Call us: +86-137-2353-4866

You use tools for the measurement of force to ensure your work is safe and effective. Consider the process of making a car seat; accurate force sensing can protect individuals or potentially put them at risk. Industries such as automotive manufacturing, aviation, and factories require precise force sensing to prevent errors and maintain safety. With numerous tools available, selecting the best one for your specific application is crucial. When evaluating your needs, you can rely on SOUSHINE for advanced force sensing resistor solutions that deliver exceptional performance.

Table of Contents

Key Takeaways

Force measurement tools help keep things safe and good in places like car factories and hospitals. Knowing the basics of force, like the Newton unit and the formula F = ma, is important for measuring well. Different forces, like gravity and electromagnetic, need special ways to measure them right. New force measurement devices, like SOUSHINE’s FSRs, are very accurate, use little power, and are easy to use in many things. Checking and fixing force measurement devices often helps them give correct numbers and last longer. Picking the best device means thinking about how much it can measure, how exact it is, where you will use it, and if it fits your needs. Force measurement is very important in robots, car tests, and medical tools to make them work better and safer. Keep learning about new tools and ideas in force measurement to make your work better.

Measurement of Force: Fundamentals

What Is Force?

You see force in your life every day. Force in physics means something that makes things move or change. If you push a door, you use force. If you pull a drawer, you use force. The Newton (N) is the unit for force. One Newton is the force to move a one-kilogram object one meter per second squared. You find force with the formula F = ma. F means force, m means mass, and a means acceleration. This idea helps you learn how force is measured in science and engineering.

- Newton (N) is the unit for force.

- Newton’s second law uses F = ma to find force.

- One Newton moves a one-kilogram mass one meter per second squared.

Why Force Measurement Matters

Force measurement is important in many parts of life. It helps keep people safe and makes products better. When you measure force, you can stop accidents and make sure machines work right. Engineers use force measurement in factories to check products. Coaches use it in sports to study how athletes perform. The table below shows why force measurement matters in different areas:

| Reason | Description |

|---|---|

| Quality Control | Makes sure products meet rules and standards. |

| Safety | Checks risks and keeps machines safe. |

| Optimization | Helps make things work better and faster. |

| Research and Development | Helps test new ideas and materials. |

| Applications in Sports | Helps study sports and design equipment. |

Tip: Using force measurement tools helps make products safer and better.

Types of Forces in Applications

There are many kinds of forces in science and industry. Each kind does something different. Measuring force means knowing these differences for good results. Here are some common types of forces:

| Force Type | Description |

|---|---|

| Gravitational Force | Pulls two things with mass together. |

| Electromagnetic Force | Happens between things with electric charge. |

| Strong Nuclear Force | Keeps protons and neutrons together in atoms. |

| Weak Nuclear Force | Causes things to break down in atoms. |

You also see other forces in life and work:

- Cohesion: Makes water drops stick together.

- Adhesion: Makes glue stick to things in factories.

You use force measurement to study tension, compression, shear, bending, and torque. These tests help keep things safe, check quality, and make designs better. New force measurement devices can show how strong and which way a force goes. This makes them important for research, process control, and making new products.

Force Measurement Devices Overview

Evolution of Force Measurement

Force measurement devices have changed a lot over time. At first, people used mechanical tools like spring scales. These tools could measure force, but they were not very accurate. They also did not have high sensitivity. Later, technology got better and people started using electrical systems. In the mid-1900s, new devices like resistance strain gauges and piezoelectric elements appeared. Capacitive sensors also became popular. These new tools gave better and faster results.

After that, MEMS technology made sensors much smaller. This let people put force measurement devices in tiny places. In the 2000s, flexible electronics and nanomaterials made a big difference. Now, force measurement devices can be used in smart wearables and advanced systems. Here is a simple timeline to show these changes:

- At first, people used mechanical systems like spring scales, but they were not very accurate.

- Then, electrical tools like strain gauges and piezoelectric sensors made measurements better.

- MEMS technology made sensors small and easy to use.

- Flexible electronics and nanomaterials helped put force measurement in wearables and smart devices.

