Call us: +86-137-2353-4866

When you look at an elastic force transducer and other sensors, you will notice they are not the same in accuracy and reliability. Load cells are very accurate and very reliable. Force sensing resistor choices are only somewhat accurate and reliable. The table below shows how they compare:

| Sensor Type | Accuracy | Reliability | Best Use Cases |

|---|---|---|---|

| Load Cells | High | Very High | Static loads, precise measurements |

| FSRs | Moderate | Moderate | Dynamic applications, flexible uses |

You must pick the right force sensing technology for your job. SOUSHINE can help you choose the best sensor for what you need.

Table of Contents

Key Takeaways

- Elastic force transducers are very accurate for steady force. They work well in labs and for checking quality.

- Force sensing resistors (FSRs) bend easily and do not cost much. They are good for moving things like robots and health tools.

- Load cells are very accurate and work well for a long time. They are best for still loads and careful measuring in many jobs.

- Pick the right sensor for what you need. Think about how accurate it is, how fast it works, and where you will use it.

- You must check and adjust force sensors often. This keeps them working right and makes them last longer.

- Think about where the sensor will be used. Things like heat and wetness can change how it works.

- SOUSHINE FSRs can be used in many ways. They work in cars and in things people use every day.

- Knowing the good and bad points of each sensor helps you choose the best one for your work.

What Is a Force Sensor?

Basic Principles

A force sensor helps you find out how much force you use on something. The sensor turns the force into an electrical signal. This makes it easy to see and record the force. Sensors use different ways to do this job. Some sensors have strain gauges. Strain gauges change their resistance when you press or stretch them. Other sensors use the piezoelectric effect. These make a tiny electric charge when you press them. Some sensors use capacitive methods. When you press them, the space between two plates changes. This change affects the electrical capacitance. Each way lets you turn force into a signal you can measure.

Tip: Force sensors are used in many areas like robotics, healthcare, and manufacturing. They help control machines, check products, and keep people safe.

Types of Force Sensors

There are many kinds of force sensors in engineering and manufacturing. Each kind works in its own way and fits different jobs. Here are some common types:

- Strain gauge load cells

- Piezoelectric force sensors

- Capacitive force sensors

- Magnetic force sensors

- Optical force sensors

- Load buttons and compression cells

- Force sensing resistors (FSRs)

You pick the sensor that matches what you need to measure. Some sensors are good for heavy loads. Others are better for small and quick force changes. Knowing the main types helps you choose the right one for your project.

Elastic Force Transducer Overview

How Elastic Force Transducers Work

An elastic force transducer helps you measure force on an object. It uses the strain gauge principle to work. When you push or pull on it, the device bends or stretches. The strain gauge inside changes its resistance. This change tells you how much force you use. The elastic force transducer works best for steady or slow-changing forces. It gives you stable readings when the force does not change fast.

Here is a table that shows how the elastic force transducer compares to other sensors:

| Type of Sensor | Working Mechanism | Measurement Type |

|---|---|---|

| Elastic Force Transducers | Based on the strain gauge principle, suitable for static and quasistatic forces. | Static and quasistatic forces |

| Piezoelectric Sensors | Based on the piezoelectric measurement principle, generates charge proportional to force. | Dynamic and quasistatic forces |

You can see the elastic force transducer is not the same as piezoelectric sensors. The elastic force transducer is better for measuring steady or slowly changing force. Piezoelectric sensors are better for quick and changing force.

Applications and Benefits

You can find elastic force transducers in many places. They are used in weighing scales, machines, and testing tools. These devices help you measure force in a simple way. You can use them to check how much weight something holds or to test how strong something is.

Some good things about using an elastic force transducer are:

- High accuracy for steady force measurements

- Reliable readings for a long time

- Easy to set up and use

Note: You can trust an elastic force transducer when you need to measure steady force in your project.

Limitations

You should know the elastic force transducer works best for steady or slow-changing force. If you need to measure fast or sudden force, you may need a different sensor. The elastic force transducer may not work well for quick force changes. You also need to make sure it fits your space and load needs.

You can pick the elastic force transducer when you want steady and accurate force readings. This device helps you get clear data in many jobs.

