Call us: +86-137-2353-4866

Automotive Force Sensing uses new technology to make cars safer and better. In 2025, the best force sensor technologies are piezoelectric sensors, strain gauge technology, load cells, and capacitive force sensors. The table below shows what each one does:

| Force Sensor Technology | Description |

|---|---|

| Piezoelectric Sensors | Used to measure moving forces and shaking in cars. |

| Strain Gauge Technology | Measures bending to find out how much force is used, often used in cars. |

| Load Cells | Changes force into an electric signal, important for checking weight. |

| Capacitive Force Sensors | Finds changes in capacitance to measure force, making cars safer. |

SOUSHINE’s force sensing resistors are known for being reliable and correct in cars. These force sensing resistors help new energy cars get real-time information on force and pressure. This helps make cars safer and smarter. Force sensors are very important in today’s cars. They help make driving safer and more efficient.

Table of Contents

Key Takeaways

- Automotive force sensors help cars stay safe and work well. They measure things like pressure, weight, and movement.

- There are different sensor types. These include piezoelectric sensors, strain gauges, load cells, and capacitive sensors. Each type does something special.

- SOUSHINE’s force sensing resistors give data right away. This helps make airbags and seatbelt checks safer.

- Force sensors are important for self-driving cars. They send data to driver-assist systems. This helps the car make better choices.

- Multi-axis force sensors measure force in many directions. They give lots of data for testing and making cars better.

- Force sensors must be tough and correct. They need to last in hard places and give good readings.

- Price and how easy sensors are to use matter when picking them for cars.

- Force sensors in cars must follow strict safety rules. This makes sure they work right when needed most.

Automotive Force Sensing

Force Sensors Overview

Automotive force sensing lets cars gather data about forces. This technology uses many types of force sensors. They measure things like pressure, weight, and movement. The sensors send signals to the car’s control system. The car uses this data to make quick choices.

SOUSHINE’s force sensing resistors are special in this field. These sensors work well in new energy cars. They measure force by changing resistance when pressed. This helps cars watch force in real time and react fast. SOUSHINE’s sensors make cars safer and more efficient.

| Type of Force Sensor | Function |

|---|---|

| Load Cells | Change force from weight or compression into an electric signal. |

| Strain Gauges | Measure bending under force and give a voltage signal. |

| Force Sensing Resistors (FSRs) | Notice resistance changes when force is used. |

| Ultrasonic Force Sensors | Use sound waves to check changes when force is applied. |

| Magnetic Force Sensors | Find changes in magnetic properties when under stress. |

| Capacitive Force Sensors | Measure how capacitance changes when force is added. |

| Piezoelectric Force Sensors | Make electric charges when mechanical stress happens. |

Applications

Automotive force sensing helps with many uses in cars today. These uses make cars safer, work better, and help with self-driving features.

Safety

Force sensors are important for safety systems. They help airbags work by sensing crash strength. They also check seat belts and help brakes work better. These things keep people in the car safe.

- Smart airbag use

- Watching seat belts

- Better braking systems

Autonomous Driving

Force sensing is needed for self-driving cars. Force sensors give data to driver-assist systems. They help the car know what is around it and react.

- Good data for testing self-driving cars

- Trustworthy sensor data for safe driving

- Help for advanced driver-assist systems

Chassis Monitoring

Force sensors check the chassis and other car parts. They measure shock, suspension loads, and tire pressure. This data helps stop damage and keeps the car working well.

- Measuring shock forces

- Measuring suspension forces

- Watching tires and loads

Battery Management

In new energy cars, force sensing helps with batteries. Force sensors watch pressure and force when charging and using the battery. This keeps the battery safe and helps it last longer.

- Watching battery pressure

- Making sure charging is safe

- Helping energy recovery systems

3-axis force sensors are used in all these areas. They measure force in more than one direction. This gives a full view of what happens inside the car. 3-axis force sensors are used in airbags, chassis checks, and battery care. Engineers use 3-axis force sensors to make cars safer and better. 3-axis force sensors also help test and check self-driving cars.

