Call us: +86-137-2353-4866

Choosing the right pressure sensor is crucial for obtaining accurate readings. A poor selection can lead to increased costs and potential system failures. It’s essential to consider the total cost of ownership to avoid complications. Mismatched pressure ranges can result in missed critical output signals. Each application requires specific features from pressure sensor sensors. For instance, food and beverage industries need sensors that are easy to clean, while laboratory equipment demands highly accurate sensors. SOUSHINE’s force sensing resistors leverage advanced technology to provide precise force sensing capabilities tailored to your requirements and designed for longevity.

| Feature | Description |

|---|---|

| Advanced Technology | Delivers precise and consistent force sensing for pressure measurement |

| Customization | Engineered to meet your specific pressure needs |

| Durable Materials | Performs reliably in challenging environments and maintains strength over time |

Utilizing tips and checklists can assist you in selecting the ideal sensor. Trust reputable brands like SOUSHINE for high-quality pressure sensor solutions.

Table of Contents

Key Takeaways

- Pick the right pressure sensor for good readings. This helps you avoid expensive problems with your system.

- Always check if the sensor works with your media. This stops damage and wrong readings.

- Choose the correct pressure range for your sensor. This keeps the sensor from breaking or missing data.

- Think about things like temperature and humidity. These can change how the sensor works.

- Make sure the sensor’s accuracy and speed fit your needs.

- Choose the right output signal type for your system. You can pick analog or digital.

- Plan to take care of your sensors often. This helps them last longer.

- Ask trusted suppliers like SOUSHINE for good sensors and help.

Common Mistakes in Pressure Sensor Sensors Selection

Media Compatibility Issues

Effects of Incorrect Material Choice

When picking pressure sensor sensors, you need to think about media compatibility. If you pick the wrong material, the sensor might break fast. Some materials can react with what you are measuring. Water, oil, or chemicals can cause rust or harm. This can make the sensor give wrong readings and need to be replaced often. You might have more system downtime and pay more for repairs. Picking the wrong sensor can also hurt the work area.

How to Ensure Compatibility

You can stop media compatibility problems by checking the sensor’s details. Find sensors made for what you are measuring. Look at the different types of pressure sensors and match them to your job. Ask the supplier if the sensor can handle chemicals, water, or other things. SOUSHINE Force Sensing Resistors have choices for many types of media. They can be changed to fit your work area. Always check if the sensor works with your media before you use it.

Pressure Range Misjudgment

Over/Under Sizing Risks

Picking the wrong measuring range for pressure sensors can cause trouble. If you pick a range that is too low, the sensor can break. Too much pressure can damage the sensor or mess up its settings. You might get wrong readings or the sensor might stop working. If you pick a range that is too high, the sensor might miss small changes. This makes the measurements less accurate.

- Sensor breaks from too much pressure

- Settings change after overload

- Zero and span errors happen

- Electrical parts can get damaged

- Safety problems in important jobs

Determining the Right Range

You need to know the pressure types and ranges in your job. Start by finding the highest and lowest pressure you will see. Pick pressure sensor sensors that cover these numbers. Think about the work area and any sudden pressure jumps. Choose a sensor with a good turndown ratio. Check the sensor often to keep it working right. SOUSHINE FSRs can be made to fit your needs and work well with many pressure types and ranges.

| Feature | SOUSHINE FSRs | Traditional Pressure Sensors |

|---|---|---|

| Customizable Shapes and Sizes | Yes | Limited |

| Durability and Reliability | High | Varies |

| Low Power Consumption | Yes | Often higher |

| Ease of Integration | Simple | May require complex setup |

Environmental Factors Overlooked

Temperature and Humidity Impacts

The work area can change how pressure sensor sensors work. High heat can change the sensor’s range. Wet air can cause rust or electric problems. You need to check the sensor’s limits for heat and wetness. If you forget these things, you might get wrong readings and more sensor failures.