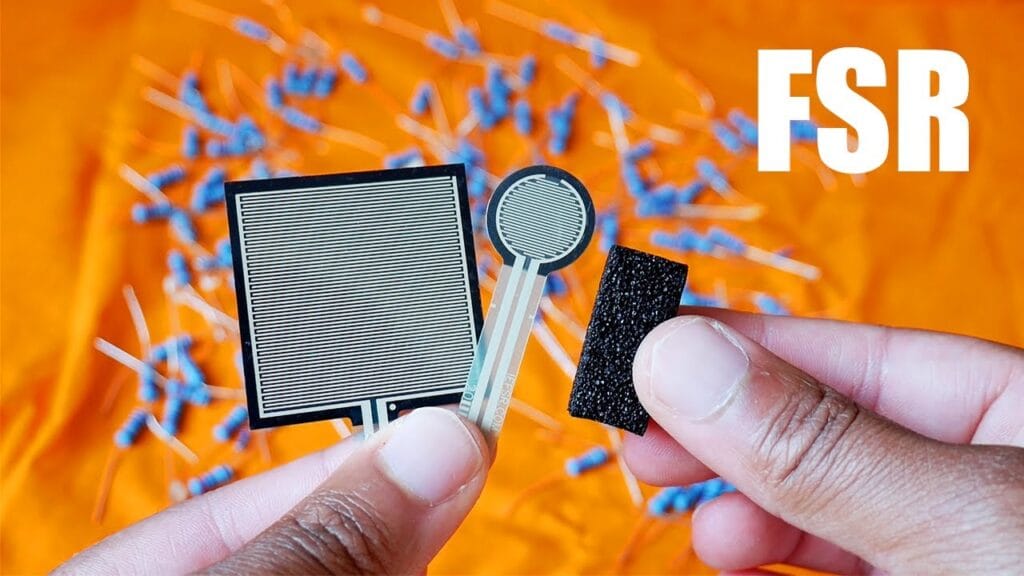

Force Sensing Resistors (FSRs) by SOUSHINE

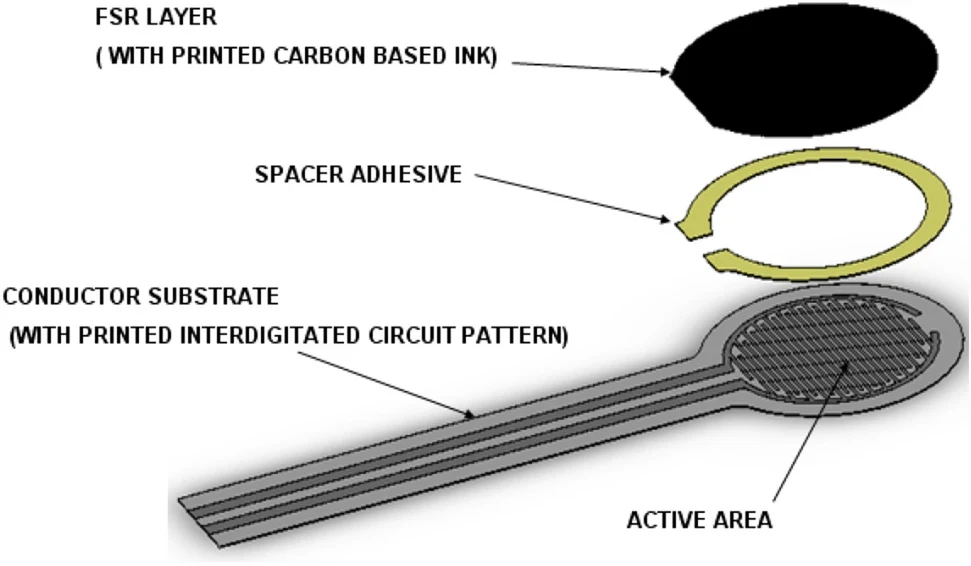

FSR Working Principle

A force sensing resistor helps you measure force on a surface. When you press the sensor, its resistance goes down. More force makes the resistance even lower. This change lets you see how much force you use. The sensor gives a steady signal, not just on or off. You can use it to watch small or big pressure changes. The thin and bendable shape fits in many products. The sensor works fast and gives results in less than 10 milliseconds.