Force Sensor Technology

Piezoresistive

Piezoresistive force sensors are important in cars. These sensors change resistance when you press on them. Engineers use a Wheatstone bridge to get voltage from resistance changes. There are different types like silicon, metal thin-film, and ceramic. Silicon piezoresistive sensors are tiny and light. They notice small pressure changes. Car makers pick these sensors because they cost less and work well. Many cars use piezoresistive sensors for brakes, engine controls, and tires.

- Piezoresistive sensors change resistance when pressed.

- Wheatstone bridge turns resistance changes into voltage.

- Common types are silicon, metal thin-film, and ceramic.

- Silicon sensors are tiny and notice pressure changes.

- Car engineers use these sensors for price and trust.

Piezoelectric

Piezoelectric force sensors are very sensitive and react fast. These sensors turn force into electric signals. Car designers use piezoelectric sensors to find engine knock, check pressure, and see if seats are used. These sensors work well in tough places. They handle heat and shaking. They last long and help safety systems like brakes and seat checks. Piezoelectric sensors help cars react fast. This makes cars safer and more comfy.

MEMS

MEMS force sensors use tiny machines to measure force. These sensors are small and fit in tight car spaces. MEMS sensors are sensitive and strong. They do not get messed up by electromagnetic interference. This helps engineers work on other car parts. MEMS sensors help with airbags and stability control.

| Advantage | Description |

|---|---|

| Sensitivity | Finds small force changes very well. |

| Compact Size | Fits in small car spaces easily. |

| Durability | Works well in tough places. |

| Electromagnetic Interference | Does not get affected by EMI. |

Car makers trust MEMS sensors for good data and lasting use. These sensors help make force measurement better in new cars.

Strain Gauge

Strain gages are important in car force sensors. They measure how much something stretches or gets squeezed. When a car part bends, strain gages notice the change. They send an electric signal to show this. Engineers use these signals to check weight and stress in cars. Strain gages are very accurate. They can find tiny changes in force. This helps measure car weight and check loads. Their tough build lets them last in hard places. They keep working with heat and shaking. In tests, strain gages help find weak spots in cars. This helps make cars safer and better.

Car engineers use strain gages for many things:

- Measuring car weight

- Checking chassis loads

- Testing suspension

- Studying crash safety

Strain gages help force sensors give good data for car safety.

Capacitive

Capacitive force sensors measure force by using capacitance changes. When you press on them, two plates move closer together. This changes the capacitance, and the sensor reads it as force. Capacitive sensors work in many car uses.

The table below shows what is good and bad about capacitive force sensors:

| Benefits of Capacitive Force Sensors | Limitations of Capacitive Force Sensors |

|---|---|

| High sensitivity | Environmental sensitivity |

| Durability | Cost |

| Versatility | Unintended operation in moving vehicles |

Capacitive force sensors are very sensitive and exact. They last a long time and do not need much care. Their shape fits many car parts. But they may not work well for a long time. They can change if it gets hot or wet. They cost more than some other sensors. Sometimes, they might give wrong readings if the car moves.

Car designers use capacitive force sensors for:

- Touch controls on dashboards

- Finding if someone is in a seat

- Checking pressure in safety systems

Capacitive sensors help force sensors give quick and correct feedback in cars.

