Call us: +86-137-2353-4866

You help create new things in 2025 when you pick custom force sensing resistor manufacturing services. SOUSHINE’s force sensing resistors change how you make new products. They help electronics become more interactive and quick to respond. You can find these custom force sensing resistor solutions in robotics, car safety, and healthcare. Custom force sensing resistor services give you help and teamwork. This lets you launch products faster.

- North America is the top region for custom force sensing resistors. It has a market size of USD 182 million and holds 27% of the share.

- Europe is next with USD 135 million, which is about 20% of the market.

- Latin America and the Middle East & Africa together have USD 74 million, making up 11%.

Custom force sensing resistor solutions let you meet special needs. They also give strong and steady performance in many industries.

Table of Contents

Key Takeaways

- Custom force sensing resistors help products react better. They make things work faster and smarter. This is very important for new ideas in robotics, cars, and healthcare.

- North America is the top place for custom force sensing resistors. Europe, Latin America, and the Middle East & Africa come next. This shows there are chances to grow in these areas.

- Working with engineers early makes designing products faster. It also saves money and time.

- Using better materials makes sensors more sensitive and strong. This helps them last longer in many uses.

- Rapid prototyping lets you test and change things quickly. This helps you get products out faster and beat others.

- SOUSHINE gives full help, from first talks to tech support. This makes it easy to add sensors to your products.

- You can pick the shape and size you need for your sensors. This helps your product work better and look nicer.

- Learning about new tech and market trends is important. It helps you find new chances and stay ahead of others.

Innovation with Custom Force Sensing Resistor

Enabling New Technologies

When you pick custom force sensing resistors, you can do more with technology. These sensors help you make robots smarter and keep places safer. They also make devices easier to use. You get better control and quick feedback. This is important for new products.

- Advanced force sensing helps robots work with more accuracy.

- Healthcare devices use custom sensors to help patients better.

- Automation systems need sensors that can detect force well.

- Sensors that react fast help make places safer.

- Touch and pressure sensing lets people and machines work together better.

Force sensing resistors help robots feel things like humans do. You can put them in robot hands, feet, or fake skin. They are flexible and you can change how sensitive they are. This helps you make the right solution for your needs. You can also use eco-friendly materials to follow new safety and green rules.

Tip: Using custom force sensing solutions helps your products stand out. You can also meet new industry rules.

Meeting Industry Needs

Every industry has its own problems. Custom force sensing resistors help you fix these with special solutions. In cars, you can put sensors in door handles to sense touch. This makes cars safer and easier to use. You can also use touch surfaces instead of buttons. This makes cars look better and feel nicer to use.

In healthcare, force sensors can go on radiotherapy machines. If the sensor feels contact, it stops the machine. This keeps patients and workers safe. Custom sensors let you design for special needs. This makes your products safer and more trusted.

| Industry | Application Description | Documented Outcome |

|---|---|---|

| Automotive | Custom force sensors in door handles to detect touch and extend the handle. | Better ways to open car doors and a nicer experience. |

| Automotive | Replacement of mechanical buttons with touch-sensitive surfaces on dashboard controls. | Cars look better inside and are easier to use. |

| Medical | Force sensors on radiotherapy machines to prevent contact during treatment. | More safety by stopping the machine if it touches someone. |

You can also use custom force sensing resistors in electronics for people. Flexible sensors work well in phones, tablets, and games. As devices bend and fold more, you can add sensors in new ways. This helps people have a better time using their devices.

Accelerating Development

You want your ideas to become real fast. Custom force sensing resistors help you make products quicker. You can work with engineers to design sensors that fit your needs. This saves time and money. It also makes your work smoother.

| Benefit | Description |

|---|---|

| Customization | Custom force sensors made for your needs can make products work better. |

| Collaboration with Engineers | Working with engineers early saves time and money. |

| Cost Reduction | Custom sensors can help you spend less on making products. |

| Shorter Design Cycle | Using FSR technology can make design changes faster. |

You get good force detection with piezoresistive technology. Thin and bendy sensors fit into many designs. When you know how to build and set up these sensors, you can use them in your projects easily.

