Call us: +86-137-2353-4866

Have you ever thought about why some machines work well but others stop working? The reason is often the pressure sensors you pick. If you choose the right sensor type, pressure range, and features, your equipment stays safe and you save money. Good pressure sensors provide accurate force sensing readings. This helps your process stay safe and operate efficiently. Think about what you need and any problems you have before you choose.

Tip: Picking the right pressure sensors can prevent costly repairs and help your system stay safe.

Table of Contents

Key Takeaways

- Picking the right pressure sensor saves money and protects your equipment.

- Know what your project needs before you pick a sensor. Think about pressure type, range, and how exact it must be.

- There are many kinds of pressure sensors for different jobs. Make sure the sensor fits what you need.

- Things like temperature and humidity can change how sensors work. Pick sensors that can handle these things.

- Choose the right output signal for your system. This helps send data correctly.

- Plan how you will mount the sensor. Good installation helps the sensor work better and last longer.

- Calibrate sensors often to keep them working right and to trust their readings.

- Ask experts for help with hard projects or special needs. This helps you avoid mistakes and pick the best sensor.

Pressure Sensors Overview

What Are Pressure Sensors?

Pressure sensors measure how much force liquids or gases push on surfaces. These devices change physical force into an electrical signal. Most sensors use a part called a diaphragm. The diaphragm bends when pressure is put on it. The sensor turns this bending into an electrical output. There are many types of pressure sensors. Some types are potentiometric, strain gauge, capacitive, inductive, piezoelectric, resonant, and optical sensors. Each type finds pressure changes in its own way.

SOUSHINE Force Sensing Resistors (FSRs) are a special kind of sensor. These sensors measure force and pressure by changing their electrical resistance when you press on them. You get steady readings, so you can see how pressure changes over time. FSRs are used in many industries. They are flexible, strong, and save energy.

Note: Pressure sensors turn force from liquids or gases into signals that machines can use.

Why Pressure Sensors Matter

Pressure sensors help keep machines and systems safe. You use them to watch and control important processes. If you pick the right sensor, you avoid expensive repairs and keep your equipment working well. Pressure sensors help stop problems like too much pressure, sudden pressure jumps, very hot or cold temperatures, and using the wrong materials. These problems can break sensors and cause failures.

Here are some common ways sensors can fail:

- Too much pressure can break the sensor forever.

- Sudden pressure jumps or water hammer can cause quick breakdowns.

- Very hot or cold temperatures can change how the sensor works.

- Using the wrong materials can cause leaks and damage.

- Blocked pressure ports stop sensors from working right.

Pressure sensors also make things safer. In cars, they check tire pressure and engine systems. In factories, they watch hydraulic and pneumatic systems. You use them to make sure everything works the way it should.

Applications of Pressure Sensors

Pressure sensors are used in many industries. They help you watch process flow, control hydraulic and pneumatic systems, and manage vacuum technology. Here is a table that shows the main types of pressure sensors and where they are used most:

| Type of Pressure Sensor | Market Share (%) | Key Applications |

|---|---|---|

| Absolute Pressure Sensors | 27.69% | Engine intake, fuel combustion |

| Differential Pressure Sensors | N/A | Aerospace, research, industrial |

| Piezoresistive Technology | 29.58% | Accurate and reliable measurements |

| Wired Connectivity Sensors | 59.24% | Reliable, cost-effective systems |

| 101 to 1000 psi Range | 27.41% | Automotive, industrial |

| Automotive Industry | 32.08% | Safety, engine management, tire pressure |

You see pressure sensors in factories, medical devices, water treatment, and petrochemical plants. SOUSHINE FSRs work well in cars, healthcare, robots, and electronics for consumers. You can use them for touch controls, checking patient health, and making machines safer.

Tip: When you pick a pressure sensor or pressure transducer, think about what you need and where you will use it. This helps you get the best results from your sensor.

Defining Your Application Needs

Identify Application Requirements

You should first figure out what your project needs from a pressure sensor. Every project is different. Look at the details before picking a sensor. Here is a simple list to help you remember what matters most:

- Understand your project. Write down what you want the sensor to do.