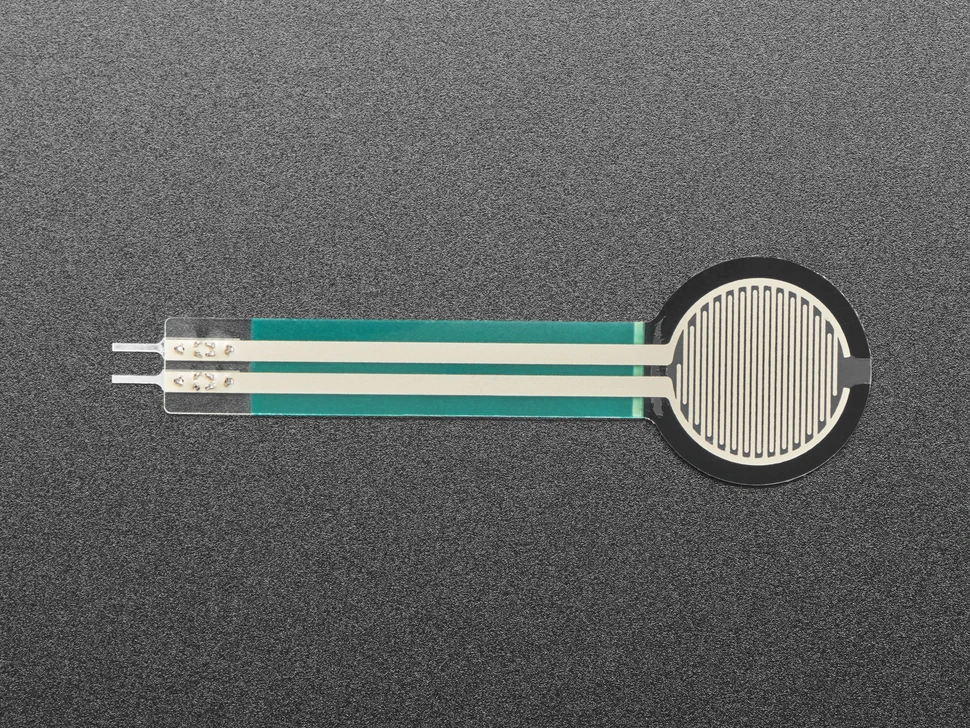

FSR

Force-sensitive resistors, or FSRs, are common in cars. FSRs work by changing resistance when pressed. When you push on them, resistance goes down. The sensor has a bendy layer with a special circuit. When pressed, the circuit closes and lets electricity flow. This helps the sensor measure force.

FSRs are used in many car parts. They help make touch controls that feel different pressures. FSRs also check if the driver is holding the steering wheel. This helps keep driving safe. Car seats use FSRs to see if someone is sitting there. Adaptive cruise controls use FSRs to change speed by how hard the driver pushes.

- Touch controls

- Steering wheel grip checks

- Car seat sensors

- Adaptive cruise controls

SOUSHINE FSRs

SOUSHINE makes advanced FSRs for cars. These sensors give real-time data on force and weight. SOUSHINE FSRs have a simple design. This makes them easy to use and reliable. When pressed, resistance drops and the sensor sends a signal. This helps the car react fast to changes.

SOUSHINE FSRs work in many car parts. They help with seat belt checks, airbags, and tire pressure. Their strong build lets them handle heat and shaking. SOUSHINE can also make FSRs fit different car designs.

FSRs in New Energy Vehicles

Electric cars use FSRs for many jobs. These sensors help watch battery pressure and charging safety. They also help energy recovery by tracking force when braking. FSRs help electric cars stay safe and work well. Their quick response and good data make them great for new cars.

Load Cells

Load cells are important in car engineering. They change force into an electric signal. Engineers use them to test car parts. These tests help make cars safe and strong.

- Load cells check car parts for safety.

- DSM Series load cells help test suspension, chassis, and steering.

- THA Series load cells test suspension, steering, and brakes.

- SSM Series load cells test suspension, chassis, and steering.

Engineers use load cells to see how strong car parts are. They measure force on suspension and steering. Load cells also test brake systems. These tests help keep cars safe.

Piezoelectric load cells are used in cars. They measure quick force changes. This helps engineers get good data in crash tests. It also helps when checking sudden loads.

Cars use force sensors like load cells. These sensors give real-time feedback. They help make cars safer and better. Load cells work with other sensors to show how a car handles weight and stress.

