Call us: +86-137-2353-4866

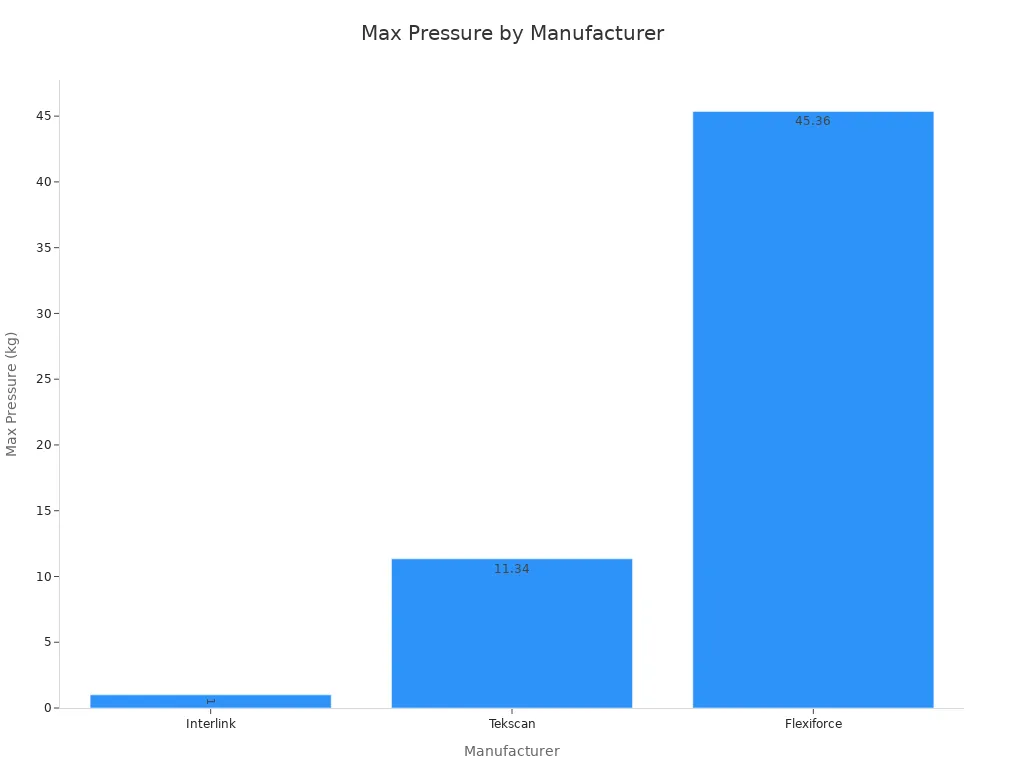

You can find the best force sensitive resistor products from SOUSHINE, Interlink, Tekscan, Flexiforce, SparkFun, Adafruit, and Sensitronics. Each brand has different shapes, sensing areas, and pressure ranges. Flexiforce is known for being very accurate. Tekscan works well for a wide sensing range. The market for force sensing is getting bigger. It is growing fast in cars and healthcare.

Tip: Pick a force sensitive resistor with the right shape and range for your project. This helps you get good results.

Table of Contents

Key Takeaways

- Pick the right force sensitive resistor for your project. Think about its shape, how sensitive it is, and the pressure it can handle.

- Force sensitive resistors can be used in many ways. You can use them in robots, healthcare tools, and smart gadgets.

- Brands have different features. SOUSHINE is good for accuracy and custom options. Interlink costs less and is easy to use.

- You need to calibrate force sensitive resistors often. This helps you get correct measurements and keeps your project working well.

- Check how strong and long-lasting the force sensitive resistor is. This matters if you use it a lot or in tough places.

- Force sensitive resistors give fast feedback. They work well when you need quick answers right away.

- Put force sensitive resistors in your design with care. Make sure they are mounted right and protected from things like dust or water. This keeps them working well.

- Test your force sensitive resistor setup before you finish your project. This helps you find problems early and makes sure it works right.

Force Sensitive Resistor Basics

How FSRs Work

A force sensitive resistor changes how much it resists electricity when you press it. The sensor has two main layers. One layer has a special material that resists electricity. The other layer has a circuit. A spacer keeps the layers apart until you push down. When you press, the layers touch each other. This makes the resistance go down. The sensor then sends a signal that matches how hard you press.

