Call us: +86-137-2353-4866

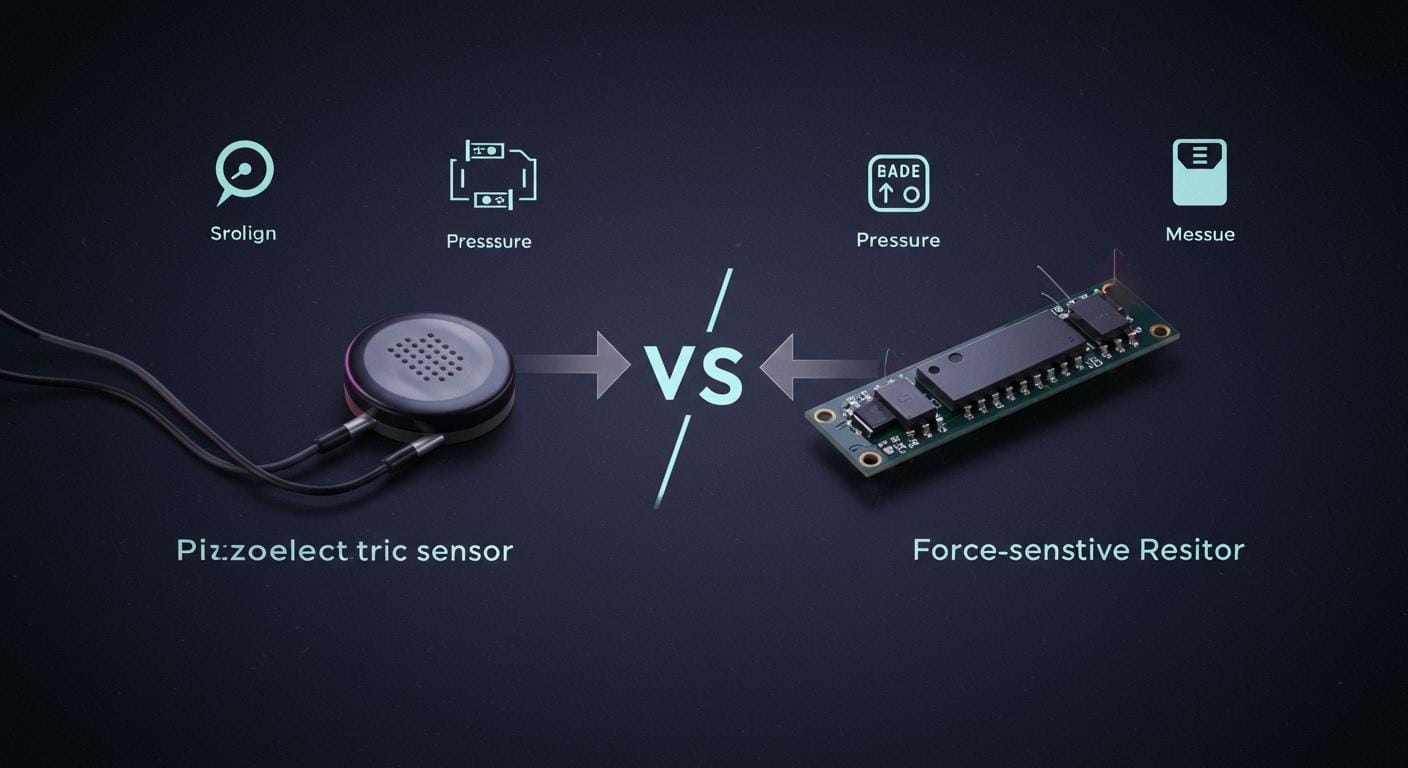

The main difference between a piezoelectric sensor and an fsr is what each one measures. In real life, a designer may need a sensor to find vibrations in a machine or see how hard someone pushes a button. Knowing how each sensor works helps people pick the right one for their project. Both hobbyists and professionals use force-sensing technology to make their designs better.

- The global force sensing resistors market was about USD 820 million in 2023.

- Experts think it could grow to USD 1950 million by 2033.

