Call us: +86-137-2353-4866

Surface pressure means how much force pushes on a surface area. Scientists say it is the air pressure at one place. This depends on how much air is above that place. People can use a force-sensing resistor to measure surface pressure. SOUSHINE has a force sensing resistor that finds changes in force and pressure. This sensor changes its resistance when force pushes on it. Many people call it a force sensitive resistor because it reacts fast to touch.

Table of Contents

Key Takeaways

- Surface pressure tells us how much force is on one area. This is important to know in many different jobs and fields.

- Force-sensing resistors, or FSRs, can sense changes in force. They do this by changing their resistance. This helps them measure pressure.

- There are many tools to measure surface pressure. Some examples are manometers, barometers, and FSRs. Each tool is good for different uses.

- FSRs do not cost much money. They are bendable and can sense small changes. This makes them great for medical tools, car safety, and robots.

- To measure surface pressure right, use this formula: Pressure equals Force divided by Area. Make sure you always use the same area size.

- FSRs need to be calibrated. This means you test them with weights you already know. This helps make sure the pressure readings are correct.

- Things like temperature and humidity can change how well FSRs work. So, you should check and take care of them often.

- If you set up and care for FSRs the right way, they last longer. This also helps you get better results in your projects.

Surface Pressure Basics

Definition

Surface pressure means how much force pushes on a certain area. People use this word when talking about air pressing down at a spot. In science, surface pressure shows how things interact with their surroundings. If you press your finger on a table, the force spreads over the spot you touch. This makes pressure in that small area. Measuring surface pressure helps people know how much force is in one place.

Many tools can measure surface pressure in real life. Some common ways are:

- Manometers use liquid to show pressure.

- Bourdon tubes get straighter when pressure goes up.

- Diaphragm pressure gauges have a part that moves with pressure.

- Piezoresistive pressure sensors sense changes in resistance.

- Capacitive pressure sensors check changes in capacitance.

- Pitot tubes compare still and moving pressure in fluids.

- Barometers measure air pressure.

- Differential pressure transducers compare pressure at two spots.

- Strain gauge pressure sensors measure bending from pressure.

- Optical pressure sensors use light to find changes.

Real-World Uses

Surface pressure measurement is important in many jobs. The table below gives some examples:

| Application Area | Description |

|---|---|

| Automotive Safety and Comfort Testing | Pressure films help study seat pressure for better design and safety. |

| Footwear and Orthopedic Design | Shows how weight spreads for making custom shoes and supports. |

| Manufacturing and Assembly Line | Checks even pressure during assembly to keep products strong and lower mistakes. |

| Medical Device Calibration and Testing | Used to set up devices like blood pressure cuffs to make sure they work right. |

| Structural and Mechanical Engineering | Looks at stress in structures to make them safer and last longer. |

Engineers use surface pressure data to make things better. In hospitals, good pressure readings help doctors care for patients. Shoe makers look at pressure to design better shoes. Car companies use pressure maps to make seats safer.

Importance

Measuring surface pressure helps keep things safe and working well. Finding leaks early stops dangerous problems. Workers get warnings when pressure changes too much, so they can fix things before they break. Keeping pressure in safe limits helps machines run better.

- Getting blood pressure right is important for patients.

- Mistakes in readings can cause wrong treatment.

- New ideas like In Vivo Blood Pressure Sensing make checks more exact.

Surface pressure data helps people choose what to do. It helps engineers, doctors, and designers. Good measurements keep people safe and make products better.