Modern Force Measurement Technologies

Today, there are many force measurement devices to pick from. Each one works in a different way and is good for different jobs. Here is a table to help you see the main types:

| Device Type | Description |

|---|---|

| Analog force gauges | Simple, cheap gauges with a pointer to show the highest reading. |

| Digital force gauges | Very accurate, fast, and can send data to other devices. |

| Manual test stands | Strong, low-cost stands for many uses. |

| Motorized test stands | Advanced stands with speed and travel controls you can set. |

| Gripping fixtures | Hold samples in place while you test them. |

| Software | Makes testing, collecting data, and looking at results easier. |

You can also find other force measurement devices, like:

- Strain gauge load cells: These measure strain and turn it into an electric signal.

- Piezoelectric force sensors: These make an electric charge when you press on them.

- Capacitive force sensors: These sense changes in capacitance when you use force.

- Magnetic force sensors: These notice changes in magnetic fields from force.

- Optical force sensors: These change how they look when you use force.

- Load buttons and compression cells: These measure pushing or pulling forces.

- Force sensing resistors (FSRs): These change resistance when you press on them.

Modern force measurement devices use digital technology to help you collect and look at data right away. You can connect these devices to your systems without wires. This makes it easy to watch machines and fix problems fast. Automated testing helps you make fewer mistakes and saves time. If you calibrate your force measurement devices often, they stay accurate and work well.

Note: Modern force measurement devices help you work faster, safer, and with more confidence.

SOUSHINE Force Sensing Resistor Technology

You can trust SOUSHINE for advanced force measurement solutions. SOUSHINE’s force sensing resistors (FSRs) are different from other force measurement devices. These FSRs have a special design that changes resistance when you press on them. This gives you measurements that are both exact and dependable.

Here is a table that shows how SOUSHINE compares to other brands:

| Feature | SOUSHINE | Competitors |

|---|---|---|

| Accuracy | High | Lower |

| Durability | Long-lasting | Varies |

| Customization | Many choices | Fewer choices |

| Power Consumption | Low | Higher |

| Integration Ease | Simple | Harder |

You get many good things when you pick SOUSHINE force measurement devices:

- High accuracy for important jobs

- Low power use, so you save energy

- Many ways to customize for your needs

- Strong materials that last a long time

- Easy to add to your products and systems

SOUSHINE force measurement devices help in many fields. You can use them in car safety, healthcare, robotics, and more. Their flexible design and strong performance make them a smart pick for your projects. When you need force measurement devices that work well, SOUSHINE gives you tools you can count on.

Strain Gauge Load Cells

Strain Gauge Load Cell Principle

A strain gauge load cell helps you measure force very accurately. It changes force into an electrical signal you can read. Here is how it works:

- Strain gauges inside the load cell sense force.

- When you put weight on the cell, the strain gauges stretch or squeeze.

- This stretching or squeezing changes their electrical resistance.

- The strain gauges are part of a Wheatstone bridge circuit.

- The circuit can find tiny changes in resistance.

- When the weight changes, the circuit makes a new voltage.

- You make this signal stronger and clearer to measure force.

This method lets you measure force in many places. A strain gauge load cell is a good tool for tracking force changes during tests.

Advantages and Limitations

It is important to know what is good and bad about a strain gauge load cell before you use it. The table below shows the main points:

| Advantages | Limitations |

|---|---|

| High Sensitivity | Installation Complexity |

| Versatility | Need for Signal Conditioning |

| Compact Size | |

| Cost-Effective |

This device is very sensitive and works in many places. Its small size means you can use it almost anywhere. The price is good for most projects. You might need to spend time setting it up and fixing the signal, but the good parts are usually worth it.

Tip: You can use a strain gauge load cell for invasive dynamometer or non-invasive cfms jobs. This makes it useful for many force measurement needs.

Common Applications

Strain gauge load cells are used in lots of industries. They help you measure force, test force, and watch loads. Here are some ways people use them:

- In aerospace and aircraft, you measure force during flight tests.

- In rail transport, you check force on train parts.

- In automotive, you test force for safety and performance.

- In materials testing, you measure force when making new products.

- In construction, you watch force in buildings.