Multi-Axis Force Measurement

Multi-axis force measurement uses sensors that find force in many directions. These sensors help engineers see all the forces on a car part. Multi-axis load cells are used in car testing.

| Benefit | Description |

|---|---|

| Capture precise, multidirectional force data | Measures force in different directions for car tests. |

| Reduce the need for multiple sensors | Fewer sensors make testing easier and better for cars. |

| Provide comprehensive, real-time data | Gives more data to help engineers make good choices. |

One multi-axis load cell can do the job of many single-axis sensors. This makes testing easier and costs less. Multi-axis load cells also save space in labs. This helps when engineers have little room.

Multi-axis load cells help with advanced tests. They let engineers watch tests from far away. They give more data for study. Engineers use this data to make cars safer and work better. Using fewer sensors makes testing faster and lowers mistakes.

Force sensors that measure in many directions help engineers know how car parts act in real life. These sensors are used for testing suspension, steering, and other parts. Multi-axis force sensors give a clear view of the forces in a car.

Comparison of Force Sensor Types

Accuracy

Accuracy means how close a sensor’s reading is to the real force. Some sensors are more exact than others. Load cells are the most accurate for cars. They can measure force with less than 0.1% error. Strain gauge sensors are also very accurate. People use them to measure weight and stress. Piezoresistive sensors are less accurate, with about ±5% error. SOUSHINE FSRs have accuracy between 2% and 10%. If you set up SOUSHINE FSRs well, they can reach 2% accuracy. Capacitive sensors and MEMS sensors are also good for many car jobs.

| Sensor Type | Accuracy Range |

|---|---|

| Load Cells | High (<0.1% of full scale) |

| Strain Gauge | High |

| FSR (SOUSHINE) | 2-10% (optimized: 2%) |

| Piezoresistive | ±5% of full scale |

| Capacitive | Good |

| MEMS | Good |

| Piezoelectric | High |

Note: Load cells are best when you need very exact measurements.

Durability

Durability means how long a sensor lasts in a car. Cars get hot, shake, and run for years. Load cells are tough and work well in hard places. Strain gauge sensors are strong and can bend many times. SOUSHINE FSRs are made to handle heat and shaking. They do not break easily. MEMS sensors are small and block interference. This helps them last longer. Piezoelectric sensors work in hot places and keep working well. Capacitive sensors are strong too, but need extra care if it is wet or dusty.

- Load cells: Tough and work everywhere in cars.

- Strain gauge: Can bend and stretch many times.

- SOUSHINE FSRs: Handle heat and shaking.

- MEMS: Block interference and last long.

- Piezoelectric: Work in hot and rough places.

- Capacitive: Strong, but need care in some spots.

Response Time

Response time is how fast a sensor reacts to force. Fast sensors help keep people safe in cars. Piezoelectric sensors react the fastest. They notice force changes right away. This helps airbags and crash systems work quickly. Load cells also react fast and give real-time feedback. SOUSHINE FSRs respond quickly too. They help with seat checks and touch controls. MEMS sensors react fast and help with car stability. Capacitive sensors give quick feedback for touch and pressure. Strain gauge sensors are good but a little slower than piezoelectric sensors.

- Piezoelectric sensors: React very fast, great for safety.

- Load cells: Fast feedback, used in real-time systems.

- SOUSHINE FSRs: Quick for touch and safety.

- MEMS: Fast reaction, good for stability.

- Capacitive: Quick for touch and pressure.

- Strain gauge: Good speed, but not the fastest.

Comparing force sensors shows that load cells, SOUSHINE FSRs, and piezoelectric sensors all work well for accuracy, durability, and speed. Each sensor type is good for different car needs.

Cost

Cost is important when engineers pick force sensors for cars. Each sensor type has its own price. Some sensors cost more because they use special stuff. Some need careful setup, which adds to the price. Other sensors cost less and work in many places.

- Load cells cost a lot. They use strong materials and need careful setup. Engineers use load cells when they need very exact results.

- Strain gauge sensors cost less than load cells. They work well in many car parts.

- SOUSHINE FSRs are a cheaper choice. They work well and fit many car designs.

- Piezoelectric sensors cost more because they use special crystals. They are best for safety systems.