Key Features of SOUSHINE FSRs

SOUSHINE’s force sensing resistor is flexible and reacts quickly. You can use it in small spaces because it is only 0.85mm thick. The sensor works in very hot or cold places, from -40°C to +85°C. It uses little power, so it is good for battery devices. The sensor can measure forces from 10g up to 1000g. You can use it for very light touches. It lasts a long time and keeps working after many uses.

Here is a table that shows how SOUSHINE FSRs compare to other brands:

| Feature | SOUSHINE FSRs | Other FSR Brands |

|---|---|---|

| Flexibility | Yes | Varies |

| Affordability | Yes | Varies |

| Quick Response Time | < 10ms | Varies |

| Thickness | 0.85mm | Varies |

| Operating Temperature | -40°C to +85°C | Varies |

| Power Consumption | Low | Varies |

| Force Measurement Range | 10g to 1000g | Varies |

| Special Features | Very light touch sensors | Varies |

Tip: SOUSHINE FSRs are flexible, fast, and strong. You can use them in many projects.

FSR Applications

You can use a force sensing resistor in lots of jobs. In factories, it helps machines work longer and safer. In farming, it checks crops and finds plant problems early. In stores, it helps track products and stops empty shelves. In cars and buses, it helps control traffic and keeps roads safe. For the environment, it checks air and water quality right away.

- Manufacturing: You make machines work better and longer.

- Agriculture: You watch crops and use resources wisely.

- Retail: You keep track of products and help shoppers.

- Transportation: You control traffic and make roads safer.

- Environment: You get quick data on air and water.

You pick a force sensing resistor when you need a sensor for many uses. It works fast and lasts a long time. SOUSHINE FSRs help you fix problems in many areas.

Load Cell and Other Sensor Types

Load Cell Basics

A load cell helps you measure force in many ways. It is a transducer that turns force into an electrical signal. You see load cells in scales and machines. Most load cells use a strain gauge to sense force. The strain gauge sticks to the load cell’s body. When you push or pull, the load cell bends or stretches. This makes the strain gauge’s resistance change. The load cell has a Wheatstone bridge circuit. This circuit finds the resistance change and shows a voltage change. The voltage matches the force you use. Load cells go back to their shape after each use. This means you can use them again and again. You get the same results every time because of this.

- A load cell changes force into an electrical signal.

- Strain gauge load cells have strain gauges stuck to them and use a Wheatstone bridge.

- When you use force, the load cell bends and the strain gauge’s resistance changes.

- The Wheatstone bridge finds these changes and shows them as voltage.

- Load cells can be used many times because they return to their shape.

You can trust load cells for steady and correct force readings. Many jobs use load cells for safety and checking quality.

Strain Gauge Sensors

A strain gauge helps you measure force by changing resistance. You stick the strain gauge to a surface. When you use force, both the surface and the strain gauge bend. The metal pattern in the strain gauge changes its resistance. You measure this change to know the force or strain. Strain gauge sensors are very good at measuring small changes. You use them to check if buildings or bridges are safe. They are also used to make sure products are made right. You can count on a strain gauge to give you detailed force information.

- Very good at measuring small changes

- Good for checking buildings and bridges

- Needed for making sure products are made right

You often find a strain gauge inside a load cell. The strain gauge helps the load cell notice small force changes. This helps you get correct results in your work.

Piezoelectric Sensors

Piezoelectric sensors use special materials to measure force. When you press on them, they make an electric charge. You use piezoelectric sensors to measure force that changes fast. They work well when the force goes up and down quickly. You see piezoelectric sensors in devices that need quick answers.

| Operational Mode | Description |

|---|---|

| Transverse | Force along a middle line moves charges at a right angle. The charge depends on the sensor’s shape and size. |

| Longitudinal | The charge matches the force you use. You can stack parts to get more charge. |

| Shear | The charge matches the force and comes out at a right angle. The size and shape do not change the charge. |

You use piezoelectric sensors when you need to measure fast-changing force. These sensors give you quick and steady data.

Capacitive and Optical Sensors

Capacitive and optical sensors are new ways to measure force. They work differently than strain gauges or piezoelectric sensors. You can find them in many modern gadgets.

Capacitive sensors find force by checking capacitance changes. When you press the sensor, two electrodes move closer together. This makes the capacitance go up. The sensor changes this into an electrical signal. Capacitive sensors can notice small pressure changes. They use little power and react fast.

