Call us: +86-137-2353-4866

A force sensor lets you see how much force you use. When you press or push it, the sensor changes its signal. This shows how much pressure you put on it. You can find force sensing technology in many things. These include touchscreens, medical devices, and robots. This tool gives you correct data. Machines and devices use this data to react to what you do.

Table of Contents

Key Takeaways

- A force sensor checks how much you push or pull. It changes this force into an electrical signal.

- Force sensors help many devices work better. They are in touchscreens, medical tools, and robots.

- There are different types of force sensors. Strain gauges and piezoelectric sensors measure force in special ways.

- When picking a force sensor, think about the force range. Also, check its sensitivity and where you will use it.

- Force sensing resistors (FSRs) are bendy and not expensive. This makes them useful for many things.

- You need to calibrate force sensors often. This helps them give correct results and work well.

- Force sensors are very important in healthcare, cars, and robots. They help make things safer and more efficient.

- If you install and care for force sensors the right way, they last longer. This also helps them stay accurate.

Force Sensor Basics

What Is a Force Sensor

A force sensor helps you know how much push or pull you use. It is a tool that changes pressing or squeezing into an electrical signal. By international rules, a force sensor is a transducer. It takes weight, tension, compression, or pressure and makes an electrical signal. This signal lets machines and computers read the amount of force. You can see and record this force easily.

Many force sensors use materials that react when pressed. For example, force-sensing resistors have a film that changes resistance when pressed. The inside material bends when you use force. This changes resistance or capacitance. The force sensor turns this change into an electrical signal. This way, you can measure force fast and correctly.

Tip: You can find force sensors in simple scales and in robots.

What Force Sensors Measure

Force sensors can measure many types of force. Each type tells you something different about how things touch or move. Here is a table that shows what you can measure with force sensors:

| Type of Force | Description |

|---|---|

| Tension | Measures the force that stretches an object. |

| Compression | Measures the force that squeezes or compresses an object. |

| Shear | Measures the force that slides parts of a material past each other. |

| Bending | Measures the force that bends an object. |

| Torque | Measures the force that causes rotation around an axis. |

| Gravitational | Measures the force due to gravity, often called weight. |

When you use a force sensor, you can watch these forces as they happen. This helps you make good choices in engineering, medicine, and robotics.

Common Uses

You can see force sensors in many jobs and products. Here are some ways people use them:

- In cars, force sensors help airbags work and check if a seat is used.

- Construction machines use force sensors to watch loads on cranes.

- Medical robots use force sensors to move carefully during surgery.

- Engineers use force sensors to check bridges and buildings.

- Automation uses force sensors to control machines and measure torque.

You also use force sensors in things at home. Digital scales, game controllers, and touchscreens use force sensors to help you use technology better.

Note: The materials in force sensors like metals, stainless steel, silicon, and composites give each sensor special features. This helps you pick the best sensor for your job, whether you need it strong, sensitive, or flexible.

How Force Sensors Work

Working Principles

You use force sensors to change force into signals. This starts with how force sensors work. When you press, pull, or squeeze, the sensor reacts. It changes its electrical properties. The way force sensors work depends on the technology inside. Some sensors use strain gauges. Others use piezoelectric materials. Some use capacitive sensing.

- Strain gauge sensors find force by stretching or squeezing material. The sensor has a thin wire or foil. This wire changes resistance when you push or pull.

- Piezoelectric sensors use special crystals. When you press these crystals, they make a small charge. You measure this charge to know the force.

- Capacitive sensors work by moving two plates. When you push, the plates get closer or farther apart. This changes the capacitance.

Force sensors help you measure tension, compression, and shear. You use force sensing technology to get quick and correct readings.

Mechanical to Electrical Signal

You start with pressing or pulling. The sensor feels this force and makes an electrical signal. This is the main idea of force sensors. For example, force-sensing resistors change resistance when pressed. Strain gauges bend under force and change resistance. Piezoelectric sensors make voltage when you press them.

When you use a force sensor, you see how force turns into a signal that machines can read.

