Call us: +86-137-2353-4866

Pressure sensors find and measure the push from gases or liquids on a surface. These devices turn mechanical force into an electrical signal. People use pressure sensors in many daily tools. You can find them in car brake systems, blood pressure monitors, and smart appliances. The market for pressure sensors is getting bigger, as shown below:

| Source | Base Year | Market Size (USD Billion) | Forecast Period | Projected Market Size (USD Billion) | CAGR (%) |

|---|---|---|---|---|---|

| Fortune Business Insights | 2024 | 20.93 | 2025-2032 | 31.33 | 5.2 |

| GM Insights | 2024 | 17.7 | 2025-2034 | N/A | 8.6 |

| BCC Research | 2022 | 14.3 | 2023-2028 | 25.0 | 9.6 |

Learning about pressure sensors helps people use Force Sensing technology. It also helps them pick the right Force Sensing Resistor for what they need. SOUSHINE gives solutions that help many industries.

Table of Contents

Key Takeaways

- Pressure sensors check the force from gases or liquids. They change this force into electrical signals. These signals help with monitoring and control.

- There are many types of pressure sensors. Some are piezoresistive, capacitive, piezoelectric, optical, and strain gauge. Each type works best for certain jobs.

- Pressure sensors help keep people safe. They make machines work better. They save energy and help protect the environment in many fields.

- SOUSHINE makes thin and bendable pressure mapping sensors. These sensors give detailed and real-time pressure data for many uses.

- Picking the right pressure sensor depends on a few things. These include pressure range, accuracy, environment, output type, and size.

- Installing sensors the right way is important. Regular calibration and maintenance help sensors last longer. This also keeps readings correct.

- Pressure sensors are used in cars, factories, and medical devices. They are also in consumer electronics and research. They help make things safer and more efficient.

- Keeping good records is important. Following the manufacturer’s rules helps users keep sensors working well. It also helps fix problems fast.

Pressure Sensors Overview

What Are Pressure Sensors

Pressure sensors check how much force a liquid or gas puts on a surface. These devices sense pressure and change it into an electrical signal. Engineers use them to watch oil, water, or gas in pipes and machines. The sensor has a part called a diaphragm. This part bends when pressure pushes on it. When it bends, it makes a small electrical signal. The signal goes to a screen or control system.

Pressure sensors come in different types. Some measure absolute pressure, which is the total pressure compared to a vacuum. Others measure gauge pressure, which compares the pressure to the air around it. Differential pressure sensors compare pressure at two places. Many pressure sensors use piezoresistive, capacitive, or piezoelectric ways to sense pressure. Some use optical or MEMS technology for special jobs.

Tip: Pressure sensors and pressure transducers both measure pressure. A pressure transducer always changes the pressure into a standard electrical output, like voltage or current.

Here is a table that shows how experts sort pressure sensors:

| Classification Basis | Categories |

|---|---|

| By Type of Pressure | Absolute pressure sensor, Gauge pressure sensor, Vacuum pressure sensor, Differential pressure sensor, Sealing pressure sensor |

| By Sensing Principle | Strain type, Piezoresistive, Capacitive, Piezoelectric, Vibration frequency, Photoelectric, Optical fiber, Ultrasonic sensors |

Pressure transducers are very important in many systems. They help watch and control pressure right away. These devices help keep things safe, high quality, and efficient in many industries.

Why Use Pressure Sensors

Pressure sensors help people and machines stay safe and work well. They give real-time data about pressure changes. This helps stop accidents and broken equipment. In factories, pressure sensors find leaks and help machines work better. In cars, they check tire and oil pressure to keep people safe.

Pressure sensors also help save energy and protect the environment. They help control emissions and keep air and water clean. In hospitals, pressure sensors help doctors check blood pressure and control ventilators. In airplanes, they measure altitude and cabin pressure to keep flights safe.

Pressure transducers and pressure sensors both help with automation. They let machines change what they do based on pressure data. This makes systems more reliable and cuts down on downtime. Pressure sensors also help with predictive maintenance. They send alerts before something breaks, so workers can fix it early.