- Custom force sensing resistors help you save money.

- You can finish your designs faster and launch sooner.

- Working with experts helps your solution work right away.

Note: Picking custom force sensing resistors gives you an advantage. You can make new products that people want in the future.

Consultation and Analysis

Understanding Requirements

Every good project starts by knowing what you need. SOUSHINE’s team talks with you to learn your goals. You share your ideas, and the experts ask questions. They want to know how your product should work. This first talk helps everyone get ready for the next steps.

The team looks at your project very closely. They use special tools like 3D scanning and software to check your design. These tools help them see every small detail. After they collect all the facts, SOUSHINE’s engineers go over the data with you. This makes sure everyone agrees before moving on.

You get a simple plan for your project. The plan shows the main steps and what you will get. It also tells you when to expect results. You get updates often, so you always know what is happening.

- Talk with experts about your needs and ideas.

- Use 3D scanning and software to study your project.

- Check and agree on all the facts together.

- Get a plan with steps, results, and dates.

- Get updates on how things are going.

Tip: Sharing your ideas early helps the team make a better product for you.

Collaborative Design

You are important in the design process. SOUSHINE thinks teamwork brings the best results. You work with engineers, designers, and people who supply materials. This teamwork helps you make smart choices for your force sensing resistor.

You join talks about printing, materials, and shapes. By working together before making a prototype, you help shape the design. This means your sensor will work better and last longer.

- Work with engineers, designers, and suppliers.

- Talk and pick the best printing and materials.

- Make choices together before building anything.

- Make your sensor better by sharing your thoughts early.

When you work as a team, you get a sensor that fits your needs. You save time, avoid mistakes, and get a product that stands out.

Note: Teamwork in design helps you get the best sensor and makes sure it works just how you want.

Design and Prototyping

Material Selection

When you pick the right materials, your product gets better. The materials you use decide how well your sensor works. They also decide how long it will last. You want sensors that react fast and keep working for a long time. SOUSHINE gives you new materials that make sensors more sensitive and tough.

Advanced Materials

You can choose special materials like conductive polymers or carbon compounds. These help your sensor feel force more accurately. They also help your sensor last longer, so you fix it less. Your sensor can work with other tech easily, so your system is safe and smooth.

| Aspect | Description |

|---|---|

| Sensitivity | Better sensitivity means your sensor can feel small changes in force. |

| Durability | Strong materials help your sensor last longer and need fewer repairs. |

| Integration Capabilities | Sensors work better with other tech, making your system safer and faster. |

- Special materials like conductive polymers and carbon compounds help sensors react faster and feel more.

- Tough materials make FSRs last longer, so you do not fix them often.

- Custom designs let you use sensors in many places for best results.

Tip: Using new materials helps your force sensing resistor work well and last longer.