Force-Sensing Resistor Overview

What Is an FSR

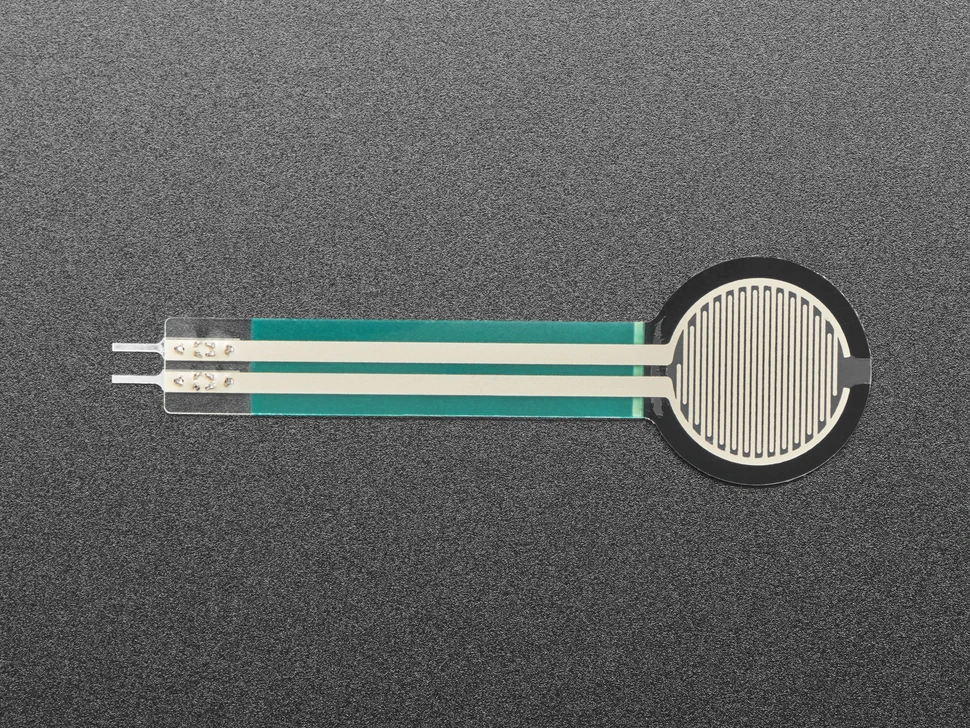

A force-sensing resistor is a sensor that finds out how much force is on its surface. People sometimes call it a force sensitive resistor or a piezoresistive force sensor. This sensor changes its resistance when you press on it. If you push harder, the resistance gets lower. Engineers use these sensors in many things to measure touch, weight, or pressure.

How FSRs Work

Force-sensing resistors use piezoresistive technology. Inside, there is a special ink between two thin layers. When no one presses, the resistance stays high. If you press down, the ink’s particles move closer together. This makes the resistance go down. The sensor works like a variable resistor in a circuit. People can check this change with a voltage divider circuit. The force and conductance have a straight-line relationship for a certain range.

Tip: FSRs do not measure pressure by itself. They measure the total force on their surface. This is not the same as pressure sensors, which measure force spread out over an area.

Here is a table that shows how force-sensing resistors and pressure sensors are different:

| Feature | Force-Sensing Resistors (FSRs) | Pressure Sensors |

|---|---|---|

| Measurement Principle | Measures total force applied | Measures pressure over an area |

| Units Used | Newtons (N) or pounds-force (lbf) | Pascals (Pa) or psi |

| Design | Film changes resistance | Diaphragm bends with pressure |

| Applications | Total force measurement | Pressure measurement over area |

SOUSHINE FSR Features

SOUSHINE makes advanced force-sensing resistors for many uses. These sensors come in many shapes and sizes. They work well in cars, hospitals, robots, and electronics. SOUSHINE FSRs use a flexible base, a spacer, and a layer that conducts electricity. This design gives results that are reliable and repeatable. The sensors use very little power, so they are good for battery devices.

SOUSHINE is special for these reasons:

- Good prices for many projects.

- Custom designs for special needs.

- Careful quality checks during making.

- Full help from design to use.

SOUSHINE FSRs help make cars safer, watch patients in hospitals, and let robots feel touch. These sensors also make electronics easier to use. People pick SOUSHINE because they trust the sensors and the support.

Pros and Cons

Force-sensing resistors have many good points for measuring surface pressure. They also have some things that are not so good. Knowing both helps people pick the right sensor for what they need.

FSRs can notice small changes in force. They are thin and bendy, so they fit in lots of products. People use FSRs in things you wear, robots, and medical tools. They do not cost much, so schools and companies can buy them easily. FSRs use little power, so they are good for things with batteries. You can use FSRs in many ways because they are flexible.

The table below lists the main good and bad things about using FSRs for surface pressure:

| Advantage | Description |

|---|---|

| Sensitivity | FSRs can notice small pressure changes very well. |

| Flexibility | They can bend and stretch, so they work in things you wear. |

| Cost-Effectiveness | FSRs cost less than other sensors, so more people can buy them. |

| Low Power | They use less than 20mA, so they are good for battery devices. |

| Versatility | FSRs work in many things because they are thin and bendy. |

| Disadvantage | Description |

|---|---|

| Precision | FSRs might not always give the same results if pressure changes. |

| Signal Drift | The output can change even if the force does not. |

| Temperature Sensitivity | FSRs can change if it gets hotter or colder, which can affect accuracy. |

FSRs give fast feedback when force changes. Their bendy shape lets engineers put them in small spaces. People use FSRs in shoes to check how people walk. Hospitals use them in beds to watch how patients move. Car makers use FSRs in seats to make them safer and more comfy.