Here are some main reasons to use pressure sensors:

- Watch pressure to meet safety and production rules

- Find leaks or pressure drops in hydraulic and pneumatic systems

- Help save energy and watch the environment

- Let systems adjust in real time for better efficiency

- Give data for predictive maintenance and lower repair costs

| Function/Aspect | Description |

|---|---|

| Real-time Monitoring | Pressure sensors give nonstop data for quick system changes. |

| Filtration System Monitoring | Find pressure drops to remind workers to fix filters. |

| Compression Ratio Control | Measure suction and discharge pressures for best performance. |

| Safety Assurance | Stop too much pressure and lower the risk of equipment failure. |

| Predictive Maintenance | Help find problems early and cut down on downtime. |

| Technological Advancements | MEMS sensors make things more accurate and reliable. |

Pressure transducers and pressure sensors make many fields safer, more efficient, and more reliable. They help people make good choices and keep systems working well.

Working Principles

How Does Pressure Sensor Work

Pressure sensors work by finding force from gas or liquid. They turn this force into an electrical signal. This helps devices measure pressure and control systems right away. The way these sensors work has a few main steps.

Mechanical to Electrical Signal

A pressure sensor has a sensing part called a diaphragm. When pressure pushes on the diaphragm, it bends a little. This small bend is important. The sensor changes this movement into an electrical signal. There are different ways to do this:

- The piezoresistive way uses strain gauges. These gauges change resistance when they stretch or get squeezed.

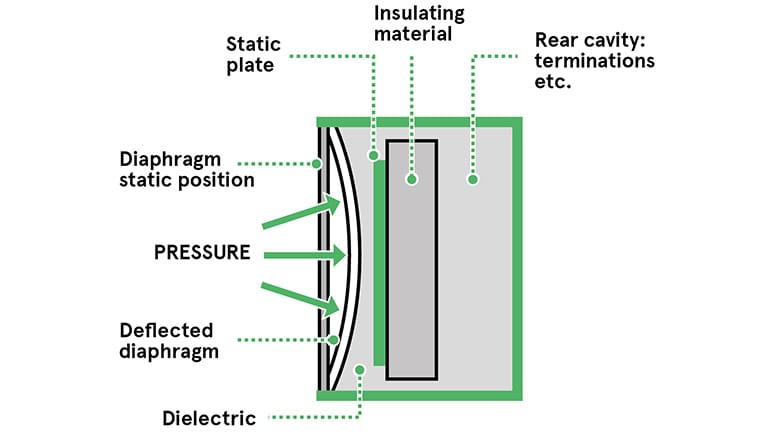

- The capacitive way uses two plates. The space between them changes when the diaphragm moves, which changes the capacitance.

- The piezoelectric way uses special materials. These materials make voltage when they are squeezed or stretched.

After making the electrical signal, the sensor’s electronics process it. The sensor makes the signal stronger, cleans it, and changes it for other devices to use. The output can be analog, like 0-5 V or 4-20 mA, or digital for new systems.

Note: Pressure transducers and sensors work in similar ways. Both use a force collector, like a diaphragm, to sense pressure and turn it into an electrical signal for measurement and control.

Key Components

Pressure sensors have a few main parts that help them work:

- Diaphragm: This thin plate bends when pressure is on it. It is the main part that senses pressure.

- Transduction Element: This part turns the diaphragm’s movement into an electrical signal. It can be a strain gauge, a piezoresistive part, or a capacitor plate.

- Wheatstone Bridge: Many sensors use this circuit to find small resistance changes. It helps make the signal more accurate.

- Electronics: These parts make the signal stronger and process it. They also help with calibration and cleaning the signal.

- Housing: The outside shell keeps the sensor safe from damage and the environment.

Diaphragms can be made from metal, ceramic, or silicon. The material depends on where the sensor will be used. Some sensors use solid-state parts, which last longer and have no moving pieces.

Piezoresistive Technology

Piezoresistive technology is used in many modern pressure sensors. This technology uses the piezoresistive effect. When a material like silicon is stretched or squeezed, its resistance changes. A piezoresistive pressure sensor uses this to measure pressure.

The sensor has a thin diaphragm with piezoresistors on it. When pressure bends the diaphragm, the piezoresistors change resistance. The sensor puts these resistors in a Wheatstone bridge. This setup turns small resistance changes into a voltage that matches the pressure.

SOUSHINE uses advanced piezoresistive technology in its Pressure Mapping Sensors. These sensors use thin, bendy materials with rows of conductive parts. Each crossing point is a sensing spot. When pressure is on it, the resistance at each spot changes. The sensor checks these changes and makes a detailed map of pressure.