- In medical devices, you use them in tensiometer and force tools.

- In robotics, you track force for careful movement.

- In architectural engineering, you measure force in big buildings.

You often use a tensiometer or a dynamometer with a strain gauge load cell for good force tests. These tools help you measure force and load right away. You can pick invasive dynamometer or non-invasive cfms systems, depending on what you need.

A strain gauge load cell gives you steady force measurement for many jobs. You can trust it for watching loads, testing force, and tensiometer readings in your work.

Piezoelectric and Piezoresistive Sensors

Piezoelectric Sensor Principle

Piezoelectric sensors help you measure force in many ways. These sensors use materials like quartz. When you press or squeeze them, they make an electric charge. Here is how it works: First, you push on the piezoelectric part. Then, it makes a charge in a certain direction. The charge amount matches the force you use. This follows the equation Q = d33 * F. Quartz crystals only make a charge when you press or let go. This gives you a fast answer. It helps you measure quick changes. You see piezoelectric sensors where you need to watch vibrations or impacts. They are also used for fast pressure changes.

Tip: Piezoelectric sensors give quick and correct results for moving force.

Piezoresistive Sensor Principle

Piezoresistive sensors measure force in a different way. When you press or bend them, their resistance changes. You find these sensors in many devices. They work well in hot or cold places. They give a steady and straight response. Piezoresistive sensors change resistance when you strain them. Many are made from silicon. These sensors are very sensitive, especially with mono-crystalline silicon. They are good for slow and steady force measurements. Piezoelectric sensors make a charge from force. Piezoresistive sensors change resistance instead. This makes piezoresistive sensors better for slow or constant force. You can use them in medical tools and machines in factories.

SOUSHINE Force Sensing Resistor Features

SOUSHINE’s force sensing resistors are special for measuring force. You get many good things when you use these sensors. They are very accurate, so you can trust the numbers. They last a long time, even if you use them a lot. You can pick from many shapes and sizes. This helps you find the right one for your job. They use little power, so you save energy. This is good for things you carry around. You can add these resistors to new or old products easily. SOUSHINE’s force sensing resistors help you measure force in cars, health care, robots, and more. Their design makes them strong and simple to use. You can trust them for easy or hard projects.

Note: SOUSHINE’s force sensing resistors give you the choices and results you need for many force jobs.

Use Cases in Industry

You find piezoelectric and piezoresistive sensors in many places. These sensors help measure force, pressure, and vibration very well. You see them in factories, cars, hospitals, and smart gadgets. Each sensor type has its own best use, so you pick the right one for your job.

Piezoelectric sensors are good for measuring fast changes. For example, they are used in car engines as knock sensors. These sensors find engine knocking and help the engine fix itself right away. You also see piezoelectric sensors in ultrasonic cleaning machines. These machines use sound waves to clean things you cannot reach by hand. In factories, ultrasonic welding uses piezoelectric actuators to join plastic parts. This way, you get strong and clean welds without glue or heat.

Piezoresistive sensors, like SOUSHINE’s Force Sensing Resistors (FSRs), give steady and trusted readings. You use them to check pressure and force in many places. For example, they are in medical devices that watch patient movement or pressure. In robots, FSRs help robots feel touch and change their grip. You also use them in sports gear to see how much force an athlete uses. These sensors are good for slow or steady force jobs.

Here is a table that lists some main uses for both sensor types:

| Application Type | Description |

|---|---|

| Piezoelectric Knock Sensors | Used in car engines to find knocking and change engine settings right away. |

| Pressure Sensors | Give good readings of changing pressure without moving parts. |

| Ultrasonic Cleaning | Use piezoelectric parts to shake cleaning liquids for hard-to-reach spots. |

| Ultrasonic Welding | Use sound waves to join plastics with piezoelectric actuators. |

| Vibration Monitoring | Used to watch buildings and keep mine workers safe. |

| Environmental Monitoring | Find changes in pressure and temperature in tough places. |

You also find FSRs in smart car seats. These sensors know if someone is sitting and help control airbags or seatbelt reminders. In factories, FSRs watch machines to keep them safe. In sports and health, FSRs track movement and help with training or recovery.