Vibration and Harsh Conditions

Shaking and tough places can hurt pressure sensors. Parts can wear out and cause mistakes in measuring. Pick sensors made for hard places. Check and fix them often to stop problems. SOUSHINE FSRs are strong and last long, so they work well in many places. Always think about where you will use the sensor before you pick one.

Tip: Always check the measuring range, media compatibility, and work area before you buy pressure sensor sensors. This helps you avoid mistakes and get the right readings.

Accuracy and Response Time Neglected

Application-Specific Accuracy

You need to match the sensor’s accuracy to your job. If you ignore this, your system can have problems. In labs or clean rooms, small mistakes let in dust or germs. Some places need very exact pressure control. Sometimes, you need accuracy as close as 0.01 to 0.15 inches of water. If you do not meet these numbers, you can have safety issues or bad results.

- Wrong pressure can let in dirt or germs.

- Small mistakes can cause big trouble in sensitive places.

- Not meeting accuracy rules can cause danger or system failure.

Always check the sensor’s accuracy and resolution. Make sure it matches what you need before you use it. SOUSHINE FSRs give high accuracy and resolution for many jobs. This helps keep your system safe and working well.

Response Time Needs

Response time shows how fast the sensor reacts to pressure changes. Some jobs need sensors that react right away. If the sensor is slow, you can miss quick changes. This can cause problems in fast systems. For example, in robots or machines, a slow sensor can cause mistakes or delays.

Always match the sensor’s response time to your needs. Check the sensor’s data sheet for this info. Pick a sensor that works with your system speed. SOUSHINE FSRs react fast, so they work well for quick jobs.

Output Signal Selection Errors

Analog vs. Digital Outputs

You need to pick the right output signal for your system. Some sensors give analog signals, others give digital signals. Analog outputs show a range of values, which helps when you need fine detail. Digital outputs give clear on/off or step values. If you pick the wrong one, you might not get the data you want.

- Analog outputs are good for systems needing fine detail.

- Digital outputs work well for simple or direct control.

Always check what your system needs before you choose. SOUSHINE FSRs can use both types, so you can match them to your setup.

Communication Protocols

You also need to think about how the sensor connects to your system. Some sensors use simple wires, others use special protocols like I2C or SPI. If you pick the wrong protocol, your sensor may not work with your controller. Many people make mistakes by mixing up gauge and absolute pressure, not thinking about the environment, or putting sensors in the wrong place. These mistakes can cause bad readings and make the sensor wear out faster.

- Mixing up gauge and absolute pressure can cause big mistakes.

- Not thinking about heat or wetness can hurt sensor performance.

- Putting the sensor in the wrong place can give wrong readings.

Always check your system’s needs and match the sensor’s protocol and placement.

