Call us: +86-137-2353-4866

SOUSHINE is a leader in Force Sensing technology. They make custom force sensing resistor solutions. The Force Sensing Resistor works by changing resistance when force is used. It uses a piezoresistive principle. The design can have many shapes and sizes. This helps meet tough medical rules. Many medical devices need a custom force sensing resistor for good results. Medical design teams trust SOUSHINE for force detection. Custom force sensing resistor choices help engineers fit special medical needs.

Table of Contents

Key Takeaways

- SOUSHINE makes custom force sensing resistors that change resistance when pressed. These help measure force in a very accurate way. Their sensors use thin, bendy films and special materials. This lets them fit many shapes and sizes for hard medical and industrial jobs. SOUSHINE gives fast, sensitive, and tough sensors. These work well in different temperatures and last through millions of presses. Clients get designs made just for them with expert help. They also get quick samples and clear updates from start to finish. Force sensing resistors from SOUSHINE are used in medical devices, industrial machines, and electronics. These help make things safer and easier to control. The company tests and sets each sensor carefully. This makes sure they work well and give the same results in real life. SOUSHINE has important quality and safety certificates. This makes their sensors trusted in medical, car, and industrial fields. Strong customer support and after-sales service help clients. They can install, take care of, and change sensors for long-term success.

Force Sensing Resistor Technology

Piezoresistive Principle

Force-sensing technology works because of the piezoresistive effect. This effect happens when a material’s resistance changes after force is put on it. In force-sensitive resistors, a special polymer with metal bits is used. When you press the sensor, the resistance goes down. Two things cause this change:

- The way the metal bits and electrodes touch changes as you push harder.

- The polymer gets flatter, so more area touches and lets current flow.

Percolation theory and quantum tunneling help explain how these sensors work. Percolation theory shows how the metal bits connect better as you press more. Quantum tunneling lets electrons jump between bits, even if they do not touch. These effects make the sensor’s reaction not straight, but you can still predict it.

Engineers use this idea to measure force right away. The sensor’s resistance change is seen as a voltage change. This voltage can be set to show the exact force.

Sensor Construction

SOUSHINE uses advanced force-sensing technology to make strong sensors. Each force sensing resistor has two thin film layers. One layer has the resistive material. The other layer has the circuit. A glue holds the layers together. When you press down, the resistive part touches the circuit. This makes the resistance go down.

- Thin, bendy films help the sensors fit in small spaces.

- The resistive layer reacts fast to force.

- The circuit layer picks up the signal to measure.

This design makes the sensors thin and easy to bend. Engineers can make the sensors in many shapes and sizes. The design works for single sensors or groups of sensors for harder jobs.

Performance Features

SOUSHINE’s force-sensing technology has many good features. These sensors react to force in just a few milliseconds. They can sense forces from 0.2N up to over 20N. The resistance starts very high with no force and drops a lot when pressed hard.

- Sensitivity: The sensors show a clear resistance change for each force.

- Response Time: They react almost right away, so they are good for real-time use.

- Durability: The sensors last through millions of presses and keep working well.

- Operating Range: They work in temperatures from -30°C to +70°C.

- Repeatability: The output stays steady, with only small changes over time.

Note: The reaction is not straight, but you can adjust the sensor to match the force. This makes resistive force sensors good for finding presence, spot, or how much force is used in many things.

SOUSHINE’s force-sensing technology makes sure every sensor works for today’s devices. The sensors give fast, steady, and repeatable force readings for jobs that need careful control.

Custom Force Sensing Resistor Solutions

Consultation Process

SOUSHINE starts each project with a careful meeting. The team gathers exact information about the job. They use 3D scanning, special software, and design templates. This helps the sensor fit the right shape and needs. Engineers check the data with the client to make sure it is correct. After learning what is needed, SOUSHINE makes a plan for the project. The plan lists the main steps, what will be delivered, and when things will happen. Clients get updates often and can see how things are going. This way, the project stays on schedule and everyone understands what is happening.