SOUSHINE’s way gives many benefits:

- Easy to install and make.

- Strong and lasts a long time.

- Very sensitive and can sense by itself.

- Works well in many places, from -20°C to 100°C.

- Checks pressure well, even in tough conditions.

Piezoresistive pressure sensors work well for many uses. They give accurate, real-time data for measuring pressure. Their way of working makes them a top choice for pressure transducers in cars, hospitals, and research.

| Sensor Type | Working Principle | Key Feature |

|---|---|---|

| Piezoresistive | Resistance changes with pressure on diaphragm | High accuracy, flexible use |

| Capacitive | Capacitance changes as diaphragm moves | Sensitive, needs calibration |

| Piezoelectric | Voltage generated by mechanical stress | Good for dynamic pressure |

Pressure transducers and sensors with piezoresistive technology help measure and control pressure in many systems. Their strong way of working and good output signal make them important for modern pressure measurement.

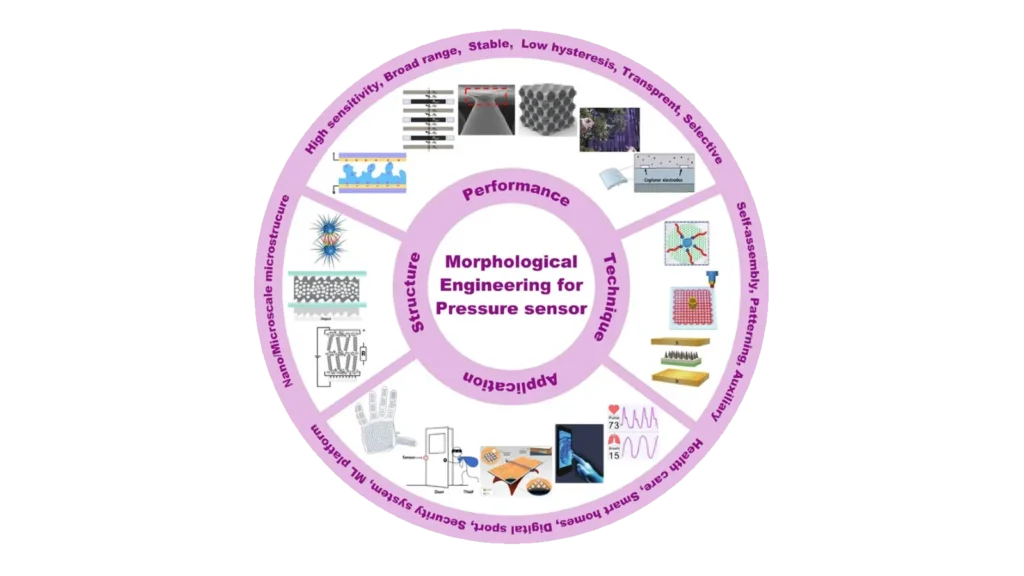

Types of Pressure Sensors

Strain Gauge

A strain gauge sensor checks pressure by seeing resistance changes. It has a thin metal foil on a bendy base. When pressure pushes or pulls the sensor, resistance goes up or down. A Wheatstone bridge circuit finds this change and makes a small voltage. This way works for both steady and moving forces. Strain gauge sensors are used in load cells. Load cells can look like beams, S-shapes, or discs. These sensors do not drift much and give the same results again and again. They also work well when temperatures change because of self-compensating gauges. Many industries use strain gauge sensors for their steady and correct readings. They are best for steady loads and give good results for a long time.

| Feature | Description |

|---|---|

| Principle of Operation | Measures strain by resistance change; uses Wheatstone bridge |

| Force Measurement Range | 5 N to 40 MN |

| Output Signal | Small voltage (mV), needs amplification |

| Construction | Metal load cells, many shapes |

| Performance | Low drift, high repeatability |

| Suitability | Steady and moving pressure |

Capacitive

A capacitive pressure sensor finds pressure by checking capacitance changes. The sensor has two electrodes. One stays still and one moves when pressure is there. When the diaphragm bends, the space between the electrodes changes. This change makes the capacitance go up or down. Circuits like oscillators turn this into an electrical signal. The sensor can be made from plastic, glass, or ceramic. These materials change how sensitive and strong the sensor is. Capacitive sensors can work without power, so they are good for wireless and implantable devices. These sensors are very sensitive and do not use much power. They also work in tough places and stay steady in hot or cold. People use them in medical tools, factories, cars, and planes. Capacitive pressure sensors are great for careful and slow pressure jobs.