You see capacitive sensors in things that need to sense touch or pressure. Here are some examples:

- Phones and tablets use capacitive sensors for touch features. Pressing harder or softer does different things.

- Medical tools use these sensors to watch pressure changes. Health monitors and test tools use this technology.

- Robots use capacitive sensors to feel grip force. This helps robots hold things without dropping or breaking them.

Tip: Capacitive sensors are good for high sensitivity and low power. You can use them in small gadgets that need to feel light touches.

Capacitive touch sensors also sense when your finger is close. This lets you measure force without pressing hard. You see this in touchscreens and control panels. Medical tools use it to track tiny pressure changes. Robots use it to feel grip force and change their hold.

Optical sensors use light to measure force or pressure. When you push on them, they see how light changes. The sensor turns this into a signal you can read. Optical sensors do not need to touch the object. This is good when you cannot touch something or want to keep it clean.

You find optical sensors in these places:

- Factories use optical sensors to check if parts are in place.

- Medical tools use them to measure pressure without touching skin.

- Labs use optical sensors to study things without changing them.

Note: Optical sensors let you measure force without touching. This helps in clean rooms or when you must not damage things.

Here is a table that shows how capacitive and optical sensors are different:

| Sensor Type | How It Works | Common Uses |

|---|---|---|

| Capacitive Sensor | Measures changes in capacitance | Touchscreens, medical tools, robots |

| Optical Sensor | Sees light changes from force | Factories, medical tools, research |

You can pick capacitive or optical sensors for fast and sensitive force checks. Sometimes you do not need to touch the object. These sensors help in many jobs.

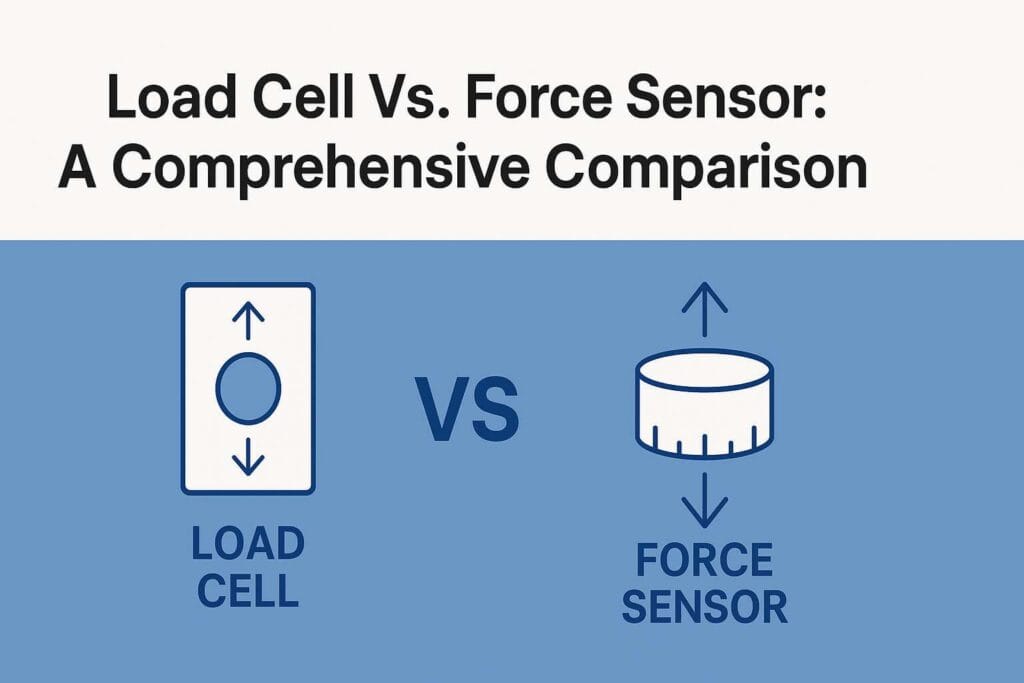

Force Sensor vs Load Cell: Key Differences

If you compare a force sensor and a load cell, you will see they are different. You need to know these differences to pick the right one. Both can measure force, but they work in their own ways. They also fit different jobs.