Design Flexibility

SOUSHINE lets clients pick many design details. Clients can choose the size, shape, and how sensitive the sensor is. The design team helps pick materials, force range, and output signals. Customers give details like material, thickness, glue, colors, amount, and artwork. Skilled engineers help with graphic overlays and make drawings from samples or ideas. The team can make sensors in square, round, or odd shapes. They also offer both regular and special sizes. This helps SOUSHINE serve medical, industrial, and consumer needs. The design process makes sure each sensor fits the force and use goals. Careful checks and expert review keep quality high during design.

Prototyping & Manufacturing

SOUSHINE moves fast from design to making samples. The team builds first samples with chosen materials and early tests. Engineers check quality many times to improve the design. When the sample is good, they start making more. The factory uses screen printing to put special inks on bendy films. Printed layers are stacked with spacers and stuck together to make a thin sensor. Clients can ask for logos, labels, or special connectors to fit their needs. Careful checks and tuning make sure each sensor works well. Making a sample takes 1 to 7 days and big orders take 1 to 3 weeks. Shipping time depends on the way it is sent. SOUSHINE sends sensors on time and helps clients even after delivery.

Force-Sensitive Resistors in Applications

Medical Devices

Medical devices use sensors to help patients and keep them safe. Force-sensitive resistors are important in many medical tools. These sensors help with patient checks and drug-delivery. They are also used in micro-needle drug-delivery devices. Design teams pick these sensors because they are thin and bend easily. They also do not use much power. Infusion pumps use sensors to find force changes in tubes. This helps spot blockages and keeps drug-delivery safe. Prosthetics use sensors to check pressure and make them more comfortable. Pressure-relief cushions use sensors to watch patients and help with posture. Micro-needle drug-delivery devices use sensors to watch force during drug use. Automated drug pumps use sensors to give feedback right away. Medical device design often needs special sensors for small spaces and different shapes.

Note: Force-sensitive resistors work well in medical tools when you only need to know if force is there. They cost less and react fast.

| Feature | Force Sensing Resistors (FSRs) | Other Sensors (Load Cells, Strain Gauges) |

|---|---|---|

| Output Type | Non-linear resistance change | Linear resistance change |

| Accuracy | Moderate | High |

| Complexity | Low | High |

| Durability | Moderate | High |

| Application | Tactile interfaces, wearables, medical devices | Structural analysis, precision measurement |

| Cost | Low | Higher |

| Environmental Stability | Moderate | Excellent |

Medical devices need sensors that fit in tight places and use little power. Drug-delivery and micro-needle drug-delivery devices use these sensors for safe and steady drug use. Design teams trust these sensors for many uses.

Industrial Equipment

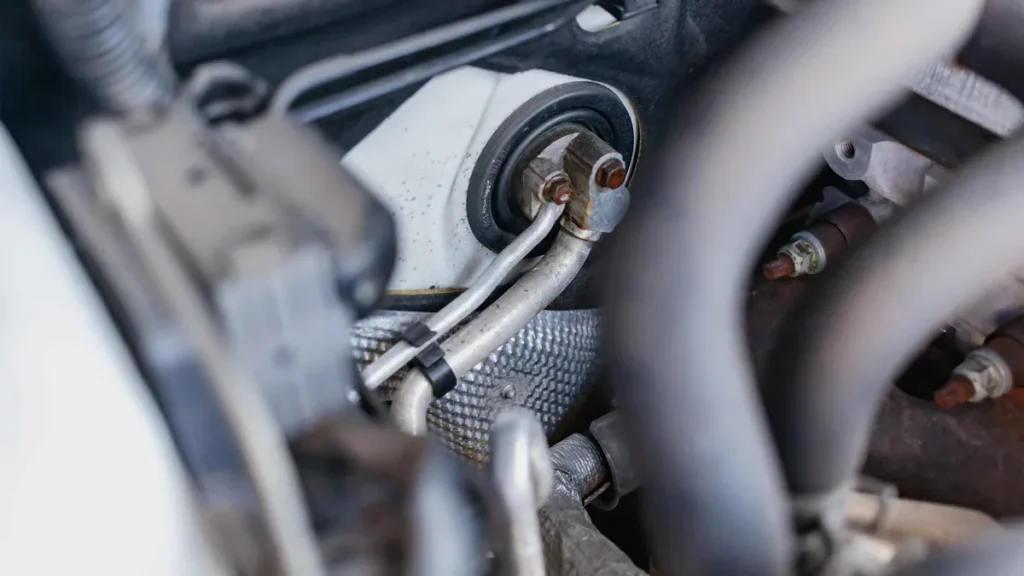

Industrial machines use sensors to make work safer and easier to control. Force-sensitive resistors help in many factory jobs. Food packaging machines use sensors to check pressure. This makes sure sealing bars line up and stops broken packages. Car assembly lines use sensors to check door seal pressure. This stops leaks and makes cars better. Airbag systems in cars use sensors to change how hard airbags fill. This keeps people safe in crashes.