- Finds pressure by checking capacitance changes from moving electrodes.

- Very sensitive, uses little power, and lasts a long time.

- Used in medical, factory, car, and plane fields.

Piezoelectric

Piezoelectric pressure sensors use special crystals that make electricity when squeezed or stretched. The voltage they make matches the pressure put on them. These sensors react fast to changes and work in places with lots of pressure. They cannot measure steady pressure because the charge goes away after a while. Piezoelectric sensors use quartz or ceramics. They can work in hard places and in high heat. People use them to check moving pressures, like turbulence, blasts, or engine burning. Medical tools use thin-film piezoelectric sensors to watch heartbeats and pulses. Other uses are alarms, musical tools, and smart gadgets. Their strong build and quick reaction make them good for fast pressure changes.

Tip: Each type of pressure sensor has its own strong points. Pick the right one for your job and the kind of pressure you need to measure.

Optical

Optical pressure sensors use light to check pressure. They send light through a fiber or a tiny space. When pressure changes, the light changes too. The sensor sees these changes and makes an electrical signal. Some common types are Fabry-Pérot interferometers and fiber Bragg gratings. Fabry-Pérot sensors have two mirrors. The space between the mirrors gets bigger or smaller with pressure. This change affects the light and helps measure pressure. Fiber Bragg gratings reflect certain colors of light. When pressure stretches the fiber, the color of the reflected light changes.

Optical pressure sensors are very sensitive. They can find even small pressure changes. This is because they measure tiny shifts in the light’s phase or strength. These sensors do not get mixed up by electromagnetic interference. This makes them good for places with strong electrical noise, like oil wells or MRI rooms. Their small size and bendy fibers help them fit in tight spaces.

Engineers can change optical sensors for different jobs. They can change the light’s power or how the fiber bends. This makes the sensor more or less sensitive. If the fiber bends a lot, the sensor is more sensitive but less steady. If the bend is bigger, the sensor is steadier but less sensitive. This ability to change sets optical sensors apart from others.

Optical pressure sensors work well in tough places. They can handle heat, chemicals, and water. Many industries use them, like oil and gas, medical tools, and labs. They react fast and can be made very small for electronics and tiny machines.

Note: Optical sensors are very sensitive and do not get bothered by electrical noise. They work well in hard places and special jobs.

Pressure Mapping Sensors

Pressure mapping sensors show how force spreads on a surface. They use a grid with many sensing points. Each point checks the pressure at its spot. The sensor makes a map to show high and low pressure areas. SOUSHINE Pressure Mapping Sensors use piezoresistive technology. When pressure pushes on a point, its resistance changes. The sensor reads these changes and makes a detailed pressure map.

SOUSHINE makes its sensors thin and bendy. Some are as thin as 0.1 mm. This helps them fit in small spaces or wrap around curves. The sensors use rows of conductive material with pressure spots at each crossing. This design gives real-time data on how pressure moves across a surface.

Pressure mapping sensors help in many areas. In factories, they check how machine parts press together. In research, they help study how people walk or sit. Medical teams use them in beds and wheelchairs to stop sores. Car makers use them in seats and airbags. Robotics engineers use them to help robots feel touch.

Here are some common uses for SOUSHINE Pressure Mapping Sensors:

- Bathroom scales

- Car airbags

- Medical tools

- Robotics

- Smart seat sensors

- Mattress sensors

- Thin film pressure sensors

The sensors give clear data for quality checks, product design, and safety. Their thin and bendy shape makes them easy to use. They work well in many places and last a long time.

| Feature | Capacitive Tactile Sensors | Resistive Tactile Sensors |

|---|---|---|

| Sensitivity | Excellent | Fair |

| Repeatability | Excellent | Poor |

| Design Flexibility | Excellent | Fair |

| Temperature Stability | Excellent | Fair |

Pressure mapping sensors, especially from SOUSHINE, give accurate, real-time pressure data. They help make products better, keep things safe, and support research in many fields.