FSRs do not always give the same number if pressure changes slowly. The signal can drift, so the output may change even if the force stays the same. If the room gets hotter or colder, the sensor reading can also change.

Note: People should test FSRs in their own setup before using them for important jobs. Calibration makes the readings better.

FSRs are best when you just need to know if force is there or if it changes. They are not the best for jobs that need very exact pressure numbers. For most projects, FSRs are a simple and cheap way to measure force.

FSRs help students learn about sensors. They let engineers make new things. Their good points make them popular in many areas. Knowing what they cannot do helps people get the best results.

Measuring Surface Pressure with FSRs

Pressure Calculation

Surface pressure tells us how much force is on an area. There is a simple formula for this. Pressure equals force divided by area. If the area gets smaller, pressure goes up. If the area gets bigger, pressure goes down.

People use different units to measure surface pressure. Some of these are:

- Pascal (Pa): One newton for each square meter.

- Atmosphere (atm): This is air pressure at sea level.

- Millimeter of Mercury (mmHg): Used in barometers.

- Inches of Mercury (inHg): Used in weather reports.

- Bar (bar): This is 100,000 pascals.

- Millibar (mbar): Used in weather science.

- Torr (Torr): About 1 out of 760 of an atmosphere.

- Pound-Force per Square Inch (psi): Used in engineering.

- Megapascal (MPa): Used for very high pressures.

- Kilopound-Force per Square Inch (ksi): Used in testing materials.

- Barye (Ba): One dyne for each square centimeter.

- Technical Atmosphere (at): Used in engineering.

Scientists use the Pascal most of the time. Other units are used for special jobs.

FSR Reading Interpretation

A force-sensing resistor helps people find force on a surface. To get surface pressure, people do these steps:

- Check the sensor with nothing on it. This is the starting point.

- Put a weight or force you know on the sensor. Write down what it shows.

- Try another known force to make sure it is right.

- Find the pressure by dividing the force by the area.

A force-sensitive resistor checks changes in resistance. The sensor gives a signal that matches the force. If you know the area, you can find the surface pressure. Engineers use these sensors in labs and factories. They check pressure on many surfaces.

Tip: Always use the same area when you compare pressure. This makes your results fair and easy to understand.

Factors Affecting Accuracy

Many things can change how well a force-sensing resistor works. Some common problems are:

- Hysteresis: The sensor may act different if force goes up or down.

- Temperature Effects: Hot or cold can change the sensor’s reading.

- Calibration Issues: Sensors need checks to stay correct.

- Zero Drift: The reading can change slowly even with no force.

- Moisture Ingress: Water can mess up the readings.

- Overload: Too much force can break the sensor.

Other things can also change accuracy:

- Temperature

- Humidity

- How thick the material is over the sensor

- How big the contact area is

- If the surface is curved

- How soft the tissue is

Researchers found that heat, shape, and softness can change the sensor’s reading. People should check the sensor often. Signal conditioning can help fix drift and hysteresis. Some experts use math formulas to match force to voltage. They also use old readings to fix mistakes.

Note: Checking the sensor often and setting it up right helps keep readings correct.

Setup and Calibration

Required Materials

Before you start, get these things ready:

- SOUSHINE force-sensing resistor

- Fixed resistor (10kΩ is common)

- Breadboard and jumper wires

- Microcontroller (like Arduino)

- USB cable for programming

- Small weights (10g, 20g, 50g, 100g)

- Ruler or caliper (to measure sensor area)

- Computer with Arduino IDE

Tip: Wash your hands and use a flat table. This keeps the sensor safe and your readings steady.

Circuit Assembly

Wiring

Follow these steps to connect the sensor:

- Put the force sensitive resistor on the breadboard.

- Connect one end of the sensor to the 5V pin.

- Attach the other end to one side of the fixed resistor.

- Connect the other side of the resistor to ground (GND).

- Link the spot between the sensor and resistor to an analog input pin.

This setup makes a voltage divider. The microcontroller checks the voltage. The voltage changes when the sensor’s resistance changes with force.

Microcontroller Use

The microcontroller looks at the voltage on the analog pin. It turns this voltage into a digital number. This number changes when you press on the sensor. The Arduino IDE shows these numbers on your computer.