Tip: Think about what you need to measure before picking a sensor. Piezoelectric sensors are best for fast, changing forces. Piezoresistive sensors, like SOUSHINE’s FSRs, are better for slow or steady forces.

Both sensor types help make products safer, smarter, and work better. Picking the right sensor helps your industry get better data and control.

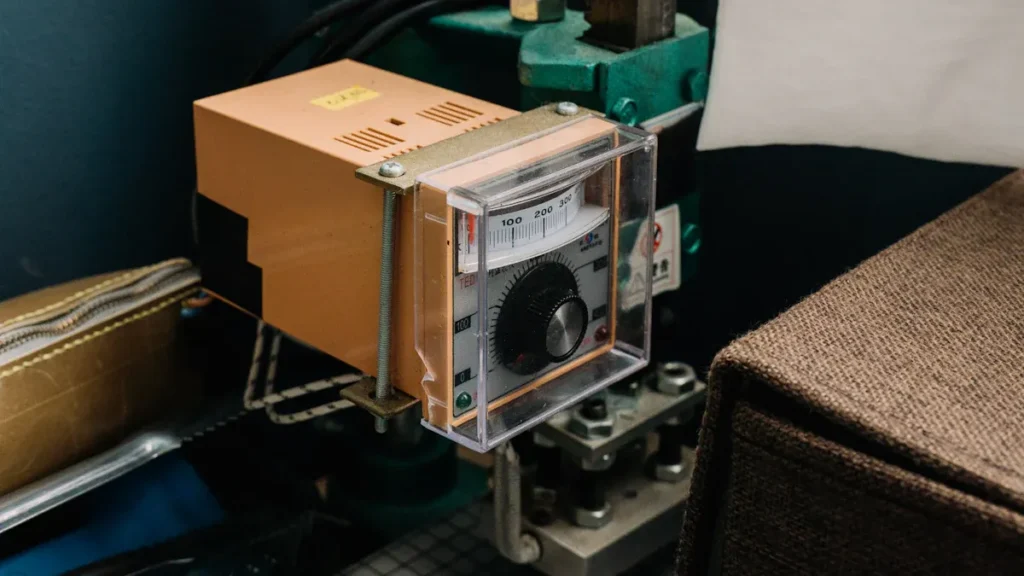

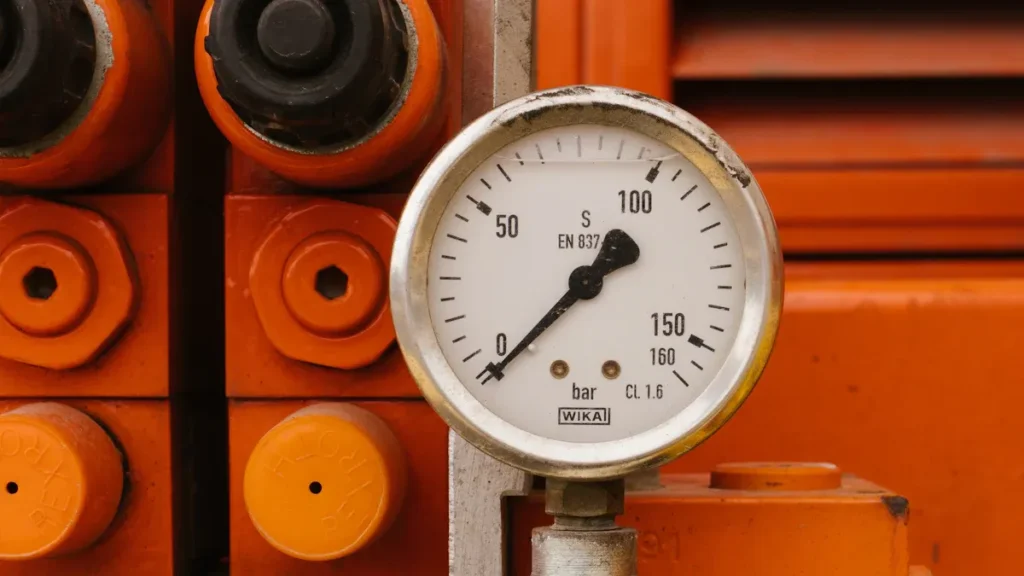

Hydraulic, Pneumatic, and Pressure-Based Devices

Hydraulic Force Measurement

Hydraulic force measurement devices are used for strong and steady results. A hydraulic load cell has a load piston that feels the force. The piston pushes on a chamber filled with fluid. When the force gets bigger, the pressure inside the chamber goes up. A pressure transducer checks this pressure. The device turns the pressure into a signal you can read. This works because of Pascal’s law. Pressure in a closed fluid spreads out the same way everywhere. Hydraulic force measurement is used in many areas:

- Weighing systems in factories and warehouses

- Material testing for strength and durability

- Construction and structural testing for safety

- Aerospace and aviation for checking aircraft parts

- Automotive industry for testing car components

Hydraulic systems are good in tough places. They give you good control and can handle high pressure.

Pneumatic Force Measurement

Pneumatic force measurement uses air, not liquid. You find these systems where things need to be clean and quick. Pneumatic devices use air that is squeezed to make and measure force. These systems work fast and are simple. You can set them up and fix them easily. Pneumatic force measurement is best for light or medium loads. You see them in packaging, assembly lines, and labs.

Here is a table to help you compare hydraulic and pneumatic systems:

| System Type | Advantages | Disadvantages |

|---|---|---|

| Hydraulic Systems | High force output, precise control, works in harsh environments | Fluid leaks, higher costs, sensitive to temperature |

| Pneumatic Systems | Fast response, simple design, clean operation, easy to install | Lower force output, less energy efficient, affected by air pressure changes |

Pneumatic systems are safe and clean for measuring force. They do not handle as much force as hydraulic systems. But they are good for many jobs.

Pressure-Based Systems

Pressure-based force measurement systems use sensors and load cells for good results. A pressure sensor has a thin part called a diaphragm that bends when you push on it. The device checks how much it bends to find the pressure. You use these systems in factories and assembly lines. They help you check the force at each step to keep quality high. Load cells in these systems show you the total force right away. This makes them work well, even if the area you press on changes.