Table of Contents

Key Takeaways

Piezoelectric sensors make electricity when you press them. They are good for checking vibrations and fast changes. Force-sensing resistors, or FSRs, change their resistance when pressed. This helps them measure steady force well. Use piezoelectric sensors if you need to sense quick movements. These are used in cars and medical tools. Pick FSRs for projects that need cheap and flexible parts. FSRs can fit in small spaces like touchpads and wearables. Each sensor has special features. Piezoelectric sensors are strong and tough. FSRs are thin and can be used in many ways. It is important to know where and how you will use the sensor. Testing sensors first can help you find problems early. This makes your project more reliable. Think about cost, sensitivity, and how to attach the sensor. This will help you pick the best sensor for your project.

Piezoelectric Sensor

Operation

Piezoelectric sensors use the piezoelectric effect. When you press on some materials, like quartz or ceramic, they make electrical charges. The Curie brothers found this effect in 1880. They learned that pushing on certain crystals creates opposite electrical charges. The amount of charge matches how hard you press. This is called the positive piezoelectric effect. There is also an inverse piezoelectric effect. Here, the material changes shape when electricity is applied. This lets piezoelectric sensors turn movement into electricity and back again. Engineers use this idea to make sensors that find changes in pressure, vibration, or force.

Measurement

Piezoelectric sensors can measure many things. These include:

- Pressure

- Acceleration

- Temperature

- Strain

- Force

The range depends on the sensor type and how it is used. Some sensors find tiny changes. Others can handle bigger forces. Piezoelectric sensors react quickly to changes. This makes them good for measuring things like vibrations or impacts. They are not good at measuring steady forces because the charge goes away over time. So, piezoelectric sensors work best when the force changes fast.

Features

Piezoelectric sensors have many important features. The table below shows the main features and what they mean.

| Key Features | Description |

|---|---|

| High Sensitivity | Finds small changes in pressure, force, or acceleration. |

| Fast Response Time | Measures things as they happen. |

| Wide Measurement Range | Can be used in many ways. |

| Compact Size | Fits in small places. |

| Ruggedness and Durability | Works in tough places. |

| Wide Frequency Range | Measures quick changes and short events. |

| Energy Harvesting | Turns vibrations into electricity. |

| Non-Intrusive Measurement | Can work without touching sensitive things. |

| Calibration Requirement | Needs careful setup to be correct. |

| Temperature Sensitivity | Accuracy can change if it gets hot or cold. |

| Non-Linearity | Output may not always match the input. |

| Hysteresis | Output can change when loading or unloading. |

| Limited Measurement Range | Some sensors only work in a certain range. |

| Complex Signal Conditioning | Needs special tools to read the signal. |

| Sensitivity to Mechanical Stress | Accuracy can change if stressed. |

| Noise Susceptibility | Needs protection from electrical noise. |

Piezoelectric sensors are very sensitive and react fast. They work well in rough places and can measure quick changes. Engineers need to set them up carefully and keep out noise. These sensors are used in cars, planes, and electronics.

Types

Piezoelectric sensors have different types. Each type uses special materials or shapes. These help the sensor find force or vibration. Engineers pick the type for the job and place.

1. Quartz Crystal Sensors

Quartz crystal sensors use quartz. Quartz has strong piezoelectric properties. These sensors work in hot places. Many factories use quartz sensors for pressure and vibration. Quartz sensors last long and give steady results.

2. Ceramic Sensors

Ceramic sensors use man-made materials like PZT. These materials show strong piezoelectric effects. Ceramic sensors cost less than quartz ones. They come in many shapes and sizes. Many gadgets use ceramic sensors. They work in microphones, buzzers, and medical tools.

3. Polymeric Film Sensors

Polymeric film sensors use plastics like PVDF. These sensors are thin and bend easily. Engineers use them in wearable devices and touch screens. Polymeric film sensors can cover big areas. They find small changes in pressure or vibration.

4. Shear Mode Sensors

Shear mode sensors measure force along the sensor surface. This design helps stop mistakes from heat changes. Shear mode sensors work well in busy places. Many labs use them for careful tests.

5. Compression Mode Sensors

Compression mode sensors measure force straight down on the sensor. These sensors can handle heavy loads. Many machines use compression mode sensors to watch big equipment.

Note:

The sensor type depends on force direction, place, and needed sensitivity.