You can look at the table below to see the main parts of a force sensitive resistor:

| Component | Description |

|---|---|

| Piezoresistive Effect | Resistance gets lower when you press harder. |

| Conductive Layers | Made with materials that let electricity flow. |

| Spacer Layers | Keeps the layers apart until you press the sensor. |

| Mechanism | Pressure pushes layers together and changes the resistance. |

This simple design lets you measure force easily. The sensor is thin and bends, so it works in many projects.

Key Benefits for Makers and Engineers

Force sensitive resistors are helpful for many reasons:

- You can use them in easy circuits without extra parts.

- They fit in small places and do not use much power.

- You can pick from many shapes, sizes, and how sensitive they are.

- Robots use them to measure grip or touch.

- They are good for smart gadgets and things you wear.

These sensors help you make force measuring systems that are simple to use. You can also change them for special jobs, like measuring big or small forces.

Note: Force sensitive resistors give you feedback right away. This helps you fix things fast in your project.

Common Applications

You will find force sensitive resistors in many real-life uses. In healthcare, they track how patients move and warn staff. Smart beds use them to check comfort and movement. Medical tools use them to give quick feedback. They also help stop mistakes by warning about too much pressure.

Here are some ways people use them:

- Robots put them in fingers and grippers to feel touch.

- Wearable devices use them to sense pressure.

- Engineers use them in rehab and ergonomic tools to record pressure from people.

Force sensitive resistors help you make things that react to touch and pressure. They are thin and cheap, so many people use them for engineering and DIY projects.

Top Force Sensitive Resistor Brands

SOUSHINE FSRs

Features & Specs

SOUSHINE force sensitive resistors work in many fields. You can use them in cars, hospitals, robots, and electronics. SOUSHINE gives you lots of choices for size and shape. You can pick how sensitive the sensor is. You can also choose the color or add your own design. These sensors use strong materials, so they last long. You can pick the output signal and force range for your project.

Here is a table that shows why SOUSHINE is special:

| Feature | SOUSHINE’s Technology | Competitors |

|---|---|---|

| Accuracy | High | Lower |

| Durability | Long-lasting | Varies |

| Customization | Many choices | Fewer choices |

| Power Consumption | Low | Higher |

| Integration Ease | Simple | Harder |

You can also change these things:

| Customization Aspect | Description |

|---|---|

| Size | Make the sensor fit your project |

| Shape | Pick square, round, or custom shapes |

| Output Signal | Choose the output signal you need |

| Calibration Specs | Set calibration for your needs |

| Materials | Pick from different materials |

| Force Range | Set how much force the sensor can measure |

| Thickness | Pick the thickness you want |

| Colors | Choose colors and finishes |

| Artwork | Add your own artwork or design |

Performance & Sensitivity

SOUSHINE sensors are very accurate and respond fast. You can use them for small or big force measurements. They use little power, so they work well in battery devices. You can add them to your project easily because of their simple design.

Pros & Cons

Pros:

- Very accurate

- Lasts a long time

- Many ways to customize

- Uses little power

- Easy to use in projects

Best Uses

SOUSHINE sensors work in many places:

- Car safety systems

- Patient checks in hospitals

- Robots for touch and grip

- Electronics for touch controls

- Special force sensors for custom jobs

Interlink FSRs

Features & Specs

Interlink makes small and bendable force sensors. You can use them in lots of projects. They are easy to add and do not cost much. These sensors work well in human-machine interfaces and simple systems.

| Feature | Interlink FSRs | Other Brands |

|---|---|---|

| Size | Small | Varies |

| Flexibility | High | Varies |

| Affordability | Affordable | Varies |

| Integration Ease | Easy to integrate | Varies |

| Application Suitability | HMI systems and more | Varies |

| Sensitivity to Light | May not sense light touches | Varies |

Performance & Sensitivity

These sensors work well for basic jobs. Interlink sensors are best for medium or strong pressure. They might not sense very light touches.

