Cracks, bends, or loose wires can cause mistakes.

- Check if the workspace has changed. Big temperature changes or shaking can make sensors less accurate.

- Look at old calibration records. Past data can show if measurements have changed over time.

- Test the sensor with known weights. If numbers are wrong, recalibration may be needed.

- Read the manufacturer’s instructions. SOUSHINE gives guides and technical help for users.

- Ask technical support if problems do not go away. SOUSHINE’s team helps users fix hard problems fast.

Tip: Engineers should keep sensors clean and dry. Dust and water can change how a sensor works.

Typical Calibration Issues:

- Temperature changes can make readings move.

- Vibrations in the workspace may cause results to jump.

- Sensor nonlinearity may need special calibration models.

- Hysteresis changes how the sensor reacts to different forces.

- Drift means the sensor slowly changes its output over time.

- Cross-axis sensitivity can affect readings in multi-axis sensors.

The table below shows how problems can change calibration:

| Problem | Effect on Calibration | Solution |

|---|---|---|

| Physical Damage | Wrong readings | Fix or replace the sensor |

| Temperature Fluctuations | Measurement drift | Use in a steady environment |

| Vibrations | Output jumps | Keep sensor away from shaking |

| Nonlinearity | Output does not match force | Use better calibration models |

| Hysteresis | Different readings for same force | Recalibrate often |

| Drift | Output changes slowly | Calibrate more often |

| Cross-Axis Sensitivity | Mixed readings | Mount the sensor the right way |

Engineers can stop many problems by using good habits:

- Make a regular calibration plan based on how much the sensor is used and where it works.

- Handle sensors gently to stop damage.

- Use sensors in steady places to avoid outside problems.

- Check sensors often to catch drift early.

- Teach everyone how to use and calibrate sensors the right way.

SOUSHINE helps users with troubleshooting guides and quick technical support. Their team answers questions about calibration, handling, and sensor performance. When engineers use these steps, force probes work well and give correct measurements.

Note: Fast troubleshooting and regular care help teams avoid problems and keep systems safe.

Getting correct force readings means knowing force probe physics and doing calibration steps. Engineers use a load cell to check if force probe readings are right. They test with the load cell many times to make sure results match. A load cell helps teams find mistakes and make sensors work better. The table below lists important research results.

| Key Takeaway | Description |

|---|---|

| Calibration Techniques | Engineers use different ways to calibrate a load cell for exact results. |

| Challenges in Measurement | Teams have problems with load cell wear and errors in measuring. |

| Methodologies for Precision | Using a load cell with reference samples makes results more trustworthy. |

ASTM E4 calibration makes sure a load cell gives correct and traceable force readings. This step keeps work safe and stops expensive errors.

Doing calibration often, taking care of tools, and using a load cell help teams get good data. SOUSHINE FSRs give strong and bendable answers for many uses. Engineers should keep learning and talk to experts about load cell calibration to get better results.

FAQ

What is a Force Sensing Resistor (FSR)?

A Force Sensing Resistor (FSR) checks force or pressure. Its resistance goes down when force pushes on it. SOUSHINE FSRs use this idea to give good readings in many jobs.

How often should engineers calibrate force probes?

Engineers should calibrate force probes once every year for most jobs. In busy or tough places, calibration every six months or every three months keeps measurements correct.

Can SOUSHINE FSRs work in wet or dusty places?

SOUSHINE FSRs are built strong. They work in many places. For best results, engineers keep sensors clean and dry so errors do not happen.

What units do force probes use?

Force probes measure force in newtons, grams-force, or pounds-force. Engineers pick the unit that matches their project. Using standard units helps teams compare results easily.

Why does temperature affect force probe readings?

Temperature changes can make sensor materials get bigger or smaller. This can change resistance and affect the readings. Engineers keep sensors at steady temperatures for best results.

How do engineers check if a force probe works well?

Engineers test repeatability by measuring the same force many times. They also use cross-validation with other sensors. Good results mean the probe works well.

Are SOUSHINE FSRs customizable for different projects?

SOUSHINE has FSRs in many shapes and sizes. Engineers can pick designs that fit their needs. Customization helps sensors work in special jobs.

Where can engineers get help with SOUSHINE FSRs?

SOUSHINE gives technical support and guides. Engineers can contact the team for help with setup, calibration, or fixing problems.