Call us: +86-137-2353-4866

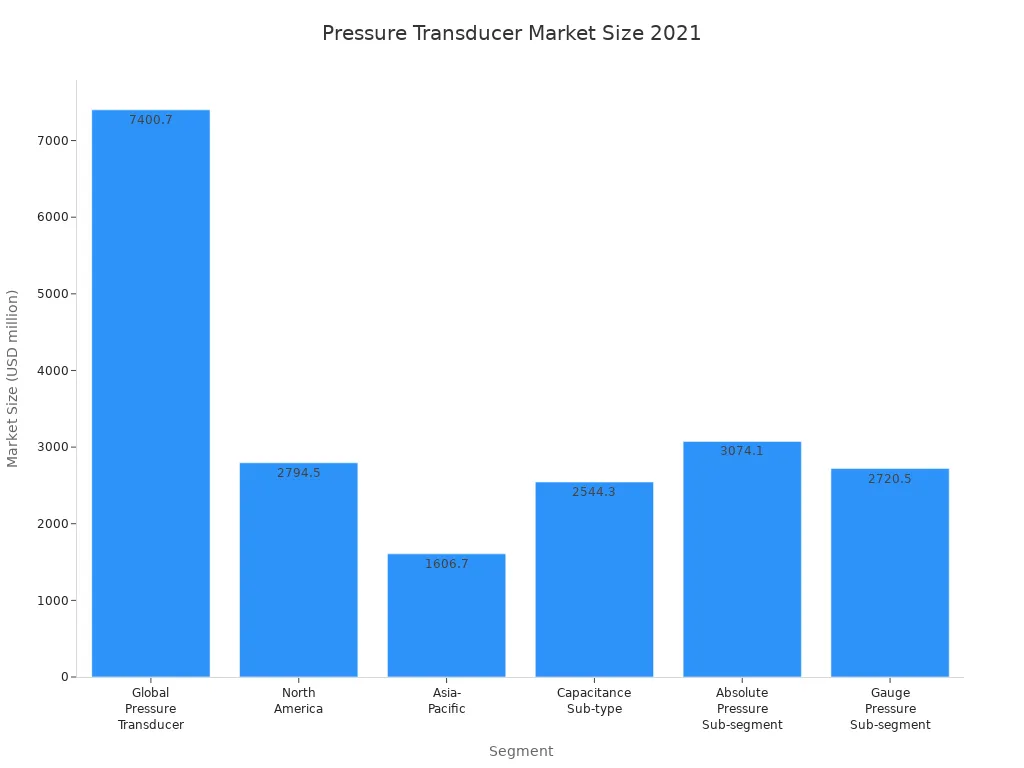

You have many options when you choose pressure transducers or pressure sensors for your project. Each type has good points and some downsides. The best choice depends on what you need. The market for these devices is growing very fast. You can see the numbers in the table below:

| Segment | Market Size (2021) | Projected Size (2030) | CAGR (%) |

|---|---|---|---|

| Global Pressure Transducer | $7,400.7 million | $19,466.1 million | N/A |

| North America | $2,794.5 million | N/A | 10.58% |

| Asia-Pacific | $1,606.7 million | N/A | 12.5% |

| Capacitance Sub-type | $2,544.3 million | $7,088.4 million | N/A |

| Absolute Pressure Sub-segment | $3,074.1 million | $8,313.4 million | N/A |

| Gauge Pressure Sub-segment | $2,720.5 million | $7,479.1 million | N/A |

Picking the right technology changes how well your system works. It also affects how long it lasts and how much you pay. SOUSHINE’s force sensing resistor technology gives a new way to measure force sensing in many areas. You will learn how these choices compare so you can pick the best one for you.

Table of Contents

Key Takeaways

- Pressure transducers change pressure into electrical signals. They are important in many devices like cars and medical tools.

- Picking the right pressure sensor affects how well your system works. It also affects how long it lasts and how much it costs. Think about what you need before you choose.

- Mechanical pressure transducers are tough and give good results. But they might react slower than electronic ones.

- Strain gauge sensors react quickly and are used in medical tools. They might drift over time and may not measure very low pressures.

- Capacitive sensors are sensitive and use little power. They are good for battery-powered devices. But they can cost more and be affected by things around them.

- Piezoelectric sensors are great for measuring fast pressure changes. Their output can be lower and they can be affected by the environment.

- When picking a pressure sensor, think about accuracy, strength, price, and the environment. This helps you find the best one for your needs.

- SOUSHINE’s Force Sensing Resistors (FSRs) bend easily and do not cost much. They work well for many uses. They are a good pick for projects that need fast and accurate force measurements.

Pressure Transducers and Sensors Overview

What Are Pressure Transducers

You use pressure transducers and sensors almost every day. You might not even notice them. These devices help measure force and pressure in many things. When you press a button on your phone, a sensor is working. When you check your car’s tire pressure, you use a sensor too. Pressure transducers turn physical pressure into an electrical signal. They have a sensing part, like a diaphragm, that moves when pressure is there. This movement makes an electrical signal. The signal gets stronger and turns into a number you can read. Pressure sensors work by finding changes in resistance or capacitance. This change becomes an electrical signal. The signal gives you a voltage output to show the pressure.

Tip: Pressure transducers and sensors help machines and devices stay safe and work right.