- Check what the sensor will touch. Some sensors work better with air, water, or chemicals.

- Learn about the place where you will use the sensor. Find out the temperature and pressure there.

- Decide what kind of signal you want. You can pick analog or digital.

- Choose how exact you need the sensor to be. Some jobs need very accurate readings.

- Think about the pressure type and range. Pick a sensor that fits your needs.

Tip: If you match the sensor to your project, you make it safer and better.

Types of Pressure to Measure

There are three main kinds of pressure sensors. Each one is good for a different job. You need to pick the right one for your project.

Gauge, Absolute, Differential

- Absolute pressure sensors measure pressure compared to a vacuum. You use them in weather tools and altimeters.

- Gauge pressure sensors measure pressure compared to the air around us. You see them in medical tools and open tanks.

- Differential pressure sensors measure the difference between two places. You use them in HVAC systems to check filters.

Note: The kind of pressure sensor you pick changes how your system works.

Environmental Considerations

Where you put your sensor can change how it works. You need to look at the place where you will put the sensor. The table below shows common things in the environment and how they affect sensors:

| Environmental Condition | Impact on Pressure Sensor Performance |

|---|---|

| Humidity | Can cause short circuits; sensors with high airtightness are recommended. |

| Corrosive Environments | Damages elasticity; corrosion-resistant sensors should be selected. |

| High Temperature | May melt coatings and alter stress structures; high-temperature sensors and cooling devices are necessary. |

| Flammable Gases | Poses risks to equipment and personnel; explosion-proof sensors are required. |

| Dust | Causes short circuits; high airtightness sensors are needed for dusty environments. |

| Electromagnetic Interference | Can lead to erroneous output; proper shielding of sensors is essential. |

You also need to know that humidity and temperature can make sensors fail. These things can change the output voltage and make the sensor less reliable. Vibration can also cause problems for your sensor.

Alert: Always check the place before you put in a sensor. This helps you stop problems and keeps your system working.

Selecting the Right Pressure Sensor

Matching Sensor Type to Application

You have to pick the right sensor for your job. First, think about what you want to measure. Some sensors are better for liquids. Others work better for gases. SOUSHINE Force Sensing Resistors (FSRs) can be used in many ways. You can use them for tank level checks, touch buttons, or robots.

Here is a table to help you pick the best sensor:

| Criteria | Description |

|---|---|

| Compatibility | Choose materials that match your fluid so you avoid damage. |

| Pressure Range | Know the lowest and highest pressure you need to measure. |

| Pressure Type | Decide if you need gauge, absolute, or differential sensors. |

| Accuracy and Precision | Pick how exact you want your readings to be. |

| Environmental Conditions | Check the temperature, humidity, and shaking where you use it. |

| Response Time | Make sure the sensor reacts fast enough for your needs. |

| Electrical Output | Pick the signal type you want, like analog or digital. |

| Cost | Balance price with how tough and accurate you need the sensor. |

| Calibration and Maintenance | Find sensors that are easy to set up and keep working. |

| Manufacturer and Supplier | Work with trusted brands like SOUSHINE for good support. |

| Regulatory Compliance | Make sure your sensor follows the rules for your job. |

Use this table to compare different sensors. For example, if you need a sensor for a tank, check if it can handle the liquid and pressure in your tank.

Tip: Always pick a sensor that fits your job and where you will use it.

Understanding Pressure Range

You need to know the pressure range before you choose a sensor. The pressure range tells you the lowest and highest pressure the sensor can measure. If you use a sensor outside its range, it can break or give wrong numbers.

- Pressure range is important for hydraulic and pneumatic systems.

- The right range keeps your system safe and working well.

- High pressure spikes can break the sensor and cause leaks.

- The sensor you pick must handle the highest pressure your system can reach.

If you use a sensor for a tank, make sure it works from empty to full. This helps you get the right numbers and stops spills.

Note: Always check the pressure range before you put in a sensor.