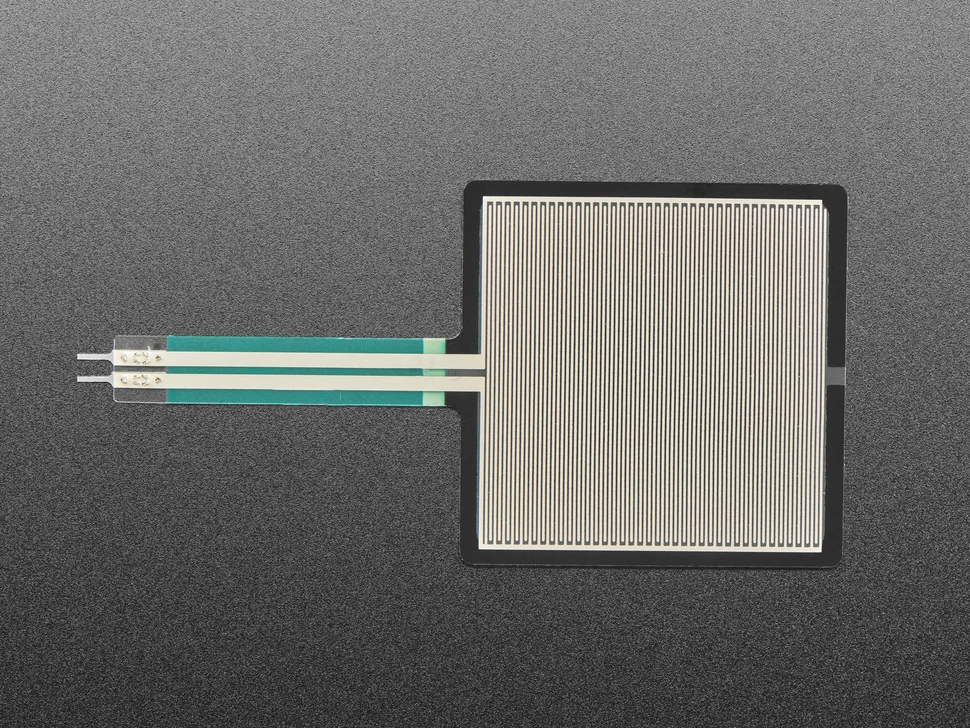

Custom Shapes and Sizes

You do not have to use only normal shapes. SOUSHINE lets you make sensors that fit your needs. You can make sensors for small spaces or curved places. This way, your sensor fits your product just right.

- You can get thin, bendy sensors for things you wear.

- You can make big, strong sensors for machines.

- You can pick shapes that match your brand.

Custom shapes and sizes help you fix problems that normal sensors cannot. You get a sensor that works for you and stands out.

Rapid Prototyping

You want your ideas to become real fast. Rapid prototyping helps you make products quickly. You can test your sensor early and fix problems before making many. This saves money and helps you get to the market sooner.

| Metric | Impact |

|---|---|

| Product Development Cost Savings | Save up to 30% |

| Time-to-Market Reduction | Get to market 50% faster |

- Find design problems early

- Make sure your idea works

- Help everyone on the team understand

You work with SOUSHINE’s team to build and test sensors fast. You get feedback quickly, so you can make changes. This helps you make good products that meet your needs.

Note: Rapid prototyping helps you launch products faster and beat your competition.

Manufacturing Services and Quality

Production Techniques

You want your products to work well every time. SOUSHINE’s manufacturing services help you feel sure about that. They make everything in their own factory, so they watch every step. This means you can trust how your sensors are made. You can pick custom force sensing resistor designs that fit what you need.

SOUSHINE uses new ways to make strong and good force sensors. Here is how they do it:

- They start with a base layer that is thin, between 75 and 175 microns.

- Next, they add a printed conducting layer. You can choose how much it conducts.

- Then, they use a glue or bonding layer. You can pick if you want it everywhere or just in some spots.

- Last, they put on a top layer, also 75 to 175 microns thick.

These steps make sensors that are thin, bendy, and tough. This helps you get the right accuracy for your job. You can make lots of sensors at once or just a few for testing. SOUSHINE’s team helps you pick the best setup for your project.

Quality Assurance

You want your force sensors to work right every time. SOUSHINE checks every step to keep your sensors working well. Their team looks at each part to make sure you get the best results.

Industry Standards

You need sensors that follow strict rules for different industries. SOUSHINE follows top rules for medical, car, and electronics uses. You get sensors that pass tests for safety, accuracy, and lasting a long time.

| Specification Type | Details |

|---|---|

| Operating Force Range | Standard options span 0.1-100kg |

| Compliance Standards | IEC 60747-14, ISO 13485, FDA 21 CFR Part 11, AEC-Q100, RoHS 3, REACH |

| Critical Parameters | Response time (<5ms), linearity error (±5-10%), temperature (-40°C to 85°C) |

| Quality Assurance | IP67 certification, 100% batch testing, MTBF data |

| Supplier Quality | Lower defect rates (<0.2%) with top partners |

You get sensors that work in hard places and meet world rules. SOUSHINE’s checks mean you can trust every group of sensors.