Here is a simple table that shows how sensor types change force:

| Sensor Type | How It Converts Force | Signal Produced |

|---|---|---|

| Strain Gauge | Material stretches or squeezes | Change in resistance |

| Piezoelectric | Crystal makes charge when pressed | Voltage |

| Capacitive | Plates move and change capacitance | Change in capacitance |

| Force Sensing Resistor | Material changes when pressed | Change in resistance |

Signal Processing

After the sensor makes a signal, you need to process it. Signal processing helps computers and machines use the data. Circuits make the signal stronger, cleaner, and ready to use. For example, a strain gauge sensor connects to a Wheatstone bridge. This circuit helps you see small resistance changes. Piezoelectric sensors need amplifiers to make the voltage bigger.

You send the signal to a display, controller, or computer. The system uses this data to make choices, control machines, or keep records. Signal processing helps you get good results from your force sensors.

Key Components

Every force sensor has parts that help it work. You find these parts in most force sensing technology:

- Sensing Element: This part reacts to force. It can be a strain gauge, piezoelectric crystal, or special film in a force-sensing resistor.

- Substrate: The base holds the sensing element. Flexible bases let you use sensors in many shapes and sizes.

- Electrical Contacts: These connect the sensor to circuits. They carry the signal from the sensing element.

- Signal Conditioning Circuit: This part works on the signal. It makes the signal stronger, cleaner, and ready to use.

- Protective Layer: Many sensors have a cover. This keeps them safe from dust, water, or damage.

Tip: When you pick a force sensor, check the parts to make sure it fits your needs. The right parts help you get the best results.

You see that how force sensors work and their mechanics help you get correct force measurements. You can use these sensors in many areas, like robots and healthcare, because they turn force into useful data.

Types of Force Sensors

Strain Gauge Sensors

Strain gauge sensors help you measure stretching or squeezing. They use a thin wire or foil. This wire changes resistance when you push or pull. This is called the piezoresistive effect. When you stretch or squeeze, resistance changes. The change matches how much strain there is.

- How It Works:

The sensor sticks to an object’s surface. When the object bends, the sensor bends too. This makes resistance go up or down. You can measure this change. It shows how much force the object feels. - Where You Use It:

- Factories use these sensors in weighing systems.

- Machines that crush or press use them too.

- Airplanes use them to check wing stress.

- Bridges and buildings use them to watch for damage.

Strain gauge sensors help keep things safe. They give real-time data about stress and force.

Piezoelectric Sensors

Piezoelectric sensors measure force by making an electric signal. When you press or tap, they create a small voltage. Special crystals inside move their charges when you push.

Here is a table that shows how force affects the signal:

| Effect Type | Description | Charge Equation |

|---|---|---|

| Transverse | A force moves charges at a right angle. | Qₓ = dₓyFᵧb/a |

| Longitudinal | The charge matches the force size or shape. | Qₓ = dₓₓFₓn |

| Shear | The force creates a charge at a right angle. | Qₓ = 2dₓₓFₓn |

You use piezoelectric sensors in many places:

- Musical instruments use them to pick up vibrations.

- Cars use them for airbag systems.

- Science labs use them to measure tiny forces.

These sensors react fast. They work well for quick or changing forces.

Capacitive Sensors

Capacitive sensors measure force by checking plate distance. When you press, plates move closer or farther apart. This changes capacitance. You measure this as an electrical signal.

Here is a table that shows strengths and limits:

| Advantages | Limitations |

|---|---|

| High precision on any material | Sensitive to environment changes |

| Immune to outside electric fields | Limited sensing range |

| Great for blocking outside interference | Higher cost |

| Can measure a wide range of forces | May not stay stable for long measurements |

| Easy to set up | |

| Flexible and strong |

You find capacitive sensors in touchscreens and smart devices. Some medical tools use them too. They give very accurate readings. They work well where you need to block outside signals.

Each type of force sensor has special features. You can pick the right sensor by thinking about what you need to measure and where you will use it.