Material and Media Compatibility

Media compatibility means the sensor must work with the fluid or gas you want to measure. If you use the wrong material, the sensor can break or stop working. You need to check this for every job.

Here is a table of common sensor materials and what they are used for:

| Material | Type | Working Temperature | Media | Pros | Cons | Limitations |

|---|---|---|---|---|---|---|

| Tantalum | Refractory metal | -196°C to 3000°C | Strong acids, alkalis | Resists corrosion | Very expensive | Not for high-stress jobs |

| Hastelloy | Nickel-based superalloy | -184°C to 1093°C | Acids, seawater, chlorine gas | Resists corrosion | Expensive | Not for high-stress jobs |

| Monel | Nickel-copper alloy | -196°C to 648°C | Seawater, hydrofluoric acid | Good against corrosion | Expensive | Not for places with lots of oxygen |

| Ceramic | Non-metallic, inorganic | -196°C to 1000°C | Corrosive liquids and gases | Does not react, lasts long | Breaks easily | Not for hard hits or stress |

If you need a sensor for a tank with strong chemicals, pick Hastelloy or Tantalum. For water or less harsh fluids, stainless steel or ceramic may be fine. Always check if the sensor material matches your fluid before you choose.

Alert: The right material helps your sensor last longer and stops leaks or breaks.

Now you can see why it is important to match the sensor type, pressure range, and material to your needs. This helps you get the best results and keeps your system safe.

Output Signal Options

When you pick a pressure sensor, you must choose how to get the signal. The output signal tells your system what the sensor finds. Each type of output works best in different places. You should pick the output that fits your system. This makes setup easy and keeps your data correct.

Here is a table that lists the most common output signals for pressure sensors:

| Output Type | Characteristics | Best Use Cases |

|---|---|---|

| Millivolt | Small signal, works best with short cables and low noise. | Short distances, low noise, compact designs. |

| Voltage | Higher-level output, less noise, handles moderate cable lengths. | Industrial settings with some electrical noise. |

| Current Loop | Resists interference, works well over long cables. | Noisy environments, long distances in process control. |

| Digital | Uses communication protocols, can send extra data and support remote setup. | Long distances, advanced diagnostics, modern controls. |

Each output type is good for certain jobs. Millivolt outputs are weak signals. You use them when the sensor is close to the system. Voltage outputs are stronger and work if there is some noise. Current loop outputs, like 4-20mA, fight interference and work with long wires. Digital outputs use special protocols like I2C or SPI. They can send more than just pressure and help with remote checks.

Tip: Choose an output signal that fits your system. This helps stop signal loss and keeps your data right.

Remember these facts:

- Pressure sensors check pressure and send a signal.

- Transducers often give voltage outputs, like millivolt or volt.

- Transmitters usually give current outputs, like 4-20mA, for big jobs.

- Digital outputs are great for smart systems and remote checks.

If you use SOUSHINE Force Sensing Resistors (FSRs), you can pick from many output types. This lets you use the sensor in simple machines or advanced robots.

Key Factors in Pressure Sensor Selection

Accuracy and Resolution

When you pick pressure sensors, accuracy and resolution are important. Accuracy means how close the sensor’s reading is to the real pressure. Resolution is the smallest change the sensor can notice. You need high accuracy for jobs that need careful control, like making medicine. Even a small mistake can change the product’s quality. Resolution helps you see small changes in pressure. If you measure tank levels or control a process, you need the right accuracy and resolution. Always check the sensor’s details and see if they fit your needs. Some sensors are better for important jobs, while others are fine for simple checks.

Tip: Make sure your sensor’s accuracy and resolution match what your job needs.

Temperature and Humidity Effects

Temperature and humidity can change how pressure sensors work over time. If you use sensors in places with heating and cooling, like hvac systems or outside, watch for changes in readings. Hot and cold cycles can bend the sensor and change its starting point. Humidity and bad gases can get inside and hurt the sensor. You can use sensors with O-ring seals to keep out water and gases. Very hot or cold weather can cause mistakes or break the sensor. The table below shows how these things affect sensors:

| Factor | Impact on Sensor Performance | Solution |

|---|---|---|

| Heating/Cooling Cycles | Bending, changes in starting point | Use strong covers |

| Humidity | Water gets in, rust | O-ring seal design |

| Extreme Temperatures | Wrong readings, sensor stops working | Pick sensors for temperature |

Always check the place before you put in a sensor. Pick sensors that can handle the temperature and humidity where you use them.