Mounting and Size Constraints Ignored

Installation Challenges

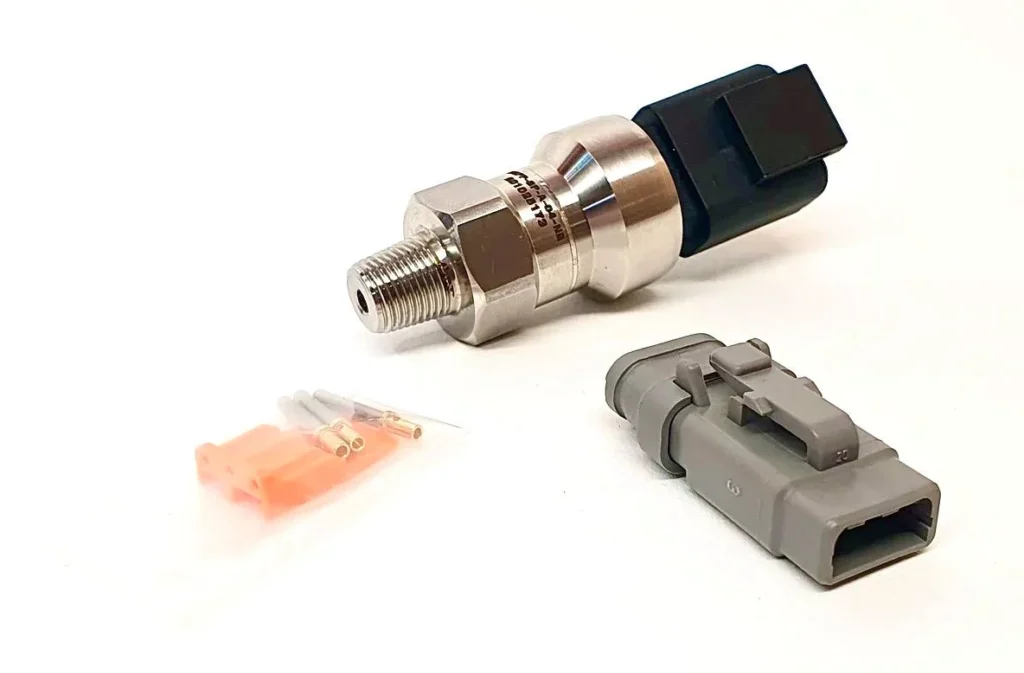

You must plan how to put in the sensor. Some sensors need special mounts or tools. If you do not plan, you might have delays or extra costs. You should check the sensor’s size and shape before you buy. Make sure you have enough space and the right tools to install it. SOUSHINE FSRs come in many shapes and sizes, so you can find one that fits your setup.

Space Limitations

Space can limit your sensor choice. Some systems have very little room for new parts. If you pick a sensor that is too big, it will not fit. Always measure your space before you choose. Look for sensors that are small and easy to fit. SOUSHINE FSRs have flexible options for tight spaces, so they are easy to use in many designs.

Tip: Always check the accuracy, resolution, response time, output type, and size before you pick a pressure sensor. This helps you avoid mistakes and keeps your system working well.

Certification and Safety Standards Missed

Compliance Requirements

You have to make sure your pressure sensor has the right certifications. Every industry has rules to keep people and machines safe. If you skip this, you might use sensors that break safety laws. Medical sensors must follow ISO 13485. This rule keeps patients safe. Car sensors need ISO/TS 16949. This rule checks for good quality and safety. Always match your sensor to these rules before you use it.

| Industry | Certification Standard | Requirements |

|---|---|---|

| Automotive | ISO/TS 16949 | Quality management for design, production, and service of automotive products |

| Medical | ISO 13485 | Quality management to ensure medical devices meet safety and regulatory requirements |

Importance of Certifications

Certifications show your pressure sensor is safe and legal. Using certified sensors keeps your team and customers safe. You also avoid fines and system problems. Always ask your supplier for proof of certification. Keep these papers for checks or audits. Certified sensors help you earn trust and keep your business running well.

Tip: Always look for ISO and other needed certifications before buying a pressure sensor. This helps you stay out of legal trouble and keeps your system safe.

Reliability and Maintenance Overlooked

Maintenance Planning

You need a plan to keep your pressure sensors working well. If you forget, sensors can break and stop your system. Most sensors need checks every six months or every year. Clean, test, and change sensors when needed. Regular checks help you find problems early. This keeps your system running and saves money.

- Differential pressure sensors need checks every six months to a year.

- Some jobs need more checks, depending on the place.

- Cleaning and testing sensors stops mistakes and failures.

Long-Term Reliability

Pressure sensors last longer if you take care of them. Most industrial gauges work for five to seven years. Heavy-duty gauges can last up to ten years or more. Pick sensors that fit your job and work area. Good sensors give steady readings and fewer problems. SOUSHINE Force Sensing Resistors are strong and last a long time. You get good data and less downtime with the right sensor.

| Type of Gauge | Average Lifespan |

|---|---|

| Standard Industrial Gauges | 5 to 7 years |

| Heavy-Duty Gauges | Up to 10 years or more |

Note: Doing regular checks and picking the right sensor helps you avoid big repair bills and keeps your pressure system working well.