Applications

Automotive

Cars use pressure sensors to keep people safe and help them work better. These sensors find quick pressure changes in doors during crashes. This helps airbags open faster to protect people. Some sensors in the front bumper feel when it bends if someone is hit. They start systems that lift the hood to lower injuries. A few cars have sensors that open special airbags for people outside the car.

Pressure sensors also check if closed systems are working right. They find leaks and stop bad gases from getting out. Tire Pressure Monitoring Systems use sensors to check tire air. They warn drivers if a tire has low pressure. This helps stop accidents. Brake sensors watch brake pressure to make sure brakes work well. Systems like ABS and ESC use sensors to keep the car steady and safe.

Engines use pressure sensors to check air and fuel pressure. This helps the car use less gas and go faster. Air and suspension systems use sensors to control air, heat, and how the car rides. These things make the car comfy and steady. As cars get smarter, they need more pressure sensors for new uses.

Industrial

Factories and big buildings use pressure sensors in many ways. HVAC systems need sensors to control heat, air, and cooling. Cleanrooms use sensors to keep the air clean and safe. Oil and gas companies use sensors to watch pipes and tanks. Chip makers use sensors to keep their work clean.

Data centers and power systems use sensors to stay safe. Water plants use sensors to make sure water is clean. Factories use sensors to check quality and keep workers safe. Building systems use sensors to move air and control pressure in big spaces. Scales and weighing machines use sensors to get the right weight. Labs use sensors to test how products work.

SOUSHINE Pressure Mapping Sensors help engineers see how pressure spreads in machines. These sensors help check quality and make sure things work right. Their thin and bendy shape lets them fit in small places, which is good for new factory needs.

Medical

Doctors use pressure sensors in medical tools to watch patient health. These sensors check pressure inside the brain, eyes, heart, or bladder. Good pressure checks help doctors see how sickness changes and plan care. Pressure sensors can watch changes all the time, not just once.

Some sensors can go inside the body and lower the chance of infection. They let doctors watch patients for a long time, even at home. New tech makes sensors more exact and dependable. Blood pressure cuffs, breathing machines, and tubes all use pressure sensors. These tools give real-time data to keep patients safe and help doctors.

SOUSHINE’s pressure mapping tech helps with research and making new medical tools. Their sensors check how pressure spreads in beds, chairs, and devices. This helps stop sores and makes patients more comfy. As tech gets better, pressure sensors are used more in medicine.

Consumer Electronics

Pressure sensors are very important in many gadgets people use. These sensors help devices react to touch and track health. They also make technology easier for people to use. Companies use different pressure sensors, like capacitive and MEMS, to make products smarter.

- Smartphones have pressure sensors for touch screens. You can press hard or soft to open apps or use features. This makes phones simpler and gives new ways to use them.

- Wearables, like smartwatches and fitness bands, use pressure sensors too. They check your heart rate, count steps, and watch your health. These sensors help people reach their fitness goals.

- Gaming devices use pressure sensors for better play. Players press buttons with different force to control games.

- Smart home appliances, like washing machines and fridges, use pressure sensors. These sensors help save energy and keep things safe. They let machines change settings based on the pressure they feel.

- Pressure sensors are now very small. MEMS technology makes them more sensitive and saves energy. This helps companies put them in tiny gadgets.

- When pressure sensors work with IoT and AI, devices get smarter. For example, a smart thermostat can change heat if room pressure changes.

Tip: More people want health tracking in their gadgets. Pressure sensors give good data for fitness and health checks.

Manufacturers must follow safety and energy rules. They pick advanced pressure sensors to meet these rules and make products better. That is why pressure sensors are now a key part of modern electronics.

Research and Biomechanics

Scientists use pressure sensors to study how the body moves. These sensors measure how pressure spreads on the body when people move. In sports, pressure sensors work with other tools to watch athletes. The sensors give real-time data about posture, balance, and force.

Pressure sensors are found in insoles, seats, and wearables. They measure how much force each body part feels. This helps scientists learn about walking, running, and sitting. For example, insoles with pressure sensors show how a runner’s foot hits the ground. Coaches and doctors use this data to stop injuries and help athletes do better.

In medical research, pressure sensors help study problems like diabetic foot disease. They measure pressure on the foot to find spots that might get sores. Researchers also use these sensors to test prosthetic devices. By checking pressure in a prosthetic socket, they can make it more comfy for users.