Table: Common Types of Piezoelectric Sensors

| Type | Material Used | Typical Use Cases |

|---|---|---|

| Quartz Crystal | Quartz | Industrial, automotive |

| Ceramic | PZT, other ceramics | Consumer electronics, medical |

| Polymeric Film | PVDF | Wearables, touch sensors |

| Shear Mode | Quartz, ceramics | Laboratory, vibration analysis |

| Compression Mode | Quartz, ceramics | Heavy machinery, load sensing |

Each piezoelectric sensor type has a special job. Engineers match the sensor to the task. This helps get good and correct results.

Force Sensor (FSR)

Operation

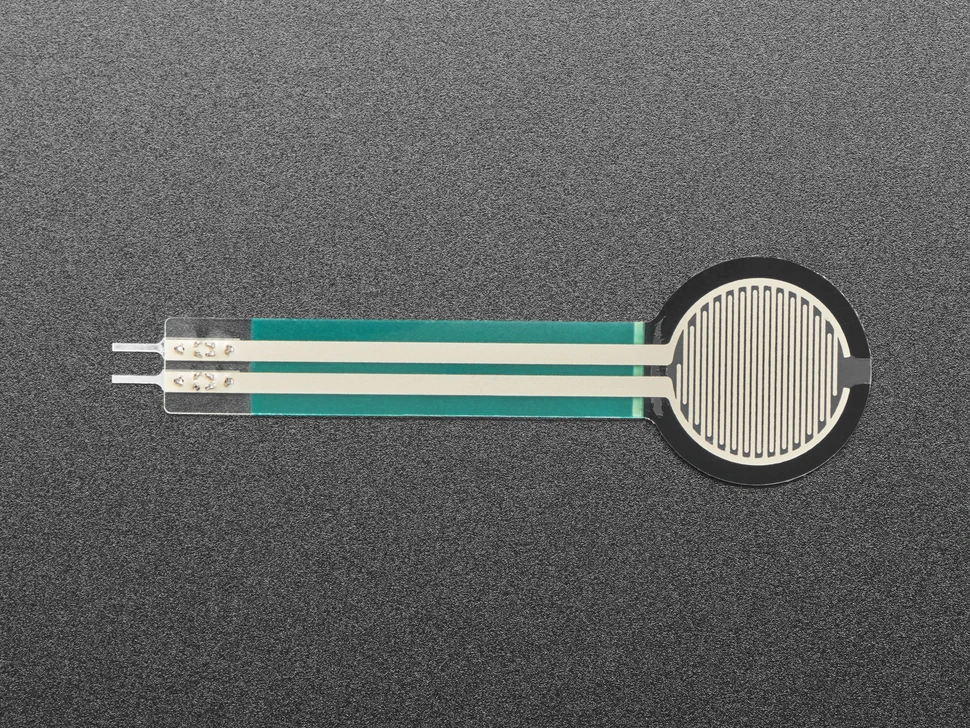

A force sensor is simple and works well. Inside, force-sensitive resistors change resistance when pressed. The sensor has a flexible base, a spacer, and a conductive layer. The flexible base holds two parts of a special circuit. The spacer keeps the circuit and conductive layer apart. When you press the sensor, the conductive base changes how it conducts. This closes the circuit and lets current flow.

A force sensor works in two main ways. The first way is called percolation. Here, resistance goes up as pressure gets higher. The second way is quantum tunneling. In this way, resistance drops when stress brings particles closer. This makes it easier for electrons to move. These two ways help force-sensitive resistors react to different forces.

SOUSHINE uses these ideas to make sensors work well. The design lets sensors work in many places. You can use them in touch buttons or robots.

| Mechanism | Description |

|---|---|

| Percolation | Resistance goes up when you press harder. |

| Quantum Tunneling | Resistance goes down when particles get close, so electrons move more easily. |

Measurement

A force sensor finds out how much force is on it. The resistors inside change resistance when you press them. This change can be measured and turned into a force value.

A force sensor can measure light and heavy forces. For example, the FSR 402 model can sense from 100 grams to 10 kilograms. The resistance can be very high with no pressure. With light pressure, it is about 100 kilo-ohms. With lots of pressure, it drops to 200 ohms. This big range helps the sensor work in many places.

| Physical Quantity | Measurement Range |

|---|---|

| Resistance | Very high (no pressure), 100KΩ (light pressure), 200Ω (max pressure) |

| Force | 0 to 20 lb. (0 to 100 Newtons) on a small area |

Force-sensitive resistors measure force all the time. They do not just turn on or off. This helps track how much force is used over time.