Supplier and Brand Evaluation Skipped

Choosing Trusted Brands Like SOUSHINE

You should pick a supplier you trust. Some people skip this and get bad sensors. Look for brands that follow the rules and show proof. SOUSHINE is a trusted brand for pressure sensing. Their Force Sensing Resistors meet strict rules and work in many jobs. You get sensors you can trust and good help from SOUSHINE.

| Criteria | Description |

|---|---|

| Industry Standards | Sensors must meet IECEx, ATEX, or other certifications |

| Quality Verification | Ask for sample testing and check delivery rates |

| Response Time | Pick suppliers who answer questions quickly |

| Certifications | Check for ISO compliance and quality control |

| Customization | Choose suppliers who offer design changes and custom options |

| Production Capacity | Look at factory size, staff, and yearly output |

Support and Warranty Considerations

You should check what help and warranty your supplier gives. Good help lets you fix problems fast. A strong warranty protects your money. SOUSHINE gives you tech help and clear warranty rules. You can ask questions and get help when you need it. This help keeps your system running and fixes problems quickly.

Tip: Always ask about help and warranty before you buy a pressure sensor. Trusted brands like SOUSHINE give you peace of mind and help you keep your system working.

Selecting the Right Pressure Sensor for Applications

Define Application Requirements

You need to know what your application needs. Every job is different. Ask yourself what you want the sensor to do. Think about what you will measure, like water, oil, or air. Check if the sensor will be in a hot, wet, or shaky place. Find out the pressure range you need. Decide if you want gauge, absolute, or differential pressure. Set how exact you need the readings to be. Some jobs need very exact numbers. Others can use less exact ones. Think about how fast the sensor should react. Pick the output signal that works with your system. Choose connectors and wires that fit your setup. Plan how you will put the sensor in place. Make sure it fits in your space. Set your budget. Try to balance cost with how well the sensor works and how long it lasts. Think about how you will check and fix the sensor. Pick sensors that are easy to test and repair. Always choose based on your job to get the best results.

Steps to define application requirements:

- Find the pressure range for your job.

- Decide what kind of pressure you need to measure.

- Set how exact you want the readings.

- Check the work area for heat, wetness, or shaking.

- Think about how fast the sensor should react.

- Pick the output signal type.

- Choose connectors and wires that fit.

- Plan how to install the sensor.

- Look at the cost.

- Think about checking and fixing the sensor.

- Pick trusted brands.

- Make sure the sensor meets the rules.

Create a Feature Checklist

A checklist helps you compare sensors for different jobs. You can use a table to list the main features. This makes it easy to see which sensor is best for you. For factories, look at pressure range, accuracy, speed, stability, output signal, and ratings for tough places. Each job might need special features. Chemical plants need sensors that do not rust. Food and medicine jobs need sensors that are easy to clean. Oil and gas jobs need sensors that work in hard places.

| Parameter | Description |

|---|---|

| Pressure Range | From low vacuum to ultra-high pressures |

| Accuracy | From ±0.1% to ±1.0% of full scale |

| Response Time | Fast response for dynamic systems |

| Stability and Repeatability | Consistent long-term performance |

| Signal Output | 4–20 mA, 0–10V, RS485, I²C, CAN |

| Environmental Ratings | IP65–IP68, ATEX/IECEx for harsh environments |

Use this checklist for every job. This helps you remember all the important features.

