Call us: +86-137-2353-4866

In the aerospace and defense sectors, performance, reliability, and safety are non-negotiable. Force sensing technology is a critical enabler, providing the precise, real-time data required for the control, monitoring, and testing of a wide range of mission-critical systems. From flight control and structural integrity to propulsion and environmental systems, force sensors deliver the measurements that drive operational excellence and safety.

SOUSHINE delivers high-performance force sensing solutions engineered to meet the stringent demands of the aerospace and defense industries. Our products provide accurate and durable performance in the extreme conditions and dynamic environments inherent to these applications.

What is Force Sensing in Aerospace & Defense?

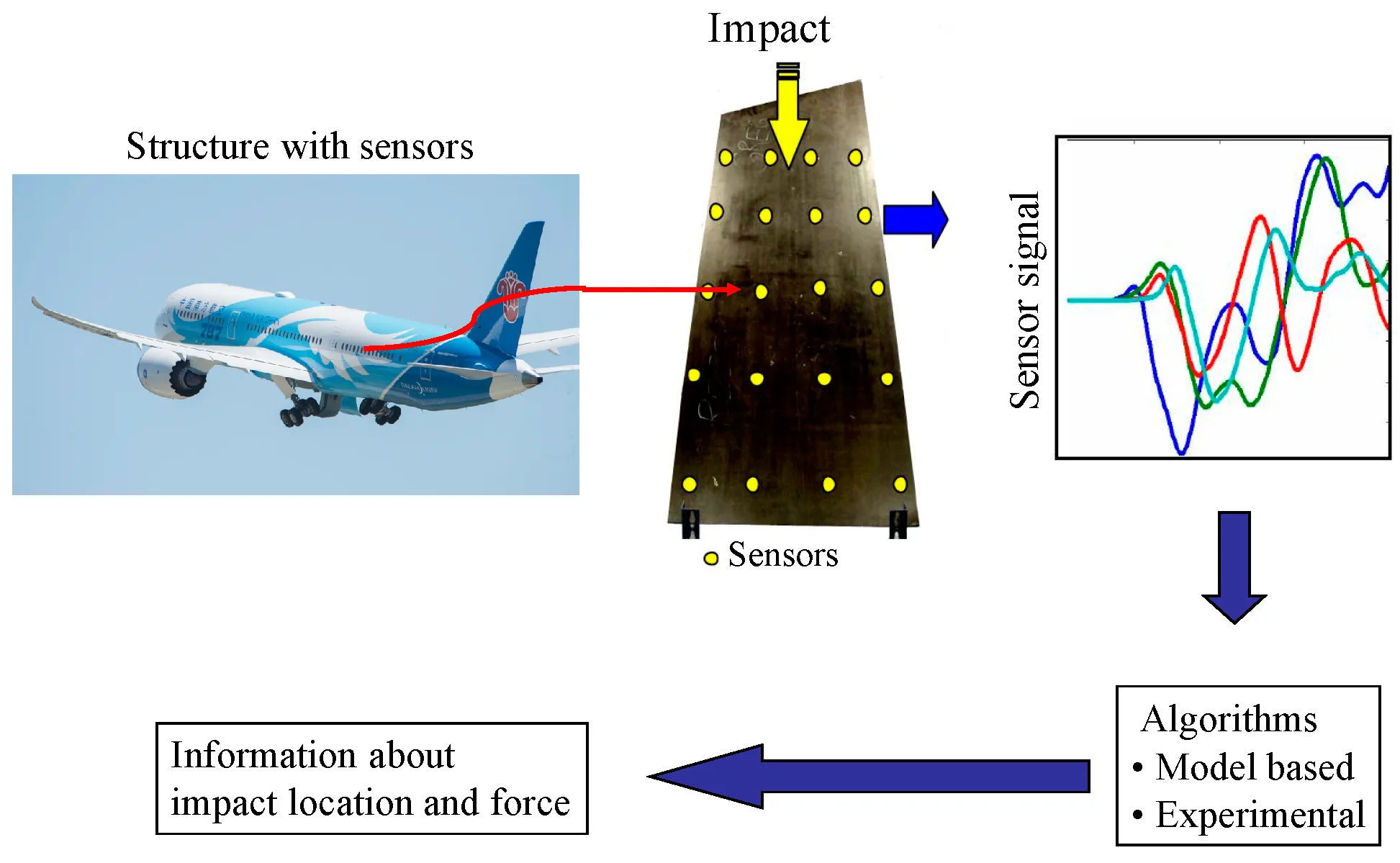

In the context of aerospace and defense, force sensing involves the measurement of pressure, weight, tension, compression, and torque. This is accomplished through specialized sensors that convert a mechanical force into a quantifiable electrical signal. This data is then fed into control systems, monitoring displays, or data acquisition platforms. The primary function of this technology is to provide actionable intelligence for the safe and efficient operation of aircraft, spacecraft, and defense hardware.

How is Force Sensing Technology Applied?

Force sensors are integrated into numerous systems to perform specific measurement tasks. For example, a sensor might be designed to measure the subtle changes in atmospheric pressure to determine altitude, or it may be built to withstand immense loads to verify the structural integrity of an airframe during testing. These sensors are engineered from robust materials and calibrated for maximum accuracy and reliability under extreme temperatures, vibration, and G-forces.

Key Application Areas:

- Landing Gear: Force measurements ensure proper weight distribution and monitor the intense forces experienced during takeoff and landing.

- Flight Control Systems: Sensors provide feedback on the force applied to control surfaces like ailerons, elevators, and rudders, enabling precise maneuverability.

- Structural Health Monitoring: Force sensors are used in the static and fatigue testing of airframes and components to ensure they can withstand operational stresses.

- Propulsion Systems: Measurement of thrust from jet or rocket engines is critical for performance validation and control.

- Weapons Systems: Sensors are integral to guidance systems and in measuring separation forces during payload deployment.

Why is Force Sensing Critical?