Vibration and Shock Resistance

Vibration and shock can change how pressure sensors work, especially in cars and machines. You need sensors that meet certain rules so they last and give good readings. In cars, look for sensors tested by rules like JIS D 1601, SAE J1211, and ISO 16750-1. These rules check if sensors can handle shaking and hard hits. If you use sensors where there is a lot of movement, pick ones that pass these tests. The table below lists important rules for vibration and shock:

| Standard | Description |

|---|---|

| JIS D 1601 | Tests for shaking in car parts |

| SAE J1211 | Checks if car electronics are tough |

| ISO 16750-1 | Tests for car electronics in tough places |

Always check if your sensor passes these rules before using it in hard places. This helps you stop problems and keeps your system working well.

Note: Good pressure sensors keep working even with shaking, hits, heat, cold, and wet air.

Mounting and Size Considerations

You need to think about how you will mount your pressure sensor. The way you install the sensor can change how well it works. If you pick the wrong mounting method, you might get bad readings or damage the sensor. You should look at the space you have and the shape of your equipment. Some sensors need flat surfaces. Others work better on curved or uneven spots.

You should check the size of the sensor before you buy it. Small sensors fit in tight spaces. Large sensors work better in open areas. If you use SOUSHINE Force Sensing Resistors (FSRs), you can choose from many shapes and sizes. This helps you match the sensor to your project.

Here are some things you should think about when you mount a pressure sensor:

- Space: Measure the area where you want to put the sensor. Make sure the sensor fits.

- Orientation: Place the sensor so it faces the right direction. This helps you get good readings.

- Surface: Check if the surface is flat, curved, or rough. Pick a sensor that works with that surface.

- Access: Make sure you can reach the sensor for cleaning or repairs.

- Protection: Use covers or shields if the sensor is in a place with dust, water, or chemicals.

Tip: If you plan your mounting method, you help your sensor last longer and work better.

You should also look at how the sensor connects to your system. Some sensors use screws. Others use clips or glue. If you need to move the sensor, pick one that is easy to remove. If you want a strong hold, use bolts or brackets.

The table below shows common mounting methods and where you might use them:

| Mounting Method | Best Use Case | Pros | Cons |

|---|---|---|---|

| Screw | Fixed installations | Strong hold | Hard to move |

| Clip | Temporary setups | Easy to remove | May slip |

| Adhesive | Small spaces | Fits tight spots | Hard to clean |

| Bracket | Heavy equipment | Supports weight | Needs extra space |

You should pick a sensor size that matches your equipment. If you use a sensor that is too big, it might not fit. If you use one that is too small, it might not measure pressure well. SOUSHINE FSRs come in many sizes, so you can find one that fits your needs.

If you want to avoid mistakes, follow these steps:

- Measure the space for the sensor.

- Pick a sensor that fits the space.

- Choose a mounting method that matches your setup.

- Make sure you can reach the sensor for checks.

- Protect the sensor from damage.

Note: Good mounting and the right size help your sensor give accurate readings and last longer.

You should always plan your mounting and size before you buy a pressure sensor. This helps you avoid problems and keeps your system working.