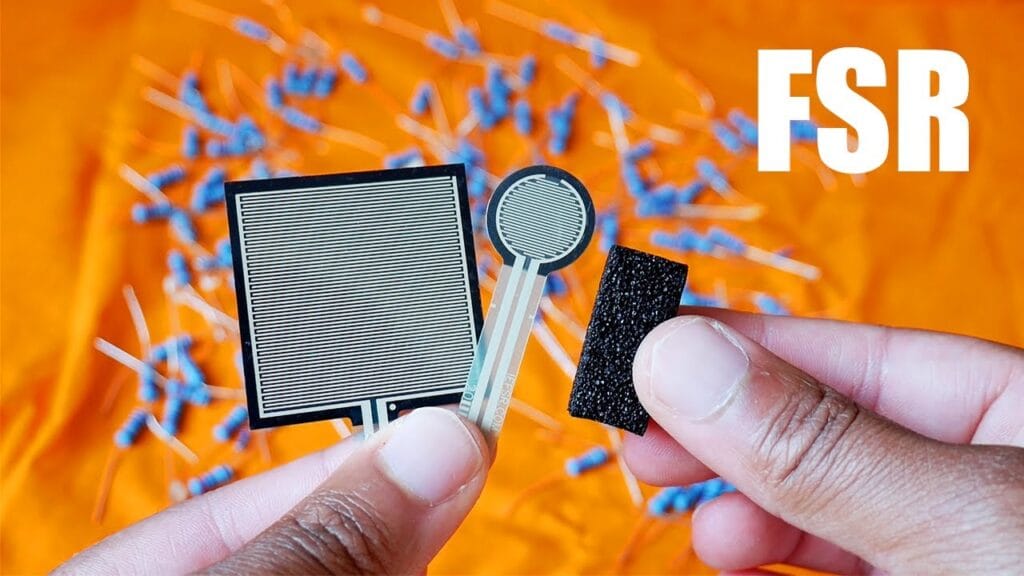

Force Sensing Resistors (FSRs)

SOUSHINE FSR Technology

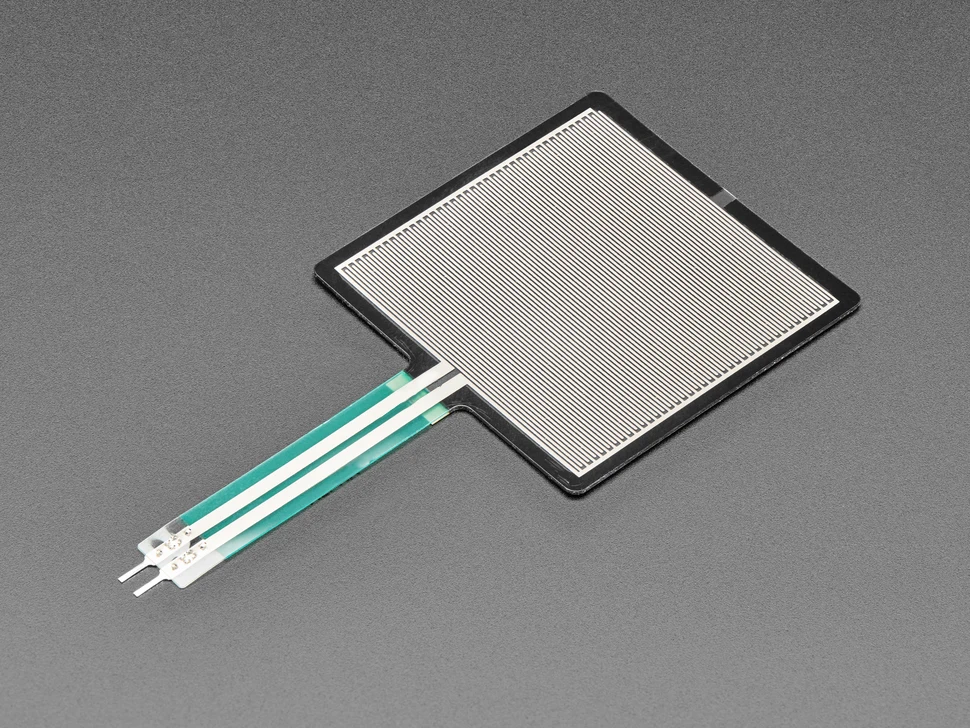

You can use force sensing resistors when you want a flexible way to measure force. SOUSHINE FSRs act like variable resistors. When you press the sensor, resistance goes down. This happens because the sensor has layers with special materials. If you push harder, resistance drops even more. This change helps you see how much force you use.

