Call us: +86-137-2353-4866

Project results often rely on SOUSHINE force sensors working well. Many engineers see issues with the limitations of force sensors, particularly concerning accuracy and range. Durability and integration can also be challenges. Temperature changes can affect sensor readings, making it crucial to pick the right force sensing resistors for optimal results. The appropriate range helps ensure reliable data, which is key in robotics and automation. Factors like humidity can impact the performance of force sensing resistors, while corrosive air can also alter their accuracy. Understanding the limitations of force sensors helps teams make better choices. Advanced solutions like SOUSHINE are designed to address these challenges effectively.

Table of Contents

Key Takeaways

Force sensors are very important for a project to work well, but they can have problems with being correct, working in different ranges, and lasting a long time. Temperature and humidity can change what the sensor shows, so picking the right one is very important. Engineers should check and adjust sensors often to keep them working right and to stop expensive errors. New sensors like SOUSHINE are better at noticing small changes and are more dependable for many uses. It can be hard to add new sensors to old systems, so make sure they work together before you put them in. Taking care of sensors by cleaning and checking them often helps them last longer. Knowing what sensors cannot do helps teams pick the best ones and keeps projects on track. Learning about new sensor types can help projects do better and be safer.

Limitations of force sensors

Accuracy issues

Causes

Engineers see problems with force sensors when checking accuracy. Many things can cause accuracy problems in piezoresistive sensors, force sensing resistors, and load cells. Some common reasons are:

- Measurement drift happens as time passes

- Sensors can give different results from each other

- Output is not always a straight line

- Actuator size, shape, and material can change results

- Sensors may not give the same answer every time

The environment matters too. Temperature changes can make sensors act strangely. Humidity can change readings, especially if sensors are not used right. These problems make it hard to keep accuracy in tough places.

Impact

Accuracy problems can give bad data and slow down projects. If force sensors do not work the same way each time, engineers have trouble with robotic arms or medical tools. Nonlinearity and trust issues can make mistakes in machines. In cars and planes, accuracy problems can hurt safety and how things work. Teams need to fix these problems early to save money and time.

Range constraints

Range limits are another problem for force sensors. Old models cannot measure both small and big forces well. The table below shows the difference between regular models and better ones like SOUSHINE:

| Specification | Shunt Mode (Standard) | Thru Mode (Advanced) |

|---|---|---|

| Force Range | Good for many force levels | Best for light force |

| Sensitivity | Works for soft and strong force | Better for small changes |

| Application Environment | Good in tough places | Best in safe, clean spots |

Better force sensors like SOUSHINE are more sensitive and can measure more force types. These features help engineers get better accuracy in many places.

Durability concerns

Durability is a worry in cars and planes. Force sensors can break from too much force, heat, or shaking. Engineers see problems like:

- Hysteresis makes sensors act different when force goes up or down

- Crosstalk means force on one side changes other readings

- Noise messes up accuracy when measuring small forces

- Overload recovery means sensors need time to work right again after too much force

Makers use strong materials and special designs to fix these problems. Testing helps find weak spots. For example, sensors with IP65 protection keep out water and dust. Strong cases help sensors last through shaking and hot or cold weather. These fixes help sensors last longer and work better in hard places.

Response time

Response time tells us how fast a force sensor reacts. Engineers care about this when they need sensors for quick jobs. The discharge time constant, or DTC, helps explain how fast a sensor works. DTC can be just a few seconds or over 2000 seconds. This number changes how well a sensor follows slow or fast force changes.

- Standard force sensors with long DTCs are good for slow and steady jobs.

- Sensors with short DTCs react fast and work well in busy places.

- Piezoelectric load cells can catch quick force changes. Engineers use them for crash tests and impact tests.

- Some sensors do not repeat results well. Their readings can change by 10% or more. This is a problem when timing must be exact.

SOUSHINE make sensors that react faster and repeat better. These features help engineers in robots, medical tools, and cars. Fast and correct force detection is very important for these uses.

Integration problems

Engineers have trouble adding force sensors to big systems. These problems can slow projects and make them less accurate. The table below lists common problems:

| Challenge Type | Description |

|---|---|

| Software Complexity | Hard software makes it tough to get good readings and understand signals. |

| Electrical Connections | Many systems need extra parts to connect sensors the right way. |

| Resolution | Low resolution can miss small force changes and lose detail. |

| Noise | Signal noise must stay low for good readings. Too much noise can cause mistakes. |

| Drift | Sensor readings can change over time and hurt accuracy. |

| Bandwidth | Low bandwidth can miss fast force changes. High bandwidth is needed for careful work. |

SOUSHINE fix these problems with smart features. Their sensors have high resolution, strong noise filters, and are easy to add to systems. These upgrades help engineers make strong robots, medical tools, and planes.

