Call us: +86-137-2353-4866

When you pick force sensing resistors, you must match each sensor to your needs. Force sensing devices are used in many places. Industrial automation is the biggest market in 2024 with almost half the share. Automotive systems are growing quickly because of safety and smart cars. Healthcare is growing fastest because of wearable health technology. Consumer electronics need tiny sensors for smart gadgets.

You should check how specifications change performance and price when picking force sensing resistors. The table below helps you compare important things:

| Specification | Impact on Performance | Impact on Cost |

|---|---|---|

| Resolution | Finds small force changes | Better resolution costs more |

| Accuracy | Makes sensors more reliable | High accuracy costs extra |

| Repeatability | Keeps measurements steady | Reliable sensors may cost more |

| Sensing Technology | Works best for some uses | Advanced types cost more |

SOUSHINE offers top Force Sensing Resistor products. When you pick force sensing resistors, think about accuracy, price, strength, and how the sensor fits your system. You can trust SOUSHINE for expert help and solutions for your project.

Table of Contents

Key Takeaways

- Pick the right force sensing resistor for your needs. Think about things like how accurate it is, how much it costs, and if it fits your use.

- Learn about different force sensors. Some are force sensing resistors, load cells, and strain gauges. Each one has its own job.

- Check the sensor’s details, like how clear and correct it is. Better sensors usually cost more. Try to match your budget with what you need.

- Force sensing resistors work well when you need fast feedback and flexibility. Load cells are better for steady and exact measurements.

- Think about how tough and dependable the sensors are. This is important if you use them in rough places. Look for things like strong builds and airtight cases.

- You can change some force sensors to fit your project better. SOUSHINE can make special solutions for your design needs.

- Take care of your sensors by cleaning and recalibrating them often. This keeps them working right and helps them last longer.

- Keep learning about new trends in force sensing technology. Things like using AI and caring for the environment can help your projects.

Force Sensing Technologies Overview

What Is Force Sensing?

Force sensing helps you find and measure forces in devices. This skill makes your projects more accurate and safe. It also helps things work better. The table below explains force sensing and where you see it:

| Definition | Application Areas |

|---|---|

| Force sensing means finding and measuring mechanical forces. It is important for making things accurate, safe, and efficient. | Automotive, Healthcare & Medical, Robotics, Consumer Electronics, Industrial, Aerospace & Defense |

You can find force-sensing technology in many things you use. Shoe insoles use it to check foot pressure. Hospital beds use it to watch patient pressure. Robots use it to feel how hard they hold things. Inventory systems use it to count items. Touch controls use it in user interfaces.

Sensor Principles

Each force sensing technology works in its own way. Here are the main ideas:

- Force sensing resistors change resistance when you press them. This helps you know how much force you use.

- Strain gauges change resistance when they stretch or squeeze.

- Load cells use strain gauges to turn force into an electric signal.

- Piezoelectric sensors make electricity when you press or bend them.

- Capacitive sensors check changes in capacitance when you push them.

All these sensors find force and turn it into a signal. Some use resistance, and some use voltage or capacitance.

Types of Force Sensors

Force Sensing Resistor

Force sensing resistors are thin, bendable, and not expensive. SOUSHINE makes these sensors. They work in wearables, robots, and touch controls. When you press the sensor, resistance goes down. You get a signal that matches the force. These sensors fit easily in many designs.

Load Cell

Load cells help you measure weight or squeezing with good accuracy. They use strain gauges inside. You see load cells in scales, machines, and tests.

Strain Gauge

Strain gauges measure small changes in shape or force. They give you exact and steady results. You find them in load cells, bridges, and special tools.

Piezoelectric Sensor

Piezoelectric sensors measure fast changes in force. They make voltage when you press them. You see them in vibration sensors, microphones, and medical tools.

Capacitive Sensor

Capacitive sensors measure force by checking capacitance changes. They work well in touchscreens and control panels.

Tip: When you pick a sensor, think about how accurate, small, and cheap it is. Also, think about how easy it is to use in your system. SOUSHINE can help you choose the best force-sensing sensor for your project.