Working Principle Comparison

A force sensor can use many types of technology. Some use piezoelectric materials. Others use capacitive or resistive ways. This means you have more choices for different jobs. A load cell uses strain gauges. When you press on a load cell, it bends a little bit. The strain gauge inside changes its resistance. This tells you how much force you use.

Here is a table that shows how each device works:

| Feature | Force Sensor | Load Cell |

|---|---|---|

| Definition | Any device used to measure force or load | A specialized device for measuring weight |

| Measurement Principle | Various technologies (piezoelectric, capacitive, etc.) | Strain measurement through deformation |

| Application | Dynamic measurements, quick responses | High accuracy and reliability in static applications |

| Sensitivity | More sensitive to slight changes | Superior precision for larger forces |

| Design | Compact and flexible | Built for high-capacity measurements |

| Response Time | Faster response times for dynamic applications | Excellent long-term performance in static scenarios |

Tip: Use a force sensor if you need fast results or work with changing force. Pick a load cell if you want high accuracy for steady force.

Performance and Accuracy

You want your force readings to be correct. A load cell gives you very accurate and repeatable results. It works well for big forces and does not change over time. A force sensor can react quickly to small changes. Some types, like piezoelectric sensors, may not be as exact as a load cell.

Check this table to see how they compare:

| Type | Measurement Accuracy | Repeatability |

|---|---|---|

| Strain Gauge Load Cell | High (low drift) | High (consistent over time) |

| Piezoelectric Sensor | Lower | Lower |

You can see a load cell is best for high accuracy and repeatable results. A force sensor is better for quick changes but may not be as accurate as a load cell.

Cost and Integration

You should also think about how much each device costs and how easy it is to use. A load cell usually costs more at first. It lasts a long time and does not need much care. A force sensor can cost less and fit in small spaces. You may need to check it more often to keep it working well.

Here is a table to help you see the main points:

| Parameter | Load Cells | Force Sensors |

|---|---|---|

| Initial Cost | Higher | Moderate to High |

| Maintenance | Low | Moderate |

| Durability | High | Variable |

| Accuracy Stability | Very Stable | Moderately Stable |

Note: Pick a load cell if you want high accuracy and long life. Choose a force sensor if you want flexibility and easy setup.

When you compare a force sensor and a load cell, you see each has good points. A load cell gives you high accuracy and stable results. A force sensor gives you fast response and flexible design. Think about what you need for force, accuracy, and cost before you choose.

Pros and Cons of Force Sensors

Elastic Force Transducer Pros and Cons

If you use an elastic force transducer, you get steady and correct readings. These devices work in labs, factories, and testing places. You can trust them for measuring force that does not change fast. They help you get good data for checking quality and safety.

Pros:

- You get very correct results for steady force.

- The readings stay the same for a long time.

- You can use them in many machines and tools.

Cons:

- Some types cost more than other force sensors.

- It can be hard to measure the highest force if the sensor feels hard.

- Where you put the sensor can change the results.

- Electrical noise can mess up the signal and make it less correct.

- If the battery gets low, the sensor may not work as well.

- These sensors might not last as long as some mechanical tools.

Tip: Always check where you put the sensor and the battery before you start.

FSR Pros and Cons

Force sensing resistors (FSRs) are a cheap and flexible way to measure force. You can put them in small or curved spaces. Their thin shape makes them easy to use in many things. You can use FSRs in robots, health tools, and electronics.

Pros:

- You save money because FSRs cost less than most other sensors.

- You can use them in small or odd-shaped places.

- Their thin and bendy shape lets you use them in many ways.

- FSRs are good for projects with little money.

| Sensor Type | Typical Cost per Unit | Flexibility | Integration Ease |

|---|---|---|---|

| FSR | $10 – $50 | High | Easy |

| Load Cell | $100+ | Low | Moderate |

Cons:

- FSRs can become less correct over time.

- Heat and wet air can change how they work.

- FSRs can break if you press too hard or if the place is rough.

- You need to check and set them often to keep the readings right.

Note: FSRs are best when you want a simple, bendy, and cheap force sensor.

Pros and Cons of Load Cells

A load cell gives you very correct force readings. You see them in factories, labs, and health tools. They help stop mistakes and keep people safe. You can use load cells for weighing, machines, and checking buildings.

Pros:

- You get very correct force readings.

- Load cells work in many jobs, like weighing and safety checks.