Compare Pressure Sensor Specifications

You need to look at sensor details before you pick one. Check how exact it is, the range, and how strong it is. Top brands have sensors for many jobs. Microsensor gives very exact and steady readings. SICK is good for making things and moving goods. Yokogawa has sensors for oil, gas, and medicine. Rosemount is known for being exact and having smart features. Ifm makes sensors that last a long time. SOUSHINE Force Sensing Resistors are good because they work in many jobs and last a long time.

| Brand | Accuracy | Range | Durability |

|---|---|---|---|

| Microsensor | High accuracy | Industrial applications | Reliable and cost-effective |

| SICK | Precise | Wide range | Robust performance |

| Yokogawa | High-quality | Oil, gas, pharma | Trusted provider |

| Rosemount | Accurate | Critical applications | Durable features |

| Ifm | Reliable | Electronic switches | Long service life |

| SOUSHINE | Precise, versatile | Customizable for many applications | Long operational life |

When you compare these details, you can see which sensor fits your job. This helps you pick the best sensor for your system.

Tip: Always match the sensor features to your job. Use a checklist and compare details to avoid mistakes.

Consult Manufacturers and Experts

It is smart to talk to manufacturers and experts first. These people know a lot about pressure sensors. They can help you pick the right sensor for your job. You can ask them about how accurate the sensor is. You can also ask if it gives the same results every time. They will tell you how each sensor reacts to pressure changes. You will find out which sensor works best for your system.

Manufacturers know how things like heat and wetness affect sensors. Rust, big temperature changes, and humidity can change how a sensor works. Experts can tell you which sensor lasts longer in tough places. They know which materials work with water, oil, or chemicals. Picking the right sensor saves you time and money.

When you talk to manufacturers, you get answers to your questions. You can ask about how to put in the sensor. You can also ask how to take care of it. They will show you how to set up the sensor and keep it working. You can ask about safety rules and certifications. This helps you follow the rules and keep your system safe.

Industry experts share tips from real jobs. They know what works and what does not work. You can learn from their experience and avoid mistakes. They can help you compare different pressure sensors. You can pick the best one for your job.

Tip: Bring details about your job when you talk to manufacturers or experts. This helps them give you good advice.

Here are some reasons to talk to manufacturers and experts:

- You learn about how accurate and repeatable pressure sensors are.

- You find out how things like rust and heat affect your choice.

- You match sensor features to your work area and save money.

- You get help with putting in and taking care of the sensor.

- You follow safety rules and certifications.

| Benefit | Description |

|---|---|

| Accuracy and Repeatability | Experts explain how sensors measure pressure |

| Environmental Matching | Advice on rust, heat, and wetness |

| Cost and Time Savings | Picking the right sensor stops problems |

| Support and Maintenance | Help with setup and care |

| Safety and Compliance | Help with rules and certifications |

You should always talk to trusted brands like SOUSHINE. Their team can help you pick the right pressure sensor for your job. You get support and answers to your questions. This makes it easier to choose and helps your system work better.

Actionable Advice for Pressure Sensors Selection

Step-by-Step Selection Process

You can use a simple plan to pick the right pressure sensor. This plan helps you avoid mistakes and keeps your system working.

- Check what kind of pressure you need to measure. Decide if you want gauge, absolute, or differential pressure.

- Look at your work area. Check the temperature, humidity, and electrical resistance.

- Make sure the sensor’s details fit your needs. Check if the sensitivity and accuracy are right for your job.

- Choose the best spot for the sensor. Put it where you get good readings.

- Connect the sensor to your system. Use the correct wires and connectors.

- Adjust the sensor so it gives correct readings. Calibrate it before you use it.

- Attach and protect the sensor. Make sure it does not move or get damaged.

- Plan to check the sensor often. Look for wear and make sure it works well.

- Clean the sensor when needed. Remove dust or dirt to keep it working.

- Follow a plan for care. Schedule checks and repairs to help the sensor last longer.

Tip: Always follow each step when you pick and install a pressure sensor. This keeps your system safe and helps you get good readings.

Key Questions Before Purchase

Ask yourself some questions before you buy a pressure sensor. These questions help you follow the right steps and avoid problems.

- What kind of measurement do you need for your job?

- What is the range you need to measure?