Comparing Force Sensing Resistors and Other Sensors

Force Sensing Resistor (FSR) by SOUSHINE

How FSRs Work

Force sensing resistors help you measure force and pressure. When you press the sensor, its resistance goes down. This change shows how much force you use. The sensor has a bendable base and a special layer. When you push, the circuit closes and sends a signal. You get feedback quickly, which helps you control things right away. SOUSHINE’s force sensing resistor is very sensitive. It can find even tiny force changes. The fast response makes it great for jobs needing instant feedback.

Key Features

SOUSHINE force sensing resistors have many good points. You can pick from many shapes and sizes. The sensor works again and again and lasts long. It uses little power, so it is good for battery devices. You can add the sensor to your system easily. You do not need hard electronics. The sensor gives steady results you can trust.

Here is a table that shows how SOUSHINE’s technology compares to others:

| Feature | SOUSHINE’s Technology | Competitors |

|---|---|---|

| Accuracy | High | Lower |

| Durability | Long-lasting | Varies |

| Customization | Many choices | Fewer choices |

| Power Consumption | Low | Higher |

| Integration Ease | Simple | Harder |

Applications

Force sensing resistors are used in many places. Medical devices use them for giving medicine and watching patients. Factories use them for safety and control. Touchpads and game controllers use them for better control. Cars use them to check airbags and door seals. Flexible sensors are used in robots and medical systems to track movement.

| Application Area | Description |

|---|---|

| Medical Devices | Sensors help give medicine safely and steadily. |

| Industrial Equipment | Sensors make factory jobs safer and easier. |

| Consumer Electronics | Sensors help touchpads and controllers work better. |

| Automotive Systems | Sensors check airbags and door seals for safety. |

| Specialized Use Cases | Flexible sensors track movement in robots and medical tools. |

You can see that fsrs are used in many industries.

Advantages

SOUSHINE force sensing resistors give you many benefits. The sensor finds small force changes. You get quick feedback. You can pick the shape and size you need. The sensor lasts long and works in tough places. It saves energy because it uses little power. You can add it to your system without problems. These sensors help you make smarter and safer products.

Load Cells

Operation

Load cells help you measure weight or force. They use strain gauges inside. When you push, the load cell changes its signal. You get exact readings for steady loads. The sensor is best for careful measurements.

Features

Load cells are very accurate and steady. You can use them for a long time. They work well for steady loads. You need to adjust for temperature changes. The sensor gives the same results again and again.

Here is a table that shows important things about load cells:

| Metric | Description |

|---|---|

| Non-linearity | Output does not always match the load exactly. |

| Static Error Band (SEB) | Biggest difference from the best line when measuring up and down. |

| Non-repeatability | Output changes when you use the same load many times. |

| Creep | Output slowly changes when the load stays the same. |

| Temperature Effects | Temperature can change accuracy; you need to adjust for it. |

Applications

Load cells are used in scales, machines, and test tools. They work best for steady load measurements. You use load cells where you need high accuracy and steady results. They help you measure weight in factories, labs, and production lines.

Here is a table that compares load cells and force sensing resistors:

| Sensor Type | Accuracy | Stability | Application |

|---|---|---|---|

| Load Cells | High | Very High | Steady loads, careful measurements |

| FSRs | Moderate | Moderate | Moving uses, flexible jobs |

Load cells are best for steady loads and careful measurements. Force sensing resistors are better for moving uses and quick feedback.

Strain Gauges

Operation

Strain gauges help you measure tiny changes in shape or force. The sensor changes resistance when stretched or squeezed. You get very exact readings. The sensor is small and fits in tight spots.

Features

Strain gauges are very precise and sensitive. You can use them in many places. They work for measuring very small changes. You must install them carefully. The sensor lasts long but can be affected by temperature.

Here is a table that compares strain gauges and force sensing resistors:

| Feature | Strain Gauges | Force Sensing Resistors (FSRs) |

|---|---|---|

| Cost | Costs more because it is complex | Costs less |

| Integration Complexity | Needs careful setup and calibration | Easy to use with simple circuits |

| Accuracy | Very accurate and steady | Not as accurate or repeatable |

| Signal Conditioning | Needs special electronics | Not mentioned |

| Durability | Lasts long but can be sensitive | Can change with time and use |

Strain gauges need careful setup and special electronics. Force sensing resistors are easier to use and cost less.