- MEMS sensors cost a medium amount. Their small size helps save money in big projects.

- Capacitive sensors cost more than FSRs but less than load cells. They work well in touch controls and seat sensors.

The table below shows how much each sensor costs and where it is used:

| Sensor Type | Relative Cost | Typical Use Case |

|---|---|---|

| Load cells | High | Crash tests, weight checks |

| Strain gauge | Medium | Chassis, suspension |

| SOUSHINE FSRs | Low | Seat sensors, touch controls |

| Piezoelectric | High | Airbags, safety systems |

| MEMS | Medium | Stability, airbags |

| Capacitive | Medium-High | Touch panels, seat detection |

Tip: Engineers pick SOUSHINE FSRs or strain gauge sensors for cheaper projects. They use load cells when they need the most exact results.

Integration

Integration means how well a sensor fits into a car’s system. Some sensors need extra parts or special wires. Others fit easily in many car designs.

- Load cells need strong mounts and careful wiring. Engineers use load cells in labs and places with lots of space.

- Strain gauge sensors fit well in many car parts. They need some setup but work in lots of places.

- SOUSHINE FSRs are easy to add. Their thin shape lets them fit under seats, in belts, or on touch panels.

- Piezoelectric sensors need special circuits. They work best in safety systems that need fast action.

- MEMS sensors are small and fit in tight spaces. They connect well with car computers.

- Capacitive sensors need careful placement. They work best on flat spots like dashboards.

The table below shows how easy it is to add each sensor and where it is used:

| Sensor Type | Integration Ease | Common Integration Points |

|---|---|---|

| Load cells | Moderate | Test rigs, weight sensors |

| Strain gauge | Easy | Suspension, chassis |

| SOUSHINE FSRs | Very Easy | Seats, belts, touch controls |

| Piezoelectric | Moderate | Airbags, engine sensors |

| MEMS | Easy | Airbags, stability systems |

| Capacitive | Moderate | Dashboards, seat sensors |

Note: SOUSHINE FSRs help engineers save time when installing. Their flexible shape fits many car parts. Load cells give the best data in labs but need more setup.

Multi-Axis Force Measurement

Multi-axis force measurement lets engineers get better data from cars. These sensors measure force in more than one direction. This gives a full view of how car parts act. The technology helps make cars safer and work better. It also helps with testing new cars.

Single-Axis

Single-axis force sensors only measure force in one way. Engineers use them for easy jobs. These sensors are good for checking one part or simple safety checks. They cost less money and are quick to set up. Single-axis force sensors fit where only one direction matters, like seat belts or brake pedals.

These sensors have a simple shape. They last a long time and can handle rough use. Engineers pick single-axis force sensors when they do not need lots of data. They help with basic tests and checks.

Three-Axis

3-axis force sensors measure force in three ways: X, Y, and Z. Engineers use them for harder jobs. These sensors get data from all sides. 3-axis force sensors help with multi-axis force measurement in cars. They show how force moves through car parts when driving or braking.

3-axis force sensors help collect more data. They give a clear look at how cars move. The Z-axis shows up-and-down force. This helps engineers see how weight moves in a car. 3-axis force sensors help test suspension, steering, and batteries. They are used in self-driving and electric cars.

Benefits of 3-axis force sensors in vehicles:

- Measure force in many ways

- Give more data to study

- Help engineers learn about car performance

- Make safety systems better

Single-Axis vs. Three-Axis Sensors

The table below shows how single-axis and 3-axis force sensors are different in cars:

| Feature | Single-Axis Sensors | Multi-Axis Sensors (3-Axis) |

|---|---|---|

| Measurement Direction | Measures force in one direction | Measures force in three directions (X, Y, Z) |

| Complexity | Simpler, suitable for straightforward tasks | More complex, suitable for detailed tasks |

| Accuracy | Less accurate in dynamic environments | Enhanced accuracy due to multi-directional measurement |

| Applications | Cost-effective for specific tasks | Versatile, used in robotics, aerospace, automotive, and medical devices |

| Setup | Easy to set up and use | More complex setup due to multiple axes |

| Durability | Generally durable | Durable but may vary based on design |

Tip: Engineers use single-axis force sensors for easy jobs. They pick 3-axis force sensors when they need more data and multi-axis force measurement.