Pros & Cons

Pros:

- Small and bendy

- Simple to use

- Not expensive

Cons:

- Might not sense light pressure

Best Uses

You can use Interlink sensors for:

- Robots to check grip strength

- Measuring how people or animals walk

- Sensors in wheelchair seats

- Electronic music tools

- Smart boxing gloves

- Shoe insoles to check pressure

Tekscan FSRs

Features & Specs

Tekscan has flexiforce sensors for advanced needs. These sensors have thin and bendy circuits. You can change the force range for your project. Tekscan sensors work well in professional and factory settings.

| Feature | FlexiForce | Shunt Mode |

|---|---|---|

| Accuracy | Higher accuracy | Lower accuracy in 0-4 N range |

| Linearity | More linear | Non-linear in tests |

| Resistance Drift | Minimal drift | Higher drift |

| Force Range | Adjustable | Limited range |

| Construction | Ultra-thin, flexible | Standard construction |

Performance & Sensitivity

Tekscan sensors are very accurate and give steady readings. They show a straight response, so you can trust the data. The sensors do not change much over time, so results stay the same.

Pros & Cons

Pros:

- Very accurate

- You can change the force range

- Thin and bendy

- Readings stay steady

Cons:

- Not as accurate at very low forces (some models)

Best Uses

Tekscan sensors work in:

- Electronics for touch and pressure sensing

- Robots and machines for exact movement

- Healthcare tools for quick pressure checks

- Car systems for safety

- Factory equipment for better work

Flexiforce FSRs

Features & Specs

Flexiforce sensors help you measure force in many projects. You can pick custom or standard force sensors from their lineup. These sensors work in places that are hot, cold, or damp. There are many sizes and force ranges to choose from. Flexiforce sensors let you calibrate them often for better results.

| Feature | Description |

|---|---|

| Calibration Importance | Regular calibration keeps your readings accurate. |

| Environmental Adaptability | Sensors work in extreme temperatures and humidity. |

| Accuracy Range | Typical accuracy is ±10%, which fits most precision needs. |

Performance & Sensitivity

Flexiforce sensors give you very exact measurements. They react fast when the force changes. Many people say these sensors last over a year with daily use. Flexiforce sensors passed tests with one million presses at 2.3 kg. After testing, they still worked well and stayed sensitive. Some users put them in smart shoes and said they worked great after six months. This means Flexiforce sensors can last a long time.

Pros & Cons

Pros:

- Very accurate for many uses

- Works in tough places

- Lasts long with few problems

- Has both custom and standard choices

Cons:

- Needs to be calibrated often for best results

Best Uses

You can use Flexiforce sensors in robots, medical tools, and factory machines. They work in smart shoes, grip testers, and pressure maps. If you need a force sensitive resistor for careful jobs, Flexiforce is a good pick.

SparkFun FSRs

Features & Specs

SparkFun has force sensitive resistors that are thin and bendy. You can use them when you do not have much space. These sensors connect easily to microcontrollers and other circuits. You can pick the force range that fits your project.

- Very sensitive to force or pressure

- Thin and bendy for small spaces

- Simple to connect to analog inputs

- Comes in different force ranges

- Fast response for real-time feedback

Performance & Sensitivity

SparkFun FSRs react quickly to changes in force. They are good for school kits and test projects. You can try out ideas before using more advanced sensors. These sensors work best for light and medium pressure. They are great for touch controls and simple feedback.

Pros & Cons

Pros:

- Easy for beginners to use

- Thin and flexible

- Good for fast test projects

- Cheap for classroom use

Cons:

- Not as exact as expensive models

- Does not last long if used a lot

Best Uses

You can use SparkFun FSRs in school projects, DIY electronics, and simple robots. They help you learn about force sensors. These sensors fit in wearables, music tools, and interactive displays.

Adafruit FSRs

Features & Specs

Adafruit has many force sensitive resistors for different needs. The most popular ones are the Round Force-Sensitive Resistor (FSR) – Alpha MF01A-N-221-A01 and the Round High Force Sensitive Resistor (FSR) – Alpha MF01A-N-221-A05. You can see their main features in the table below.

| Model Name | Force Range | Link |

|---|---|---|

| Round Force-Sensitive Resistor (FSR) – Alpha MF01A-N-221-A01 | 0.3 ~ 10 Newton | Product Page |

| Round High Force Sensitive Resistor (FSR) – Alpha MF01A-N-221-A05 | 1 ~ 100 Newton | Product Page |

Adafruit also gives you helpful guides and instructions for their sensors.

| Title | Description |

|---|---|

| Using an FSR | Guide on how to use a force sensitive resistor. |

| Connecting to an FSR | Instructions for connecting FSRs in projects. |

Performance & Sensitivity

Adafruit FSRs work well in many projects. They sense both soft and hard pressure. You can use them in displays, touch controls, and pressure mats. Adafruit’s guides help you set up and test your sensors fast.