Reliability Testing

You want sensors that last a long time. SOUSHINE tests every group to make sure your sensors stay strong and work right. The team checks the materials, tests resistance, and checks the first sensor before making more.

| Quality Assurance Process | Description |

|---|---|

| Pre-Production Inspection | Checks raw materials for consistency and traceability. |

| Resistance Testing | Tests resistance and activation thresholds to match your needs. |

| First Article Verification | Confirms the first sample matches your approved design before full production. |

You get sensors made to be used again and again. They work in tough places and use very little power. This makes them great for devices that save energy in many fields.

| Attribute | Description |

|---|---|

| Durability and Reliability | FSRs are made for repeated use, giving you long-lasting performance. |

| Low Power Consumption | Sensors use minimal power, ideal for battery-operated and efficient devices. |

You can pick single-zone, discrete array, or matrix array types. This lets you use force sensors in many things, like healthcare or factories. SOUSHINE’s services help your business grow and meet new needs.

Tip: When you pick SOUSHINE, you get custom force sensors that last, use little power, and have great quality checks. You can trust your products to work every time.

Delivery and Support

Seamless Integration

You want your new product to work right away. SOUSHINE helps you make that happen. Their team makes sure your custom force sensing resistor fits into your design with no trouble. You get sensors that match your product’s size, shape, and function. This means you do not need to change your plans or redesign your device.

You can count on SOUSHINE to deliver force sensors that connect easily with your electronics. They test every sensor before shipping. You receive parts that work as soon as you install them. You save time and avoid problems during assembly.

- You get sensors with the right connectors for your system.

- You receive clear instructions for setup.

- You can ask for help if you need to adjust the sensor for your force measurement.

Tip: When you choose SOUSHINE, you make your product launch smoother. You avoid delays and keep your project on track.

Technical Support

You never have to solve problems alone. SOUSHINE gives you strong technical support from start to finish. Their experts answer your questions about force sensing, installation, and testing. You get help with both hardware and software.

If you need to fine-tune your custom force sensor, SOUSHINE’s team guides you step by step. They help you set up your force measurement system for the best results. You can reach out by phone, email, or online chat.

| Support Feature | What You Get |

|---|---|

| Fast Response | Answers to your questions within 24 hours |

| Troubleshooting | Help with sensor setup and calibration |

| Application Guidance | Advice for using force sensors in your field |

| Documentation | Easy-to-read guides and manuals |

You get more than just a product. You gain a partner who cares about your success. SOUSHINE’s service helps you solve problems quickly and keep your project moving forward.

Note: Great support means you can focus on your ideas. Let SOUSHINE handle the details of force sensing.

SOUSHINE Advantage

Product Features

You want sensors that work well every time. SOUSHINE gives you special features that make your products better. The sensors react fast and are very sensitive. They work well even in hard places and can be used many times. You can pick shapes and sizes that fit your design. The sensors are thin and bend easily, so you can put them in small or curved spots. They use little power, so your devices last longer. The sensors notice force changes in less than five milliseconds. You can count on them to be accurate and strong for tough jobs.

- Fast reaction

- Sensitive to force

- Thin and bendy

- Custom shapes and sizes

- Use little power

- Work well in tough places

You feel sure when you use SOUSHINE sensors. Your products get noticed in the market.

Industry Applications

SOUSHINE’s sensors work in many areas. They help you fix problems in automation, healthcare, and robotics. You get better control and safety in your systems. The sensors fit into medical tools, cars, and smart electronics. You can make quality checks and keep things safe. The sensors measure force in hydraulic and pneumatic systems. You can use them for pressure mapping and flow checks.