Pressure Sensor Technologies

There are many types of pressure sensors you can find. Each type uses its own way to measure pressure. Here is a quick look at the main groups:

| Category | Types |

|---|---|

| Type of Technology | Capacitive, Electromagnetic, Optical, Piezoresistive, Resonant Solid-State, Other Sensing Technology |

| Type of Connectivity | Wired Sensors, Wireless Sensors |

| Type of Pressure Range | Up to 100psi, 101 to 1000 psi, Above 1000 psi |

| Type of End User | Automotive, Aviation, Consumer Devices, Manufacturing, Marine, Medical, Oil & Gas, Utilities, Others |

| Type of Sensor | Absolute pressure sensors, Differential pressure sensors, Gauge pressure sensors, Sealed pressure sensors, Vacuum pressure sensors |

Let’s see how some common pressure sensing technologies work:

- Bourdon tube sensors use moving parts to turn pressure into a signal.

- Strain gauge sensors check for resistance changes in a wire when it stretches.

- Capacitive sensors use a diaphragm as part of a capacitor. Pressure changes the space between plates.

- Piezoresistive sensors use a silicon chip with resistors. Pressure changes the resistance.

Each technology has its own way to measure pressure. Some use moving parts. Others use electronic parts.

Why Technology Choice Matters

You want your pressure sensors to work well and last long. The technology you choose affects how your system works, how reliable it is, and what it costs. For example, bonded foil strain gauge sensors work well in high-pressure places and save money. Ceramic diaphragm sensors can handle chemicals and tough places. Silicon sensors give fast and accurate readings. This helps in automation and medical devices. Thin-film sensors fit in small spaces and react quickly.

Picking the right pressure sensor technology gives you the best results. You save time, avoid trouble, and keep costs down. Pressure measurement is important in many industries. Choosing the right sensor helps your system work smoothly.

Mechanical Pressure Transducers

How They Work

Mechanical pressure transducers are used in many places. These devices have moving parts that measure pressure. When the pressure changes, a part like a Bourdon tube or diaphragm moves. This movement connects to a pointer or sensor. The pointer shows the pressure on a dial. Some designs use a potentiometer or strain gauge. These turn the movement into an electrical signal.

Here’s a quick look at common designs:

| Type of Transducer | Description |

|---|---|

| Strain Gauge | Measures small and different pressures. Detects gauge or absolute pressure. |

| Capacitance | Uses diaphragm movement. Works for low vacuum and high pressure. |

| Potentiometric | Changes gauge output to electronic signal. Connects to Bourdon or bellows. |

| Resonant Wire | Makes a wire vibrate at a set speed. Detects low, absolute, and gauge pressures. |

Each type senses pressure in its own way. Some use wires. Some use plates. Some use tubes.

Pros and Cons

Advantages

Mechanical pressure sensors give strong and steady readings. You can use them in tough places. They work for many pressure levels. Many models are very accurate. Bourdon tubes can repeat measurements within 0.1% of the full scale. Their range goes from 10 kPa up to 100 MPa. Diaphragm gauges can be accurate to 0.5% of the full scale.

Here are some key advantages:

- Very strong

- Wide measuring ranges

- Very accurate

Disadvantages

Mechanical pressure transducers have some downsides. They are often slower than electronic types. Some designs do not work for every job. You might see limits where you need fast or tiny measurements.

Common disadvantages include:

- Slower response times

- Limits in some uses

Note: Always check if you need fast response or small size before you pick mechanical pressure sensors.

Common Uses

Mechanical pressure transducers are used in many industries. They help keep systems safe and working well. Here are some common uses:

| Industry | Applications |

|---|---|

| Hydraulic Systems | Booster cylinders, gas-liquid boosters, compressors |

| Safety Control Systems | Pressure monitoring for safety |

| Injection Molding | Precise pressure for molding |

| Mining | Pressure checks in mining operations |

| HVAC Systems | Air-conditioning and refrigeration equipment |

| Automotive Manufacturing | Pressure checks in car systems |

| Aerospace Engineering | Safety and performance in aircraft |

| Medical Equipment | Pressure monitoring in medical devices |

| Industrial Process Control | Keeping pressure right in industrial processes |

You see them in HVAC, cars, planes, medical, and factories. These devices help keep everything working right.

Mechanical pressure transducers give a simple way to measure pressure. You get clear pros and cons with this technology. If you need a strong and accurate device for many pressures, this choice works well.

Strain Gauge Pressure Transducers

How They Work

Strain gauge pressure transducers are used in lots of devices. These sensors change their electrical resistance when you press on them. When you push on the sensor, the strain gauge gets longer or shorter. This change in shape makes the resistance go up or down. A Wheatstone bridge circuit checks this change and makes an electrical signal. The signal shows how much pressure is on the sensor. This way, you can measure pressure directly.

Pros and Cons

It is important to know the good and bad points before choosing a sensor. Strain gauge pressure transducers have some strong points and some weak points. Look at this table to see how they stack up:

| Advantages | Disadvantages |

|---|---|

| Fast response time | Cannot measure very low pressure ranges |

| Easy to adjust for temperature changes | Low output signal levels |

| Not affected much by acceleration | Sensitive to vibration (unbonded types) |

| Some types may not work with all fluids | |

| Can drift over time | |

| Adhesives may cause slow changes (creep) |

Tip: Make sure the sensor’s good points fit your project.

Applications

Strain gauge pressure transducers are found in many places. Here are some ways people use them:

- Blood pressure monitors

- Respiratory machines

- Infusion pumps

- Checking fluid pressures in hydraulic systems

- Controlling fuel systems

- Managing oil pressures

You will see these sensors in medical tools and cars. They help you watch and control pressure as it happens.

Capacitive Pressure Sensors

How They Work

Capacitive pressure sensors use two metal surfaces close together. One surface is called a diaphragm. When you press on the sensor, the diaphragm bends. This bending changes the space between the metal surfaces. The sensor checks how far apart they are. It measures this as a change in capacitance. The sensor turns this change into an electrical signal you can read.