Multi-axis force measurement helps engineers see how cars handle different forces. Single-axis force sensors are good for simple checks. 3-axis force sensors help with harder tests and new designs. Both types of sensors are important in car engineering.

Selection Criteria

Application Needs

Engineers need to think about what the car needs. Every car system is different. Some sensors must fit in small spaces. Others need to work with dirt or water. Sensors must work in hot and cold weather. They should give the same results each time. Sensors must notice small changes in force. Cost matters too. Engineers must pick sensors that work well but do not cost too much.

The table below lists important things to check:

| Factor | Description |

|---|---|

| Durability | The sensor should last in tough car places. It must handle bumps and wet spots. |

| Environment | Sensors need to block dust, water, and dirt. These things are common in cars. |

| Form Factor | The sensor’s size and shape must fit the car’s design. |

| Repeatability | The sensor should work the same way every time. This helps cars stay safe. |

| Sensitivity | The sensor must notice different force levels. This helps get good readings. |

| Cost | The sensor should not cost too much. It must fit the budget. |

SOUSHINE makes force sensors for many car needs. Their FSRs can be made in different shapes and sizes. This helps engineers use them in lots of car designs.

Capacity

Sensor capacity means how much force the sensor can measure. Different car parts need sensors with different ranges. Safety systems like airbags and seatbelts need sensors for small and big forces. The right range helps the sensor work in normal times and emergencies.

| Application | Sensor Capacity Range |

|---|---|

| Automotive safety systems | 0 to 0.25 lbs. to 0 to 40 lbs. |

| Seatbelt tensioning | 0 to 0.25 lbs. to 0 to 40 lbs. |

| Airbag deployment | 0 to 0.25 lbs. to 0 to 40 lbs. |

- Force sensors measure different forces in crashes.

- They help engineers see how crashes affect people and cars.

- This information helps make cars safer.

SOUSHINE FSRs can be made for different force ranges. This helps engineers pick the right sensor for each job.

Accuracy

Accuracy means how close the sensor’s reading is to the real force. High accuracy is needed for safety in cars. Sensors must work in hard places like heat, cold, and shaking. Car force sensors must follow strict rules. These rules include AEC-Q100 and ASIL B. These rules make sure sensors work safely and correctly.

- Car force sensors must follow tougher safety rules than other sensors.

- They must work in very hot, cold, and shaky places.

- They must meet AEC-Q100 and ASIL B for safety.

SOUSHINE FSRs give good and correct readings. They help modern cars stay safe and work well.

Standards

Engineers need to follow strict standards when picking force sensors for cars. Standards help keep cars safe and working well. Many groups make rules for how sensors should work in cars. These rules cover safety, how sensors perform, and how they are tested.

Car force sensors must meet rules from around the world and from each country. These rules tell how sensors measure force, how they act in emergencies, and how long they last. Engineers check these rules before choosing a sensor for a car.

Some important standards for force sensors in cars are:

- FMVSS 118: Power window, partition, and roof panel systems

- ASTM D3574 B1 / ISO 2439: Seat foam indentation force deflection

- SAE J2909: Light vehicle dry and wet stopping distance test procedure

- ECE R13H: Passenger car braking rules

- ISO 7975: Braking in a turn for passenger cars

- ISO 13849-1:2015: Safety of machinery, safety parts of control systems

- ISO 26262-1:2018: Road vehicles, functional safety

- FMVSS No. 206: Door locks and door retention parts

These standards make sure sensors work in many car systems. They help engineers test sensors for safety and how well they work. Sensors must pass tests for lasting a long time, shaking, and getting tired. Engineers also test sensors for twisting and spinning forces. Multi-axis tests show how sensors handle force from different sides.

