Call us: +86-137-2353-4866

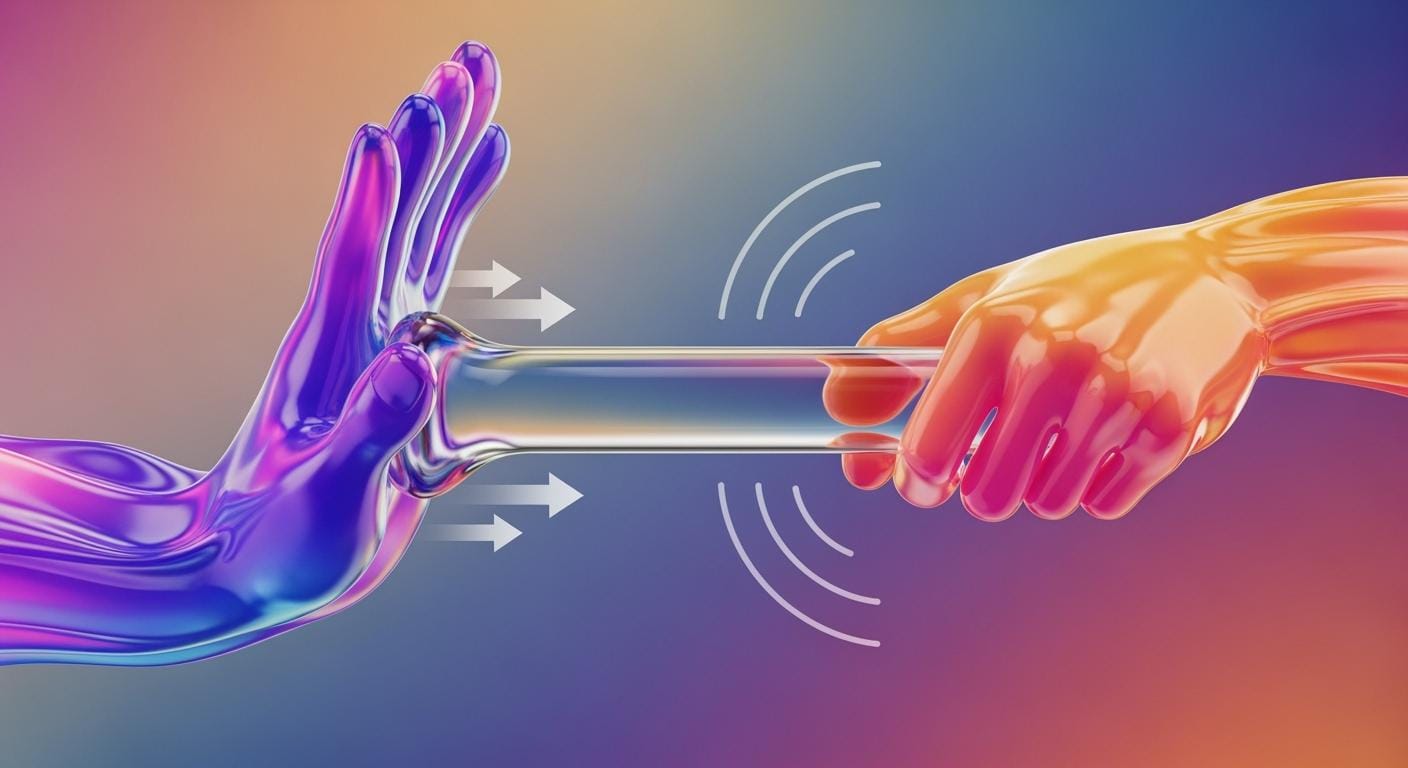

You might wonder if compression force or tension force is more important. The answer changes based on what you make or design. Imagine a bridge. Some parts need to hold up heavy weight pushing in. Other parts must not break from being pulled apart. In healthcare, force sensing resistors help check pressure points or measure grip strength. SOUSHINE’s force sensing resistor gives you good force sensing for both kinds of force. These sensors work in healthcare, robotics, and civil engineering to give steady results.

| Industry | Application Description |

|---|---|

| Healthcare | Used for patient checks, rehab tools, surgery tools, and fake limbs |

| Robotics | Helps robots feel touch for holding and moving |

| Civil Engineering | Makes buildings safer by checking pressure |

Table of Contents

Key Takeaways

- Compression force pushes things together. Tension force pulls things apart. Knowing this helps you design better.