Features

Force-sensitive resistors have many good features. SOUSHINE’s sensors are flexible, strong, and can be made in different shapes.

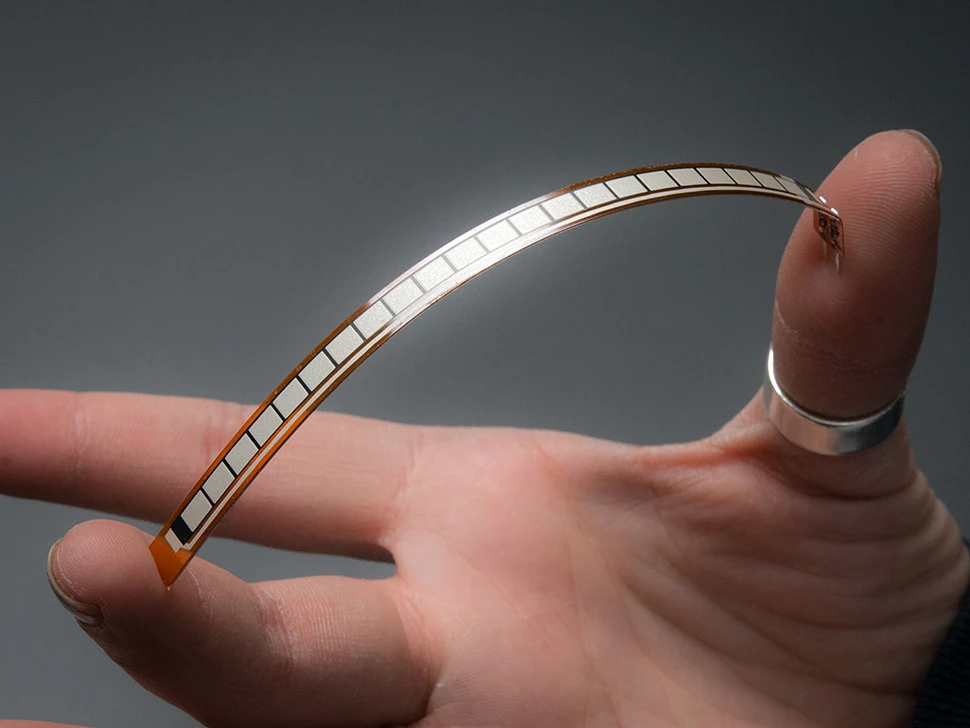

- Thin and bendy, so they fit in small or curved places.

- Very sensitive, so they find small changes in force.

- Strong, so they last a long time even with lots of use.

- Wide resistance range, so they measure many kinds of force.

- Can be made in special shapes and sizes for projects.

- Use little power, so they work in battery devices.

- Work well in cars, health tools, robots, and electronics.

| Feature | Description |

|---|---|

| Model | FSR 402 |

| Functionality | Measures force by changing resistance when pressed. |

| Applications | Used in medical tools, car airbags, and robots for touch. |

| Sensitivity | Very sensitive, finds small changes in force. |

| Durability | Made to last, good for many uses. |

| Flexibility | Thin and bendy, great for phones and mobile devices. |

| Resistance Range | Measures from a few ohms to many megaohms, so it works in many ways. |

SOUSHINE helps customers with expert advice and careful checks. The company makes sure each sensor works well and is reliable. This helps people use force-sensitive resistors in their projects with trust.

Types

Force sensing resistors (FSRs) have different types. Each type does a special job. Engineers pick the type that fits their project. SOUSHINE makes many FSRs for different uses.

1. Standard FSRs

Standard FSRs are round or square. These sensors find force in small spots. Designers use them in buttons and touchpads. They also work in simple switches. The sensor has a bendy base and a layer that conducts. This lets it bend and fit in tight places.

2. Strip FSRs

Strip FSRs are long and thin. These sensors measure force along a line. Robot hands use strip FSRs to check grip strength. Medical tools use them to watch pressure on surfaces. The strip shape covers more space without being thick.

3. Matrix FSRs

Matrix FSRs use a grid shape. Each spot in the grid senses force. This type helps map force over big areas. Touch panels and smart mats use matrix FSRs. The grid design makes detailed pressure maps.