Manufacturers use copper, indium tin oxide (ITO), or printed ink to make these sensors. Copper works well on circuit boards and flexible materials. ITO is good for clear sensors, like touch screens. The diaphragm is usually made of stainless steel or a mix of glass and ceramic. These materials help the sensor last longer and work well.

Tip: Capacitive sensors can measure many pressure levels. They work in lots of different devices.

Pros and Cons

Advantages

Capacitive pressure sensors have many good points. They are very sensitive and can notice small pressure changes. These sensors use little power, so they are great for battery devices. They give steady and repeatable readings. This helps when you need reliable data. They work with many pressure ranges, so you can use them in lots of places.

Disadvantages

There are some things to think about before you pick this sensor. Capacitive sensors can cost more than resistive ones. They may react to things like humidity or temperature. Over time, you might see problems with long-term measurements.

Here’s a quick look at the pros and cons:

| Performance Benefits | Limitations |

|---|---|

| High Sensitivity | Long-term measurement challenges |

| Low Power Consumption | Environmental sensitivity |

| Stability and Repeatability | Higher costs compared to resistive types |

| Wide Operating Range |

Applications

Capacitive pressure sensors are used in many places. Here are some common uses:

- Wearable health devices use them to check blood pressure and heart rate.

- Smart home controls use them for touch switches and gesture controls.

- Gaming and virtual reality gear use them to sense grip strength and finger pressure.

- Consumer electronics use them for pressure-sensitive screens and stylus input.

- Cars use them in touch panels for climate and audio systems.

You can find these sensors in lots of modern gadgets. They help make devices smarter and easier to use. When you look at pressure transducers, each type has good and bad points. Capacitive sensors are great when you need high sensitivity and low power use.

Piezoelectric Pressure Transducers

How They Work

Piezoelectric pressure transducers use a special effect. This is called the piezoelectric effect. When you push or squeeze certain materials, they make electricity. Both natural and man-made materials can do this. Inside these sensors, you find different materials.

| Operating Mechanism | Common Materials |

|---|---|

| Turning mechanical stress into electricity using the piezoelectric effect | Natural: Quartz, Rochelle salt, Topaz, Tourmaline; Synthetic: PVDF, Barium titanate, Lead titanate, PZT, Potassium niobate, Lithium niobate, Lithium tantalate, and other lead-free ceramics |

When you press the sensor, it sends out a signal. The sensor changes the force into electricity. You can use this signal to see pressure changes right away.

Tip: Piezoelectric pressure transducers are great for measuring fast pressure changes.

Pros and Cons

It is good to know the ups and downs before picking a sensor. Piezoelectric pressure transducers have some strong points and some weak points.

Advantages

These sensors give you some nice benefits:

- They do not need extra power. The sensor makes its own signal.

- They work well in places with fast changes.

- You can make them in many shapes and sizes.

Here is a table with the main good points:

Advantages

- Easy to use

- Makes its own signal

- Can be shaped easily

Disadvantages

There are also some things to watch out for:

- The sensor makes a small amount of electricity. You might need more electronics to read it.

- The signal can change if the environment changes.

- The output is lower than some other sensors.

See the table below for a quick look:

Disadvantages

- Small signal

- Affected by the environment

- Lower output

Note: Piezoelectric pressure transducers are good for quick and moving measurements, but you should check the signal strength and watch for changes from the environment.

Applications

You can find piezoelectric pressure transducers in many places. People use them in:

- Factories to watch for fast pressure jumps

- Car engines to check pressure during burning

- Medical tools to measure pulse and sound waves

- Science labs for testing shock waves and blasts

- Electronics for touch and vibration sensing

These sensors help you see quick pressure changes. They let you track pressure as it happens.

Resonant Wire Pressure Transducers

How They Work

Resonant wire pressure transducers work in a special way. They use a thin wire stretched tight between two points. One end is fixed, and the other connects to a sensing diaphragm. When pressure changes, the diaphragm moves and pulls on the wire. This changes how tight the wire is. An oscillator makes the wire vibrate at its own natural speed. When the pressure changes, the wire’s tightness changes too. This makes the vibration speed, or frequency, go up or down. A digital counter checks this change in frequency. It turns the change into a pressure reading you can use.

Here’s what happens inside these sensors:

- The wire is held tight between a fixed part and a diaphragm.

- An oscillator makes the wire vibrate at its natural speed.

- Pressure changes make the wire tighter or looser, changing the vibration speed.

- A digital counter finds the new vibration speed for accurate measurement.

- Both high and low-pressure diaphragms can sense pressure differences.

- A magnetic field helps the wire vibrate, and backup plates keep it safe from too much pressure.

These sensors give a direct digital signal. This makes them easy to use with computers and microprocessors.

Pros and Cons

Advantages

Resonant wire pressure transducers have some strong points. They are very accurate, sometimes up to 0.1% of the set range. They give steady and repeatable results. The output is digital and strong, so you can use it right away. You can also see very small changes in pressure.

- Very accurate and steady

- Results are repeatable

- Strong digital output

- Can see small pressure changes

Tip: These sensors work for both low and high-pressure jobs.

Disadvantages

There are some things to watch out for. These sensors can be affected by temperature changes. You need special parts to keep readings steady when it gets hot or cold. The output is not always a straight line, so you may need extra electronics to fix it. These sensors can also cost more than other types.

- Sensitive to temperature changes

- Need extra parts for temperature control

- Output is not always straight

- Cost more than some other sensors

Applications

You will find resonant wire pressure transducers where accuracy and steady results matter. Many industries use them for careful measurements. Here are some common uses:

- Controlling pressure in factories

- Research labs for science

- Airplanes and space systems

- Tools that check other pressure sensors

- Stations that watch the environment

These sensors help you get good pressure readings in tough places. If you need a sensor with a digital signal and strong results, this type is a good choice. When you look at the good and bad points, you can see why engineers pick resonant wire sensors for important jobs.

