Call us: +86-137-2353-4866

SOUSHINE makes custom force sensing resistor solutions with clear steps. Their team talks to each client and makes sensors for their needs. Advanced electronic force sensor technology is in every force sensing resistor. This helps the sensors give exact measurements. The piezoresistive principle lets these sensors react to different force levels with accuracy. SOUSHINE gives flexible choices for every project. Each force sensing resistor fits special uses.

Table of Contents

Key Takeaways

- SOUSHINE begins each project by talking with clients. They want to learn what the client needs and what the industry rules are.

- They use special tools like 3D scanning and design software. These tools help them make sensors that fit well and work right.

- They pick materials and design the sensor to match what is needed. This includes how sensitive it is, its size, and how much force it can measure.

- They make and test a sample sensor before making many of them. This helps make sure the sensors are good and work well.

- Making the sensors uses careful screen printing and putting parts together. This helps make sensors that bend and last a long time.

- Clients can choose different shapes, connectors, logos, and ways to install the sensors.

- SOUSHINE checks each sensor very carefully. They test to make sure the sensors are correct, work the same way every time, and are safe.

- The company makes sensors quickly. They give expert help and good service after you buy, with a one-year warranty.

Consultation

SOUSHINE starts each project by talking with the client. The team asks questions to learn what the client wants. They find out what the project needs. This helps SOUSHINE make sure their work fits the job.

Application Needs

Industry Use Cases

SOUSHINE works with many different industries. Each industry has its own problems and needs. The table below shows how each industry uses custom force sensors and what they need:

| Industry | Unique Application Needs |

|---|---|

| Aerospace | Custom force sensing solutions tailored to aerospace requirements |

| Defense | Specialized FSR applications for defense industry |

| Industrial Power | Customization for industrial power applications |

| Manufacturing | Force sensing adapted to manufacturing processes |

| Medical Device | Pressure sensing mats to reduce bedsores; real-time pressure data collection and analysis |

| Oil & Gas | Custom FSR solutions for oil & gas industry needs |

| Transportation | Force sensing resistor applications in transportation |

SOUSHINE’s sensors help medical device engineers make pressure mapping systems. These systems help take care of patients. In factories, sensors watch machine force to keep things safe and working well. In transportation, sensors check how weight is spread in vehicles. Every project starts with a talk about where the sensor will go, how much force it will measure, and how it will fit in.

Requirement Analysis

SOUSHINE uses different ways to study what the project needs. The team collects exact data to help design the sensor. Here are some main ways they do this:

- 3D scanning finds the shape and size of the user or device, like a foot for a medical insole.

- Measurement software, such as Autodesk Inventor, saves the curves and load areas.

- 3D scanned shapes go into design software to make templates that fit the user.

- High load areas are marked with DXF curves to help make the sensor stronger.

- Slicing software, like Slic3r or Simplify3D, gets models ready for 3D printing with special fill patterns.

These steps help SOUSHINE decide where to put sensors and how they should work. The team checks all the data with the client to make sure it is right before moving on.

Project Planning

Once SOUSHINE knows what the project needs, they make a plan. The plan shows the timeline, important steps, and what will be delivered. The team tells the client what to expect for design, testing, and making the product. Clients get updates and can check the work at each step. This way, every project stays on schedule and meets the client’s needs.

Force Sensing Resistor Design

SOUSHINE works together with clients to design sensors. The team helps pick materials and set details for each job. This way, every force sensing resistor fits what the force measurement system needs.

Material Selection

Picking the right material changes how well the force sensitive resistor works. SOUSHINE engineers look at many things when they choose:

- The substrate type changes how bendy and strong the sensor is.

- The conductive layer changes how well it senses and sends signals.

- How the layers are put together changes the sensor’s range and how straight it works.

- How well it handles heat and how easy it is to set up also matter.

Substrate Options

SOUSHINE often uses bendy polyester films for substrates. These films help the sensor bend and stay strong. The thickness of the film changes how thin and bendy the sensor is. Glue and backing help the sensor stick and spread out pressure. The right substrate helps the sensor work in moving or still places.

Conductive Materials

The conductive layer is the main part of the force sensing resistor. SOUSHINE picks from silver-based inks, carbon-based inks, or mixes of both. Silver ink makes the sensor very sensitive and quick. Carbon ink lasts longer and costs less. The ink choice changes how sensitive, strong, and costly the sensor is. Sometimes, SOUSHINE uses a semiconductive top and conductive lines on the bottom. This setup helps the sensor find force exactly and keeps the signal steady.

Sensor Specifications

SOUSHINE sets each sensor’s details based on what the client wants. The team looks at sensitivity, force range, shape, and size to make sure the sensor fits.