Pressure mapping sensors, like SOUSHINE’s, are very sensitive and accurate. They collect lots of data fast. Special software helps show and explain this data. This helps with quality checks, planning care, and watching progress in research and clinics.

Choosing Pressure Sensors

Application Needs

Every job needs a different pressure sensor. Some jobs need sensors that work in tough places. Other jobs need sensors that fit in small spaces. The type of pressure to measure is important too. It can be gauge, absolute, or differential. For example, a car tire sensor checks gauge pressure. A weather station may need absolute pressure. Some industries need sensors that are safe in dangerous areas. Others want sensors that give digital signals for easy data use. Picking the right sensor helps systems work well and stay safe.

Key Factors

Range

The pressure range shows how much force a sensor can measure. Users must pick a sensor with the right range for their job. If the range is too low, the sensor could break. If the range is too high, the readings may not be clear. Some sensors handle very high pressures. Others work best with small forces.

Accuracy

High accuracy means the sensor gives numbers close to the real value. Some jobs, like lab tests, need very high accuracy. Other jobs, like checking air in a tire, do not need exact numbers. Accuracy can change with temperature, so users should check the sensor’s specs. Good accuracy keeps machines safe and products high quality.

Environment

Sensors must work where users put them. Some sensors face water, dust, or chemicals. Others must handle shock or big temperature changes. The sensor’s material must match what it touches to avoid damage. For example, a sensor in a chemical plant needs strong, safe materials.

Output Type

Sensors can give analog or digital signals. Some systems need a simple voltage or current. Others use digital signals for computers or smart devices. The right output type makes it easy to connect the sensor to other tools.

Size and Shape

The size and shape of the sensor matter for fitting into devices. Small sensors fit in tight spots. Thin and flexible sensors, like SOUSHINE’s, can wrap around curves or fit under seats. The right shape helps the sensor work well without getting in the way.

Tip: Always check the sensor’s datasheet for details like burst pressure, temperature range, and how the sensor handles shock.

SOUSHINE Product Selection

SOUSHINE has many choices for picking a pressure sensor. Their Pressure Mapping Sensors use high accuracy piezoresistive technology. These sensors are thin, flexible, and fit many shapes and sizes. SOUSHINE helps users pick the best sensor for their needs. They offer design help, technical support, and even custom sensors for special jobs.

SOUSHINE’s support includes:

- Design help from start to finish

- Custom sensors for special projects

- Quality checks for every sensor

- A Flex Sensor Library for easy design and testing

- Direct contact for questions and help

SOUSHINE’s team helps users with setup, calibration, and fixing problems. Their guides and resources make it easy to use high accuracy sensors in many fields. With SOUSHINE, users can trust their pressure sensors will work well and last long.

Using and Maintaining Sensors

Installation Tips

Installing pressure sensors the right way helps them last. Pick a spot that is clean and dry. Do not put the sensor near strong shaking or hits. Use brackets or pads to hold the sensor in place. This stops it from moving and keeps it safe.

Use sealed boxes to keep out dust and water. In wet places, use dehumidifiers or special boxes. This stops rust and keeps the sensor working. Make sure wires are tight and clean. Loose wires can make the sensor give wrong signals.

Be gentle with sensors. Do not drop or hit them. Store extra sensors in a place with good air and temperature. Always follow the maker’s steps for putting in the sensor. This helps you avoid mistakes and keeps the sensor working right.

Tip: Put labels on each sensor and its wires. This makes checking and fixing them easier later.

Calibration

Calibration helps pressure sensors stay correct. Use a tool that is much more accurate than the sensor. Check the sensor at all the pressures it will see. This helps find mistakes or drift.

Do calibration at the same temperature the sensor works in. Hot or cold can change the readings. Calibrate often, especially in tough places. Some sensors need it every year. Others need it more often.

Here are the steps for calibration:

- Look at the sensor for dirt or damage.

- Hook up the sensor to a very good standard.

- Put on known pressures and write down what the sensor shows.

- Change zero and span if you need to.

- Write down all results and keep the papers safe.

Only change the span if you must. Changing zero is safer and keeps the factory settings. Always check that your standard is steady and right.

Note: Keep good records of all calibration work. This helps you watch how the sensor works and find problems early.

Troubleshooting

If a pressure sensor gives wrong numbers, look at it first. Check for loose wires, dirt, or broken parts. Clean the sensor and its holes if needed. Make sure all wires are tight.