- What output signal does your system need?

- Is the sensor good for the medium you will measure?

- How exact do you need the readings to be?

- What things in your work area could change how the sensor works?

- What kind of connection fits your setup?

Use these questions as a checklist. This helps you pick a sensor that works for you.

Preventing Common Pitfalls

You can stop many problems by following some easy steps. Here are ways to avoid mistakes with pressure sensors:

- Handle and install sensors the way the manufacturer says.

- Set up a plan to check and fix sensors often.

- Make sure the sensor fits your work area. Check for heat, wetness, or shaking.

- Adjust sensors to keep readings correct.

- Teach your team how to use and handle pressure sensors safely.

Note: Following these steps helps you avoid big mistakes and keeps your pressure system working well.

Quick Reference Checklist for Pressure Sensor Sensors

Pressure Sensor Selection Checklist

This checklist helps you pick the right pressure sensor. It shows the main steps you should follow. You can use it to avoid mistakes and get good results.

- Decide what you need the sensor to do for your job.

- Find out the pressure range you need. Make sure the sensor can handle sudden spikes.

- Pick the type of pressure you want to measure. Choose from absolute, differential, or gauge.

- Select the output signal that works with your system.

- Decide how much accuracy you need. More accuracy can cost extra money.

- Check if the sensor works with what you are measuring, like water, oil, or air.

- Look at your work area. Think about heat, wetness, and shaking.

- Make sure the sensor fits in your space and is simple to put in.

- Check if the sensor meets safety and certification rules for your job.

- Plan to check and take care of the sensor often.

- Pick a trusted brand that gives help and a good warranty.

Tip: Use this checklist every time you pick a pressure sensor. It helps you remember the steps and makes mistakes less likely.

Summary Table of Features and Mistakes

The table below lists features to check and mistakes to avoid when picking pressure sensors.

| Feature | What to Check | Common Mistake |

|---|---|---|

| Application | Match sensor to job | Ignoring job needs |

| Pressure Range | Cover normal and spike levels | Picking wrong range |

| Pressure Type | Absolute, differential, or gauge | Mixing up types |

| Output Signal | Analog or digital | Wrong signal for system |

| Accuracy | Needed for your job | Overlooking accuracy |

| Media Compatibility | Sensor material matches media | Wrong material choice |

| Environment | Handles heat, humidity, vibration | Not checking environment |

| Size and Mounting | Fits space and setup | Ignoring space limits |

| Certification | Meets safety standards | Missing certifications |

| Maintenance | Easy to check and repair | No maintenance plan |

| Supplier Support | Trusted brand, good warranty | Skipping supplier check |

Note: Look at this table before you buy a pressure sensor. It helps you find problems early and pick the best sensor for your job.

Double-Check Pressure Sensor Choices

Review Requirements

You should check your needs before buying a pressure sensor. This step helps you avoid mistakes and saves money. First, figure out what job the sensor will do. Think about where you will use it. Check if it will get very hot or cold. See if there are any strong chemicals around. Find out if shaking or moving will affect the sensor. Decide what pressure range you need, like psi, bar, or inches of water. Think about how much time you have to set up the sensor. Decide if you want one that is ready to use. Pick the type of pressure you need to measure, like gauge, absolute, or differential. Set how exact you need the readings. Think about how big the sensor can be and how much you can spend.

Checklist for reviewing requirements:

- Figure out what job the sensor will do.

- Think about heat, cold, and strong chemicals.

- Check if shaking or moving is a problem.

- Decide what pressure range you need.

- Think about setup time and if you want a ready-to-use sensor.

- Pick the type of pressure you need to measure.

- Set how exact, big, and costly the sensor can be.

Tip: Going over these points helps you pick the right pressure sensor for your job.