Optical Pressure Sensors

How They Work

Optical pressure sensors use light to measure pressure. A light, like from a laser or LED, shines on a special part. When pressure changes, this part bends or moves. The way the light travels or bounces off changes too. The sensor sees these changes and makes an electrical signal. You can read this signal to know the pressure. These sensors react quickly to pressure changes. They do not have moving metal parts. They use light instead, which makes them different from other types.

Pros and Cons

Advantages

Optical pressure sensors work well in hard places. You can use them where it gets very hot. They also work where there is a lot of electromagnetic noise. These sensors are good in places with chemicals or strong magnets. Some main good points are:

- They are not bothered by electromagnetic noise.

- Their small size fits in tight spots.

- They react fast and give real-time data.

- They can handle very high heat and pressure.

Tip: Use optical pressure sensors where other sensors might not work.

Disadvantages

There are some bad points too. These sensors can be affected by loud sounds or shaking. They are delicate and can break in rough places. Some common problems are:

- They are sensitive to loud sounds.

- They are not as tough in harsh places.

- You must be careful when you put them in.

Think about these good and bad points before you pick optical pressure sensors.

Applications

You find optical pressure sensors in many areas. In hospitals, doctors use fiber-optic sensors to watch breathing and heartbeats. They help find health problems early and check recovery after surgery. In factories, they are in machines and energy pipes. They work well in dangerous or extreme places. These sensors help keep workers safe and make machines work better.

Some common uses are:

- Medical tools for watching patients

- Factory machines in risky places

- Energy pipes for safety checks

- Science labs for careful tests

You can trust optical pressure sensors for good data in tough places.

MEMS Pressure Sensors

How They Work

You can find MEMS pressure sensors in lots of things. MEMS means Micro-Electro-Mechanical Systems. These sensors have tiny parts made on a silicon chip. They use different ways to sense pressure, like piezoresistive, capacitive, resonant, and piezoelectric. Most MEMS sensors use the piezoresistive effect. When pressure pushes on the sensor, the resistance inside changes. A Wheatstone bridge circuit checks this change and gives a signal.

Manufacturers follow special steps to make these sensors. Here is how they do it:

- Wafer processing puts the sensing parts and circuits on one wafer. They use photoresist and masks for this.

- Cavity processing cuts and shapes the wafer. This makes a space for the sensor to move.

- Conductive layer processing adds thin metal films. These films make parts like varistors or capacitors.

- Packaging seals the sensor. They use wafer-level or plastic packaging to keep it safe.

Deep reactive ion etching (DRIE) helps make smaller chips and saves money. Diaphragm etching lets companies make many sensors at once. These steps help MEMS pressure sensors work well and fit in small spaces.

Tip: MEMS sensors use tiny parts and smart building steps. They measure pressure in many ways.

Pros and Cons

Advantages

MEMS pressure sensors have many good points. They are small and do not cost much. These sensors work fast and fit in tight spots. You can use them in many devices because they are easy to make in large numbers. MEMS sensors use little power, so they help save energy.

Here are some main advantages:

- Small and light

- Fast response

- Low power use

- Easy to make in large numbers

- Good for many devices

Disadvantages

There are some things to think about too. MEMS pressure sensors can be sensitive to temperature changes. Sometimes, they need extra protection from dust or water. The small size can make them weak against strong pressure. You may need special packaging to keep them safe.

Common disadvantages include:

- Sensitive to temperature

- Needs protection from dust and water

- Not always strong for high pressure

- May need special packaging

Note: Always check your needs before you pick MEMS pressure sensors. Think about where you will use them and what you want them to do.

Applications

You can find MEMS pressure sensors in many places. In cars, they help check tire pressure, engine settings, and airbag systems. You see them in smartphones and wearables. Home devices use them to sense changes in air or water pressure.

Here are some common uses:

- Tire pressure checks in cars

- Engine management in vehicles

- Airbag systems for safety

- Smartphones and smartwatches

- Wearable health trackers

- Home automation devices

MEMS pressure sensors help make devices smarter and safer. You get quick readings and small parts that fit almost anywhere. When you look at the good and bad points, you see why MEMS sensors are used in many industries. You can use them in cars, electronics, and smart home systems.