Here is how different industries use SOUSHINE’s custom sensors:

| Industry Sector | Primary Applications |

|---|---|

| Industrial Applications | Process control, automation, quality checks, safety |

| Healthcare | Medical tools, prosthetics, wearable devices |

| Automotive | Pressure mapping, hydraulic and pneumatic system checks |

| Robotics | Touch and pressure sensing, automation |

| Consumer Electronics | Smart shelves, checkout systems |

| Aerospace & Defense | Level sensing, flow checks |

You see force sensing resistor uses everywhere. They are in smart shelves, checkout systems, and wearable devices. The sensors help you make safer and smarter products.

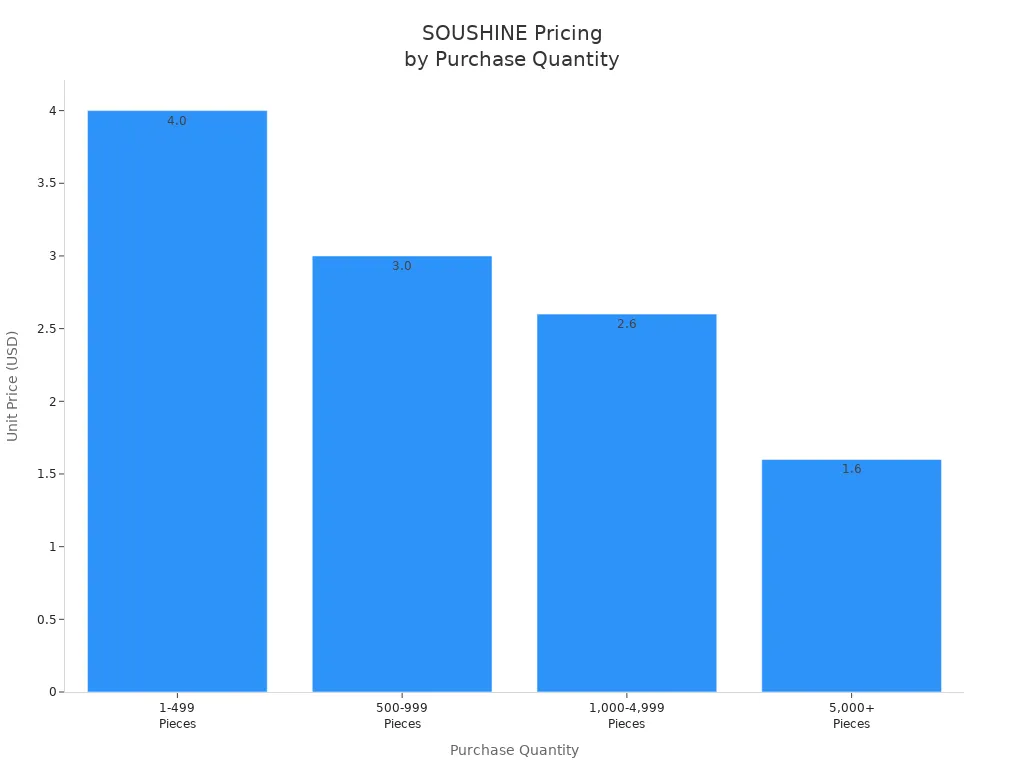

Competitive Pricing

You want good prices for your money. SOUSHINE gives you deals that help you save as you buy more. You pay less for each sensor when you order a lot. The prices work for small orders and big ones.

| Purchase Quantity | Reference FOB Price |

|---|---|

| 1-499 Pieces | US$4.00 |

| 500-999 Pieces | US$3.00 |

| 1,000-4,999 Pieces | US$2.60 |

| 5,000+ Pieces | US$1.60 |

You get more for your money when you order more. You can start new products without high costs. SOUSHINE helps you beat others with good prices for custom sensors.

Pick SOUSHINE for your next project. You get cool features, support for many industries, and prices that fit your budget.