4. Custom-Shaped FSRs

SOUSHINE makes FSRs in special shapes. Clients can ask for any size or shape. This helps with unique designs. For example, cars may need sensors for curved dashboards. SOUSHINE works with clients to make these sensors.

Note:

Custom sensors fit the project’s needs exactly. SOUSHINE helps from design to making the sensor.

5. Flexible and Rigid FSRs

FSRs can bend or stay stiff. Flexible FSRs twist and bend easily. These work in wearables and curved places. Rigid FSRs do not bend. They fit flat surfaces and fixed spots.

Table: Common Types of SOUSHINE FSRs and Their Uses

| Type | Shape/Design | Typical Use Cases |

|---|---|---|

| Standard FSR | Round/Square | Buttons, touchpads, switches |

| Strip FSR | Long/Narrow | Robot grips, medical sensors |

| Matrix FSR | Grid | Touch panels, smart mats |

| Custom-Shaped FSR | Any shape | Automotive, special projects |

| Flexible FSR | Bendable | Wearables, curved surfaces |

| Rigid FSR | Stiff | Flat panels, fixed equipment |

SOUSHINE checks every FSR for quality. The company tests each sensor to make sure it lasts. Clients get help with design, testing, and setup. SOUSHINE FSRs are used in cars, health tools, robots, electronics, factories, and planes. This big choice and support help engineers pick the best sensor for their project.

Comparison

Principle

The biggest difference between a piezoelectric sensor and an FSR is how they work. A piezoelectric sensor uses something called the piezoelectric effect. When you press or bend it, the special material inside makes electricity. This lets the sensor turn things like force or vibration into an electric signal. Engineers use this to measure fast changes in force.

An FSR works in another way. It finds force by checking how much resistance changes. Inside, there is a special material between two soft layers. When you push on it, the film inside gets squished and resistance goes down. If you do not press it, resistance stays high. The more you push, the lower the resistance gets, and it lets more electricity through. This is why FSRs are good for finding touches, grip strength, or when something is too heavy in safety systems.

Key Points:

- Piezoelectric sensors make electricity when pressed or bent.

- FSRs change resistance when you push on them.

Sensitivity

Piezoelectric sensors are very sensitive to small changes in force. They can notice quick and tiny movements. This helps when you need to measure things like vibrations or hits. These sensors are great for fast forces but do not keep a steady signal if the force stays the same.

FSRs are somewhat sensitive. They can feel both light and strong pushes. The sensor gives a signal that matches how hard you press. But FSRs might not notice very tiny changes as well as piezoelectric sensors. They work best when the force changes slowly or stays the same.

| Sensor Type | Sensitivity to Small Changes | Best For |

|---|---|---|

| Piezoelectric | Very high | Vibrations, impacts |

| FSR | Moderate | Touch, grip, steady pressure |

Response

Piezoelectric sensors react very fast to changes in force. They can catch quick events and short bursts of pressure. How long they hold a charge depends on how they are made. Some last just a few seconds, others much longer. This quick reaction makes them good for measuring vibrations or shocks.

FSRs also react fast, but not as fast as piezoelectric sensors. They give a steady signal as long as you keep pressing. The sensor follows changes in pressure over time. This makes it good for watching forces that change slowly or stay the same.

Tip:

Pick a piezoelectric sensor for fast, moving measurements. Use an FSR for steady or slow changes in force.

Durability

Durability is very important when picking a sensor. Piezoelectric sensors and FSRs are strong in different ways.

Piezoelectric sensors are made from hard things like quartz or ceramics. These materials do not wear out fast. Many piezoelectric sensors last a long time, even in rough places. They can take high heat and strong shaking. Factories and cars use them because they do not break easily.

FSRs from SOUSHINE are made with bendy materials. These sensors can bend and twist without breaking. They work well in things that move or change shape. FSRs can handle being pressed many times. People use FSRs in things like touchpads and wearables that get used a lot.

| Sensor Type | Durability Highlights |

|---|---|

| Piezoelectric | Withstands heat, vibration, and heavy use |

| FSR | Flexible, resists repeated pressing, long life |

Tip:

Use piezoelectric sensors for strong, fixed places. Pick FSRs for things that move or need to bend.