Applications

Strain gauges are used in bridges, load cells, and special tools. They help measure tiny changes in buildings and machines. You find strain gauges in research, engineering, and safety checks.

Tip: Pick strain gauges when you need very accurate and steady results. Use force sensing resistors when you want flexibility, quick feedback, and easy setup.

- Advantages of strain gauges:

- Very precise

- Small size

- Works in many places

- Used for many jobs

- Lasts long and is reliable

Each sensor type is good for different jobs. You should pick the sensor that fits your needs. Testing and comparing sensors helps you choose the best one.

Other Force Sensitive Resistors

Force sensing resistors come in different types. FlexiForce and Interlink are two well-known brands. These force sensing resistors help you measure pressure and force. Each brand has special features for certain jobs. When you compare them, you see which works best for your project.

FlexiForce

FlexiForce force sensing resistors are very sensitive. You can use them in labs and sports gear. These sensors measure small force changes. Many people pick FlexiForce for tests and experiments. You can change the sensors for different force levels. This makes them good for custom setups.

FlexiForce sensors work well when you need to track quick changes. You might use them in sports gear to check grip or pressure. Some people use them in medical research to study movement. FlexiForce sensors fit into thin spaces and bend easily. You can add them to many devices.

Interlink

Interlink force sensing resistors are also very sensitive. You often see them in human-machine interface systems. These sensors help you make touchpads and control panels. Interlink sensors react fast to touch and pressure. You can use them in smart devices and electronics.

Interlink force sensing resistors come in many shapes and sizes. You can pick the best one for your project. They work well when you need quick feedback. Many people use them in gaming controllers and touch switches. Interlink sensors help you make products that feel smooth and easy.

Comparing FlexiForce, Interlink, and SOUSHINE

You may wonder how FlexiForce and Interlink compare to SOUSHINE force sensing resistors. The table below shows the main features of each brand:

| Feature | FlexiForce | Interlink | SOUSHINE |

|---|---|---|---|

| Sensitivity | High | High | Very High |

| Accuracy | ±3% | Good | Very Good |

| Customization | Adjustable | Various models | Easy integration |

| Application Suitability | Research, sports | HMI systems | Versatile use in robotics, health tools |

All three brands have strong force sensing resistors. FlexiForce and Interlink are good for special uses like research or touch controls. SOUSHINE force sensing resistors give you very high sensitivity and easy setup. You can use SOUSHINE sensors in robotics, healthcare, and electronics.

When you pick force sensing resistors, think about what your project needs. FlexiForce is best for tests and sports. Interlink works well in touch systems. SOUSHINE gives you a flexible solution for many uses. You can trust SOUSHINE force sensing resistors for high performance and easy setup.

Tip: Always match your force sensing resistors to your project. This helps you get the best results and makes your device work better.

You can find force sensing resistors in many products today. They help you build smarter and safer devices. When you pick the right force sensing resistors, your project stands out.

Selection Criteria for Force Sensing Solutions

Accuracy & Precision

You want your force sensors to be very accurate. Accuracy means the sensor shows the real force. Precision means the sensor gives the same result each time. You should check both accuracy and precision when picking sensors. Load cells are very precise and work well in labs and factories. Force sensing resistors need careful checking, so you must look at their sensitivity and accuracy.

The table below helps you compare accuracy and precision for different sensors:

| Feature | Load Cells | Force Sensing Resistors (FSRs) |

|---|---|---|

| Accuracy | High accuracy and reliability | Needs careful reading of results |

| Precision | High precision, repeatable | Less precise, repeatability can vary |

Pick sensors that fit your force detection needs. If you need very precise measurement, load cells are best. If you want flexible force detection and fast feedback, force sensing resistors are good. Sensitivity helps your sensor find small changes. SOUSHINE makes custom force sensors with high sensitivity for many jobs.

Cost & Value

You need to think about cost and value when picking sensors. Some sensors cost more because they have special features. Other sensors work well and cost less. You should compare prices and see which sensor fits your budget and needs.