If it still does not work, test it with a good standard. See if the sensor matches the right value. If not, calibrate it again. Change old parts like seals or wires if needed.

Some common steps are:

- Look for dust or water inside the box.

- Make sure the sensor is held tight.

- Test the sensor at different pressures.

- Check old calibration notes for drift.

Teach workers how to find and fix sensor problems. Good training stops mistakes and keeps things working well.

Tip: Use trusted calibration services for better help and accuracy.

Maintenance

Proper maintenance helps pressure sensors work well for a long time. Regular care keeps sensors accurate and reliable. Users should follow a simple routine to check and clean their sensors.

Key Maintenance Steps:

- Visual Inspection:

Users should look at the sensor and its wires often. They can spot dirt, dust, or damage. If they see cracks or loose parts, they should fix them right away. - Cleaning:

Clean sensors work better. Users can wipe the sensor with a soft, dry cloth. For sticky dirt, they can use a damp cloth. They should avoid harsh chemicals or water sprays. These can harm the sensor or its parts. - Check Connections:

Wires and plugs must stay tight. Users should check for loose or frayed wires. They should replace damaged wires to stop signal loss or errors. - Protect from Environment:

Sensors last longer in safe places. Users should keep sensors away from water, oil, and strong chemicals. If the sensor works in a tough place, they can use covers or sealed boxes. - Monitor Sensor Output:

Users should watch the sensor’s readings. If numbers change a lot or seem wrong, the sensor may need cleaning or repair. - Schedule Regular Checks:

A set schedule helps users remember to check sensors. They can make a checklist for each sensor. This helps them track what they have done.

Tip: Users should keep a logbook for each sensor. They can write down cleaning dates, repairs, and any problems. This record helps find patterns and plan future care.

Common Maintenance Tools:

| Tool | Use |

|---|---|

| Soft cloth | Wipe dust and dirt |

| Small brush | Clean hard-to-reach spots |

| Multimeter | Check electrical signals |

| Screwdriver | Tighten or loosen screws |

| Protective cover | Shield sensor from damage |

Best Practices:

- Store spare sensors in a dry, cool place.

- Handle sensors with care. Dropping or bending can cause damage.

- Train workers on proper cleaning and handling.

- Replace worn-out parts before they fail.

Sensors that get regular care last longer and give better data. Good maintenance saves money and time. It also helps keep machines and people safe.

Note: SOUSHINE offers guides and support for sensor care. Users can contact SOUSHINE for help with maintenance or questions about their sensors.

Pressure sensors let people check force in lots of areas. These devices change pressure into signals for machines. Picking the right sensor keeps systems safe and working well. SOUSHINE gives tools and help to anyone wanting to learn more. With the right knowledge, readers can try new things and make their projects better.

Keep learning and see how pressure sensors can help you! 🚀

FAQ

What does a pressure sensor measure?

A pressure sensor checks how much force a gas or liquid puts on a surface. The sensor turns this force into an electrical signal. This signal lets machines or people see and use the pressure data.

How do SOUSHINE Pressure Mapping Sensors work?

SOUSHINE Pressure Mapping Sensors use piezoresistive technology. Each sensing spot changes resistance when pressed. The sensor reads these changes and makes a detailed pressure map.

Where can people use pressure sensors?

People use pressure sensors in cars, factories, hospitals, and electronics. These sensors help control machines, check safety, and collect data for research. SOUSHINE sensors also help with product design and clinical studies.

How often should someone calibrate a pressure sensor?

Calibration keeps a sensor working right. Most people check calibration once a year. In tough places, more checks may help. Always follow the maker’s advice for best results.

Can pressure sensors fit into small or curved spaces?

Yes. SOUSHINE Pressure Mapping Sensors are thin and flexible. Users can put them in tight spots or on curved surfaces easily.

What should someone do if a sensor gives strange readings?

First, check the wires and connections. Clean the sensor if needed. If the problem stays, recalibrate the sensor. Contact SOUSHINE support for more help.

Do pressure sensors need special care?

Regular cleaning and checks help sensors last longer. Users should keep sensors dry and safe from harm. A simple checklist helps track care and find problems early.

What output signals do pressure sensors provide?

Pressure sensors can give analog signals, like voltage or current, or digital signals for computers. The output type depends on the sensor model and the system it connects to.