// Simple Arduino code to read FSR value

int fsrPin = A0;

int fsrReading = 0;

void setup() {

Serial.begin(9600);

}

void loop() {

fsrReading = analogRead(fsrPin);

Serial.println(fsrReading);

delay(500);

}

Calibration Steps

Calibration Curve

Calibration helps match sensor numbers to real forces. Do these steps:

- Lay the sensor flat on the table.

- Connect it to the Arduino with the voltage divider.

- Write down the reading with no weight. This is your starting point.

- Save this number for later.

- Put a known weight on the sensor. Wait for the number to stop changing.

- Write down the new number.

- Do this again with other weights (10g, 20g, 50g, 100g).

- Take a few readings for each weight and find the average.

- Make a graph with averages on one side and weights on the other. This is your calibration curve.

Using Weights

Known weights help you make the calibration curve. Put each weight on the sensor, write down the number, and repeat. Use the graph to find the force for any sensor number.

Note: Calibration mistakes can happen. Hysteresis, non-linearity, and drift can change results. Temperature and humidity can also affect readings. Check the sensor often and recalibrate if you need to.

Measurement and Data

Taking Readings

People use SOUSHINE force sensors to collect data about how much force presses on a surface. They place the sensor flat and make sure nothing blocks it. They connect the sensor to a microcontroller. The microcontroller reads the sensor’s output. Each time someone presses on the sensor, the microcontroller shows a number. This number changes when the force changes. People can press with a finger, use a weight, or test with other objects. They wait for the reading to settle before writing it down.

Tip: Always use the same spot on the sensor for each test. This keeps the readings steady.

Data Recording

Recording data helps people track changes and compare results. They write down the sensor reading, the weight used, and the time. Some people use a notebook. Others use a computer spreadsheet. They make a table like this:

| Test Number | Weight Used (g) | Sensor Reading | Time (s) |

|---|---|---|---|

| 1 | 10 | 120 | 0 |

| 2 | 20 | 250 | 10 |

| 3 | 50 | 480 | 20 |

| 4 | 100 | 900 | 30 |

People check the table for mistakes. They repeat tests if numbers look odd. They keep the sensor clean and dry during tests.

Calculating Surface Pressure

People use the data to find surface pressure. They know the force from the weight. They measure the area of the sensor. The formula is:

Pressure = Force ÷ Area

They use newtons for force and square meters for area. For example, if the weight is 0.1 newton and the area is 0.01 square meter, the pressure is 10 pascals. They write down the pressure for each test. They compare results to see how pressure changes with different weights.

People use force sensors in science labs, factories, and schools. They learn how objects press on surfaces. They use the results to solve problems and improve designs.

Note: Always check the units before calculating. Using the wrong units can give wrong answers.

Tips and Troubleshooting

Consistent Contact

Keeping the force-sensing resistor touching the surface helps make measurements better. When the polymer inside the sensor gets pressed, resistance goes down. Adding force slowly makes the polymer surface flatter. This creates more paths for electricity to move. More paths let more current flow and give clearer readings.

Electrodes that are not lined up help stop polymer creep. This keeps the sensor working well for a long time. Picking the right voltage helps stop drift. A steady voltage makes the sensor work better and gives more accurate results.

Tip: Put the sensor flat on the surface. Press down slowly and evenly. This helps the sensor work in a steady way.

Common Mistakes

Sometimes people use force-sensing resistors the wrong way. These mistakes can make the data less helpful. Here are some things people do wrong:

- Using the sensor on a bumpy or dirty surface.

- Pressing too fast or not evenly.

- Not calibrating before starting.

- Using weights that are too heavy for the sensor.

- Not thinking about temperature or humidity changes.

| Mistake | Impact on Measurement |

|---|---|

| Uneven force | Readings jump around |

| Dirty surface | Resistance goes up |

| No calibration | Results are not correct |

| Overloading | Sensor can break |

| Ignoring environment | Signal can change |

Check the sensor before you use it. Clean the surface and make sure the sensor is flat. Take time to calibrate and use weights that are safe for the sensor.

Sensor Care

Taking care of SOUSHINE force-sensing resistors helps them last longer. Good heat control stops the sensor from burning. Keeping the sensor dry and clean helps it work well. Do not use too much force on the sensor.

- Keep the sensor away from water and dirt.

- Store the sensor in a cool, dry spot.

- Do not bend or twist the sensor a lot.

- Clean the sensor gently if you need to.

Note: Check the sensor often to find problems early. Get a new sensor if you see damage or wear.

Looking after the sensor helps you get good measurements for a long time. People who follow these steps get better results and avoid problems.