Applications of Pressure Sensors in Industry

Industrial Automation

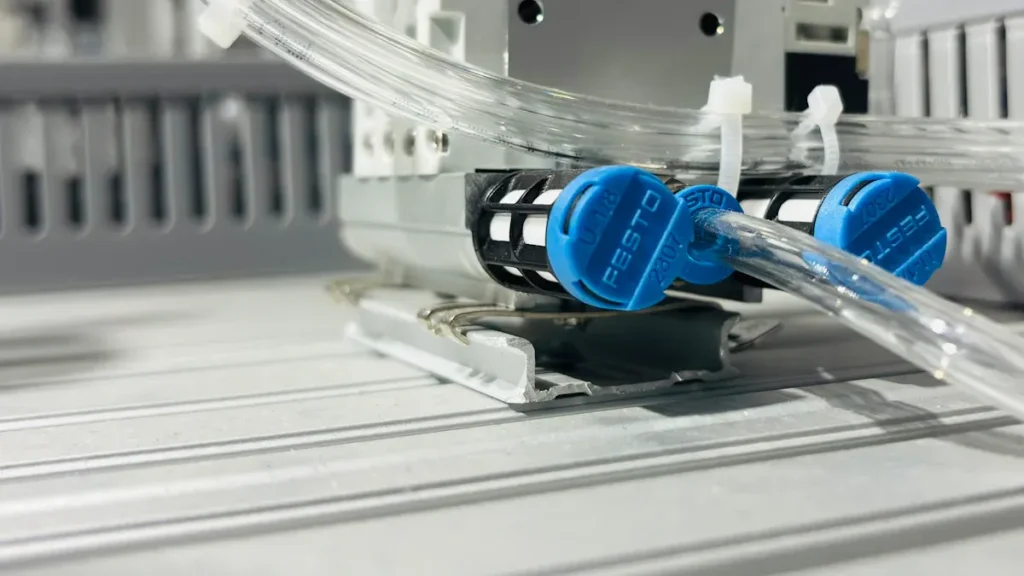

Pressure sensors are used in many factory machines. They help control machines and keep things working right. You find them in hydraulic systems, pneumatic machines, and fluid handling jobs. These sensors give correct readings. This helps stop mistakes and keeps equipment safe.

Here is a table that shows how pressure sensors are used in factories and what you should check for:

| Application | Performance Metrics |

|---|---|

| Hydraulic systems | Accuracy, Stability |

| Pneumatic machinery | Response time, Environmental considerations |

| Fluid handling processes | Operational reliability, Predictive maintenance |

Factories also use ultrasonic sensors and capacitance level sensors. Ultrasonic sensors measure liquid levels without touching the liquid. Capacitance level sensors help find changes in tank levels. Pressure transducer devices are often in control panels. These devices send signals to computers that run machines. In water treatment plants, pressure sensors check filters and pumps. You can find problems early and fix them before damage happens.

Automotive Applications

Pressure sensors are very important in cars and trucks. They check tire pressure, engine parts, and brakes. In brakes, pressure sensors give correct numbers. This helps you stop safely and avoid crashes. Here is how these sensors help you:

- Pressure sensors give correct pressure numbers for good braking.

- They find problems in the brakes, like leaks or broken parts, and tell the brake control module.

- They change hydraulic pressure using real-time data. This makes braking better, especially when you stop hard.

Ultrasonic sensors are also used in parking and crash detection. These sensors help you avoid hitting things and keep your car safe. In vehicle hvac systems, pressure sensors help control air and temperature. This gives you a comfortable ride and saves energy.

Healthcare and Medical Devices

Pressure sensors are found in many medical machines. They help watch patients and control devices like ventilators. You use pressure sensors to check airflow and pressure. This keeps patients safe and helps doctors act fast.

- Pressure sensors are needed to watch airflow and pressure in ventilators. This helps patients breathe well.

- They give feedback on how devices work. This lets doctors make changes quickly to keep patients safe.

- Differential or gauge pressure sensors are put between valves and regulators. This makes sure air and oxygen mix right.

- Some sensors have digital signal processing. This helps fix problems with non-linearity and temperature.

Small surface-mount sensors are good for ventilators. You can pick sensors with analog or digital outputs, like I2C. These sensors use little power but still work well. Ultrasonic sensors help measure blood flow and find blockages. Pressure sensors keep air pressure right in ventilators. This stops problems like barotrauma. Advanced digital signal processing and noise filtering help you get better readings and respond to patient needs.

Tip: Always choose the right sensor for your job. This keeps your system safe and working well.