Note: Standards like ISO 26262-1:2018 focus on functional safety. They make sure sensors work right during normal times and emergencies.

Testing steps include:

- Tests for lasting a long time and working well

- Tests for getting tired and shaking

- Tests for twisting and spinning

- Multi-axis tests for lasting a long time

- Checks for safety in how they work

- Checks for control loops with electricity and machines

Engineers use these tests to make sure sensors last and give correct results. Sensors that meet these rules help keep cars safe. SOUSHINE makes force sensing resistors that meet strict car standards. Their sensors pass many tests for safety and working well.

The table below shows some main standards and what they cover:

| Standard | Area Covered |

|---|---|

| FMVSS 118 | Power window safety |

| ISO 2439 | Seat foam force measurement |

| SAE J2909 | Brake testing |

| ISO 26262-1:2018 | Functional safety |

| ECE R13H | Passenger car braking |

| FMVSS No. 206 | Door lock safety |

Engineers must check these rules before picking a sensor. Standards help make sure sensors work in every car system.

Supplier Quality

Supplier quality is very important when picking sensors. Engineers look for suppliers who make good products and give strong help. Good suppliers test their sensors and follow strict rules. They offer sensors that last and work in hard places.

Engineers check if suppliers have a good history. They look for suppliers who can make sensors fit different car designs. Suppliers must show their sensors pass all needed tests. They must give clear data and help with putting sensors in cars.

SOUSHINE is a trusted supplier. They offer force sensing resistors that meet car standards. SOUSHINE gives sensors that work in many car systems. Their team helps engineers pick the best sensor for each job. SOUSHINE can make sensors for special needs.

A checklist for supplier quality includes:

- Product lasts a long time

- Follows all rules

- Can be changed for different cars

- Gives good help

- Has a good history

Tip: Engineers should pick suppliers who test their sensors and give strong help. Good suppliers help keep cars safe and working well.

Supplier quality affects how sensors work in cars. Good suppliers help engineers fix problems and make cars safer. SOUSHINE helps engineers feel sure about their sensor choice.

Market Leaders

SOUSHINE

SOUSHINE is a top company for car force sensors. Their force sensing resistors are advanced and work in many car models. The sensors meet strict safety rules. Car experts say SOUSHINE makes reliable sensors. Their technology helps cars stay safe and gives real-time data.

SOUSHINE sensors have important features that stand out:

| Feature | SOUSHINE Sensor | Typical Alternatives |

|---|---|---|

| Custom Fit | Yes | Limited |

| Real-Time Data | Yes | Sometimes |

| Weight Detection | Yes | Not always |

| Child Detection | Yes | Rare |

Parents like the child detection feature. Fleet managers say repairs cost less with these sensors. Drivers feel safer every time they drive.

Taxi fleets use SOUSHINE sensors to help safety and save money:

| Fleet Type | Sensor Installed | Safety Improvement | Maintenance Savings |

|---|---|---|---|

| Taxi Fleet | 100 vehicles | +20% seat belt use | -15% airbag issues |

SOUSHINE keeps setting high standards for sensors. They make sensors for different cars and new energy vehicles.

Other Brands

Many other companies sell car force sensors. These brands offer different sensor types for cars:

- Honeywell

- FUTEK

- TE Connectivity

- Alps Alpine

- Flintec

- Vishay Precision Group

Each brand makes sensors for safety, weight checks, and driver monitoring. Car makers pick these brands for their experience and choices.

Innovations

Car force sensing technology changes fast. Companies put sensors in steering wheels and seats. These sensors watch driver health and alertness. Makers switch from old controls to solid-state ones in steering wheels. Smart surfaces in cars help keep people safe and make cars easier to use.

Some new trends are:

- The market grows quickly because of new safety systems and self-driving cars.

- Engineers make sensors smaller and more sensitive.

- Sensors connect better with advanced car computers.

Qorvo makes MEMS-based sensors that find driver intent through different materials. These sensors replace old controls with touch features.