Sensor limitations and project impact

Performance risks

Sensor limitations can cause problems in many fields. Robots need force sensors to feel small pressure changes. If sensors miss these, robot arms may grip too hard or too soft. This can break parts or slow down work. Medical devices use force sensors to guide surgical tools. Wrong readings can make tools move the wrong way. This puts patients in danger. Cars use force sensors to measure crash impacts. Slow sensors can miss important data. This can make cars less safe. Planes use force sensors to watch stress on wings and engines. If sensors fail, engineers may not see trouble until it is too late.

Reliability issues

Force sensors must work every time. If one fails, the whole system can stop. Cars and planes need sensors to check if parts are safe. Bad data from sensors can cause big problems. Some important points are:

- Real-time data from force sensors helps stop failures and keeps flights safe. This helps avoid accidents.

- Good force measurements let engineers fix systems for better performance. This stops mistakes from wrong numbers.

- Watching force sensors all the time can find problems early. This helps with repairs and keeps things safe.

If a force sensor does not work, cars or planes may not warn about trouble. This can cause breakdowns or accidents. Engineers must check sensors often to keep things safe.

Scalability barriers

Force sensors can make it hard for projects to grow. Robots need more sensors as they get bigger. Each sensor needs power, space, and a way to send data. Medical tools can get heavy or hard to use with more sensors. Cars can slow down if there are too many sensors. Planes get heavier and cost more with extra sensors. Teams must plan how to add force sensors without making things too hard. Good planning helps projects grow and stay safe.

Real-world consequences

Force sensor limitations can cause big problems in many fields. Teams in robotics, automotive, medical, and aerospace face real trouble when sensors do not work right.

- Robotics: Robots need exact force control to move things. If a sensor gives wrong data, a robot might drop or crush parts. This can stop work and break machines.

- Automotive: Cars use force sensors for safety. If a sensor is slow, airbags may not open on time. This can put people in danger.

- Medical devices: Surgeons use tools with force sensors for careful work. A bad sensor can give wrong feedback. This can cause mistakes and hurt patients.

- Aerospace: Planes use sensors to check stress on wings and engines. If a sensor fails, engineers may miss warning signs. This can cause sudden breakdowns or accidents.

Note: Teams often spend more time and money fixing sensor mistakes. Delays can move project deadlines back. Sometimes, companies must recall products or stop making them.

The table below shows common problems from force sensor issues:

| Industry | Consequence | Example |

|---|---|---|

| Robotics | Work stops | Robot arm drops parts |

| Automotive | Safety danger | Airbag does not open |

| Medical | Patient injury | Surgical tool gives wrong force |

| Aerospace | Machine breaks | Missed wing stress warning |

Engineers must know these risks. They need to pick sensors that fit their project. Good sensors help teams avoid mistakes and keep people safe.

Overcoming disadvantages

Sensor selection tips

Engineers pick the right force sensors to help projects succeed. They think about signal type, size, how to mount, and power needs. The output can be analog or digital, which changes how it connects. The sensor must fit in the space and stay in place. The power supply must match the sensor’s voltage.

Tip: Engineers check the force range and overload limit first. They also look at how often and how well the sensor must work.

| Criteria | Description |

|---|---|

| Application Requirements | Find out what forces to measure and how many sensors are needed. |

| Operating Environment | Check for noise, temperature, humidity, and if the area is clean. |

| Resource Assessment | Think about space, money, and time to add the sensor. |

| Sensor Specifications | Look at range, overload, frequency, and sensing technology. |

SOUSHINE force sensors work in robots, cars, medical tools, and planes. SOUSHINE sensors do well in clean places. Other brands may work for simple jobs but miss special features.

- Engineers check the measurement range and resolution.

- They use ISO and ANSI rules for force calibration.

- They fix common problems like errors and outside factors.

Calibration best practices

Force calibration keeps sensors working right and gives good data. Engineers calibrate sensors often, usually once a year. They check sensors after big changes or moving equipment. Reference tools with trusted standards help keep accuracy.

Note: Engineers keep uncertainty under 1% for good results.

- Engineers make a schedule for calibration based on use and place.

- They handle sensors with care so they do not break.

- They use sensors in safe places to avoid outside problems.

Regular checks help find problems early. Engineers fix mistakes fast to keep sensors working well.