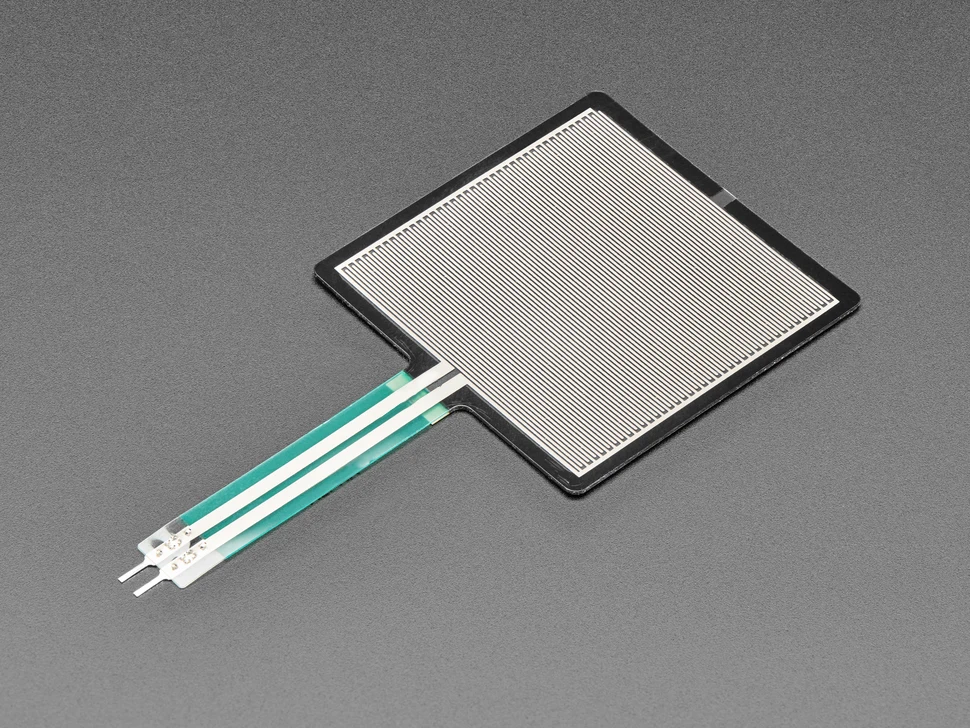

Force Sensing Resistors (FSRs) by SOUSHINE

How FSRs Work

SOUSHINE’s Force Sensing Resistors (FSRs) are easy to use. These sensors help you measure force and pressure. When you press on an FSR, the resistance inside changes. This happens because of two things in the sensor’s polymer: percolation and quantum tunneling. Here is what happens inside:

- The FSR has a polymer with tiny particles.

- When you push on it, the particles get closer.

- The resistance between the electrodes and polymer goes down.

- The sensor gives a new electrical signal based on the force.

This design lets you get a clear signal that matches the pressure you use. You can use this signal in many devices that need to sense touch or force.

Pros and Cons

Advantages

SOUSHINE’s FSRs have many good points compared to other pressure sensors. These sensors are thin, flexible, and respond quickly. The table below shows how SOUSHINE’s FSRs are different:

| Feature | SOUSHINE FSRs | Other FSR Brands |

|---|---|---|

| Flexibility | Yes | Varies |

| Affordability | Yes | Varies |

| Quick Response Time | < 10ms | Varies |

| Thickness | 0.85mm | Varies |

| Operating Temperature | -40°C to +85°C | Varies |

| Power Consumption | Low | Varies |

| Force Measurement Range | 10g to 1000g | Varies |

| Special Features | Very light touch sensors | Varies |

You can trust SOUSHINE’s FSRs for:

- Fast and accurate force measurement

- Low power use for battery devices

- Custom shapes and sizes for your needs

- Good performance in many places

Tip: If you need a sensor for small spaces or one that bends, FSRs are a smart pick.

Disadvantages

When you look at the good and bad points, SOUSHINE’s FSRs give you many reasons to use them for your project.

Industry Applications

SOUSHINE’s FSRs work in many fields. These sensors help solve problems where other pressure sensors may not work well. Here are some important industries:

- Automotive: Use FSRs for seat checks, touch controls, and safety.

- Healthcare: Put FSRs in patient monitors, rehab tools, and wearables.

- Robotics: Help robots feel touch for better control.

- Consumer Electronics: Make touchpads, game controllers, and smart devices better.

- Industrial Automation: Watch force in assembly lines and quality checks.

- Aerospace: Use FSRs in cockpit controls and safety systems.

You get a sensor that works in many places. SOUSHINE’s FSRs help you make smarter, safer, and easier-to-use products. If you want a flexible and strong way to measure force, these sensors are a great choice.

Analog vs Digital Pressure Sensors

Analog Pressure Sensors

Analog pressure sensors give a signal that changes smoothly. The sensor turns pressure into voltage or current. You can see the signal go up or down right away. This helps you notice small changes as they happen. People use analog sensors in factories, labs, and weather stations. You can connect them to simple meters or control systems. They are good when you need to watch pressure all the time.

Digital Pressure Sensors

Digital pressure sensors work in another way. They change pressure into a digital number. You get the data in steps, not a smooth line. The sensor has a tiny computer chip inside. You can send the data to a computer or screen. Digital sensors often give more exact readings. People use them when they need very accurate numbers, like in medical tools or smart gadgets.

Pros and Cons

Analog Advantages

- You see changes right away with no wait.

- The signal is smooth and always moving.

- Simple tools can read the signal.

- Good for watching quick pressure changes.

Analog Disadvantages

- The signal can get mixed up by noise from wires.

- You might need to fix the sensor often.

- It is hard to send the signal far away.

- The readings can slowly change over time.

Digital Advantages

- You get very exact and clear numbers.

- The sensor does not pick up much noise.

- You can send data far without losing quality.

- Easy to use with computers and smart devices.

Digital Disadvantages

- The data comes in steps, not a smooth line.

- Sometimes, the sensor uses more power.

- Setting it up can be harder.

- There might be a small wait for the data.

Tip: When you pick between analog and digital sensors, think about what is most important for your project. Do you want to see changes right away, or do you need very exact numbers?

You can see the main differences in this table:

| Feature | Analog Pressure Sensor | Digital Pressure Sensor |

|---|---|---|

| Output Type | Continuous | Digital (steps) |

| Accuracy | Good | Higher |

| Noise Resistance | Lower | Higher |

| Real-Time Monitoring | Yes | Limited |

| Setup Complexity | Simple | More complex |

Electronic pressure sensors can be analog or digital. Each type has good and bad points. Some jobs need fast changes from analog sensors. Other jobs need exact numbers from digital sensors. Pick the one that fits your system best.

Application Differences

You might ask when to use analog or digital pressure sensors. The answer depends on what you want your system to do. Each type works best for different jobs because of how they handle signals and data.