Trends and Future Outlook

Emerging Technologies

In 2025, new technology changes how you use force sensing resistors. Smart systems need sensors that work fast and fit in small places. You want sensors that connect with smart homes and medical devices. These sensors also work in wearable tech. Miniaturization lets you put sensors in tiny gadgets. Flexible designs help you add sensors to curved or moving things.

Material science makes force sensors stronger and more sensitive. This helps robots, healthcare, and automation work better. Robots use force sensors to feel and react more accurately. Medical devices use them to watch patient movements and keep people safe. These sensors last longer and work well in tough places.

Here are some important trends to know:

- Smart device integration helps your products work better at home and in hospitals.

- Small and flexible force sensors fit into wearables and medical tools.

- New materials make sensors more sensitive and tough.

- Robots and automation use force sensors for better control and safety.

You can be a leader by using new force sensing technology. Your products get smarter and more dependable.

Market Landscape

In 2025, many companies compete to make the best force sensing resistors. They work together and spend money on research to stay ahead. More companies are growing in Asia Pacific and North America to meet demand.

Customization is very important for force sensing resistor manufacturing. You want sensors that match your needs exactly. Companies give you custom options with different sizes and sensitivity. You can also pick how fast the sensor reacts. Design software and prototyping tools help you make special sensors quickly.

- Customization helps you fix special problems in your field.

- You can choose force sensors that fit your product’s shape and job.

- Fast prototyping lets you test and improve your ideas before selling.

| Market Trend | What It Means for You |

|---|---|

| Strategic Partnerships | More choices and better technology for your projects |

| Geographic Expansion | Faster delivery and support in your region |

| Focus on R&D | New force sensing features and improved performance |

| Custom Solutions | Tailored sensors for your unique applications |

You can stay ahead by picking custom force sensing resistor solutions. You get sensors that fit your needs and help your products stand out. The market likes new ideas and flexibility. You can shape the future with your ideas and the right force sensing technology.

Pick custom force sensing resistors to find new opportunities and lead your field.

When you pick SOUSHINE’s custom force sensing resistor services, you open new doors. Special force solutions help you check quality and stop mistakes. New ways of making sensors use less material and cost less money. This makes your sensors cheaper and better for the planet. Using force sensing in machines helps your business stay strong and win against others. Experts help you all the way and answer your questions. Many people say force sensing made their products better and helped them do well. You can be a leader in your field with SOUSHINE’s force technology. Start your project with trust and see how force sensing helps.

- Special force solutions make things work better and last longer.

- New methods use less and help you save money.

- Using force sensing in machines keeps your business in front.

Pick SOUSHINE and let force sensing help you create new things.

FAQ

What is a custom force sensing resistor?

A custom force sensing resistor is a sensor made just for you. You pick how it looks and how sensitive it is. This makes your product work better and get noticed.

How do I start a custom FSR project with SOUSHINE?

You reach out to SOUSHINE with your idea. Their experts listen and help you at every step. You get a simple plan and help from beginning to end.

Can I get FSRs in special shapes or sizes?

Yes, you can order FSRs in many shapes and sizes. SOUSHINE helps you design sensors for small spaces or curved surfaces. You can make sensors for special products.

How fast can I receive prototypes?

You get prototypes very quickly. SOUSHINE uses fast methods to send samples in days. This lets you test and fix your design sooner.

Are SOUSHINE’s FSRs reliable for tough environments?

Yes, SOUSHINE’s FSRs use strong materials and pass hard tests. You can trust them in hot, cold, or rough places. They work well even with heavy use.

What industries use custom FSRs?

Custom FSRs are used in cars, healthcare, robots, electronics, and factories. These sensors help solve problems and make products smarter in many areas.

Does SOUSHINE offer technical support after delivery?

Yes, you get help even after you get your sensors. SOUSHINE’s team answers questions and helps you set up. You always have experts to help you.

How do custom FSRs help my product stand out?

Custom FSRs give your product special features. You make things easier to use and add smart functions. This helps your product win in a busy market.