- Use SOUSHINE Force Sensing Resistors (FSRs) to measure both compression and tension forces. They work well in many situations.

- Pick materials for their strength. Steel is best for tension. Concrete is best for compression.

- Check the load and stress on cables and supports often. This helps stop failures and keeps your projects safe.

- In building, balance compression and tension forces. This keeps structures strong and stops accidents.

- In healthcare, FSRs can check grip strength and pressure points. This helps patients get better care and recover faster.

- For DIY projects, know what forces are there. This helps you build safe and strong things.

- Always think about which way the forces go. Compression forces push in. Tension forces pull out.

What Is Compression Force?

Compression Force Definition

Simple Explanation

Compression force happens when you push on something from both sides. The object gets shorter or smaller because you press it in. You can see this when you squeeze a sponge or push down on a spring. Compression force moves in a straight line toward the middle of the object.

Direction and Effect

Compression goes inward. It pushes the ends of a material closer together. When you push, the object tries to stay the same shape. The stress inside the material gets bigger as you add more weight. If you keep pressing, the material might bend, crack, or break. The way compression force moves changes how strong a material is under pressure. Some materials are good at handling compression, but others are not.

- Compression force can cause:

- Buckling, which is when long, thin things bend under pressure.

- Cracking, if the material cannot take the stress.

- Deformation, where the shape changes but does not break.

Compression strength means how much stress a material can take before it fails. Compression members, like building columns, need enough strength to hold up weight without bending or breaking.

Compression Force in Action

Everyday Examples

You see compression force all around you every day. When you sit on a chair, your weight pushes down on the seat. The chair legs handle this compression. When you walk, your feet press on the ground, and the ground pushes back with the same force. In buildings, columns and walls hold up the weight above them using compression.

Many devices use sensors to check compression. SOUSHINE’s Force Sensing Resistors (FSRs) help you measure compression right away. You find these sensors in:

- Wearable health and fitness devices

- Smart textiles and seating sensors

- Robotics grippers and haptic controls

- Touch-sensitive user interfaces

- Pressure mats and consumer electronics

Material Response

Materials act differently when you push on them. Some, like steel or concrete, can take a lot of compression. Others, like foam or rubber, change shape easily when pressed. Long, thin objects are more likely to buckle. The size of the cross-section matters too. A thick column is better at stopping buckling than a thin one.

| Test | Description |

|---|---|

| Drift during static compression | Static loads from 10 to 200 kPa for 5 min each. Sensor drift checked every 30 s. |

| Drift during cyclic compression | Cyclic loading from 0–300 kPa at 1 Hz. Sensor drift checked. |

| Walk–sit–stand accuracy | Simulated prosthesis use with compressive loads: walk (cyclic 0–300 kPa), sit (10 kPa), stand (30 kPa). |

| Effect of curvature | Static compression on curved surfaces, pressures from 50 to 300 kPa for 15 s each. |

| Effect of shear | Static compression with different levels of shear stress. |

You can use SOUSHINE FSRs to see how much compression force is on different things. This helps you make safer products and check material strength right away.

What Is Tension Force?

Tension Force Definition

Simple Explanation

Tension force happens when you pull something from both ends. You can see this when you stretch a rope or a rubber band. The force moves away from the middle and makes things longer or tighter. Tension force holds things together by pulling them apart.

Tension force is a pulling force that goes through things like ropes, strings, or cables when you pull them tight from both sides. This force helps machines and buildings work. You find tension in bridges, elevators, and even in your muscles.

Direction and Effect

Tension force always pulls outward. When you pull a rope, the force moves along the rope, away from the center. The rope gets longer and tighter. If you pull too hard, the rope can break. Tension force shows how much something can stretch before it snaps.

The way tension force moves changes how things work in building and making stuff. You need to know how things react to pulling. Some things stretch a lot before breaking. Others break fast. How you use tension force can change how safe and strong your project is.

| Factor | Description |

|---|---|

| Material Properties | Different things act in their own way with tension; knowing this is important for control. |

| Speed and Acceleration | Fast changes in speed can make tension go up and down, which can hurt the material. |

| Friction and Drag | Lots of friction can make tension uneven, which can lower quality; less friction is better. |

| Environmental Factors | Things like heat and wetness can change how materials act, so you may need to adjust tension. |

| External Forces | Wind or shaking can mess up tension; systems should fix these problems. |

Tension Force in Action

Everyday Examples

You see tension force in many places. When you hang clothes on a line, the line pulls tight between two posts. Tension keeps the line straight. In sports, tennis rackets use tension in their strings to hit the ball. Elevators use cables with tension to move up and down. Your muscles use tension to move your bones.