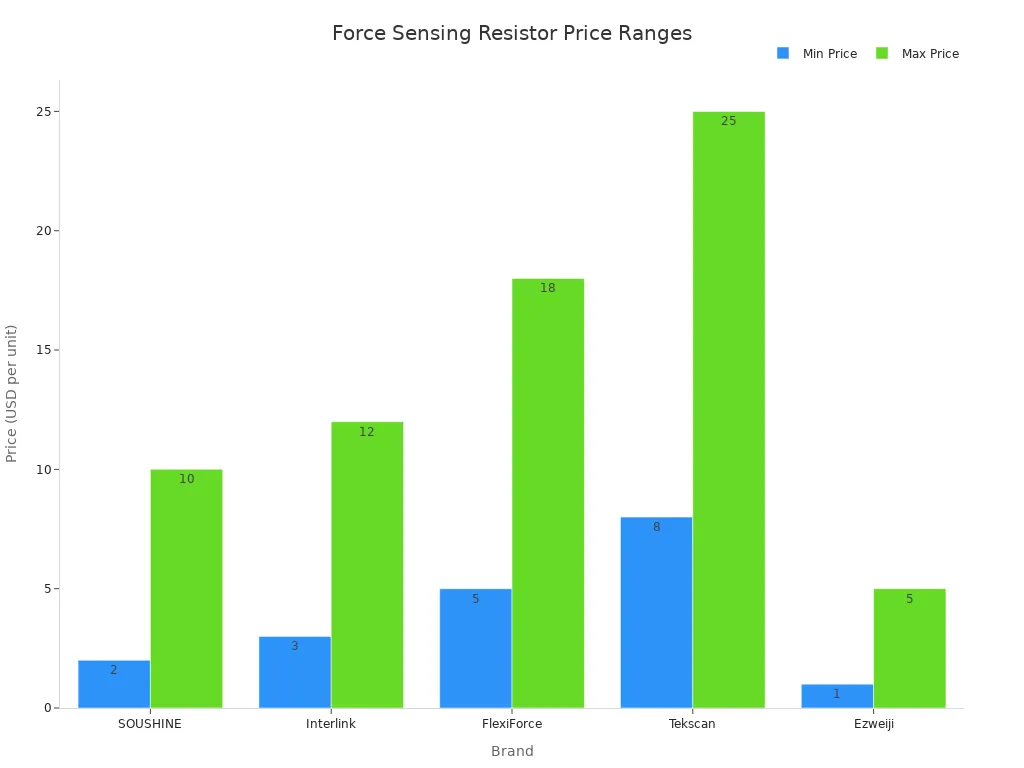

Here is a price comparison table for popular brands:

| Brand | Price Range (USD per unit) | Main Focus |

|---|---|---|

| SOUSHINE | $2 – $10 | Customization, durability |

| Interlink | $3 – $12 | Sensitivity, reliability |

| FlexiForce | $5 – $18 | Thin design, flexibility |

| Tekscan | $8 – $25 | High accuracy, research |

| Ezweiji | $1 – $5 | Low cost, basic use |

SOUSHINE sensors give good value for many uses. You get strong and custom sensors for a fair price. When you compare sensors, look at price and features. Some systems need special sensors, but others work with basic ones. Always check prices before you choose.

Durability & Reliability

Durability and reliability are important for sensors in tough places. You want sensors that last long and work well in hard conditions. Some sensors face heat, water, shock, and vibration. Pick sensors that can handle these problems.

Common durability and reliability challenges include:

- Parts must work in extreme environments.

- Tests for shock, vibration, humidity, and temperature.

- Shows damage and how well the sensor works.

Sensors with airtight and strong designs work best in harsh places. The table below shows features that help sensors last longer and work better:

| Feature | Description |

|---|---|

| Airtight Construction | Airtight sensors protect against water and dust. |

| Rugged Design | IP68+ designs are made for tough jobs. |

| Reliable Operation | Works well in wet, dirty, or gloved-hand places. |

| Temperature Resistance | Handles very hot or cold and wet places. |

| Shock and Vibration | Works even when shaken or hit. |

SOUSHINE makes custom sensors that pass hard tests for durability. You can use these sensors in cars, hospitals, and factories. Pressure mapping and force measurement systems need sensors that last a long time. Always check if your sensor is reliable before using it.

Tip: Pick sensors with high sensitivity and strong durability for the best results in force detection and measurement.