Pros & Cons

Pros:

- Many models to choose from

- Good guides and support

- Simple to set up

- Works for soft and strong force

Cons:

- Not made for very exact factory jobs

Best Uses

You can use Adafruit FSRs in maker projects, school kits, and art. They work in touch toys, pressure mats, and simple robots. If you want to learn about force sensing or need a sensor for a fun project, Adafruit has many choices.

Sensitronics FSRs

Features & Specs

Sensitronics is different because their sensors have new designs. They use water-based FSR ink. They print on materials that can be recycled or break down in nature. You can ask for custom sensors to match your project. Sensitronics has made force sensing resistors for over 40 years. Their products are high quality and good for the environment.

| Feature | Description |

|---|---|

| Innovative Design | Sensitronics makes membrane sensors that are interactive and expressive. |

| Environmental Focus | Uses water-based ink and materials that are safe for the earth. |

| Customization | Makes special sensors for many different uses. |

| Experience | Has more than 40 years working with FSR technology. |

| Production Quality | Keeps high standards and offers good prices. |

Performance & Sensitivity

Sensitronics sensors give you steady and reliable results. They made a special LowDrift Force-Sensing Resistor. This sensor keeps your readings stable for a long time. You can use these sensors when you need results that do not change much.

Sensitronics fixed the problem of ‘drift’ in Force-Sensing Resistors with their LowDrift Force-Sensing Resistor.

Pros & Cons

Pros:

- You can get sensors made just for your project.

- The sensors use materials that are good for the planet.

- They have low drift and give steady readings.

- The company has lots of experience.

Cons:

- Custom sensors might take longer to make.

Best Uses

Sensitronics FSRs work in many areas. The table below shows where you can use them:

| Project Type | Applications |

|---|---|

| Healthcare | Used in patient beds, rehab tools, and health trackers |

| Automotive | Used for seat sensors, dashboard buttons, and pressure controls |

| Consumer Electronics | Used for touch input in phones, game controllers, and smart gadgets |

| Industrial Automation | Used for pressure tracking, quality checks, and machine safety |

| Aerospace | Used for force checks in aircraft controls and door safety |

You should choose Sensitronics FSRs if you want sensors that fit your needs, help the earth, and give you results you can trust.

Choosing a Force Sensitive Resistor

Picking the right force sensitive resistor helps your project work well. You should think about a few important things before you choose. Every project is different, so match the sensor to what you need.

Key Selection Criteria

Sensitivity & Range

You need a sensor that can sense the right force. Some sensors feel light touches. Others can measure heavy pressure. Most force sensitive resistors work from 0.2N (20g) to 20N (2kg) or more. They react very fast, in just a few milliseconds. This makes them good for quick feedback. Here are some common features:

| Specification | Description |

|---|---|

| Force Sensitivity Range | 0.2N to 20N or more, model dependent |

| Operating Voltage | 1V to 5V, works with microcontrollers |

| Response Time | Milliseconds |

| Durability | Millions of actuations |

| Linearity | Non-linear, needs calibration |

| Operating Temperature | -30°C to +70°C |

| Thickness and Flexibility | 0.2mm to 1mm |

| Resistance Range | Megaohms to hundreds of ohms |

| Actuation Force | Minimum 20g |

| Repeatability and Drift | ±2% to ±5% |

Size & Form Factor

The sensor’s size and shape change how you use it. You can pick small circles, big squares, or long strips. Here are some common sizes and shapes:

| Size/Shape | Description |

|---|---|

| 0.2″ Diameter Circle | Good for touch control |

| 0.6″ Diameter Circle | Larger area for more force |

| 1.5″ Square | Fits bigger surfaces |

| 4.0″×0.4″ Strip | For linear force sensing |

Durability & Lifespan

You want a sensor that lasts a long time. Many FSRs can handle millions of presses. If your project faces dust or water, pick a sealed sensor. If you make lots of devices, repeatability is important. Sensors that work the same every time help with big projects.