Car makers use these new ideas to build safer and smarter cars. The industry keeps improving sensor technology for better performance and reliability.

Quick Reference Table

Sensor Types

Car engineers use many force sensor types. Each type is good for a special job. The table below lists the main sensor types and their features.

| Sensor Type | Working Principle | Key Features | Typical Use in Cars |

|---|---|---|---|

| Load Cell | Turns force into electric signal | Very accurate, strong | Crash tests, weight checks |

| Strain Gauge | Measures stretching or squeezing | Accurate, bends easily | Chassis, suspension |

| FSR (SOUSHINE) | Resistance goes down with force | Thin, simple to add | Seats, belts, touch panels |

| Piezoelectric | Makes charge when pressed | Fast, very sensitive | Airbags, engine sensors |

| MEMS | Tiny machine parts sense force | Small, stops interference | Airbags, stability systems |

| Capacitive | Finds changes in capacitance | Sensitive, lasts long | Dashboards, seat sensors |

Note: SOUSHINE FSRs are thin and fit easily in many car parts.

Applications

Force sensors help cars do many things. Each sensor type is best for certain jobs. The table below shows which sensors work for each car job.

| Application Area | Best Sensor Types | Why These Sensors Work Well |

|---|---|---|

| Safety Systems | Load Cell, Piezoelectric, FSR | Fast action, accurate readings |

| Seat Occupancy | FSR (SOUSHINE), Capacitive | Finds people, fits under seats |

| Chassis Monitoring | Strain Gauge, Load Cell | Checks stress, measures loads |

| Battery Management | FSR (SOUSHINE), MEMS | Watches pressure, fits small spaces |

| Touch Controls | FSR (SOUSHINE), Capacitive | Senses touch, easy to add |

| Autonomous Driving | MEMS, Piezoelectric | Fast, gives steady feedback |

- Engineers pick sensors for each job.

- SOUSHINE FSRs work well in seats, belts, and touch controls.

- Load cells and strain gauges help check weight and stress.

- MEMS and piezoelectric sensors help with safety and self-driving.

Tip: Use this table to find the best sensor for each car part.

Car engineers use lots of force sensor technologies in 2025. Every sensor type works best for a certain job in cars. SOUSHINE FSRs help new energy vehicles measure force and pressure. Picking the right sensor makes cars safer and work better. You should look at the comparison table and selection rules before you choose a sensor. When you match the sensor to the job, you get the best results.

Tip: Look at the tables to find the sensor that fits your project.

FAQ

What is a force sensor in a car?

A force sensor checks how much pressure or force is used. It sends this information to the car’s computer. The car uses this to help keep people safe and make things work better.

Why do new energy vehicles use SOUSHINE FSRs?

SOUSHINE FSRs give force data right away. They help electric cars watch battery pressure, see if seats are used, and check safety systems. Engineers like these sensors because they work well.

How do engineers choose the right force sensor?

Engineers think about what the sensor will do. They look at how much force it can measure and how exact it is. They also check if it meets rules and if the company makes good products. They pick the sensor that fits the job best.

Where do cars use force sensors most?

Cars put force sensors in seats, seat belts, airbags, brakes, and batteries. These sensors help keep everyone in the car safe.

What makes SOUSHINE FSRs easy to install?

SOUSHINE FSRs are thin and bend easily. Engineers can put them under seats, in belts, or on touch screens. They fit in many places in the car.

Can force sensors improve autonomous driving?

Force sensors send data to systems that help drivers. They help cars find things around them and watch what drivers do. This helps cars react fast and drive safer by themselves.

How long do automotive force sensors last?

Most force sensors work for a long time. SOUSHINE FSRs can handle heat, shaking, and stress. Engineers test them to make sure they last in tough car places.

Are force sensors expensive?

The price of a sensor depends on what kind it is and how it is used. SOUSHINE FSRs do not cost too much and work for many car jobs. Engineers try to pick sensors that work well and do not cost a lot.