Call us: +86-137-2353-4866

SOUSHINE specializes in the design and manufacturing of custom membrane switches that provide reliable performance across a wide spectrum of industries. While commonly integrated into consumer electronics, medical devices, and industrial controls, the versatility of membrane switch technology extends to numerous other specialized applications. This page details the utility of our membrane switches in sectors where precision, durability, and resilience to environmental factors are critical operational requirements. Our engineering focus is on delivering a human-machine interface (HMI) solution that meets the specific functional demands of your unique application.

What is a Custom Membrane Switch in These Applications?

In the context of specialized applications such as public-use equipment or outdoor terminals, a membrane switch is not just a user interface; it is a critical component engineered for high performance under varied and often challenging conditions. It is a sealed, multi-layered electrical switch that opens and closes a circuit upon pressure. Unlike mechanical switches, its low-profile design and sealed construction protect internal circuitry from contaminants like dust, moisture, and chemicals, ensuring operational integrity in environments ranging from public kiosks to marine control panels. For each unique application, the materials, graphic design, and tactile feedback are specified to meet the exact operational and environmental demands.

How Membrane Switches are Integrated into Specialized Equipment

The integration of a membrane switch into diverse equipment is a function of its adaptable design. At SOUSHINE, the process involves:

- Custom Design: Each switch is designed to fit the specific form factor of the equipment, whether it’s the curved surface of a gasoline pump or the compact control panel of a security keypad. The graphic overlay is custom printed with specific iconography, branding, and functional instructions.

- Sealed Assembly: The switch layers are bonded with specialized adhesives, creating a fully sealed unit. This assembly can be mounted onto a rigid backer panel or directly adhered to the equipment housing, providing an IP-rated (Ingress Protection) barrier against environmental elements.

- Circuit Integration: The flexible tail of the membrane switch, which contains the conductive circuit traces, is connected to the main PCB or control unit of the device. We offer various connector options (e.g., ZIF, female connectors) to ensure seamless electronic integration with your host system.

This streamlined integration process reduces assembly time and component count compared to traditional mechanical switch interfaces.

Why SOUSHINE Membrane Switches are the Optimal Choice

Choosing a SOUSHINE membrane switch for your specialized application provides distinct, quantifiable advantages. The decision is based on engineering requirements for reliability and longevity in the field.

- Environmental Resistance: For equipment exposed to weather, liquids, or dust, such as outdoor kiosks or marine controls, the sealed nature of our membrane switches (rated up to IP67) is a primary technical advantage. This prevents internal component failure due to contamination.

- Durability and Longevity: Membrane switches are designed for high actuation life, often rated for millions of cycles. This ensures consistent performance in high-traffic, repetitive-use scenarios like vending machines or access control systems, minimizing downtime and maintenance costs.

- Low Profile & Space Efficiency: The thin, flexible construction is ideal for integration into compact devices or equipment where space is at a premium. This allows for more streamlined and modern product designs without compromising functionality.

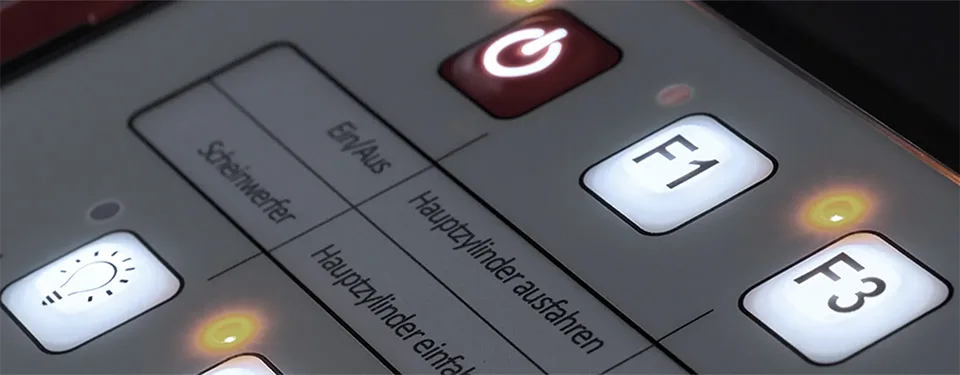

- User Interface Customization: The ability to customize the graphic overlay allows for clear, intuitive user interaction. This is critical for public-use equipment where operational clarity and user experience are paramount. Backlighting and tactile feedback options like embossing can be incorporated to enhance usability in various conditions.

Refined Application Directions

SOUSHINE provides membrane switch solutions for a multitude of specialized sectors. Below are examples of specific use-cases.

FAQ

Can membrane switches be used in outdoor environments?

Yes. We utilize UV-resistant graphic overlay materials and adhesives to create fully sealed, IP-rated membrane switches that are designed to withstand prolonged exposure to sunlight, rain, dust, and temperature fluctuations.

How do you ensure the reliability of switches in high-use applications like a vending machine?

Our membrane switches are constructed with high-quality polyester and conductive inks, engineered for a lifespan of over one million actuations. We can incorporate metal or polyester tactile domes to provide consistent user feedback and extend the operational life of the switch.

Can the interface be illuminated for use in dark environments?

Yes. We offer several backlighting options, including embedded LEDs for specific key or icon illumination, and Light Guide Film (LGF) for uniform backlighting across the entire interface. These options are integrated while maintaining the switch’s low profile.

Are your membrane switches resistant to chemicals?

Absolutely. We can select overlay materials and hard-coat finishes that are specifically resistant to a wide range of chemicals, cleaning agents, and industrial solvents, which is a common requirement for applications like gasoline pumps or industrial test equipment.

How can a membrane switch be customized for a new, unique application?

Our engineering team works directly with your design team. The process starts with understanding your operational environment, user interface requirements, and electronic integration needs. We then customize every aspect, including the physical shape, graphic overlay, circuit layout, tactile feedback, backlighting, and connector type, to create a purpose-built HMI solution.