SOUSHINE makes its FSRs with a bendable base and a special material. This design lets you put the sensor in many shapes and sizes. You can use these sensors where other force sensors may not fit. The thin shape, less than 0.5 mm, makes them easy to add to projects. You can bend or shape them to fit curved things.

SOUSHINE FSRs use carbon-based inks. These inks help the sensor react fast to force changes. You can pick different types, like ShuntMode or ThruMode, for your needs. Each type lets you measure force in a different way. You can choose what works best for your project.

Tip: SOUSHINE FSRs make it easy to turn force into a signal. You can use them in many devices without hard electronics.

FSR Applications

You will find force sensing resistors in many fields. SOUSHINE FSRs help in cars, healthcare, robots, and electronics.

- Automotive: You can use FSRs to check if someone sits in a car seat. They also help airbags by measuring impact force.

- Healthcare: FSRs help you watch patients. You can use them in beds, wheelchairs, or rehab tools to track pressure.

- Robotics: Robots use FSRs to feel touch. This helps them pick up things gently or avoid bumping into stuff.

- Consumer Electronics: You find FSRs in game controllers, touchpads, and smart gadgets. They let you control things with a press.

Here is a table that compares FSRs to other sensors:

| Feature | FSRs | Strain Gauge Force Sensors | Capacitive Sensors |

|---|---|---|---|

| Cost | Low | Medium to High | High |

| Flexibility | Very Flexible | Rigid | Somewhat Flexible |

| Integration | Easy | Moderate | Moderate |

| Sensitivity | Moderate | High | High |

| Thickness | < 0.5 mm | Thicker | Varies |

You can see FSRs are cheap and flexible. They work well in small or curved spaces. You can use them where shock resistance is needed. Other sensors may be more sensitive, but FSRs are easy to add to products.

Note: If you want a thin, bendable, and simple force sensor, a force sensitive resistor from SOUSHINE is a good pick. You can use it in many ways, like in cars or medical tools.

Comparing Force Sensor Types

Sensitivity and Accuracy

You want your force sensors to give correct results every time. Sensitivity means how well a sensor finds small force changes. Accuracy shows if the reading matches the real force. Strain gauge force sensors are very accurate. You can use them for jobs that need exact numbers, like weighing or testing. Piezoelectric sensors react fast to force changes. You use them for quick events, but their accuracy is not always the same. Force sensing resistors are good for many uses and flexible shapes, but their readings can change more than other types.

Things around your sensor can change how well it works. Here are some things that can affect your results:

- Temperature changes can make parts bigger or smaller, causing mistakes.

- Humidity and water can lower resistance, making signals unstable.

- Shaking and bumps can cause noise and wrong readings.

- Electromagnetic waves from other devices can make errors and spikes.

You should always check where you put your sensor to keep your results good.

Durability

You want your force sensors to last a long time. Durability means how well a sensor handles heat, shaking, and rough use. You can see how different force sensors compare in this table:

| Sensor Type | Durability Description | Measurement Accuracy |

|---|---|---|

| Load Cells | Strong, works in tough places | Less than 0.1% mistake |

| Piezoelectric | Works in hot and rough places | ±5% mistake |

| FSRs | Handles heat and shaking | 2% to 10% mistake |

You can use load cells for heavy loads and hard jobs. Piezoelectric sensors work well in hot or shaking places. FSRs handle heat and shaking, so you use them in flexible or portable things.

Most force sensors last many years. In factories, a sensor can work for 25 to 30 years. Some sensors last up to 40 years if you take care of them.

Tip: If you need a sensor for a hard job, check its durability before you buy.

Cost

You want to get good results without spending too much. Some force sensors cost more because they are more accurate or have special features. Strain gauge force sensors and capacitive sensors usually cost more because they need careful setup. Piezoelectric sensors cost a medium amount. Force sensing resistors are cheaper, especially if you need something flexible and easy to use.

Here is a simple list to help you compare prices:

- Strain gauge force sensors: Cost more, best for exact jobs.

- Piezoelectric sensors: Medium price, good for fast force changes.

- FSRs: Lower price, great for flexible and portable designs.