You pick pressure-based systems when you want steady and repeatable force measurement. These systems help keep your products safe and your work running well.

Tip: Choose the best system for your job. Hydraulic systems are for heavy loads. Pneumatic systems are fast and clean. Pressure-based systems give you good force readings in many places.

Application Scenarios

You find hydraulic, pneumatic, and pressure-based force measurement devices in many places. These devices help keep machines safe and working well. They stop machines from breaking and help protect people. You use them in factories, cars, and big machines. Each system does a special job, but all help you measure and control force or pressure.

Here is a table that shows where you use these devices and what they do:

| Application Area | Description |

|---|---|

| Hydraulic Systems | Used for closed-loop control of forces, managing pressure spikes during sudden control spool movements. |

| Industrial Applications | Essential for regulating pressure and monitoring performance in systems using pressurized fluids or gases. |

| Automotive Braking | Ensures stability and safety in braking systems by maintaining correct hydraulic fluid pressure. |

| Heavy Equipment | Critical for controlling force application in equipment like excavators and hydraulic presses. |

| Pneumatic Systems | Found in air brakes, compressors, and tire monitoring to ensure effective operation and safety. |

Hydraulic force measurement is used in machines that need strong and steady control. You see them in excavators, hydraulic presses, and car brakes. These devices help keep the right force so machines work safely. In cars, hydraulic sensors help brakes work fast and not fail. In heavy equipment, they help lift and move big things safely.

Pneumatic force measurement is best for fast and clean jobs. You find these in air brakes for trucks and trains. They also help control air compressors and check tire pressure. Pneumatic sensors make sure air systems work right and keep vehicles safe.

Pressure-based systems are used in factories and automation. You use them to watch and control pressure in pipes, tanks, and machines. These sensors stop leaks and keep systems from failing. They also help keep products safe and meet quality rules.

- Pneumatic Systems: You use these in air brakes, air compressors, and tire pressure checks. They help keep air systems safe and working.

- Hydraulic Systems: You find these in car brakes, power steering, and big machines like excavators. They help control force and keep machines steady.