- Robotic grippers use sensors to get the right grip.

- Sensors check grip force as it happens.

- Sensors find mistakes and help with quality.

- Sensors watch for hits on breakable things.

- Sensors help track materials in storage.

Sensors in machines help keep workers safe and stop long breaks. They help watch and control many jobs.

| Industrial Application Area | How FSRs Improve Functionality or Safety | Impact on Industrial Equipment |

|---|---|---|

| Food Packaging Industry | Pressure mapping makes sure sealing bars line up right, even when it is hot, so there are fewer broken packages. | Saves time on setup and fixing, stops long breaks, and keeps packages safe. |

| Automotive Assembly | Electronic pressure checks replace hand checks for door seals, so hinges and latches can be set just right. | Stops noise, wind, and water leaks, cuts down on repairs, and makes cars seem better. |

| Airbag Calibration in Vehicles | Pressure checks find out who is in the seat and change airbag force. | Makes cars safer by stopping airbag injuries, especially for babies. |

Consumer Electronics

Consumer electronics use sensors to make devices more fun and easy to use. Force-sensitive resistors are in many gadgets. Touchpads use sensors to feel pressure and give better control. Game controllers use sensors for buttons that feel how hard you press. Electronic drum kits use sensors to tell how hard you hit.

- Touchpads use sensors for commands based on pressure.

- Game controllers use sensors for better game control.

- Electronic drum kits use sensors for louder or softer sounds.

These sensors react fast and fit many device shapes. Their thin and bendy design makes them easy to put in new gadgets. People get better control and more fun from their devices. Sensors in electronics help many uses and make devices work better.

Force-Sensing Technology Integration

Material Selection

The materials used in a sensor change how it works. SOUSHINE engineers pick materials for each job. They use bendy bases for devices that need to fold. For tough jobs, they use strong plastics that last longer. The team thinks about how each material reacts to force. Some sensors need thin layers to react fast. Others need thick layers to handle more force. The right glue keeps the sensor in place. Special inks make the parts that sense force and must fit the electric needs. Each step in design looks at how the sensor will work in the end. The materials picked change how sensitive and strong the sensor is. They also help the sensor fit in many shapes. SOUSHINE’s know-how helps them pick the best materials for each job.

Sensor Arrays

Sensor arrays help sensors do more things. By putting sensors in a grid, engineers can see pressure in many spots. This way, they get more than just one point of force. It shows a full map of how force spreads out. In robots, arrays help machines feel shapes and force patterns. Robotic skins and pads use these grids to sense touch in many places. This is key for robots to be safe around people. Arrays also help medical tools check pressure in many spots. SOUSHINE uses screen printing to put different sensors, like force, heat, and wetness, on one soft sheet. This lets them put sensors inside tricky systems. Arrays help with smart control in jobs like holding things or keeping balance. The way each array is made depends on what the job needs, like how many sensors, how far apart, and how they connect.

System Compatibility

System compatibility means sensors work well with other tech. SOUSHINE faces some problems when adding sensors:

- No set rules can make things hard, mostly in cars and health tools.

- Better force-sensing tech makes sensors more correct and steady in hard places.

- Fancy sensor designs can cost more, which is tough for small companies.

- Many jobs need sensors to pass strict safety and work rules.

- Other pressure sensors can have different good points.

SOUSHINE’s team helps clients fix these problems. They make sensors that fit the client’s system, thinking about wires and data. The team checks each sensor to make sure it works right. They also help clients add sensors to their products. Careful design and testing help SOUSHINE give good, working sensors for every job.