You should think about your budget and what you need to do. If you want a sensor for a simple or flexible project, FSRs are a smart choice.

Note: You can find a force sensor that fits your needs and your money. Always pick the sensor type that matches your job for the best results.

Choosing a Force Sensor

Force Range

You must know how much force your project needs. Pick a sensor that matches the force you want to measure. This helps you get good and steady results. In robotics, you may need to measure soft touches and heavy weights. Some robots move light things. Others lift big parts. Choose a sensor with the right range for your job.

Here is a table to help you pick:

| Factor | Description |

|---|---|

| Force Range and Sensitivity | Pick a sensor that covers the force you expect. It should have enough detail for careful control. |

| Low-range, High-sensitivity | Good for handling gentle objects. |

| Higher Impact or Payload Forces | Needed for robots that lift heavy things. |

If you work with small forces, use a sensor that is very sensitive. It should have a low range. For big jobs, pick a sensor that can handle strong forces. Make sure it will not break.

Sensitivity Needs

Sensitivity shows how well a sensor finds small force changes. Think about what you need for your project. In healthcare, you often need sensors that are very sensitive. Patient monitors must notice tiny pressure changes. Flexible mechanical force sensors work well because they fit the body. They do not bother the patient.

In cars, you need sensors that are tough. They must work even in hard places. You may not need the highest sensitivity. You do need sensors that last and keep working.

- Healthcare tools need high sensitivity for small changes.

- Car systems need sensors that are strong and work under stress.

- Flexible sensors are best for comfort and close contact in medical tools.

Tip: Always match the sensor’s sensitivity to your job. If it is too high or too low, you may get bad results.

Environment

Think about where you will use your force sensor. Different places can change how your sensor works. In factories, you may have wet air, heat, chemicals, or shaking. These things can change how the sensor reads force.

Here is a table that shows what can happen:

| Environmental Condition | Impact on Force Sensor Performance |

|---|---|

| Humidity | Can cause short circuits; needs sensors that keep water out. |

| Temperature Extremes | High heat can melt parts or change the sensor; use sensors made for hot places. |

| Corrosive Environments | Can hurt the sensor; pick sensors that resist rust and damage. |

| Vibration | Can make readings wrong; sensor design should help with shaking. |

| Electromagnetic Interference | Can cause errors; use sensors with good shields. |

| Exposure to Chemicals | Can harm sensors; choose strong materials and good seals. |

Always check the place where you will put your sensor. Pick a sensor that can handle the problems in that spot. This helps your sensor work well and last longer.

Size and Mounting

You need to think about the size and mounting of your force sensor before you start your project. The right size helps you fit the sensor into your device without trouble. Many force sensors come in different shapes and sizes. For example, you can find sensors as small as 0.62 x 0.15 inches or as large as 7.50 x 6.00 inches. Each size supports different load capacities, from just 1 pound up to 7,000 pounds. Most sensors work well in temperatures from -40°F to 140°F, so you can use them in many places.

When you mount a force sensor, you want to make sure it stays safe and works well. You should always apply force straight down on the sensor. Avoid pushing from the side, as this can damage the sensor or give you wrong readings. If you need to bend the sensor, keep the bend gentle. For example, keep the bend radius above 300 mm for the sensor and above 3 mm for the tail. You can use double-sided tape for a quick and easy mount. If your device allows, you can also use screws. Just make sure the screws do not press too hard on the sensor.

Here is a quick look at common mounting options:

- Double-sided tape (thin for sensors, thick for electronics)

- Screw mounting (for devices that accept screws)

- Custom holders or brackets for special shapes

SOUSHINE FSRs give you even more freedom. You can choose the size and shape that fits your project. You can pick round, square, or custom designs. This makes it easy to add the sensor to curved or tight spaces.

Budget

Your budget plays a big role when you pick a force sensor. If you work on a large project or need many sensors, cost matters even more. Many companies look for sensors that give good results without a high price. Force sensing resistors (FSRs) stand out because they use cost-effective materials and simple designs. This keeps the price low while still giving you reliable performance.

Manufacturers often choose FSRs for big projects because they help save money. You can find FSRs that meet quality standards and still fit your budget. Some sensors, like wide-range 6-DoF force torque sensors from China, also offer good prices for businesses that want to keep costs down.