Price & Availability

You should think about cost and what you need. Some sensors have extra features, but you might not need them. Pick a sensor that fits your budget and is easy to buy.

Here is a summary of what to look for:

| Criteria | Description |

|---|---|

| Durability | Handles rough use and lasts long |

| Environment | Works in dust, moisture, or harsh places |

| Form Factor | Fits your device because of size and shape |

| Repeatability | Gives the same results every time |

| Sensitivity | Detects the right force for your project |

| Cost | Meets your needs without extra expense |

Matching FSRs to Projects

You should match the sensor’s features to your project. Calibrate your sensor for best results. Protect it from too much force. Mount the sensor flat and do not bend it. If your project faces temperature changes, use software to fix drift. These steps help your sensor work well.

- Calibrate for your application

- Use overforce protection

- Mount flat and avoid twisting

- Adjust for temperature if needed

Integration Tips

You can make your project better by following these tips:

| Technique | Description |

|---|---|

| Regular checks and cleaning | Keeps readings accurate and sensors working well |

| Stable power supply | Prevents spikes and keeps measurements steady |

| Noise reduction | Use short wires and add a capacitor to filter signals |

| Sensor positioning | Place away from moving parts and use soft pads |

| Tail extenders | Protects connections and allows better placement |

Tip: Test your sensor setup before you finish your project. This helps you find problems early and makes sure your system works.

FSR Product Comparison

Feature Comparison Table

You might want to know how top brands compare. The table below lists important features. Use it to help pick the right sensor for your project.

| Brand | Accuracy | Durability | Customization | Power Use | Size Options | Price Range |

|---|---|---|---|---|---|---|

| SOUSHINE | High | Long | Many | Low | Wide | $$ |

| Interlink | Medium | Medium | Few | Low | Small | $ |

| Tekscan | High | Long | Some | Low | Thin | $$$ |

| Flexiforce | High | Long | Many | Low | Many | $$$ |

| SparkFun | Medium | Medium | Few | Low | Small | $ |

| Adafruit | Medium | Medium | Some | Low | Many | $-$$ |

| Sensitronics | High | Long | Many | Low | Custom | $$-$$$ |

SOUSHINE, Tekscan, and Flexiforce are very accurate and last long. Interlink and SparkFun are good if you want to save money. Sensitronics is special because you can get custom designs.

Performance in Real-World Use

You want a sensor that works well in real projects. Engineers test force sensitive resistors in many ways. They check how sensors handle lots of use, how fast they react, and if the readings stay steady.