Analog sensors are good for places like factories. They help you watch pressure all the time. These sensors give a smooth signal. You see changes right away. For example, in a water plant, you want to find leaks fast. Analog sensors help you spot drops in pressure quickly. You can connect them to simple meters or alarms. You do not need a computer to read the signal.

Digital pressure sensors are better when you need exact numbers. You see these sensors in medical tools, smart gadgets, and cars. If your device sends data to a computer or phone, use a digital sensor. These sensors give clear numbers. You can save the data or send it far away without losing quality. For example, in hospitals, doctors use digital sensors to check blood pressure. The data goes straight into the computer.

Here are some common uses for each type:

| Application Area | Analog Sensors Used For | Digital Sensors Used For |

|---|---|---|

| Factories | Real-time pressure monitoring | Data logging and remote monitoring |

| Water Plants | Leak detection, pump control | Automated reporting |

| Medical Devices | Simple pressure gauges | Patient monitoring, smart devices |

| Cars | Oil and fuel pressure gauges | Tire pressure monitoring, engine control |

| Consumer Electronics | Basic pressure switches | Smart home devices, wearables |

Tip: Pick analog if you need to see pressure changes as they happen. Pick digital if you want to record, share, or process data.

You should also think about cost and setup. Analog sensors usually cost less and are easy to put in. Digital sensors may take more work to set up, but they have more features. Electronic pressure sensors can be analog or digital, so you have many choices.

When you look at the good and bad points, you see both types have their place. Your choice depends on what you want your system to do. Pick the one that fits your job, and you will get better results.

Comparing Pressure Transducer Technologies

Accuracy and Precision

If you want the best accuracy, you need to pick the right sensor. Strain gauge and resonant wire sensors are very good at showing small pressure changes. These types can notice tiny differences. Capacitive sensors also work well, especially for low pressures. Piezoelectric sensors are great for fast changes, but their readings might not stay steady for a long time.

Mechanical pressure sensors are accurate for many uses. But they are not as good as the best electronic sensors. MEMS sensors are precise in small things like phones and wearables. Optical sensors can be very accurate, mostly in clean or special places.

Digital pressure sensors help you see exact numbers if you need to watch small changes. Analog sensors give a smooth signal, which is good for seeing trends over time. Always choose a sensor that fits your job. Some jobs need very high precision, but others just need a clear signal.

Tip: Check the sensor’s accuracy rating before you buy it. This helps you avoid mistakes in your system.

Durability and Stability

You want your pressure transducers to last a long time. Durability means the sensor keeps working in tough places. Stability means the sensor gives the same reading every time.

Mechanical pressure sensors are strong and work well in rough spots. They can handle dust, water, and bumps. Strain gauge sensors also last long, but their readings might drift after many years. Capacitive sensors work well, but they can change if it gets hot or wet.

MEMS sensors are tiny and fit in small spaces, but they need to be kept safe from dirt and water. Piezoelectric sensors do not wear out quickly, but their readings can change if the environment changes. Optical sensors work well where there is a lot of noise or heat, but you must be careful with them.

If you want a sensor that stays stable, pick one with a good history. Some sensors need to be checked or calibrated to keep their readings true.

Cost and Value

You want to spend less money, but you also want a good sensor. Mechanical pressure sensors usually cost less at first. They work well for simple jobs. Strain gauge and capacitive sensors cost a bit more, but they are more accurate and have more features.

MEMS sensors are cheap when you need a lot of them, like in electronics. Piezoelectric and optical sensors cost more, but they solve special problems. Resonant wire sensors are the most expensive, but they are the most accurate.

When you think about value, look at how long the sensor will last and how much work it saves you. Some sensors cost more at first, but they last longer or need less care, so you save money later.

Here’s a quick table to help you compare:

| Sensor Type | Upfront Cost | Value Over Time | Best For |

|---|---|---|---|

| Mechanical | Low | Good | Simple, tough jobs |

| Strain Gauge | Medium | High | Accurate, stable readings |

| Capacitive | Medium | High | Sensitive, low-pressure jobs |

| Piezoelectric | High | Medium | Fast, dynamic measurements |

| Resonant Wire | High | Very High | Top accuracy, critical tasks |

| Optical | High | High | Harsh or noisy environments |

| MEMS | Low (in bulk) | Good | Small, mass-produced devices |

Note: Always think about what you need the sensor to do. Sometimes, paying more at first means fewer problems later.

Maintenance Needs

When you pick a pressure transducer, you want to know how much work it takes to keep it running. Some types need more care than others. If you use mechanical pressure transducers, you might need to check moving parts often. Dust or dirt can get inside and cause problems. You may need to clean or replace parts to keep readings true.

Strain gauge sensors need you to check for drift. Over time, the readings can change. You might have to calibrate them every few months. Capacitive sensors do not have many moving parts. You still need to watch for changes in humidity or temperature. Sometimes, you need to recalibrate them if the environment changes a lot.

Piezoelectric sensors do not need much care. They last a long time if you use them in the right place. You should check the wiring and make sure nothing is loose. Resonant wire sensors need you to check for temperature changes. You may need to adjust them if the readings start to drift.

Optical sensors need you to keep the light path clean. Dust or smudges can block the signal. You might need to clean the sensor lens or fiber. MEMS sensors are small and sealed. You do not need to do much, but you should keep them away from water or dust.

Digital pressure sensors often need less care than analog ones. You do not have to worry about signal drift as much. You should still check the connections and make sure the software is up to date.