When you plan your project, always balance cost with what you need the sensor to do. If you need high accuracy and special features, you may pay more. If you want a flexible, easy-to-use sensor, FSRs give you a smart and affordable choice.

SOUSHINE Product Selection

You want a sensor that matches your project needs. SOUSHINE FSRs give you many options to get the right fit. You can pick the size, shape, and thickness that work best for your device. You can also choose the force range, output signal, and even the color or artwork for your sensor.

Here is a table to help you see what SOUSHINE FSRs offer:

| Feature | Description |

|---|---|

| Accuracy | High accuracy for precise measurements |

| Durability | Long-lasting materials for extended use |

| Customization | Many options for size, shape, and design |

| Power Consumption | Low power use for better efficiency |

| Integration Ease | Simple to add to many types of devices |

You can also select from different materials and calibration settings. This helps you get the best results for your project. SOUSHINE FSRs work well in many fields, such as automotive, healthcare, robotics, and consumer electronics.

Tip: If you need help choosing the right sensor, you can look at SOUSHINE’s product range. You will find options for almost any application, from small gadgets to large machines.

Applications of Force Sensors

Industrial Automation

Force sensors are very important in factories. They help machines work safely and do their jobs right. You use them to check force during making, putting together, and checking products. In factories, robots, presses, and conveyor belts use force sensors. These sensors help keep products safe and meet rules.

Here is a table that shows how force sensors are used in factories:

| Application Area | Description of Use |

|---|---|

| Automotive Manufacturing | Checks clamp force on joins to keep quality high. |

| Aerospace | Tests loads on parts to make things safer and follow rules. |

| Food Processing | Uses sensors to check weight so food stays the same each time. |

| Medical Devices | Watches force when making devices to keep them precise. |

| Construction | Checks load on buildings to help with safety. |

When you pick a sensor for factory work, look at these things:

- Accuracy: You need exact force readings for good quality.

- Range: The sensor must handle the biggest force in your job.

- Response Time: Fast sensors help you find problems quickly.

- Environment: See if heat or wet air will change how the sensor works.

Tip: The right force sensor in factories makes work safer, faster, and cuts down on waste.

Healthcare Devices

Force sensors are used in many healthcare tools. They help doctors and nurses watch patients and give better care. When you use force sensors at home, it is easier for patients to check their health. This means better care, faster help, and treatment that fits each person.

You can find force sensors in these healthcare tools:

- Infusion pumps: Watch pressure and flow to give medicine safely.

- Dialysis machines: Measure force when cleaning blood.

- Prosthetics: Feel force from the user and help move like a real limb.

- Patient monitoring: Use special insoles to check walking or catheters to watch heart force.

Force sensors in healthcare give you these good things:

- Patients follow their care plans better.

- Doctors can find problems sooner.

- Care is more personal and works better.

Note: Force sensors make healthcare safer and more comfortable for everyone.

Robotics

Force sensors help robots feel touch. Robots need to know how much force they use when picking up or moving things. This helps them hold things gently and not break them. In factories, robots use force sensors to put parts together with the right pressure. In labs, robots use these sensors to learn new ways to work with people and the world.

Here are some ways robots use force sensors:

- Holding things without breaking them.

- Knowing when a robot arm touches something.

- Helping robots walk or stand by measuring ground force.

- Teaching robots to react to changes around them.

Adding force sensors makes robots smarter and safer. This helps them work with people and things in new ways.

Consumer Electronics

You use force sensors in your gadgets every day. Most people do not even notice them. These sensors help your devices react to your touch. Many electronics use force measurement for better features. Phones, tablets, and game controllers all use force sensors. They make your experience more fun and easy.

Touchscreens can feel how hard you press. If you tap softly, your phone might open an app. Pressing harder can show extra choices. This makes your device smarter and easier to use. Game controllers use force sensors too. If you press a button harder, your character can run faster or jump higher. This gives you more control in games.

Wearables like smartwatches and fitness trackers use force sensors. They measure how hard you step or press. This helps you see how active you are each day. Some smart shoes use force sensors to check how you walk or run. This can help you stay healthy and avoid getting hurt.