Circuitry

Piezoelectric sensors and FSRs use different circuits. Engineers pick the right circuit for each sensor and project.

| Sensor Type | Circuit Complexity | Signal Type | Common Components | Power Needs |

|---|---|---|---|---|

| Piezoelectric | High | Voltage Output | Charge amplifier, filters | Low (self-powered) |

| FSR | Low | Resistance Change | Voltage divider, ADC | Low (external power) |

Piezoelectric Sensor Circuitry

- Engineers use charge amplifiers to read signals from these sensors.

- The sensor makes a small voltage when you press or bend it.

- Filters help clean up the signal and remove noise.

- The circuit has parts to protect against electrical spikes.

- Piezoelectric sensors do not need extra power to sense things. They make their own signal.

FSR Circuitry

- FSRs use simple circuits that are easy to build.

- Engineers use a voltage divider to check resistance changes.

- The circuit connects to an ADC to get digital readings.

- FSRs need a little power to work.

- The design lets you connect them easily to microcontrollers.

Tip:

Piezoelectric sensors need more advanced circuits to work well. FSRs use simple circuits and fit with many electronic boards.

Piezoelectric sensors are good for projects needing fast, exact measurements. FSRs are better for simple and flexible force sensing. The best choice depends on what your project needs and what electronics you have.

Applications

Piezoelectric

Piezoelectric technology is used in many fields. Engineers use these sensors to find changes in pressure, vibration, and movement. These sensors react fast to moving forces. In cars, piezoelectric knock sensors help engines run better by finding detonation. Doctors use piezoelectric transducers for ultrasound images. This helps check on babies and guide surgeries. Some treatments use focused sound waves to break kidney stones and treat tissue without cutting. Factories use piezoelectric actuators for ultrasonic cleaning. This cleaning removes dirt from places that are hard to reach. Ultrasonic welding uses these actuators to join plastic parts. Phones and tablets use piezoelectric sensors in MEMS devices. These include gyroscopes and accelerometers.

| Industry | Application Example |

|---|---|

| Automotive | Knock sensors help engines by finding detonation. |

| Medical | Ultrasound images help check pregnancies and guide surgeries. |

| Medical | Focused sound waves break kidney stones and treat tissue. |

| Industrial | Ultrasonic cleaning shakes liquids to clean objects. |

| Industrial | Ultrasonic welding joins plastics with sound waves. |

| Consumer Electronics | MEMS devices in phones and tablets use gyroscopes and accelerometers. |

FSR

FSR technology measures steady and ongoing force. SOUSHINE FSRs are used in many areas. Car makers use FSRs in dashboards and seats to make cars safer and more comfortable. Healthcare tools use FSRs in prosthetics and wearable monitors. These track how patients move and feel pressure. Robot engineers use FSRs for touch feedback and control. This lets robots feel and react to things around them. Phones, tablets, and game consoles use FSRs for touch features. Factories use FSRs to make work better and safer in making and moving products. Planes and space projects use FSRs for control, navigation, and research.

| Sector | Applications |

|---|---|

| Automotive | Dashboards, seat sensors, and smart panels use FSRs. |

| Healthcare | Prosthetics, health monitors, patient care, and telemedicine use FSRs. |

| Robotics | Robots use FSRs for touch, control, and to interact with things. |

| Consumer Electronics | FSRs give touch features to phones, tablets, games, and wearables. |

| Industrial Automation | FSRs help with process control, safety, and tracking in factories. |

| Aerospace | FSRs are used in control, navigation, and research projects. |

Use Cases

Piezoelectric sensors are best for measuring moving forces. They find vibrations, hits, and quick changes. Engineers use them in machines that need to sense movement or pressure changes. FSRs work best with steady or ongoing force. They measure how hard someone presses a button or how much weight is on something. SOUSHINE FSRs help keep cars safe, watch patients in hospitals, and let robots feel touch. Phones and tablets use FSRs for touch screens. Factories use FSRs to check pressure and improve how things are made. Planes and space projects use FSRs for control and navigation.

Tip:

Pick piezoelectric sensors for moving force and vibration. Choose FSRs for steady or ongoing force in cars, healthcare, robots, electronics, factories, and planes.

Pros and Cons

Piezoelectric

Piezoelectric sensors are good at measuring force and vibration. They react fast when things move or change. These sensors can find tiny movements and give correct numbers for quick events. Many companies use them because they last long and work in tough places. They make their own signal, so they do not need extra power.