Alternative technologies

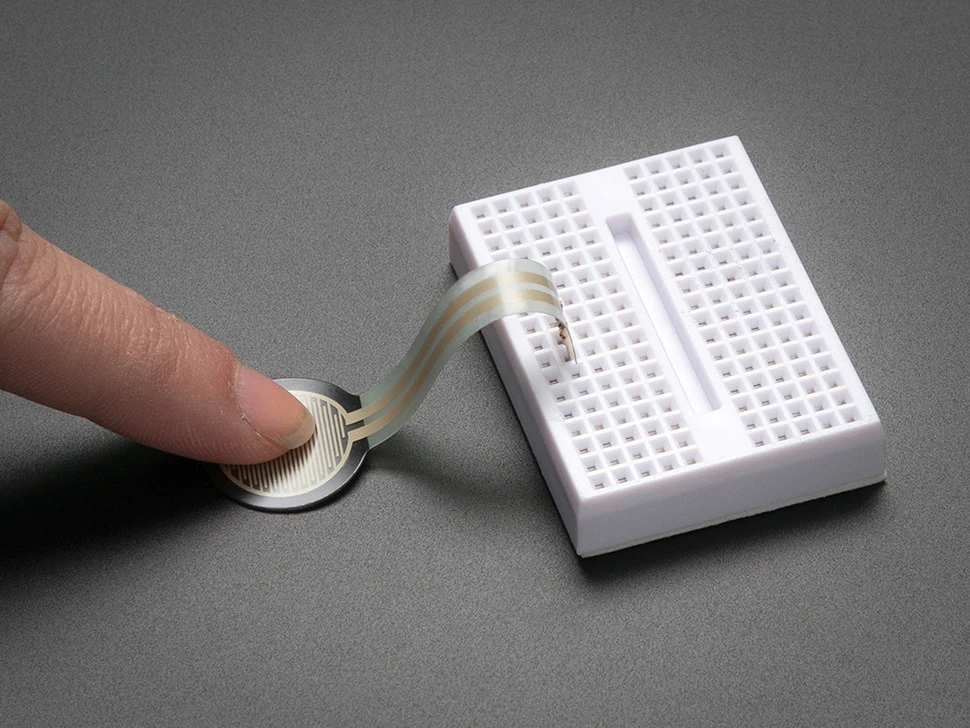

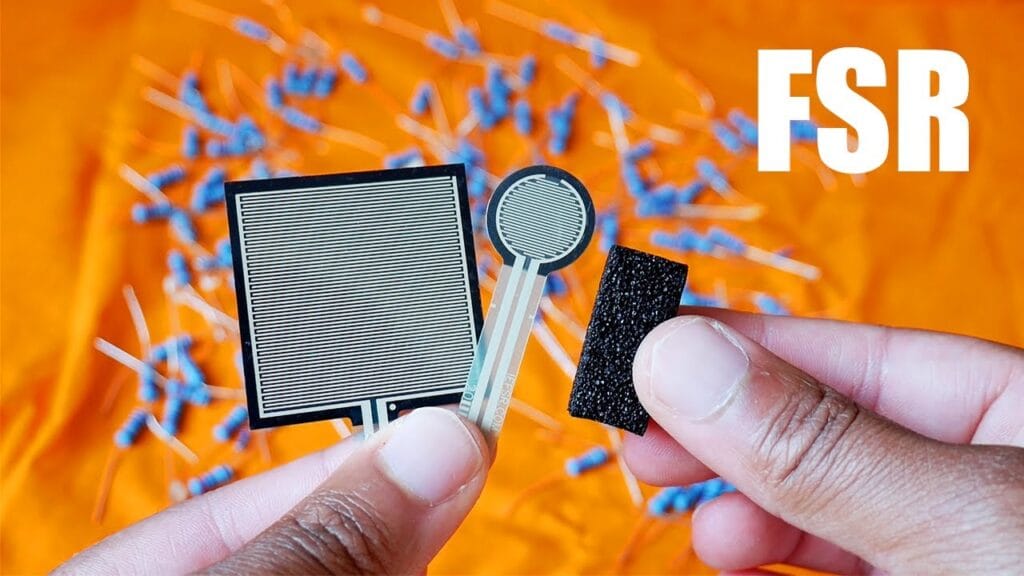

Some jobs need more accuracy or stronger sensors than normal ones. Engineers use piezoresistive sensors like FlexiForce, which are thin and cheap. These sensors have a special layer between polyester sheets.

AC force sensors use solid-state piezoelectric parts. These sensors fix themselves after bending and block low-frequency noise. They give very good accuracy in hard places.