Here is a table that shows how force is used in electronics:

| Device Type | How Force Is Used |

|---|---|

| Smartphones | Touchscreen pressure, gesture control |

| Game Controllers | Button pressure, trigger sensitivity |

| Smartwatches | Step tracking, touch response |

| Laptops | Touchpad force, keyboard feedback |

| Smart Shoes | Gait analysis, step force measurement |

Laptops also have force sensors. Touchpads let you click or scroll with different pressure. Some keyboards use force to give you feedback when you type. This makes typing easier and more comfortable.

Tip: When you buy a new gadget, check if it uses force measurement. These features can make your device more fun and simple to use.

Force sensors make your electronics smarter and more helpful. You get better control and more cool features. As technology gets better, you will see even more ways force sensors help you every day.

Using and Maintaining Force Sensors

Installation Tips

You want your force sensors to work well from the start. Begin by choosing a clean, flat surface for mounting. Make sure you do not bend or twist the sensor during installation. If you use adhesives, press the sensor gently and evenly. Avoid sharp objects that could damage the sensor. For best results, apply force directly over the sensing area. Do not press on the edges. If you use screws, tighten them just enough to hold the sensor in place. Too much pressure can affect how the sensor reads force.

Tip: Always check the manufacturer’s guide before you install your force sensor. This helps you avoid mistakes and keeps your sensor working longer.

Calibration

You need to calibrate your force sensors to get accurate results. Calibration means you set the sensor to match known force values. Start by placing a known weight or force on the sensor. Record the reading. Repeat this step with different weights. Use these readings to create a simple chart or table. This chart helps you match the sensor output to real force values.

Here is a basic calibration process:

- Place the sensor on a stable surface.

- Apply a known force, such as a weight.

- Record the sensor output.

- Repeat with several different forces.

- Create a table to compare force and output.

| Applied Force (N) | Sensor Output (units) |

|---|---|

| 0 | 0 |

| 5 | 120 |

| 10 | 240 |

| 15 | 360 |

You should recalibrate your force sensors if you move them or use them in a new environment. Regular calibration keeps your measurements correct.

Troubleshooting

Sometimes, your force sensors may not work as expected. If you see strange readings, check the wiring first. Loose wires can cause errors. Make sure the sensor sits flat and does not have any folds or bends. If the sensor gives no output, test it with a known force. If the reading stays at zero, the sensor may need replacement.

Common problems and solutions:

- No reading: Check power and connections.

- Unstable output: Look for loose wires or vibration.

- Wrong force values: Recalibrate the sensor.

- Slow response: Make sure nothing blocks the force from reaching the sensor.

Note: Keep your force sensors clean and dry. Dust or moisture can affect how they measure force.

You can solve most problems by checking installation, calibration, and connections. Good care helps your force sensors last longer and work better.

You now know what a force sensor does and how it works. You also learned about the main types you can use. Force sensors help you measure force in lots of different devices. You can pick the best sensor by thinking about force range, sensitivity, and where you will use it. SOUSHINE FSRs give you choices that are flexible and work well for your projects.

Tip: Look at SOUSHINE’s products or ask an expert to help you find the best sensor for what you need.

FAQ

What is the main job of a force sensor?

You use a force sensor to measure how much push or pull you apply. The sensor changes this force into an electrical signal that machines can read.

Can I use force sensors in wet or hot places?

You can use some force sensors in wet or hot places. Always check the sensor’s rating for temperature and water resistance before you install it.

How do I know which force sensor to choose?

You should look at your project’s needs. Think about force range, sensitivity, size, and budget. SOUSHINE FSRs work well for flexible and cost-effective solutions.

Do force sensors need calibration?

Yes, you need to calibrate force sensors for accurate results. Calibration matches the sensor’s output to known force values.

Where do I see force sensors in daily life?

You find force sensors in digital scales, touchscreens, game controllers, and even car safety systems. Many devices use them to sense pressure or touch.

How long do force sensors last?

Most force sensors last for years if you use them correctly. You should follow care tips and avoid damage for the best results.

Can I cut or shape SOUSHINE FSRs for my project?

Yes, you can customize SOUSHINE FSRs in size and shape. This helps you fit them into many different devices and designs.