Application Fit

You need to make sure your sensor matches your project. Each force sensing solution works best in certain jobs. Some sensors fit small spaces. Others handle heavy loads. You should look at your application and decide what matters most.

Start by asking these questions:

- What type of force do you want to measure? (Touch, pressure, weight, or impact)

- How much space do you have for the sensor?

- Do you need the sensor to bend or stay flat?

- Will the sensor face water, dust, or heat?

- How fast do you need the sensor to respond?

If you work with wearables or smart devices, you may need a thin and flexible sensor. In factories, you might want a sensor that handles heavy loads and gives steady readings. In healthcare, you need sensors that are safe and reliable for patient use.

SOUSHINE offers many force sensing options. You can pick sensors for cars, robots, medical tools, or sports gear. You can also ask for custom shapes and sizes. This helps you get the best fit for your project.

Tip: Always match the sensor’s features to your real-world needs. This makes your device work better and last longer.

Integration & Support

You want your force sensing solution to work well with your system. Easy setup saves you time and money. SOUSHINE designs sensors for quick and simple installation. You can connect them to many devices, both wired and wireless.

Here is a table that shows how SOUSHINE helps you with integration and support:

| Feature | Description |

|---|---|

| Customization Options | You can tailor the sensor’s size, shape, output, and calibration to your needs. |

| Installation and Integration | Setup is quick and easy. Sensors work with many types of devices and systems. |

| Technical Support | You get help with integration and troubleshooting. Contact details are always available. |

| Intelligent Connectivity | Sensors connect to devices for data collection, both wirelessly and with cables. |

| Measurement Capabilities | Sensors give you real-time and accurate data for force, pressure, and touch. |

If you need help, SOUSHINE offers support by email, phone, or on-site visits. You can ask questions about setup, calibration, or troubleshooting. The team helps you solve problems fast. You can also request custom sensors for special projects.

Note: Good support and easy integration help you finish your project faster. You get better results and fewer problems.

Top Force Sensing Resistors for Applications

Automotive Solutions

Car Seat Sensors

Force sensing resistors help car seats work better. They can tell if someone is sitting down. They also measure how much pressure is on the seat. This helps the car know when to remind you about seatbelts. It can also move the seat to fit you. The car uses this data to keep you safe and comfortable.

Airbag Control

Force sensing resistors are important for airbags. These sensors check how hard and when someone is in the seat. The car uses this to know when to open the airbags. It also helps airbags use the right amount of force. This keeps people safer during a crash.

Healthcare & Medical Devices

Patient Monitoring

Hospitals use force sensing resistors in smart beds. These sensors can see if a patient moves or is in bed. Nurses can watch patients without bothering them. Infusion pumps use these sensors to check force. This helps control how fast medicine goes to the patient. It keeps patients safe and makes sure they get the right care.

Rehabilitation Equipment

Rehabilitation tools use force sensing resistors to help patients. The sensors measure how much force a patient uses in exercises. Therapists use this to change treatment and watch recovery. Prosthetics use these sensors to check grip force. This helps patients hold things in a natural way.

Here is a table showing what force sensing resistors need in healthcare:

| Requirement | Description |

|---|---|

| Accuracy | Measures force the same way in many jobs. |

| Durability | Works well even when used a lot in hospitals. |

| Compliance | Made to follow medical safety rules. |

| Integration | Fits easily into different medical devices. |

You also see these sensors in breathing machines and blood pressure tools. They help check pressure and keep patients safe.

Robotics & Automation

Touch Sensing

Robots use force sensing resistors to feel things. You can put these sensors on robot hands or arms. They can sense strong or light touches. Robots can pick up heavy or gentle things, like medicine bottles. This helps robots work safely and carefully.

- You can measure how hard a robot grips something.

- Robots can change grip strength for different jobs.

- This makes robots safer and more accurate.

Process Control

Force sensing resistors help robots move the right way. Old sensors like load cells are big and heavy. Force sensing resistors are smaller and lighter. They help robots grip things better and fit into more places.

- Robots use the right force to hold things.

- This helps factories work faster and better.

- Automation gets smarter and works more smoothly.