Quality and Reliability

Calibration Methods

SOUSHINE uses careful steps to make sure each force sensing resistor works right. The team puts known weights on each sensor and checks what it shows. Special machines press the sensors in small steps. This helps them see how force and resistance are linked. Engineers write down the numbers and use them to set up the sensor. They do this for every group of sensors. This keeps the readings steady and correct. Calibration helps when sensors are used in different devices. Each sensor can fit medical, industrial, or consumer needs. These steps help SOUSHINE get the best fsr performance for every job.

Tip: Checking calibration often helps sensors stay correct over time.

Testing Protocols

SOUSHINE uses strict rules to test every sensor. The team checks how fast the sensor reacts and if it gives the same reading each time. Machines press the sensors thousands of times to see if they last. Engineers also test the sensors in hot and cold places. They want to know if the sensor works in all kinds of weather. The team looks for changes in the sensor after long use. They also check for any damage or wear. Every sensor must pass these tests before it is sent out.

- Response time test: Checks how fast the sensor reacts.

- Repeatability test: Makes sure the sensor gives the same result each time.

- Durability test: Presses the sensor many times to see if it lasts.

- Environmental test: Puts the sensor in heat and cold.

These tests help SOUSHINE give sensors that work well in real jobs.

Certifications

SOUSHINE has important certifications for quality and safety. ISO13485 is needed for medical devices. This shows SOUSHINE follows strong rules for safe medical products. ISO9001 and AS9100 help with quality in factories and medical places. For cars and factories, IATF 16949 is important. RoHS compliance is needed for consumer products because it limits bad substances.

| Certification | Application Area | Description |

|---|---|---|

| ISO 9001:2015 | General Quality Management | Makes sure factories have good quality systems for all kinds of products. |

| AS9100D | Industrial/Aerospace | Quality rules for making things in planes and factories. |

| IATF 16949 | Automotive/Industrial | Quality system for car factories and other big jobs. |

| RoHS Compliance | Environmental Compliance | Stops harmful stuff in electronics, which is good for people and the planet. |

These certifications show that SOUSHINE’s sensors meet high standards. People in medical, industrial, and consumer fields can trust SOUSHINE’s force sensing resistors for quality and safety.

Case Studies

Robotics & Automation

SOUSHINE FSR sensors help robots and machines work better. Engineers put these sensors in robotic grippers to check grip force. Robots can hold breakable things without breaking them. In remote surgery, sensors give doctors feedback during surgery. This feedback helps doctors move tools carefully. Wearable robots use sensors to watch how joints move. The sensors fit inside soft exoskeletons and help people move. Factories use sensor arrays to watch pressure on machines. This helps machines keep working and stops them from breaking. Robots in warehouses use sensors to check force when moving boxes. These sensors help robots work safely with people.

Automotive Systems

Car engineers use SOUSHINE FSR sensors in many car parts. Airbag systems use sensors to see who is in the seat. The system changes airbag force for each person. Door seals in cars use sensors to check pressure. This stops leaks and keeps cars quiet. Car seats use sensors to watch how drivers sit. The sensors help make seats more comfortable. In electric cars, sensors watch battery pack pressure. This keeps batteries safe when shipping and using them. Assembly lines use sensors to check force when putting parts together. This helps make sure every car is safe.

Specialized Use Cases

SOUSHINE FSR sensors work well in special jobs. Flexible wearable sensors help watch movement in medical and robot systems. Engineers use materials like polydimethylsiloxane, hydrogels, and conductive polymers to make sensors better. These materials block electromagnetic interference and work with machine learning and IoT.

- Healthcare: Motion tracking gloves, smart clothes, and surgical tools use sensors to find force. Micro-needle drug-delivery devices use sensors to watch force during drug delivery. These sensors help make drug delivery safe and steady in medical devices.

- Robotics: Remote surgery robots and wearable robots use sensors for careful control. Sensors in rehab tools and prostheses watch movement and force.

- Wearable Devices: Smart clothes and muscle trackers use sensor arrays to watch movement in real time. These devices help track health and fitness.

- Drug-delivery devices: Micro-needle drug-delivery devices use sensors to watch force and make sure drugs are given right. Automated drug-delivery devices use sensors for feedback during delivery.

SOUSHINE FSR sensors use special polymer films with conductive particles. This design makes sensors very sensitive and strong, lasting over 10 million uses. Sensor arrays measure many forces at once, helping in wearables and smart devices. New materials and designs lower signal drift and make sensors more reliable. These features make sensors easy to add to smart devices and AI. Sensors find small force changes and keep working in many conditions. Special use cases show how SOUSHINE sensors help in medical, robot, and consumer jobs.