Sensitivity and Range

Sensitivity shows how well the sensor finds small force changes. SOUSHINE changes the materials and layers to set the right sensitivity. Most force sensitive resistors can sense from a few grams to many kilograms. The force range is usually from 0.2 newtons to 20 newtons. When you push harder, the sensor’s resistance goes down. This lets the sensor give correct force numbers. The piezoresistive principle makes this happen. When pressure pushes the layers together, resistance drops in a known way. Calibration matches these changes to force, so the sensor is exact.

Tip: Calibration is very important for correct force numbers. SOUSHINE uses weights and checks the sensor’s output to make a good calibration curve.

Shape and Size

SOUSHINE has many shapes and sizes for force sensing resistor designs. Some are round with sizes like 0.2, 0.25, and 0.6 inches. There are also strips and big matrix arrays. Custom shapes are made for special jobs. The table below shows common details:

| Specification | Details |

|---|---|

| Force Sensing Range | 0.2 N to 20 N |

| Sensitivity | Few grams to several kilograms |

| Active Sensing Area Size | 0.2″, 0.25″, 0.6″ diameter, strips |

| Thickness | Around 0.01 inch |

| Repeatability | ±2% |

| Hysteresis | +5% |

| Form Factor | Flexible, ultrathin |

Prototyping

SOUSHINE follows simple steps to make custom force sensing resistor prototypes:

- First, engineers and clients talk about needs, draw plans, and pick materials.

- Next, they build early models and test them to see how they work.

- After that, they start building with clear steps and check quality.

- Last, they handle making, storing, and sending the sensors on time.

This step-by-step plan helps SOUSHINE make better prototypes and check that everything is right before making lots of sensors.

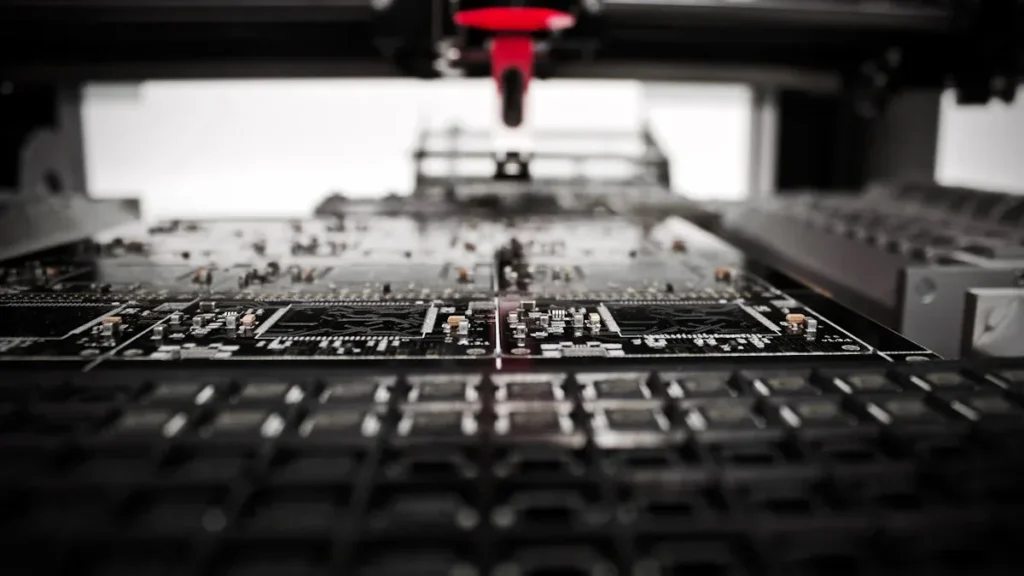

Manufacturing

SOUSHINE has a careful way to make custom force sensing resistors. The team follows steps to make sure each sensor is right for the client. The process has making, changing, and checking for quality.

Production Steps

Screen Printing

Engineers get the substrate ready first. They use screen printing to put conductive inks on flexible films. The team picks the best ink, like silver or carbon, for the sensor’s design. Screen printing makes the circuit pattern on the sensor. This way, each layer is flat and correct. The printed films dry in special rooms to keep the circuit steady.

Assembly

After printing, the team puts the sensor together. They stack the printed substrate, a spacer, and another conductive layer. The spacer keeps layers apart until force is used. The team lines up each layer with care. They use heat or pressure to stick the layers together. The finished sensor is thin and bends easily. This way, sensors can be many shapes and sizes.

Customization

SOUSHINE gives many ways to change each sensor. The team works with clients to make the sensor fit the job.

Branding

Clients can add their own labels or logos to the sensors. SOUSHINE prints names or logos on the sensor or box. This helps clients show their brand and be different from others.