Engineers compare SOUSHINE, and other brands for each job. They pick the technology that fits the project and the place.

Force sensors integration

Hardware compatibility

Engineers need to check if the hardware fits before adding force sensors. They look at a few important things. The sensor must fit in the space and mount the right way. The output format should match the system’s data needs. Communication protocols and voltage must work with the hardware. The sensor should connect straight to edge devices or gateways for quick action. The system must give the sensor enough power. These checks help stop problems during setup. They also make sure the sensors work well in the end.

Software setup

Software setup is very important for force sensors to work. Engineers install drivers and set up software to read data. They check if the software can use the sensor’s output. Many systems need special code or plugins for new sensors. Engineers test the data flow to find mistakes early. They also set alerts for strange readings. Good software setup helps teams get correct data and fast answers from their force sensors.

Tip: Try the software with sample data before using it everywhere. This helps find bugs and makes sure things run smoothly.

Maintenance

Regular maintenance keeps force sensors working well for a long time. The table below shows common ways to care for sensors and how often to do them:

| Maintenance Practice | Frequency | Description |

|---|---|---|

| Regular Cleaning | Daily | Turn off the sensor, wipe it with a soft cloth and alcohol, and make sure nothing is left behind. |

| Inspecting for Physical Damage | Daily | Look for scratches, check connectors, and mounting points to keep the sensor working. |

| Recalibration | Monthly | Calibrate the sensor often for good results, following best practices. |

| Software Updates | Monthly | Check for updates to improve how the sensor works and fix problems. |

| Mechanical Inspections | Monthly | Look for wear and tear, especially on connectors and other important parts. |

Teams that do these steps keep their force sensors working and accurate. If you skip maintenance, sensors can break or give wrong data. Engineers should make a plan and follow it.

Note: Good setup and regular care help force sensors last longer and work better anywhere.

Durability and environment

Harsh conditions

Force sensors sometimes work in very tough places. Hot or cold weather, too much force, dust, or water can change how they work. Many jobs, like in cars and planes, use sensors where things change fast. These changes can hurt the sensor and make it less accurate.

- Too much force can bend the sensor’s diaphragm. This makes the sensor measure force less well.

- Hot weather can stress the sensor’s parts. Over time, this can make the sensor lose shape or stop working.

- Being in very hot or cold places for a long time can make the sensor’s parts weak or stiff. This can make the sensor not last as long.

- Dust, water, and chemicals can get inside the sensor. These things can cause rust or short circuits.

SOUSHINE force sensors have ways to handle heat and too much force. These features help them work when things change. Engineers pick sensors with strong cases and seals to keep out dust and water. They also want sensors with shields to block electrical noise.

Sensors that work in tough places help teams stop problems and keep machines working.

Lifespan extension

Engineers use different ways to help sensors last longer. They clean and check sensors often and watch them closely. The table below shows ways to help sensors last:

| Practice | Description |

|---|---|

| Routine Cleaning | Clean sensors often to get rid of dirt and dust. This helps stop damage and wear. |

| Regular Inspections | Check important parts often. Look for damage before it gets worse. |

| Technology Monitoring | Use special tools to watch sensors. These tools find problems early and help stop breakdowns. |

| Predictive Maintenance | Watch sensor data for warning signs. Fix small problems before they get big. |

SOUSHINE sensors are easy to care for. Their design lets teams check and clean them quickly. Teams use software to watch how sensors are doing. This helps engineers plan fixes and stop sudden problems.

Cleaning and watching sensors helps them last longer, even in hard places.

Engineers also use covers and keep sensors away from heat or chemicals. They follow a schedule for cleaning and checking. These steps help sensors stay right and work well for a long time.

Decision guide

Self-assessment

Project teams need to check if sensor problems affect their work. A simple checklist helps engineers find issues early. They can use these questions to look at their setup:

- Does the project have wrong measurements?

- Do force sensors miss small or big changes?

- Has the team seen slow sensor response during important jobs?

- Do sensors break or lose accuracy in tough places?

- Are there problems when adding sensors to new hardware or software?

- Does the system need recalibration often to stay accurate?

- Have there been surprise failures or downtime from sensor problems?

Tip: Teams should answer each question honestly. If they say “yes” to two or more, sensor problems may slow down the project.

A table helps teams organize what they find:

| Issue Detected | Yes | No |

|---|---|---|

| Wrong measurements | ||

| Missed force changes | ||

| Slow response | ||

| Durability problems | ||

| Integration trouble | ||

| Frequent recalibration | ||

| Surprise failures |

Teams fill out this table during project checks. This helps them spot patterns and decide if upgrades are needed.