- Industrial Automation: You use pressure sensors to watch and control pressure in factories. They help stop problems before they start.

Tip: Think about where you will use a force measurement device. The right device helps keep your system safe, working well, and reliable.

Force measurement devices are important in many industries. They help stop accidents, make things work better, and keep everything running smoothly. When you know where and how to use these devices, you make better choices for your work and safety.

Force Measurement in Industrial Applications

Cutting Force Measuring Systems

Cutting force measuring systems are used in factories. These systems show how much force is on a tool. You need to know this during machining. Measuring cutting force helps tools last longer. It also makes products better. These systems give you data right away. This is important because cutting force changes fast. You need systems that show small details.

Cutting force measuring systems must work with many movements. Modern machines move in lots of ways. Sensors must track force from different sides. The shape of the tool and workpiece changes how force spreads. Steel and aluminum change the force you measure. It can be hard to put sensors in small or fast machines. Heat and shaking can make readings wrong.

When you pick a cutting force device, think about these things:

- It should measure force right away and show small changes.

- It must sense force from many directions.

- It should work with different tools and workpieces.

- It needs to fit in small spaces.

- It should not be bothered by heat or shaking.

You use a dynamometer to test how easy it is to cut. This helps you pick the best tool and way to cut. You can also see how different materials react to cutting. Cutting force measuring systems help you make good choices in factories.

Automation and Robotics

Force measurement is important in robots and machines. Force sensors help robots know how much force they use. This lets robots work better and do new jobs. When you add force sensors, robots can check their grip and movement.

Force measurement devices help robots work with people. Sensors tell if a robot touches something or someone. The robot can stop or change its path. This keeps people safe at work. Load cells and torque sensors help robots not get too heavy. They give data about the load. Robots can work better and last longer.

Here are some good things about force measurement in robots:

- Robots can feel bumps and change how they move.

- You get better control and accuracy.

- Robots can make small changes right away.

- Load cells show data about weight and load.

- You make robots safer and work better.

Force measurement helps you make robots work their best. You can control force and load with data right away. This makes robots more reliable and saves time.

Automotive and Aerospace

Force measurement is used to test cars and planes. You need special load cells for these tests. These devices give fast and correct force readings. You use them to check how parts work under force.

Force measurement devices help you follow safety and quality rules. In aerospace, you must meet rules like AS9100. Accurate force measurement makes sure every part is safe. You also use these devices to check quality in factories. They help you watch force at every step.

You use force measurement for these jobs:

- Testing planes with exact load data

- Getting fast and correct force readings

- Making sure parts work well

- Meeting safety and quality rules

- Making quality checks easier

Force measurement gives you the data to build safer cars and planes. You can trust these devices to help you follow rules and make good products.

Medical and Health Devices

Force measurement devices help doctors and nurses every day. These devices keep patients safe and make sure equipment works right. You want medical devices to be reliable and accurate. Force sensors, like SOUSHINE’s Force Sensing Resistors (FSRs), help reach this goal.

Force sensors are found in many medical tools. Hospital beds use sensors to check if someone is in bed. Infusion pumps use sensors to watch fluid pressure. Prosthetic limbs use sensors to help people move naturally. Sensors give feedback right away, so you can act fast if something changes.

You need to calibrate and test these devices often. Calibration makes sure the device measures force correctly. Safety tests check that the device will not break when used. These steps lower the risk of problems during patient care. You protect patients and help treatments go well.

Force measurement also tests how strong medical tools are. You measure how much force breaks a suture or bends a stent. This helps you know if the tool is safe inside the body. Texture analysis checks if materials are strong enough for surgery. You want tools to stay strong and not break or bend during use.

You must check equipment often to keep it safe. Regular inspection, maintenance, and calibration help you find problems early. Torque testers check that screws and fasteners are tight enough. If a fastener is too loose, the device might not work. If it is too tight, it could break. These checks keep devices working safely.