Customer Support

Technical Assistance

SOUSHINE gives strong help to every customer. The support team helps at each step of using the sensor. They make sure installing and using force sensing resistors is easy and works well. The team knows each job might need a different design, so they give advice for each project.

- The team gives simple steps for putting in the sensor. They help customers get tools ready, set up a safe area, and put the sensor in the right spot. This helps get good measurements right away.

- SOUSHINE explains how to connect wires and cables. They show how to link the sensor to data systems or controllers. The team also tells when extra circuits are needed for the job.

- The team gives tips for calibration. They show how to use known weights and change the sensor output. They use the maker’s rules to keep readings correct.

- Testing and starting steps help make sure the sensor works before using it. The team checks if the readings are steady and the sensor works right.

- Maintenance tips include checking the sensor, calibrating, cleaning, and testing with loads. These steps help the sensor last longer and work well.

- SOUSHINE helps with making the sensor fit special needs. They help change the sensor’s size, shape, and sensitivity for each job.

- The support team also explains the warranty. They help fix problems, repair, or replace the sensor if needed.

SOUSHINE’s technical team works closely with engineers and designers. They answer questions fast and help fix problems at every step.

Post-Sales Service

SOUSHINE cares about helping customers for a long time. After sending the product, they keep helping with good service. The team answers quickly if there are any problems with the sensor. They help find and fix problems that come up.

Customers can ask SOUSHINE for help with how the sensor works, how to use it, or if they want to change the design. The team keeps notes on each project, so they can give advice for each design. If a customer needs a new sensor for a new job, SOUSHINE helps with the change. They also give new parts and repair help if needed.

SOUSHINE’s service after the sale makes sure each sensor keeps working for its job. The team’s promise to help customers builds trust and helps every project do well.

SOUSHINE helps with hard jobs by making custom force sensing resistor solutions.

- The team works with doctors to make sensors for medical devices.

- Medical devices need sensors for giving medicine, watching patients, and helping with prosthetics.

- These sensors help medical machines give medicine safely.

- Medical teams trust SOUSHINE to make sure medicine is given right.

- Devices that give medicine or watch patients use these sensors for steady work.

- Tools that give medicine need sensors to keep patients safe.

- Medical devices for care and medicine use SOUSHINE sensors for good results.

- Devices that give medicine help doctors care for patients.

- Medical teams pick SOUSHINE for safe medicine delivery in devices.SOUSHINE gives strong help for medicine delivery and medical devices. Contact SOUSHINE for custom sensors in medicine delivery devices.

FAQ

What is a force sensing resistor (FSR)?

A force sensing resistor is a sensor that changes resistance when you press it. SOUSHINE FSRs help measure how much force is used in different devices.

How does SOUSHINE customize FSRs for different projects?

SOUSHINE works with clients to pick the right size, shape, and sensitivity. The team uses special materials and designs for each project. Clients can get samples before making a big order.

Which industries use SOUSHINE FSRs?

SOUSHINE FSRs are used in medical devices, machines, electronics, and cars. Engineers use them to find pressure, keep things safe, and make controls.

How long does it take to receive custom FSR samples?

SOUSHINE usually sends samples 1 to 7 days after the design is set. Big orders can take 1 to 3 weeks. Shipping time depends on how it is sent.

Can SOUSHINE FSRs work in harsh environments?

Yes. SOUSHINE makes FSRs that work in hot and cold places. The sensors last through many uses and tough conditions.

What support does SOUSHINE offer after purchase?

SOUSHINE gives technical help, shows how to install, and helps fix problems. The team answers questions fast and helps with calibration, care, and repairs.

Are SOUSHINE FSRs certified for medical and industrial use?

Yes. SOUSHINE has certifications like ISO13485 for medical devices, ISO9001 for quality, and IATF 16949 for cars. These show the sensors are safe and high quality.

How do clients start a custom FSR project with SOUSHINE?

Clients contact SOUSHINE and share their project details. The team checks what is needed, gives ideas, and makes a plan. SOUSHINE helps from design to delivery.