Application Testing

Testing the sensor before using it makes sure it works well. You can try different ways to see if the sensor is good for your job. Static calibration means you connect the sensor to a reader but do not add pressure. You write down what it shows. The number should stay the same. If it changes a lot, the sensor might be bad. Dynamic calibration uses a table that shakes. You put the sensor on it and change how fast it moves. Then you check the sensor’s numbers with another sensor that you know is right. If the numbers do not match, you need to look into it. The comparison method means you test your sensor with one that is already known to be correct. If the numbers are very different, your sensor may not be good. Some sensors can check themselves. You follow steps to see if it works. If it does not work, you need to check more. External testing uses special tools to see if the sensor is right. If it fails, you may need to fix it.

| Testing Method | Description |

|---|---|

| Static Calibration | Connect the sensor to a reader but do not add pressure. Write down the number. If it changes a lot, the sensor may be bad. |

| Dynamic Calibration | Put the sensor on a shaking table. Change how fast it moves. Check the numbers with a good sensor. If they do not match, check more. |

| Comparison Method | Test your sensor with one that is already correct. If the numbers are very different, your sensor may not be good. |

| Self-Calibration | Some sensors can check themselves. Follow the steps. If it does not work, check the sensor more. |

| External Testing | Use special tools to see if the sensor is right. If it fails, you may need to fix it. |

Note: Testing helps you make sure your pressure sensor is right before you use it.

Supplier Consultation

Talking to suppliers like SOUSHINE helps you feel sure about your choice. Their team can help you pick the right sensor. They can also help you put it in and fix problems. You can ask them to make a sensor just for your project. They will help you fix and upgrade your equipment, so it keeps working well.

| Advantage | Description |

|---|---|

| Expert Guidance | Talking to SOUSHINE gives you advice on picking, putting in, and fixing sensors. This helps you avoid mistakes. |

| Custom Solutions | SOUSHINE can make a sensor just for your project. This saves time and makes sure it fits. |

| Ongoing Support | Their team helps you fix and upgrade your equipment, so it works well. |

Tip: Always talk to your supplier before you decide. This step helps you get the best pressure sensor for your job.

Picking the right pressure sensor helps your system work well. It also saves you money and makes things more reliable. If you choose carefully, you can stop shutdowns. Your system will keep running without problems. Here are some steps to follow:

- Find out what type of pressure sensor you need.

- Check the pressure range for your job.

- Look at the conditions where you will use the sensor.

- Think about how long it takes to install.

Cleaning and checking your sensors often helps them last longer. Trusted brands like SOUSHINE can help with your pressure sensor needs.

| Benefit | Description |

|---|---|

| Reliable Monitoring | Stops your system from shutting down |

FAQ

What is a pressure sensor?

A pressure sensor measures the force of a liquid or gas. You use it to get data about pressure changes in your system. This helps you control machines and keep them safe.

How do I choose the right pressure sensor for my job?

First, list your needs. Check the pressure range, type, and environment. Match the sensor to your system. Ask experts or suppliers for advice if you feel unsure.

Why does media compatibility matter?

Some liquids or gases can damage sensors. You need to pick a sensor that works with what you measure. This helps your sensor last longer and gives you better data.

How often should I check or replace my pressure sensor?

You should check your sensor every six months or once a year. Replace it if you see wrong readings or damage. Regular checks help you avoid system problems.

Can I use SOUSHINE FSRs in small spaces?

Yes, you can use SOUSHINE FSRs in tight spaces. They come in many shapes and sizes. You can fit them into small devices or equipment.

What output signals do pressure sensors provide?

Pressure sensors can give analog or digital signals. You pick the type that matches your system. Analog signals show a range. Digital signals give clear steps or on/off data.

Do I need certifications for my pressure sensor?

Yes, you need to check for certifications. Some jobs require sensors to meet safety rules. Always ask your supplier for proof before you buy.

Who can help me if I have questions about pressure sensors?

You can contact your supplier or the manufacturer. Brands like SOUSHINE offer support and advice. They help you pick, install, and care for your sensor.