The integration of precise force sensing technology is fundamental to the advancement and safety of aerospace and defense systems.

- Enhanced Safety: Provides real-time data that can prevent structural failures, ensure stable flight, and confirm the proper functioning of critical components.

- Improved Performance and Efficiency: Enables the fine-tuning of engine thrust, fuel systems, and aerodynamic controls for optimal performance and fuel efficiency.

- Data for Design and Validation: Delivers the empirical data necessary for validating new designs, conducting material tests, and refining aerodynamic models.

- Predictive Maintenance: Continuous monitoring of forces on structural components can help identify potential issues before they become critical failures, enabling proactive maintenance schedules.

Refined Applications

SOUSHINE force sensing solutions are utilized in highly specific and demanding applications within the aerospace and defense sectors.

FAQ

What types of force sensors are used in aerospace applications?

A variety of sensors are used, including strain gauge load cells, pressure transducers, and piezoelectric sensors. The choice depends on the specific application, required accuracy, environmental conditions, and the type of force being measured (e.g., tension, compression, pressure).

How do your sensors withstand the extreme environments of aerospace and defense?

Our sensors are constructed with high-grade, durable materials. They are designed and tested to operate reliably under a wide range of temperatures, high vibration, and significant G-forces. We offer solutions with specific certifications and qualifications to meet industry standards.

Can your force sensors be customized for a specific defense application?

Yes. We work directly with engineering teams to develop custom force sensing solutions that meet the unique geometric, performance, and environmental requirements of specific aerospace and defense projects.

What is the importance of sensor calibration for aerospace?

Calibration is critical. It ensures that the sensor’s output signal accurately corresponds to a known applied force or pressure. For aerospace and defense, where precision is paramount for safety and performance, regular and traceable calibration against established standards is mandatory.

How does force sensing contribute to aircraft structural testing?

During structural testing, force sensors (load cells) are integrated into test rigs to apply and measure specific loads on airframe components, such as wings and fuselage sections. This process validates that the structure can withstand the forces it will encounter during its operational life, including extreme maneuvers and landing impacts.