SOUSHINE’s Force Sensing Resistors (FSRs) help you measure tension force right away. You can use these sensors in robots to check how hard a robot hand grips something. In healthcare, FSRs measure the force in therapy bands or check how strong a patient’s grip is. These sensors give fast and correct results.

Material Response

Materials act differently with tension. Steel cables stretch a little before breaking. Rubber bands stretch a lot but snap if pulled too hard. Some fabrics can take high tension, but others tear easily. You must pick the right material for your job.

When you use SOUSHINE FSRs, you can test how much tension a material can handle. This helps you choose safe and strong materials for your work. You can also find problems early, like when a cable starts to stretch too much. This keeps your projects safe and working well.

Tip: Always check the tension in ropes, cables, or bands before you use them. This helps stop accidents and keeps your equipment working well.

Compression Force vs Tension Force

Key Differences

Direction of Force

Compression force and tension force act in different ways. Compression force pushes inward. This makes things shorter or smaller. Tension force pulls outward. This makes things longer or tighter. If you push on a column, you get compression. If you pull on a rope, you get tension. These differences change how you build things.

Material Behavior

Materials act differently with compression and tension. Tension makes a material stretch and get longer. Compression makes a material get shorter. Both forces put stress inside the material. The way the material changes shape is not the same. Tensile stress makes things longer. Compressive stress makes things shorter. You need to know how strong your material is before you use it.

| Material | Under Compression | Under Tension |

|---|---|---|

| Steel | Handles high compressive stress | Stretches before snapping |

| Concrete | High compressive strength | Weak in tension, cracks fast |

| Polymers | Deform under compressive stress | Stretch, then snap |

Failure Modes (Buckling vs Snapping)

Different failures can happen in structures. Compression members, like columns, can buckle. Buckling happens when a long, thin part bends or falls over. Tension members, like cables, can snap. Snapping happens when you pull too hard and the material breaks.

- Engineers figure out how much load stops buckling.

- Buckling happens a lot in thin steel columns.

- Compression failures can cause buckling or crushing.

- Tension failures happen when a cable stretches too far and snaps.

- Tensile failure can mean stretching, thinning, and then breaking.

You must check if materials can handle compression and tension. This keeps your structure safe.

Real-World Scenarios

Bridges and Buildings

Bridges and buildings use both forces. In a bridge, the deck and supports take compression. Cables or rods take tension. If you do not plan for these forces, columns can buckle or cables can snap. Good design spreads the weight across the whole structure. In buildings, columns hold up weight and resist compression. Beams and braces handle tension and keep things steady.

Note: Every bridge needs both compression and tension. If you do not balance them, the bridge can fail.

Cables and Ropes

Cables and ropes work with tension. You see this in elevators, cranes, and machines. If you do not control the load, cables can snap. Sudden stops or side pressure can break ropes. In factories, bad tension control can break ropes and stop machines.

| Stage | Description |

|---|---|

| 1 | Cracks start near where the load is and small pieces fall off. |

| 2 | Tension damages the edges and you see signs of failure. |

| 3 | The material splits with rough cracks along its length. |

| 4 | Crushing breaks the material into small pieces as the load grows. |

You should check the load and stress on cables and ropes often. This keeps your equipment safe and working.

Automotive, Healthcare, and Industrial Automation

Cars use both compression and tension in their suspension. Compression springs take in shocks and keep the car steady. Tension springs pull parts together and keep them lined up. If you do not balance these forces, the car can break down.

In healthcare, SOUSHINE Force Sensing Resistors help you watch both forces in devices. You can track how a patient moves or how strong their grip is. These sensors turn force into electrical signals. You get quick and correct data.

In factories, machines use both forces to move parts and lift things. SOUSHINE FSRs help you measure and control these forces. This makes your machines safer and more reliable.

Tip: Use SOUSHINE FSRs to check both compression and tension in your projects. You get fast feedback and make things safer.

Choosing the Right Force for Your Application

Critical Force Scenarios

Home and DIY Projects

You use compression force and tension force in many home projects. When you hang a swing, the ropes are tension members. The load pulls on the ropes. Tension keeps the swing steady. If you build a shelf, the supports take compression force. The weight pushes down. The structure must not bend or buckle.