But piezoelectric sensors have some problems too. They are not good at measuring steady forces. The signal gets weaker if the force does not change. You need special circuits to read their signals. If it gets hot or cold, the sensor may not be as correct. You also have to keep away electrical noise to get good data.

Note:

Piezoelectric sensors are best for projects that need quick reaction and can sense small movements.

FSR

FSRs are easy to use for measuring force. They can fit in tight spots and bend to fit curves. Many people pick them because they are cheap and simple to set up. FSRs can measure both soft and hard pushes, so they work in many jobs.

The table below lists the main good and bad points of FSRs from what users and experts say:

| Advantages | Disadvantages |

|---|---|

| Versatility | Sensor drift |

| Small profile | Hysteresis |

| Low cost | Sensitivity to environmental factors |

| (temperature, curvature, tissue compliance) |

FSRs can change their readings over time. Hysteresis means the number may not go back to the same after you stop pressing. Things like heat or bending can make the sensor give different numbers. Even with these issues, many engineers use FSRs when they want a sensor that is simple and works in many ways.

Tip:

FSRs are great for projects that need to measure force all the time and need sensors that can bend or fit anywhere.

Choosing a Sensor

Factors

Picking the best sensor means thinking about many things. Every project is different, so you need to plan well to avoid problems.

- Cost: Pick a sensor that fits your budget. Do not pay for things you do not need.

- Environment: Some sensors work better in tough places. FSRs can handle dust, water, and hot or cold weather.

- Form Factor: Thin and bendy sensors fit in small or curved spots, like in wearables.

- Repeatability: Sensors should work the same every time. This helps stop quality issues.

- Sensitivity: Newer sensors can feel many levels of force.

- Accuracy and Sensitivity: If you need exact numbers, use sensors that are very accurate.

- Output Signal and Compatibility: The sensor should connect easily to your system.

- Size and Mounting: Make sure the sensor fits and stays in place.

- Environmental Conditions: Heat, shaking, and heavy loads can change how piezoelectric sensors work. These things might make the signal wrong.

- Robust Sensor Selection: Choose sensors made for tough places and built to last.

- Pilot Testing: Try out sensors before using them everywhere. This helps find and fix problems.

- Training: Teams need the right tools and know-how to use sensor systems.

⚠️ Some common mistakes are picking a sensor with the wrong range, mixing up accuracy and precision, or using the wrong sensor for the place. These mistakes can mess up your data or make the sensor break early.

Piezoelectric sensors and FSRs do different jobs. Piezoelectric sensors are good at finding fast changes. They work well for things that shake or move quickly. FSRs are better for measuring steady force. They can fit into many shapes and places. Picking the right sensor depends on how exact you need it, the range you want, and how it fits in your project.

| Sensor Type | Best Use | Key Point |

|---|---|---|

| Piezoelectric | Vibration, quick changes | High sensitivity |

| FSR | Steady force, touch | Simple, flexible, affordable |

- Pick piezoelectric sensors for jobs with fast movement.

- Choose FSRs when you need to measure steady force.

Tell us about your sensor projects or ask questions below.

FAQ

What is the main difference between a piezoelectric sensor and an FSR?

A piezoelectric sensor makes voltage when you press or bend it. An FSR changes how much it resists electricity when you push on it. These sensors measure force in their own ways.

Can FSRs measure static force?

Yes. FSRs can measure steady force that does not change. They keep sending a signal as long as you keep pressing.

Are piezoelectric sensors good for measuring vibrations?

Yes. Piezoelectric sensors are great for finding quick changes and vibrations. They react fast to moving forces.

Where can engineers use SOUSHINE FSRs?

Engineers put SOUSHINE FSRs in cars, health tools, robots, electronics, factories, and planes.

Do FSRs need complex circuits?

No. FSRs use easy circuits. You can read their signals with a voltage divider and a converter.

How long do SOUSHINE FSRs last?

SOUSHINE FSRs last a long time. Their bendy design lets them handle lots of pressing and bending.

Can piezoelectric sensors measure steady pressure?

No. Piezoelectric sensors work best with forces that move or change. Their signal gets weaker if the pressure stays the same.

Are FSRs customizable for special projects?

Yes. SOUSHINE makes FSRs in many shapes and sizes. Custom FSRs can fit special project needs.