Fixing Issues

When a force-sensing resistor (FSR) does not work as expected, users can follow a few steps to find and solve the problem. Many issues have simple solutions. The following list shows common problems and how to fix them:

- Check for Moisture

FSRs react to moisture. Water or humidity can cause the sensor to give wrong readings. Users should keep the sensor dry. If the sensor gets wet, they should let it dry before testing again. - Inspect the Circuit

The resistor in the voltage divider affects the sensor’s output. A resistor value higher than 20k ohms can cause problems. Users should use a resistor with a value less than 20k ohms. This helps the sensor give steady readings. - Review the Code

Sometimes, the way the code averages sensor readings can cause bias. Users should check the code to make sure it collects enough samples and averages them correctly. If the code uses only one reading, the result may jump around. Using several readings and finding the average gives a more stable result. - Look for Loose Connections

Wires that are not connected well can cause the sensor to work poorly. Users should check all wires and make sure they fit tightly in the breadboard or connectors. - Test with Known Weights

Users can place known weights on the sensor to see if the readings match expected values. If the numbers do not match, the sensor may need calibration. - Check for Sensor Damage

Bending, twisting, or pressing too hard can damage the FSR. Users should look for cracks or changes in the sensor’s shape. If the sensor looks damaged, it may need to be replaced. - Control the Environment

Temperature changes can affect the sensor. Users should try to keep the sensor in a room with a steady temperature. If the room is too hot or cold, the readings may change.

Tip: Users should keep a log of changes they make during troubleshooting. This helps them see what works and what does not.

If the sensor still gives odd readings after these steps, users can try a new sensor. Sometimes, sensors wear out after many uses. Keeping the sensor clean, dry, and safe from too much force helps it last longer.

A table can help users track problems and solutions:

| Problem | Possible Cause | Solution |

|---|---|---|

| Unstable readings | Moisture, loose wires | Dry sensor, check connections |

| Low sensitivity | Wrong resistor value | Use resistor < 20k ohms |

| Readings jump around | Code issue | Average more samples |

| No response | Sensor damage | Replace sensor |

By following these steps, users can solve most problems with SOUSHINE FSRs. Careful checks and small changes often fix the issue.

Measuring surface pressure with SOUSHINE force-sensing resistors is easy. Users can collect data that helps them learn. Beginners should know these important things:

| Key Feature | Description |

|---|---|

| Sensitivity | Finds small pressure changes for better results. |

| Durability | Works well in many places and lasts a long time. |

| Range of Forces | Measures still and moving forces for lots of jobs. |

Anyone can set up, test, and write down data with simple tools. Many people use these sensors in science, engineering, and health care. People who want to know more can try harder projects:

| Application Type | Description |

|---|---|

| Hydraulic System Monitoring | Checks fluid pressure to keep things safe. |

| Regulation of Gas and Liquid Processes | Controls flow and keeps products good. |

| Applications under High Pressure | Watches pressure in tough places. |

| Uses in Medicine | Measures blood pressure and oxygen. |

| Applications in Aerospace and Aviation | Checks air and fluid systems to keep people safe. |

Trying SOUSHINE FSRs helps users learn about pressure and make their projects better.

FAQ

What is a force-sensing resistor (FSR)?

A force-sensing resistor is a sensor that changes how much electricity can pass through it when you press on it. People use FSRs to find out how much force or pressure is on a surface.

How does SOUSHINE’s FSR measure surface pressure?

SOUSHINE’s FSR notices when its resistance changes if you push on it. You connect the sensor to a circuit. The sensor gives a number that helps you figure out surface pressure. You use the formula: pressure is force divided by area.

Can students use SOUSHINE FSRs for school projects?

Students can use SOUSHINE FSRs in science and engineering projects. These sensors are simple to set up. You only need basic tools like Arduino boards.

What materials do users need to measure pressure with an FSR?

You need a SOUSHINE FSR, a fixed resistor, a breadboard, jumper wires, a microcontroller, weights, and a ruler. These things help you build the circuit and collect your data.

How do users keep SOUSHINE FSRs working well?

Keep the sensor dry and clean. Do not bend or twist the sensor. Store it in a cool, dry place so it lasts longer.

What should users do if the sensor gives odd readings?

Check for water, loose wires, and the right resistor value. Test the sensor with weights you know. Look at your code. If the sensor is broken, get a new one.

Can SOUSHINE FSRs measure very small forces?

SOUSHINE FSRs can notice small changes in force. Calibrate the sensor carefully to get good results for light touches or gentle pressure.