Here’s a quick list to help you compare:

- Mechanical: Clean and check moving parts

- Strain Gauge: Calibrate for drift

- Capacitive: Watch for humidity and recalibrate

- Piezoelectric: Check wiring

- Resonant Wire: Adjust for temperature

- Optical: Clean light path

- MEMS: Keep away from dust and water

- Digital: Update software and check connections

Tip: If you want less work, pick a sensor with fewer moving parts and good sealing.

Response Time

Response time tells you how fast a sensor reacts to pressure changes. If you need to track quick events, you want a sensor that responds right away. Piezoelectric sensors give you the fastest response. You can use them for shock or vibration tests. MEMS sensors also react quickly. They work well in phones and smart devices.

Capacitive sensors have a fast response, but not as quick as piezoelectric types. Strain gauge sensors respond fast enough for most jobs. Mechanical sensors are slower. They have moving parts, so you might see a delay.

Resonant wire sensors give you steady readings, but they may not catch very fast changes. Optical sensors can react quickly, but you need to keep the light path clear. Digital pressure sensors process data fast. You can use them in systems that need real-time pressure measurement.

Here’s a table to show how fast each type reacts:

| Sensor Type | Response Time | Best Use Case |

|---|---|---|

| Piezoelectric | Very Fast | Shock, vibration, quick tests |

| MEMS | Fast | Phones, wearables |

| Capacitive | Fast | Touch, smart controls |

| Strain Gauge | Moderate | Cars, medical devices |

| Mechanical | Slow | Gauges, slow changes |

| Resonant Wire | Moderate | Steady, accurate readings |

| Optical | Fast | Clean, special environments |

| Digital | Fast | Real-time data, automation |

Note: Always match the sensor’s response to your job. If you need to catch quick changes, pick a sensor with a fast response.

Choosing the Right Pressure Sensor

Industrial Needs

When you pick pressure sensors for factories, you have many choices. Each job needs something different. Some places need sensors that can handle dirt or water. Other places need sensors that work in high heat. Sometimes, you need a sensor that gives steady readings for a long time. You may want a sensor for big machines or one that fits in tight spots.

Think about these things before you choose:

- What pressure do you need to measure?

- How fast do you need the sensor to react?

- Will the sensor face dust, water, or chemicals?

- Do you need to check pressure all the time or just sometimes?

Many factories use strain gauge or capacitive sensors. These types are accurate and last a long time. If you need to measure force on moving parts, you might use a force sensing resistor. SOUSHINE’s FSRs are thin and bend easily. They use little power, so you can use many at once.

Tip: Always pick a sensor that matches the job. This helps your machines work well and keeps problems away.

Medical Applications

Hospitals and clinics need safe and reliable pressure sensors. Medical tools use pressure transducers to check blood pressure or breathing. You want sensors that give quick and correct numbers. Doctors and nurses use these numbers to help patients.

Some ways sensors are used in medicine:

- Blood pressure monitors

- Breathing machines

- Infusion pumps

- Patient beds with pressure mapping

MEMS sensors fit in small devices like wearables. They give fast results and fit in tiny spaces. For touch-sensitive tools, force sensing resistors help track how much force is used. SOUSHINE’s FSRs can be made in special shapes for medical tools.

Note: Always make sure the sensor is safe for health use before putting it in a medical tool.

Automotive Solutions

Cars and trucks use many kinds of pressure sensors. You find them in engines, brakes, and seats. These sensors help keep you safe and make cars work better. Tire pressure sensors warn you if a tire is low. Engine sensors help control fuel and air.

Here are some places you might use pressure sensors in cars:

| Area | Example Use |

|---|---|

| Engine | Fuel and oil pressure |

| Tires | Tire pressure monitoring |

| Brakes | Brake system pressure |

| Seats | Occupant detection |

| Climate | Air conditioning controls |

SOUSHINE’s FSRs are good for seat sensors and touch buttons. They help the car know if someone is sitting or if a button is pressed. These sensors are thin and fit under covers or inside panels.

Tip: Pick a sensor that can handle heat, bumps, and long use in cars and trucks.

Aerospace Requirements

Working in aerospace is hard. Planes and rockets need sensors that work in tough places. These sensors must handle big changes in temperature and pressure. There is a lot of shaking and bumping during flight. Sensors must keep working even when things get rough.

When you choose pressure transducers for aerospace, look for these things:

- High accuracy for safe flying

- Strong design for shaking and bumps

- Can handle hot and cold

- Light weight to save fuel

You find these sensors all over planes. They help with cabin pressure and fuel checks. They also watch engines. Satellites and rockets use them too. These sensors help keep people safe and missions working.

Tip: Always make sure the sensor meets aerospace rules before you put it in a plane or rocket.

Consumer Electronics

You use pressure sensors every day. You might not notice them. Phones, tablets, and smartwatches have these sensors. They make your life easier. When you press a button or swipe, the device reacts. These sensors help with touch and screen pressure. They also help track fitness.

Here are ways pressure sensors help in electronics:

- Touchscreens know how hard you press

- Game controllers feel your grip

- Wearables count steps and check heart rate

- Smart home gadgets react to touch

You want sensors that are small and light. They should use little power. They need to fit in thin devices and last long. Fast sensors make your device feel smooth.

Note: When you make a new gadget, think about where the sensor goes and how it helps the user.

SOUSHINE Product Options

SOUSHINE’s Force Sensing Resistors (FSRs) fix many sensing problems. These sensors work in lots of industries. You can use them in cars, medical tools, robots, and planes. SOUSHINE’s FSRs measure force fast and accurately. You can pick different shapes and sizes for your project.

Here is what you get with SOUSHINE FSRs:

| Feature | Benefit |

|---|---|

| Thin and flexible | Fits in tight spaces |

| Low power use | Good for battery devices |

| Custom options | Matches your design needs |

| Fast response | Tracks quick changes |

| Durable build | Works in tough environments |

You can ask SOUSHINE for help with your project. Their team can help you pick the right sensor. If you want a sensor that is easy and reliable, SOUSHINE FSRs are a good choice.