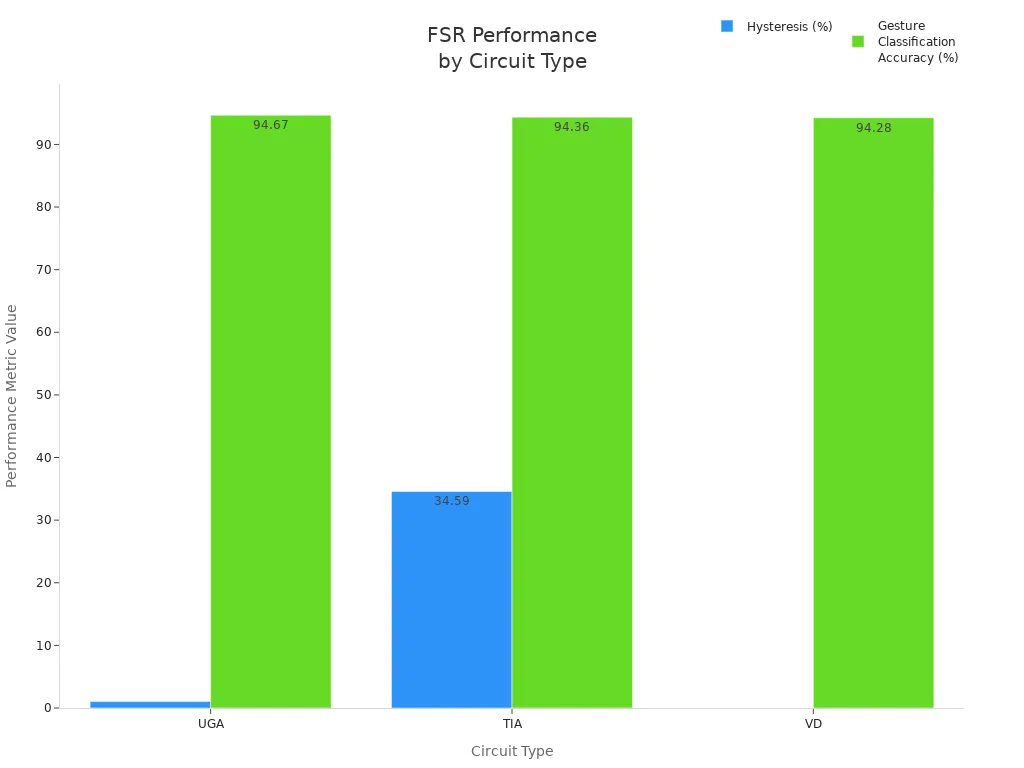

The table below shows results from gesture tests. It shows how different circuits change performance.

| Circuit Type | Hysteresis (%) | Gesture Classification Accuracy (%) | IDNN Value | WD Value |

|---|---|---|---|---|

| UGA | 1.03 | 94.67 (SD 6.71) | Highest | N/A |

| TIA | 34.59 | 94.36 (SD 4.20) | N/A | Lowest |

| VD | N/A | 94.28 (SD 6.88) | Largest | N/A |

UGA circuits have low hysteresis and high accuracy. TIA circuits have more hysteresis but still work well. VD circuits have the biggest IDNN value. Most sensors get over 94% accuracy in gesture tests. This means you can trust these sensors for touch and force jobs.

Best Value Picks

You want the best sensor for your money. Some sensors are better for certain jobs. The table below helps you choose the right one.

| Application Need | Best FSR Type | Example Use Case |

|---|---|---|

| Wide force measurement | Shunt Mode | Car seat sensors |

| Light touch detection | Thru Mode | Robotic grippers |

| Fast response | Thru Mode | Touch panels |

| Heavy-duty environments | Shunt Mode | Industrial machines |

If you need a sensor for car seats or machines, use shunt mode FSRs. For touch panels and robot grippers, thru mode FSRs are best. You can save money by picking the right sensor for your job.

Tip: Pick a sensor that fits your project’s needs. You will get better results and spend less.

Top Choice for Professionals

If you work on tough engineering projects, you need force sensitive resistors that react quickly and last a long time. Engineers want sensors that can be used many times and still give good data. You should pick a sensor that fits your needs and does not cost too much.