Connector Options

SOUSHINE has many connector types. Clients can pick FPC 1.0mm, male pins, female connectors, or bare terminals. The team also has solder tabs and connectors like Nicomatic 14106-12. These choices help connect the sensor to many devices. The table below shows some ways to change the sensor:

| Customization Aspect | Details / Options |

|---|---|

| Shape and Size | Custom working area, lead length, thickness |

| Trigger Force | Set minimum trigger force |

| Force Measurement Range | Adjustable range |

| Resistance Change Range | Custom resistance interval |

| Product Softness | Adjustable softness |

| Working Environment | Adaptable to temperature and humidity |

| Installation Method | Stickers, screw holes |

| Connector Types | FPC1.0mm, male pins, female connectors, bare terminals, solder tabs |

| Branding | Private label, custom logos |

Note: SOUSHINE’s design team helps clients pick the best connector and logo for their project.

Quality Control

SOUSHINE checks quality at every step. The team looks at each sensor while making it. They use force sensing resistors to watch machine setup and check pressure on products. This helps find mistakes early and keeps things going right.

- Engineers check machines before making sensors.

- They check pressure on products at each step.

- The team uses sensors to cut waste and save money.

- Automation helps stop supply chain problems.

- Pressure sensors help lower mistakes and bad products.

- Skilled engineers work in modern labs to keep quality high.

SOUSHINE follows rules from the country and the world. The team keeps notes for each batch. This makes sure each sensor works well and lasts a long time.

Testing

SOUSHINE has a careful testing process for each force sensing resistor. The team checks every sensor to make sure it works right. They look for accuracy and reliability before sending sensors to clients. This helps keep high standards for all force measurement systems.

Functional Checks

Sensitivity Testing

Engineers test if each sensor can find small force changes. They use special weights and put them on the sensor’s active area. The team writes down what the sensor shows at different force levels. This step checks if the sensor reacts to both light and heavy pressure. If a sensor does not match the needed response, the team fixes or swaps it. Sensitivity testing makes sure the sensor will work well in real life.

Repeatability

Repeatability checks if a sensor gives the same result many times. The team puts the same force on the sensor again and again. They write down the output each time. If the numbers stay close together, the sensor passes. This is important for jobs where people need steady data over time. SOUSHINE’s steps make sure each sensor can be used many times without losing accuracy.

Compliance

Standards

SOUSHINE follows strict rules for all custom force sensing resistors. The team makes sure each sensor has UL and CSA certifications for safety and performance. For medical devices, SOUSHINE meets ISO13485 certification to show strong quality. The company also follows ISO9001 for good business and improvement. Environmental safety is important too. SOUSHINE follows REACH and RoHS rules to limit bad substances. The team uses UL 94-rated plastics for fire safety. They also avoid conflict minerals by following the Dodd-Frank Act.

- UL and CSA certifications for safety and performance

- ISO13485 for medical device quality

- ISO9001 for business practices

- REACH and RoHS for environmental safety

- UL 94 for fire safety

- Conflict minerals compliance

Documentation

SOUSHINE gives full paperwork for every batch of sensors. Clients get test reports that show how the sensor did during checks. Calibration records help track each sensor’s accuracy and repeatability. Inspection checklists show the sensor matches design needs. The company also gives quality control certificates and compliance papers. This paperwork helps clients trust the product’s quality and safety.

Note: Full paperwork helps clients follow their own industry rules and makes it easier to use the sensors in their systems.

Delivery and Support

Logistics

SOUSHINE plans how to ship products very carefully. The team makes a plan for each client’s needs. They want to move products fast and keep them safe.

Packaging

SOUSHINE puts products in paper boxes. Each box fits the order’s size and weight. The team follows a list of materials for each step. Engineers check every part of the process. Every order has a one-year warranty. SOUSHINE tracks each order to make sure it ships well.

| Aspect | Details |

|---|---|

| Quality Control | Careful steps with a material list; skilled engineers; one-year warranty. |

| Packaging | Paper boxes sized for each order. |

Shipping

SOUSHINE gives clients many ways to ship. Clients can pick UPS, FedEx, DHL, TNT, or others. Delivery takes 3 to 20 days after payment. The company takes trade assurance, TT, West Union, and PayPal. Clients pay before the order ships. SOUSHINE uses smart planning to move products better and save money. The warehouse is set up to help orders go out right.

- Special shipping plans for each client

- Smart planning for faster product flow

- Warehouse setup for better work and fewer mistakes

- Extra services like lot code tracking and checking

Integration Help

SOUSHINE helps clients after they get their order. The team answers questions about using the sensors.

Technical Support

SOUSHINE gives lots of help to clients. Experts know about materials, hardware, software, and making things. The team helps from design to delivery. Clients can ask for training on the product. Remote help is given with tools like TeamViewer. There are also FAQs and ways to get customer support.

| Support Type | Description |

|---|---|

| Customization Assistance | Expert help to change FSR sensors for many uses |

| In-house Expertise | Help from experts in materials, hardware, software, and making sensors |

| Advisory Support | Help from start to finish |

| Specialized Solutions | Hybrid sensors, sensor fusion, IoT sensors, tough sensors |

Troubleshooting

SOUSHINE gives guides and resources for using sensors. The team works with partners for custom software. If there is a problem, support helps fix it fast. Clients can ask for help any time.