Here is a table that shows how force measurement is used in medical devices:

| Device Type | Force Measurement Role |

|---|---|

| Hospital Beds | Detects patient presence and movement |

| Infusion Pumps | Monitors fluid pressure and flow |

| Prosthetics | Measures force for natural movement |

| Surgical Tools | Tests strength and safety before use |

| Rehabilitation Gear | Tracks patient progress and safety |

Tip: Always follow a regular schedule for calibration and maintenance. This keeps your medical devices safe and reliable.

Force measurement devices help you care for patients. You make sure every device meets safety rules. SOUSHINE’s FSRs are accurate, strong, and easy to use in many medical jobs.

Selecting Force Measurement Devices

Capacity and Range

When you pick a force measurement device, you need to think about capacity and range first. This helps stop overload and gives you correct readings. Your device should handle the load you expect and any extra force that might happen. Here are some things to think about:

- Sensor Mounting Characteristics: Decide if you want to measure a still or moving load. Pick the right way to mount it, like a female or male thread, or a side mount, so it fits your setup.

- Capacity Requirements: Set the smallest and biggest load your device must handle. Make sure it can take extra force without breaking.

- Size and Geometry Requirements: Think about the shape and size you need. Check if you need special features, like working underwater or in hot places.

- Output Type: Choose the output that works with your system. You can pick analog, digital, or serial for real-time checks.

Always match the device’s range to your job. If you use a dynamometer, know the highest and lowest load it will measure. Picking the right range helps you get good data for making your process better.

Tip: Pick a device with a little more capacity to handle surprise loads.

Accuracy and Precision

Accuracy and precision are very important for force measurement. You want your device to give the right numbers every time. If it is not accurate, your products might fail or be unsafe. Bad readings can cause expensive recalls, especially when you measure tensile strength or torque.

- You need accuracy and precision for important jobs.

- Good readings help you avoid mistakes when you calibrate.

- Knowing these terms helps you set the right rules.

- Reliable force measurement is needed for testing and quality checks.

- Bad resolution can miss small changes in load.

- High-resolution systems with low accuracy can give wrong but steady results.

- You get better data and fewer mistakes by focusing on accuracy and precision.

You should also check the static error band. This shows the biggest difference between the real force and what your device says. Errors can happen from bad setup or calibration. Repeat your tests to make sure your device gives the same answer each time.

Note: Always look at the accuracy and precision details before you buy a force measurement device.

Environmental Factors

Environmental factors can change how your force measurement device works. You need to think about where you will use it. Temperature and humidity are two big things that can change how well it works. The table below shows how these can affect your device and ways to fix problems:

| Environmental Factor | Impact on Measurement | Mitigation Strategy |

|---|---|---|

| Temperature | Drift, sensitivity change | Compensation, shielding, stabilization |

| Humidity / Moisture | Instability, corrosion | Sealed sensors, IP-rated protection |

If you use your device in a hot or cold place, temperature changes can make it drift or less sensitive. You can use shielding or compensation to help. If you work in a wet or humid place, moisture can make your device unstable or rusty. Sealed sensors or IP-rated protection can help stop these problems.

Always check the environment before you pick a force measurement device. This helps you get the best results and keeps your device working longer.

Tip: Pick a device that fits your environment for the best force measurement and load checks.

Application Fit

You need to pick a force measurement device that matches your job. This helps you get good results and avoid mistakes. Every job is different. You should think about what you want to measure. You also need to know how you will use the data. Make sure the device fits how you work.

The table below can help you see if a device is right for your job:

| Criteria | Description |

|---|---|

| Measurement Quality | Checks if the device gives reliable and accurate force measurement that matches top standards. |

| Decision-Making Utility | Looks at whether the data helps you make good choices and if you can use it over time. |

| Organizational Feasibility | Considers if you can use the device easily, if it fits your budget, and if it saves you time. |

Ask yourself these questions before you choose:

- Does the device measure the force you need?

- Will it work with your machines or systems?

- Can you use the data to make things better?

- Is it easy to set up and take care of?

- Does it fit your budget and schedule?

If you work in a factory, you may need a device for heavy loads and quick feedback. In sports, you might want a sensor for small force changes. If you use a dynamometer, you need a device for both big and small loads.

Always test the device in your real work area before you decide. This helps you see if it works for you and gives the right data.