Upgrade timing

Engineers need to know when to upgrade force sensors. Waiting too long can hurt safety and slow work. These signs show a project may need better sensors like SOUSHINE:

- The project needs better accuracy for safety or quality.

- The current sensors cannot measure new force ranges.

- The team wants to grow the system or add more sensors.

- The environment is tougher, with more heat, dust, or shaking.

- Old sensors cannot connect to new hardware or software.

- Maintenance costs are higher from repairs or recalibration.

Note: Upgrading to better force sensors can make systems more reliable, cut downtime, and help new project goals.

Engineers should plan upgrades before problems get worse. They can make a timeline based on project needs and budget. Early upgrades help teams avoid delays and keep things working well.

A simple upgrade plan looks like this:

- Check how current sensors work.

- Compare features of better sensors.

- Set goals for accuracy, range, and durability.

- Plan installation and testing.

- Teach staff about new sensor technology.

Teams that do these steps can get better results and be ready for future problems.

Future trends

Sensor technology

Sensor technology is changing fast. Companies make sensors smaller now. Small sensors fit into tight spaces. Robots use these sensors for careful jobs. Factories are safer with better sensors. Miniaturization helps sensors work more accurately. It also makes manufacturing more efficient. Wireless connectivity means no long wires are needed. This makes setup simple and saves money. Wireless sensors send data right away. Engineers can fix problems faster with real-time data.

AI integration gives force sensors new skills. Sensors look at data as soon as it comes in. AI can guess when a sensor might break. Teams can fix things before work stops. AI helps find mistakes in products. This improves quality control. The table below lists the main sensor technology trends:

| Trend | Description |

|---|---|

| Miniaturization | Smaller sensors fit tiny spaces and work better. |

| Wireless Connectivity | Sensors send data without wires, making setup quick. |

| AI Integration | Sensors use AI to study data and spot problems. |

Engineers use these new features in many fields. Small sensors help robots hold things gently. Wireless sensors are easy to put in cars and planes. AI sensors watch machines and warn teams about trouble.

Brand innovations

SOUSHINE will add new features soon. SOUSHINE’s sensors will take the place of buttons in electronics. These sensors measure force, pressure, and weight very well. People will see smoother surfaces on smart home devices. Gaming controllers will feel better to use.

In 2025, force sensors will be in smartwatches and VR systems. These sensors will make devices more fun to use. Fitness devices will track resistance and movement. Smart shoes will measure how you walk. Athletes will use this data to get better.

SOUSHINE works on making sensors more reliable. Their sensors will help make lots of products quickly. They will work well in tough places. New models will handle temperature changes better. They will also protect against too much force. These features help teams build safer machines.

Teams should look for new sensors coming out. These new features will help projects work better and meet higher goals.

Force sensors have some problems. They are not always accurate. Their range and durability can be limited. These problems can slow down projects. They can also make things riskier in robotics, cars, and medical work. Teams should look for these issues early. They can use the decision guide to check how sensors work. Newer sensors like SOUSHINE help engineers fix these problems. They also help teams get better results. Learning about new sensor technology helps projects do well in the future.

- Acting early stops expensive problems.

- Better sensors make things work more often.

FAQ

What is a force sensor?

A force sensor tells how much force is on it. Engineers use them in robots, cars, and planes. They also use them in medical devices. These sensors help machines stay safe and work right.

How often should teams calibrate force sensors?

Teams should check force sensors once every year. They also check after moving things or seeing odd numbers. Regular checks help keep the numbers correct.

Can force sensors work in wet or dusty places?

Some force sensors have tough cases and seals. These keep out water and dust. SOUSHINE sensors are made to work in hard places.

What problems can force sensors cause in projects?

Force sensors can give wrong numbers or break under stress. Sometimes they react too slow. These problems can stop machines or make things unsafe. Projects can get delayed too.

How do engineers choose the right force sensor?

Engineers look at the force range and the size. They check the output type and where it will be used. They compare brands like SOUSHINE. The best sensor fits what the project needs.

Why does temperature affect force sensor accuracy?

When it gets hot or cold, sensor parts change shape. This can make the numbers change. SOUSHINE sensors use special features to keep numbers steady.

What maintenance do force sensors need?

Teams clean sensors and look for damage. They check connectors and recalibrate them. They also update software. Taking care of sensors helps them last longer and work better.

Are wireless force sensors available?

Wireless force sensors are made today. They send data without any wires. Engineers use them for easy setup and quick data sharing.