SOUSHINE’s force sensing resistors help cars, hospitals, and robots. You get sensors that work well and fit your needs. They give you good and steady results.

Consumer Electronics

Force sensing resistors are important in today’s electronics. You find them in wearables and smart devices. These sensors help you use technology in new ways. They give you better control and make things easier.

Wearables

Wearables are things you use every day. Smartwatches and fitness bands need force sensing resistors. These sensors check how hard you press or touch. You can tap softly or press harder to control your device. This makes wearables simple and fun to use.

Force sensing resistors help wearables last longer. You do not need buttons that break. The sensors stay hidden until you touch them. Designers can make thin and cool devices.

Here is a table with key features of force sensing resistors in wearables and smart devices:

| Feature | Description |

|---|---|

| Enhanced User Interface (UI) and Experience (UX) | You get more ways to control your device. |

| Improved Durability and Reliability | No buttons means your device lasts longer and keeps out water and dust. |

| Design Freedom | Thin sensors let designers make stylish and smooth devices. |

| Precision and Responsiveness | Sensors notice even light touches and react fast. |

Tip: Wearables with good force sensing resistors have more features and last longer.

Smart Devices

Smart devices use force sensing resistors to help you. You see these sensors in tablets, phones, and remotes. You can press harder to do more things or change the volume. The sensors react quickly and give you feedback right away.

Companies use force sensing resistors to make slim and nice-looking devices. You do not see big buttons. The sensors fit in small spaces and work with many materials. Your device looks good and works well.

SOUSHINE Product Highlights

Customization

SOUSHINE lets you change force sensing resistors in many ways. You can pick the size and shape you want. You can change the output signal for your project. Calibration can be set for your needs. You can add your logo or special packaging. You only need to order two pieces to make changes.

| Customization Option | Details |

|---|---|

| Size and Shape | Pick what fits your project |

| Output Signal | Change to match your needs |

| Calibration | Set for your job |

| Branding Elements | Add logos or special packaging |

| Minimum Order | Only 2 pieces needed for changes |

Note: SOUSHINE helps you make force sensing resistors that fit your brand and needs.

Quality Assurance

You want sensors that last and work well. SOUSHINE checks every sensor to make sure it is good. The company follows ISO9001:2015 rules. All sensors meet RoHS and ZHB Environment System standards. These steps keep sensors safe and good for the environment.

SOUSHINE says you should clean and check sensors often. Recalibrate them when needed. Replace sensors if they are damaged. Use covers for sensors outside or in wet places. Store sensors in cool, dry places when not using them. Check sensors for wear often.

| Maintenance Task | Frequency | Benefit |

|---|---|---|

| Cleaning | Monthly/Quarterly | Gets rid of dust and helps sensors work better |

| Inspection | Monthly | Finds problems before sensors stop working |

| Recalibration | As needed | Fixes small errors and keeps sensors accurate |

| Replacement | When required | Makes sure sensors keep working well |

Tip: Your devices work better and last longer if you take care of force sensing resistors.

Troubleshooting & Optimization

Common Issues

When you use force sensing resistors, you might have problems. Knowing these problems helps you fix things fast and keep your system working.

- Calibration Problems: If you skip calibration or do it wrong, your sensor may show wrong numbers. Always follow the right steps for calibration.

- Hysteresis: Sometimes, the sensor does not go back to the same value after you stop pressing. This can make repeated measurements wrong.

- Non-linearity: The sensor may not change evenly when you press harder. You might see bigger or smaller jumps than you expect.

- Drift Errors: Over time, the sensor can slowly change even if the force stays the same. This drift can make your results less accurate.

- Sensitivity to Loading Rates: If you press too fast or too slow, the sensor may act differently. This can make your data less trustworthy.

Tip: You can fix many problems by using careful calibration and testing. Some advanced systems use both voltage and capacitance readings to get better accuracy.

Calibration Tips

You need to calibrate your force sensing solution to get good results. Follow these steps to make sure your sensor works right:

- Get all your tools ready. You need the sensor, weights, a strong support, and calibration tools.

- Pick a quiet place with steady temperature and humidity. This helps you avoid mistakes from the environment.

- Attach the sensor tightly. Make sure it does not move while you calibrate.

- Connect the sensor to your data system. Set up the right settings for your test.