SOUSHINE Product Reliability

You want your force measurement tools to last and work well. SOUSHINE makes products that are strong and reliable. You can trust these devices for long-term use.

- SOUSHINE products work well even with heavy loads. You do not need to buy new ones often.

- The strong design keeps your equipment working for a long time. This helps you avoid problems and save money.

- SOUSHINE tests their products to see how they handle stress and force. This helps make sure the devices last.

- The company cares about how long their products work. You get tools that keep working year after year.

- SOUSHINE always tries to make their products even better. You get the newest ideas in force measurement.

You can use SOUSHINE force measurement devices in many jobs, like cars or healthcare. The products work with different loads and types of force. You get good data for every job. You can count on SOUSHINE for tools that help you measure and control force.

Tip: Pick SOUSHINE for force measurement devices that help your business and give you peace of mind.

Maintenance and Troubleshooting

Calibration Best Practices

You need to check your force measurement device to keep it working right. Calibration means you make sure your device gives correct numbers. You should do this on a regular schedule. Most experts say to calibrate at least once every year. If you use your device a lot or in hard places, do it more often.

Here are some good ways to calibrate:

- Test your device with a weight or force you know.

- Make sure the room is steady. Keep the temperature and humidity the same.

- Clean your device before you start to calibrate.

- Write down the results every time you calibrate.

- If you find big mistakes, fix the device or call the maker.

Tip: Always use the instructions from the company for the best results when calibrating.

Common Issues

You might have some problems with force measurement devices. Knowing about these problems helps you fix them fast.

| Issue | Possible Cause | Solution |

|---|---|---|

| Inaccurate readings | Dirt, wrong calibration | Clean and recalibrate |

| Signal drift | Temperature changes | Use temperature compensation |

| No output signal | Loose wires, power loss | Check connections and power |

| Fluctuating readings | Vibration, unstable setup | Secure the device, reduce noise |

| Slow response | Device overload | Use the right range for force |

If you see any of these problems, fix them quickly. Check your device, how it is set up, and the room. Fixing small problems early keeps your device working well.

Maintenance Tips

You can keep your force measurement device working well with easy steps. Taking care of your device helps it last longer and stay correct.

- Keep your device in a clean, dry place.

- Do not drop or hit your device.

- Look at cables and connectors for damage.

- Clean your device with a soft, dry cloth.

- Test your device with a known force before you use it.

- Change old or broken parts as soon as you see them.

Note: Good care saves you time and money. It also helps your force measurement stay correct.

If you follow these tips, your device will work its best. You will also have fewer mistakes when you measure force.

You learned about different force measurement devices. Some examples are strain gauge load cells, piezoelectric sensors, and force sensing resistors. Each device measures force in its own way. Each one works best for certain jobs. You should pick the right device for your force needs. First, write down what you need to measure. Then, check which device matches your goals. If you want help you can ask SOUSHINE for advice on force measurement.

FAQ

What is a force measurement device?

A force measurement device helps you find out how much force you use on an object. You can use it in many fields like factories, cars, and sports.

How do Force Sensing Resistors (FSRs) work?

FSRs change their electrical resistance when you press on them. You get a lower resistance with more force. This lets you measure how hard you press.

Where can you use SOUSHINE FSRs?

You can use SOUSHINE FSRs in cars, medical devices, sports equipment, and robots. They help you measure pressure, touch, or movement in many products.

How do you choose the right force sensor?

You should check the force range, accuracy, and size you need. Think about where you will use the sensor and what you want to measure.

Why is calibration important for force sensors?

Calibration makes sure your sensor gives correct readings. You should calibrate your sensor often to keep your data accurate and reliable.

Can you use force sensors in wet or hot places?

Yes, you can use some force sensors in wet or hot places. You should pick sensors with special protection, like sealed or IP-rated models, for these environments.

How long do SOUSHINE FSRs last?

SOUSHINE FSRs last a long time. They use strong materials and go through strict testing. You can trust them for repeated use in tough jobs.

Who can you contact for help with SOUSHINE products?

You can contact SOUSHINE by email, phone, or on their website. Their team helps you choose the right sensor and answers your questions.