- Special team for sensor setup

- Guides and resources for using sensors

- Partners help with custom software

- Quick help for problems

After-Sales Service

SOUSHINE checks each order after it ships. The team makes sure products arrive on time and are not damaged. If something is wrong, SOUSHINE fixes it fast. Clients get all paperwork, like test and calibration reports. Every product has a one-year warranty. This support helps clients trust SOUSHINE’s force sensing resistors.

Note: SOUSHINE’s after-sales service gives every client good help and clear answers during the whole time they use the product.

Why SOUSHINE

Process Benefits

Efficiency

SOUSHINE has a simple way to help clients get custom force sensing resistors fast. The team works with clients from the start to the end. Engineers help turn ideas and samples into product drawings. The company makes custom samples in about seven days. After clients say yes to samples, SOUSHINE finishes making lots of sensors in two to three weeks. This quick process helps clients finish projects on time. Checking samples first also makes delivery faster and stops extra changes.

Flexibility

SOUSHINE lets clients change their sensors in many ways. Clients can pick the size, shape, output signal, and calibration for each sensor. The team helps make sure each sensor is right for the job. Sensors work with many systems and are easy to install. This flexibility helps clients use the sensors in many projects.

SOUSHINE’s way gives both speed and choices. Clients get sensors that fit their needs without waiting long.

Here is a table that shows how SOUSHINE’s way helps with speed and choices:

| Aspect | Description |

|---|---|

| Customization Flexibility | Sensor size, shape, output signal, and calibration can be changed for each job. |

| Design Support | Engineers help turn ideas and samples into product drawings. |

| Production Timeline | Custom samples made in about 7 days; mass production done in 2-3 weeks after samples are approved. |

| Sample Confirmation | Checking samples first makes delivery faster and cuts down on changes. |

| Installation & Compatibility | Easy to install and works with many systems for better speed. |

Success Stories

Applications

SOUSHINE’s force sensing resistors are used in many areas. In healthcare, engineers use them in pressure mapping systems to help doctors and nurses care for patients. In robotics, the sensors help machines feel touch and change their grip. In consumer electronics, designers use them to make smart controls and touchpads. Industrial teams use the sensors to watch machine force and keep equipment safe.

Testimonials

Clients trust SOUSHINE for sensors that work well and good support. One medical device company said SOUSHINE’s team helped them design a sensor for a new patient care product. The company finished the project on time and got better results. An industrial client said the sensors worked well in tough factory places and lasted longer than they thought. Many clients say SOUSHINE’s fast help and expert advice make projects easier.

“SOUSHINE’s engineers helped us turn our idea into a working product. The sensors arrived fast and worked as promised.”

— Product Manager, Medical Device Company

SOUSHINE helps clients at each step, from start to finish. The team uses new technology and checks quality often. Clients get help they can trust and easy updates. Many industries pick SOUSHINE for custom force sensing resistor solutions.

- Pick SOUSHINE for your next project.

- Talk to the team to begin your custom sensor design.

FAQ

What is a force sensing resistor (FSR)?

A force sensing resistor checks how much force is on it. When you press it, the sensor’s resistance changes. SOUSHINE uses this in many different fields.

How does SOUSHINE customize FSRs for different projects?

SOUSHINE talks with each client to pick materials, shapes, and sizes. The team changes how sensitive the sensor is and its range. Clients can ask for special connectors or their own logo. This way, the sensor matches the project.

How long does it take to receive a custom FSR order?

SOUSHINE makes samples in about seven days. After clients say yes, making lots of sensors takes two to three weeks. Shipping time depends on where the client is and how they want it sent.

Can SOUSHINE’s FSRs work in harsh environments?

SOUSHINE builds FSRs to work in tough places. The team picks materials that can handle heat, water, and chemicals. Clients can ask for sensors made for special places.

What industries use SOUSHINE’s FSRs?

Many fields use SOUSHINE’s FSRs. Some examples are medical devices, robots, factories, electronics, and transportation. Each field uses them for good force measurement.

How does SOUSHINE ensure quality and reliability?

SOUSHINE checks every sensor while making it. The team tests for sensitivity, repeatability, and if it meets rules. Clients get all the paperwork and calibration records.

What support does SOUSHINE offer after delivery?

SOUSHINE gives technical help, guides, and training. Clients can ask for help with setup or using the sensor. Every product has a one-year warranty.

Need more help? Contact SOUSHINE’s support team for quick answers.