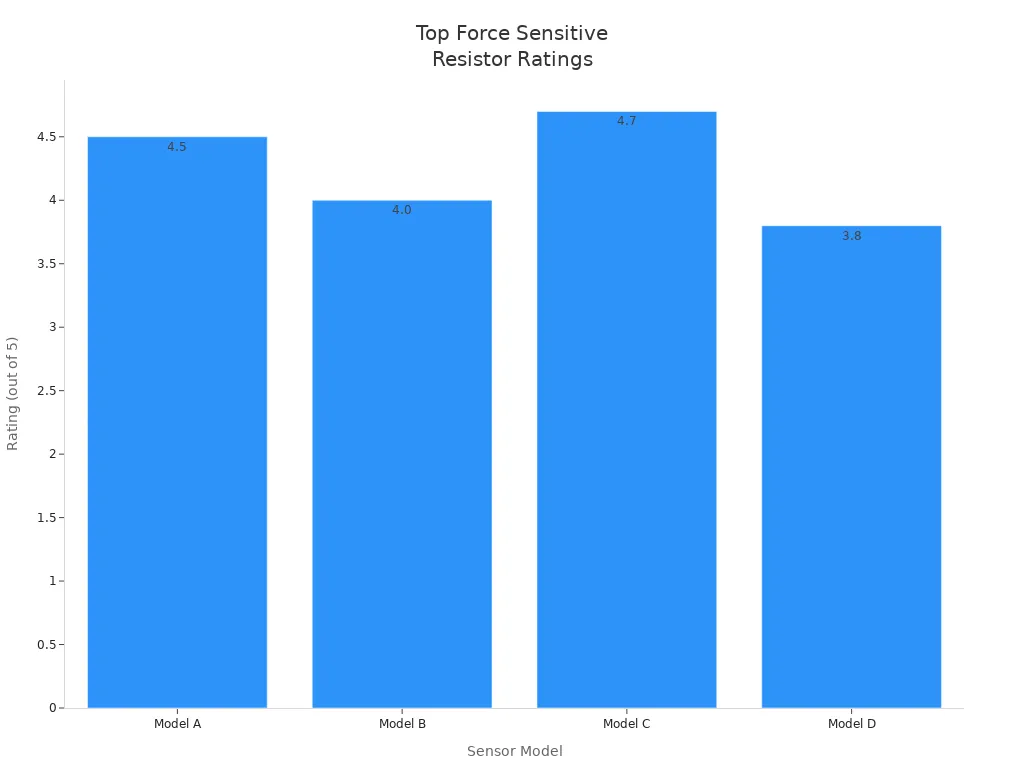

You can look at the table below to compare the best models. The table shows things like how fast the sensor reacts, how sensitive it is, how long it lasts, the price, and what users think.

| Sensor Model | Response Time (ms) | Sensitivity (N) | Durability (Cycles) | Price ($) | Rating (out of 5) |

|---|---|---|---|---|---|

| Model A | 5 | 0.5 | 1,000,000 | 15 | 4.5 |

| Model B | 7 | 0.7 | 800,000 | 12 | 4.0 |

| Model C | 6 | 0.6 | 1,500,000 | 18 | 4.7 |

| Model D | 4 | 0.4 | 500,000 | 10 | 3.8 |

Model C is the best in the group. It lasts the longest with 1,500,000 cycles and has the highest rating of 4.7 out of 5. Model A is also good because it reacts fast and has a strong rating. If you want to spend less money, Model D is cheaper but does not last as long.

Tip: Pick a sensor with a high rating and long life if you want results you can trust.

Engineers often pick Model C for hard jobs. You can use it in robots, medical tools, and factory machines. It lasts a long time, so you do not have to change it often. It is very sensitive, so it can measure small forces. Model A is a good pick if you want something fast and not too expensive.

When you choose a sensor, think about how many times you will use it. Check how fast it reacts if you need quick feedback. Make sure it can sense the right amount of force for your project. Price is important, but you should also care about how well it works and how long it lasts.

Use this information to help you find the best sensor for your project. If you need more help, ask the company or look at the datasheet. Always test the sensor in your project before you finish your design.

You can pick from many good force sensitive resistors. SOUSHINE is great if you want accuracy and to change how your sensor looks or works. Interlink and SparkFun have sensors that are easy to use and do not cost much. Tekscan and Flexiforce are best when you need very exact measurements. Adafruit and Sensitronics let you choose sensors for special or different projects.

| Factor | Description |

|---|---|

| Durability | Stays strong but can be affected by glue, wet air, and heat |

| Integration | Needs careful sticking, lining up, and setting up |

| Signal Conditioning | Needs special electronics to work the best |

- Put covers on sensors to stop damage from water or rubbing.

- Adjust for heat or cold so your readings stay correct.

Try out your sensor and read the datasheet before you finish your project.

FAQ

What is a force sensitive resistor (FSR)?

You use a force sensitive resistor to measure force or pressure. When you press on the sensor, its resistance changes. This change lets you detect how much force you apply.

How do I connect an FSR to my project?

You connect an FSR to a microcontroller using two wires. One wire goes to an analog input. The other wire connects to ground. You read the changing voltage to measure force.

Can I cut or shape an FSR for my design?

You should not cut or trim an FSR. Cutting can damage the sensor and stop it from working. Choose a sensor that matches your size and shape needs.

How long does an FSR last?

Most FSRs last for millions of presses. You can use them in projects that need many cycles. Always check the datasheet for exact numbers.

Do FSRs need calibration?

Yes, you should calibrate your FSR for best results. Calibration helps you get accurate force readings. Use known weights to set up your sensor.

Are FSRs waterproof?

Most FSRs are not waterproof. You should protect them from water and moisture. Use covers or sealants if you need to use them in wet places.

What is the typical response time of an FSR?

FSRs respond in a few milliseconds. You get quick feedback when you press the sensor. This speed works well for real-time applications.

Can I use FSRs with Arduino or Raspberry Pi?

Yes, you can use FSRs with Arduino or Raspberry Pi. Connect the sensor to an analog input. Use simple code to read the force values.