Tip: Contact SOUSHINE if you need help or want to try a sample for your next product.

Practical Selection Tips

Environmental Factors

You want your pressure sensor to work well in its environment. Start by thinking about where you will use it. Will it face water, dust, or chemicals? Some sensors handle wet places. Others work better in dry or clean rooms. If you use a sensor outside, check if it can handle rain or sun. High heat or cold can change how a sensor works. Some pressure transducers keep working in hot engines or cold freezers. Others may stop working if the temperature changes too much.

Here are some things to check:

- Temperature range

- Water or dust protection (look for IP ratings)

- Chemical resistance

- Vibration or shock

Tip: Always read the sensor’s datasheet. It tells you what the sensor can handle.

Accuracy Requirements

You need to know how exact your readings must be. Some jobs need very precise numbers. Others just need a rough idea. If you work in a hospital or lab, you want high accuracy. If you check tire pressure or water tanks, you may not need the highest accuracy.

Think about these points:

- What is the smallest change you need to see?

- How much error can you accept?

- Will you use the sensor for safety or just for checks?

Here is a simple table to help you match accuracy to your job:

| Application | Needed Accuracy |

|---|---|

| Medical devices | Very high |

| Factory machines | High |

| Car tire checks | Medium |

| Home gadgets | Low to medium |

Note: Higher accuracy often means a higher price. Only pay for what you need.

Budget Considerations

You want to get the best value for your money. Some pressure sensors cost more because they offer special features. Others are simple and cost less. Before you buy, set your budget. Decide what features matter most. Do you need a sensor that lasts many years? Or do you want one that is easy to replace?

Here are some ways to save money:

- Choose only the features you need

- Buy in bulk for lower prices

- Pick sensors with easy installation to save on labor

You can also ask suppliers for advice. They may suggest a sensor that fits your needs and budget.

Tip: Do not pick the cheapest sensor if it will fail early. A good sensor saves money over time.

Integration and Compatibility

You want your pressure sensors to work with your system. If you pick a sensor that does not fit, you might face problems later. You should check a few things before you buy or install a sensor.

First, look at the output signal. Some sensors give analog signals. Others give digital signals. Your system may need one type or the other. If you use a digital controller, you need a sensor that sends digital data. If you use a simple meter, you may want an analog signal.

Next, check the voltage and current levels. Your sensor must match your system’s power supply. If the sensor needs more power than your system can give, it will not work. If the voltage is too high, you might damage your equipment.

You should also look at the connector type. Some sensors use wires. Others use plugs or special connectors. Make sure the sensor fits your cables and ports. If you pick the wrong connector, you may need extra adapters.

Communication protocol matters too. Some pressure transducers use I2C, SPI, or UART. Others use simple voltage or current outputs. Your system must understand the sensor’s language. If you use a microcontroller, check if it supports the sensor’s protocol.

Here is a table to help you compare:

| Feature | What to Check | Why It Matters |

|---|---|---|

| Output Signal | Analog or Digital | Matches your system input |

| Power Supply | Voltage and Current | Prevents damage |

| Connector Type | Wire, plug, or custom | Fits your cables and ports |

| Communication | I2C, SPI, UART, voltage | System can read sensor data |

You should also think about software. Some sensors need drivers or special programs. If you use a computer or smart device, check if you can get the right software. If you cannot find drivers, the sensor may not work.

Tip: Always read the sensor’s datasheet. It tells you what you need to know about integration.

If you want to use more than one sensor, check if your system can handle it. Some systems have limits on how many sensors you can connect. If you use many sensors, you may need a hub or extra controller.

You should test the sensor before you use it in your final product. Connect it to your system and check if it gives the right readings. If you see errors, fix them before you finish your project.

When you pick pressure transducers or pressure sensors, make sure they fit your system. If you check these things first, you save time and avoid trouble later.

You have many choices when it comes to pressure transducers and pressure sensors. The right pick depends on what you need for your project. Each technology has its own strengths and weaknesses. Make sure you match the features to your requirements. If you feel unsure, talk with experts or reach out to SOUSHINE. Take a moment to review your needs before you decide.

FAQ

What is a pressure transducer?

A pressure transducer changes pressure into an electrical signal. You use it to measure force or pressure in machines, cars, or gadgets. It helps you see pressure changes as numbers.

How do I choose the right pressure sensor for my project?

First, think about what you need to measure. Check the pressure range, size, and how fast you need results. Look at your budget. Ask the supplier if you feel unsure.

Can I use pressure sensors outdoors?

Yes, you can use many pressure sensors outside. Make sure the sensor can handle rain, dust, and temperature changes. Always check the datasheet for outdoor use.

What is the difference between analog and digital pressure sensors?

Analog sensors give a smooth, changing signal. Digital sensors give numbers in steps. You pick analog for real-time changes. You pick digital for exact numbers and easy computer use.

Where do I find force sensing resistors (FSRs) in real life?

You see FSRs in car seats, medical devices, touchpads, and robots. They help machines know when you press or touch something.

How often should I calibrate my pressure sensor?

You should check and calibrate your sensor every few months. If you use it in tough places, check it more often. Calibration keeps your readings true.

Are MEMS pressure sensors good for small devices?

Yes, MEMS sensors fit well in small gadgets. You find them in phones, watches, and smart home tools. They use little power and work fast.

Can I get custom-shaped pressure sensors?

Yes, some companies like SOUSHINE make custom-shaped sensors. You can ask for a size or shape that fits your project.