Robotics and Consumer Electronics

Pressure sensors are used a lot in robots and electronics. These sensors help robots and devices feel touch and force. They also sense changes around them. When robots have pressure sensors, they can feel things. This helps them pick up objects and press buttons. Robots can move carefully because of these sensors.

Robots need to measure where they touch things. Pressure sensors help track the spot and force used. This lets robots do careful jobs. They can grip fragile items or put together small parts.

Here is what pressure sensors do in robots:

- They measure where and how hard something is touched.

- You can set up sensors for different robot jobs.

- Robots get instant feedback and can act like humans.

Pressure sensors help robots know what is around them. Big groups of sensors show how force is spread out. Robots can feel gentle touches or bumps. Some sensors find water or dust. This helps robots stay safe from harm.

| Application Area | Description |

|---|---|

| Tactile Feedback | Pressure sensors tell robots about touches and bumps. Robots react to these forces. |

| Environmental Awareness | Sensors show force maps. Robots sense their area and change how they move. |

| Weatherproofing | Sensors find water or dust. Robots protect themselves from damage. |

In electronics, pressure sensors are in touch screens and smart watches. They are also in gaming controllers. These sensors let devices react when you touch them. You get a better experience. Devices know how hard you press or swipe.

New MEMS sensors and flexible arrays make sensing better. Robots and devices can feel force and touch in more ways. You can check inside pressures and outside forces. Robots become better at moving and working with people. Machine learning helps robots learn from touch and get better.

- You can always check force and pressure.

- Flexible sensors fit many shapes and surfaces.

- Machine learning helps robots work well with people.

SOUSHINE Force Sensing Resistors (FSRs) are great for these uses. Capacitive technology makes them more accurate and less noisy. SOUSHINE FSRs give clear readings for force and torque. They are good for robots and research. You can use them in smart devices and interactive systems. Their flexible design fits many projects. You get strong performance and easy setup.

Tip: When picking pressure sensors for robots or electronics, choose ones with high accuracy and flexible design. Real-time feedback helps your system work smarter and safer. SOUSHINE FSRs make your devices better and more responsive.

Pressure Sensor Selection Checklist

Step-by-Step Checklist

You can use this checklist to help pick a pressure sensor. Each step helps you match the sensor to your project and avoid mistakes.

- Look at the measuring range. Make sure the sensor works for normal use and does not go over the highest pressure.

- Pick the accuracy. Try to balance cost and how well it works. High accuracy is best for jobs that need careful control.

- Check if the sensor works with your fluid or gas. This helps the sensor last longer and not break.

- Choose the pressure reference type. Match the sensor to what you need to measure. Decide if you need gauge, absolute, or differential sensors.

- Think about the environment. Look at temperature, humidity, and shaking. This helps you avoid problems in tough places.

- Pick the output signal. Choose analog, digital, or current loop for your system. This makes sure the sensor fits your setup.

- Plan how to mount the sensor and check the size. Measure the space and pick a sensor that fits. This helps you install it without trouble.

- Make sure the sensor follows safety and industry rules. This keeps your project and users safe.

- Compare different suppliers. Work with trusted brands for good support and quality. This helps you get sensors you can trust and help when you need it.

Tip: Use this checklist every time you pick a pressure sensor. You can avoid common mistakes and get better results.

Decision Flowchart

The flowchart below gives you easy steps to follow when picking pressure sensors. Start at the top and answer each question. Move to the next step if you say yes.

| Step | Question | Yes → Next Step | No → Action |

|---|---|---|---|

| 1 | Does the sensor cover your pressure range? | Go to Step 2 | Pick a new sensor |

| 2 | Is the accuracy right for your application? | Go to Step 3 | Adjust accuracy |

| 3 | Is the sensor compatible with your medium? | Go to Step 4 | Choose new material |

| 4 | Is the pressure reference type correct? | Go to Step 5 | Change sensor type |

| 5 | Can the sensor handle your environment? | Go to Step 6 | Pick a tougher sensor |

| 6 | Does the output signal fit your system? | Go to Step 7 | Select new output |

| 7 | Will the sensor fit your mounting space? | Go to Step 8 | Pick a different size |

| 8 | Does the sensor meet safety rules? | Go to Step 9 | Find compliant sensor |

| 9 | Is the supplier reliable? | Ready to install | Compare other suppliers |

Note: Use this flowchart to check each step. You can make sure your pressure sensors fit your needs and work well in your project.