Some home projects need force measurement:

- Ropes or cables hold up things, like swings or planters

- Chains in pulleys help lift heavy objects

- Things hanging at angles, like flagpoles

- Bridge cables hold up garden bridges

- Supports share weight in furniture or sheds

You need to measure tension to keep projects safe. Good measurement helps you stop failures and keep things steady. SOUSHINE Force Sensing Resistors give fast feedback for both forces. You can check the load on a rope or stress in a support.

Industrial and Engineering Uses

Factories and construction sites have bigger loads and harder jobs. Engineers pick materials for their compressive strength and tensile strength. Steel is good for tension members. Concrete is strong in compression.

| Material | Tensile Strength | Compressive Strength |

|---|---|---|

| Steel | High | Moderate |

| Concrete | Low | High |

Mechanical properties show how materials act under tension, compression, and shear. You must know these to stop stress and bending. Loads that repeat can cause fatigue and cracks. You need to check load and stress often to keep things safe.

SOUSHINE FSRs help you watch force in real time. You can use them in robots, cars, and medical tools. These sensors make things safer by giving you correct force data.

Compression Force or Tension Force: Which Matters Most?

Application-Based Guidance

You must pick which force matters most for your project. If you build a column, focus on compression force. If you design a cable or rope, tension is most important. Knowing about tension and compression helps you use less material, keep things strong, and find weak spots.

Mechanical properties tell how materials react to load. Metals like steel are good with tension. Concrete is best for compression. You must match the force type to the material and job.

Tip: Always check which way the load goes. Compression force pushes in. Tension force pulls out. Pick materials that can handle the stress.

Safety and Material Selection

Safety means knowing your material’s limits. Engineers use safety margins to make sure things hold up. The margin of safety is the failure load divided by the design load. A positive margin means it is safe.

Industry rules need correct force measurement. Calibration follows ISO/IEC 17025:2017 and ASTM E74. You must use sensors that meet these rules for good results.

| Application Field | Benefit of FSRs |

|---|---|

| Medical Devices | Cheap and flexible for measuring force |

| Robotics | Makes robots work better and measure force well |

| Automotive Controls | Gives steady sensing of force and pressure |

SOUSHINE FSRs are sensitive and accurate. You can use them in many areas, like robots and healthcare. These sensors help you watch both forces, making things safer and better.

Using materials for a long time with repeated load can cause fatigue. Stress and strain build up and cause cracks or breaks. You must check tension members and compression supports often. Regular checks stop accidents and keep things strong.

Note: Always match the force to the material. Steel is best for tension. Concrete is best for compression. Use SOUSHINE FSRs to watch load and stress for safer projects.

You should know when compression force or tension force is important. Both forces help decide if your project is strong and safe.

- Tension and compression both affect how long metal structures last.

- Tensile strength tells you when metal will break from pulling. Compressive strength shows how much weight metal can take when pushed.

| Criteria | Description |

|---|---|

| Project type | Pick sensors for robots, healthcare, or games |

| Force range | Choose for light or heavy force |

| Durability | Make sure sensors last |

You can use SOUSHINE’s Force Sensing Resistors to check both forces. This helps you make products that are safer and work better.

FAQ

What is the main difference between compression and tension force?

Compression force pushes things together. Tension force pulls things apart. Columns use compression. Ropes use tension.

Can SOUSHINE FSRs measure both compression and tension?

Yes. SOUSHINE Force Sensing Resistors measure both forces. You can use them for many jobs.

Why do bridges need both compression and tension?

Bridges use compression in supports. Cables use tension. Both forces keep bridges strong and safe.

How do I know which force matters most for my project?

Check how your structure works. If you push, focus on compression. If you pull, focus on tension. Pick materials for the main force.

Where can I use SOUSHINE FSRs?

SOUSHINE FSRs work in healthcare, robotics, and cars. You can use them in factories too. They measure force right away.

What happens if I ignore tension or compression in my design?

Ignoring these forces can break things. Columns might bend. Cables might snap. Always check both forces to stay safe.

How do I choose the right material for tension or compression?

Use steel for tension jobs. Use concrete for compression jobs. Match the material to the force you need.

Do I need special tools to install SOUSHINE FSRs?

No. You do not need special tools. Follow the instructions to install them easily.