- Set the zero point. Write down the sensor reading when there is no force.

- Put weights on the sensor one at a time. Write down the reading for each weight.

- Draw a calibration curve. Match the weights to the sensor readings to see how they relate.

- Change the sensor’s settings. Adjust sensitivity and offset if needed to fit the curve.

- Check your work. Test the sensor again with the same weights to make sure the readings are right.

- Keep a record of your calibration steps and results.

Note: Calibrating often keeps your sensor working well and accurate. Always write down your steps so you can check them later.

Maintenance Best Practices

You can help your force sensing solution last longer with good care. Here are some easy ways to keep your sensor working:

- Clean the sensor gently with a soft, dry cloth. Do not use water or strong chemicals.

- Check the sensor often for damage, dirt, or wear.

- Calibrate the sensor again if you see drift or strange readings.

- Store sensors in a cool, dry place when you are not using them.

- Keep sensors safe from heat, cold, or moisture.

- Replace sensors that have cracks, tears, or do not work well.

Tip: Good care helps your force sensing system stay accurate and last longer. Regular cleaning and checks stop most problems before they happen.

Future Trends

You will see lots of new changes in force sensing soon. New ideas and tools let you use force sensors in more places. These changes affect how you design and use your projects.

Today, force sensors are in robots that work with people. These robots use force sensors to stay safe and react fast. Artificial intelligence helps robots learn from force data. Robots can make better choices and work safely with you.

Virtual reality and augmented reality use force sensors more now. When you play games or use simulators, force feedback feels real. You can touch or move things in a digital world and feel it. This helps you learn faster and enjoy new ways to use technology.

Engineers use force sensors in hard places like underwater. These sensors measure force in windmills and solar panels. You can check if machines work well in tough spots. Wireless force sensors help you get data from far away.

Companies care more about the environment now. Many force sensors use recycled or recyclable materials. This helps protect the planet and cuts down on waste. When you pick these sensors, you help green technology and the earth.

Saving energy is more important every year. Force sensors help watch and improve how machines use energy. Clean energy projects use these sensors to track and save power. You can use this data to make smart choices and spend less.

Machine learning changes how you use force data. Smart programs find patterns and help you spot problems early. You can fix things before they get worse and keep systems working well. Cloud platforms store and study your data, so teams can work together anywhere.

Force sensors will join bigger systems soon. These systems show you how your machines work in real time. You can make better choices and improve your products with this information.

The future of force sensing brings smarter, safer, and greener solutions. You will get stronger tools and better ways to use force data in every industry.

When picking a force sensing solution, check if it is accurate. Think about how much it costs. Make sure it will last a long time. See if it fits your project well. Force sensing resistors are good for flexible designs. They also give quick feedback. Load cells are best for measuring steady loads. They are very accurate. Strain gauges help you find tiny changes. SOUSHINE has quality products and expert help. You can ask SOUSHINE for advice or custom solutions. First, write down what you need. Then, reach out for help with your project.

FAQ

What is a force sensing resistor (FSR)?

A force sensing resistor checks force or pressure. When you press it, resistance changes. You can use this change to see how much force you use.

How do I choose the right force sensing solution?

Start by thinking about what you need. Look at accuracy, price, and how strong the sensor is. Make sure the sensor fits your project. SOUSHINE can help you find the best choice.

Can I use force sensing resistors in wet or harsh environments?

Some FSRs work in tough places. Pick sensors with airtight or strong designs. Always read the product details for water and dust safety.

How do I calibrate a force sensing resistor?

Put known weights on the sensor and write down the readings. Use these numbers to make a calibration curve. This helps you get the right results.

What industries use force sensing resistors?

FSRs are used in cars, hospitals, robots, and electronics. They help with safety, checking things, and controls.

Can I customize the size and shape of my FSR?

Yes, SOUSHINE lets you change the size, shape, and output. You can pick what fits your project. Contact SOUSHINE to learn more.

How long do force sensing resistors last?

FSRs last a long time if you use them right. Clean and check them often. Replace them if you see damage or odd readings.

Where can I get support for my force sensing project?

You can talk to SOUSHINE by email, phone, or in person. The team helps with setup, fixing problems, and making custom sensors.