When to Consult Experts

Complex or Custom Applications

You may face situations where picking a pressure sensor becomes hard. Some projects need special sensors or have tough requirements. You might work with high temperatures, strong chemicals, or tight spaces. Sometimes, you need sensors for new machines or custom designs. In these cases, you should talk to experts or manufacturers like SOUSHINE.

Here are common times when you should ask for expert help:

- You need a sensor for a new or custom machine.

- Your project has strict rules or safety needs.

- You must measure pressure in harsh places, like high heat or strong chemicals.

- You want to make sure your sensor matches your system and works well.

- You need help fixing or checking sensor problems.

Experts can help you pick the right sensor for your job. They know about different sensor types and can guide you through the selection process. You can avoid mistakes and get a sensor that fits your needs. If you have trouble with your sensor, experts can help you find and fix problems. This keeps your equipment safe and working.

Tip: If you feel unsure about your sensor choice or face a tough project, reach out to SOUSHINE for advice.

Technical Support and Manufacturer Guidance

Manufacturers offer support to help you use their products. You can ask questions about sensor types, installation, and troubleshooting. SOUSHINE gives you help from start to finish. You get answers about product selection and how to use sensors in your project.

Here is a table that shows the types of support you can get from manufacturers:

| Type of Support | Description |

|---|---|

| Application Support | Help with picking products and answering questions about your project. |

You can contact SOUSHINE for help with sensor selection, installation, and repairs. Their team can guide you if you need a sensor for a special job or face problems with your equipment. You get advice on matching the sensor to your system and making sure it works well.

If you work on a big project or need a custom sensor, you should talk to SOUSHINE early. Their experts can help you design a sensor that fits your needs. You save time and avoid costly mistakes. You also get support for repairs and upgrades.

Note: Good technical support helps you solve problems fast and keeps your project running.

You should not wait until you have a problem. Ask for help when you start planning your project. This way, you get the best sensor and support from the beginning.

You can choose the right pressure sensors by following a clear process. This approach helps you spot risks early and keeps your system reliable. When you select a sensor, match the type, range, and features to your application. Use the checklist to guide your choice and lower the chance of failure. You can also:

- Check the environment and installation site.

- Review your specific needs.

- Plan for regular calibration.

- Think about long-term costs.

If you need help, reach out to experts like SOUSHINE. You have the tools to make smart choices and build safer systems.

FAQ

What is a pressure sensor?

A pressure sensor checks force from liquids or gases. It changes this force into an electrical signal. Machines use this signal to understand pressure.

How do I choose the right pressure sensor for my project?

First, look at your pressure range. Next, check your environment and what fluid or gas you have. Pick a sensor that matches your needs for the best results.

Can SOUSHINE FSRs work in wet or dusty places?

SOUSHINE FSRs work in many places. For wet or dusty spots, use models with covers. You can also ask SOUSHINE for help.

What output signals do pressure sensors provide?

Pressure sensors give signals like analog, digital, voltage, or current loop. Pick the signal type that works with your system.

How often should I calibrate my pressure sensor?

Check and calibrate your sensor often. Most people do this once a year or if the readings seem wrong.

Can I use pressure sensors in medical devices?

Yes, you can use pressure sensors in medical devices. They help watch patient health and control machines like ventilators.

What should I do if my sensor gives wrong readings?

Look for damage, dirt, or wiring problems. Clean the sensor and check if it is installed right. If it still does not work, contact SOUSHINE support.

Do pressure sensors need special mounting?

Pick a mounting method that fits your space and equipment. You can use screws, clips, or glue. Always follow the instructions from the manufacturer.