- Their good results help stop mistakes and keep things right.

- You can use them for pulling and pushing force.

Cons:

| Disadvantage | Description |

|---|---|

| Bulky in size and rigid construction | Load cells are often big and not bendy. |

| Costly signal conditioning electronics | You need extra parts to handle the signal. |

| Not suitable for OEM/Design-in applications | Hard to use in custom or small products. |

Tip: Pick a load cell if you need very correct and steady results, but make sure you have enough space and money for the extra parts.

You can see each force sensor has good and bad points. When you choose a sensor, think about what you need for correctness, price, space, and how you will use it. This helps you get the best sensor for your job.

Other Sensor Types

You can find other force sensors for special jobs. Capacitive, optical, and piezoelectric sensors have good and bad sides. You might use these sensors if you need quick answers or low power. Some let you measure force without touching the object.

Capacitive Force Sensors

Capacitive sensors check force by looking at the gap between two plates. When you press the sensor, the plates get closer together. This changes the electrical charge. The sensor sends a signal that matches the force.

Advantages:

- Simple and strong build

- Works in hot and cold places

- Uses little power, good for wearables

- Gives steady results with few mistakes

- Responds quickly

Disadvantages:

- Output can change if the gap is uneven

- Sensitive to shaking or vibration

- Needs careful design to stop extra signals

Piezoelectric Force Sensors

Piezoelectric sensors use special materials that make electricity when pressed. You use these sensors to measure quick force changes. They do not need a battery to work.

Advantages:

- Works well in tough places

- Needs little or no power

- Gives very accurate and fast results

- Simple build with cheap materials

Disadvantages:

- Only measures changing force, not steady force

- Needs special electronics to read the signal

- Sensitive to shaking, so you may need to fix that

Optical Force Sensors

Optical sensors use light to measure force. When you press the sensor, the light changes. The sensor reads this change and gives you a signal.

Advantages:

- Measures force without touching the object

- Works well in clean rooms or with fragile items

- Not affected by electrical noise

Disadvantages:

- Needs careful setup to keep light steady

- Can cost more than other sensors

- May not work well in dusty or dirty places

Here is a table to help you compare capacitive and piezoelectric sensors:

| Sensor Type | Advantages | Disadvantages |

|---|---|---|

| Capacitive | Simple, strong, works in many temperatures, low power, quick | Output can change, sensitive to vibration, needs good design |

| Piezoelectric | Tough, low power, very accurate, fast, simple build | Only for changing force, needs special electronics, sensitive to vibration |

Tip: Pick a sensor type based on what you need. If you want fast results and low power, try capacitive or piezoelectric sensors. If you need to measure force without touching, optical sensors work best.

You should always think about your project needs before you choose a sensor. Each type gives you different benefits and challenges.

Choosing the Right Force Sensor

Factors to Consider

You should think about a few things before picking a force sensor. Each sensor works best in certain places. You need to match the sensor to your job for good results.

- Calibration keeps your sensor correct. You must check and adjust sensors often.

- Sensors can change as they get older. You need to plan for fixing them.

- How you put in the sensor matters. Always follow the maker’s steps.

- Cost is important. Pick a sensor that fits your money plan and needs.

- The place you use the sensor can change how it works. Tough places can make it less correct.

- The sensor’s range should fit the force you want to measure.

- Sensitivity helps you see small force changes. Pick a sensor that matches your needs.

Here is a table with important things to think about:

| Criteria | Importance |

|---|---|

| Measuring Range | Should match the real measuring range for accurate readings. |

| Accuracy and Precision | Accuracy means correct readings. Precision helps you see small changes. |

| Sensor Type | Pick the right sensor for your operating conditions. |

You need to balance price and how well the sensor works. Good sensors can save you money later by needing less fixing and stopping fewer times.

Tip: Always check where you put the sensor and the place before you start measuring.

Application Scenarios

You can find force sensors in many jobs. Each job needs a different sensor. You must know where and how you will use the sensor.

| Industry Application | Description |

|---|---|

| Automotive | Makes cars safer and more reliable. |

| Healthcare & Medical | Measures and watches patients for safety. |

| Robotics | Gives robots a sense of touch for learning and change. |

| Consumer Electronics | Makes devices easier to use. |

| Industrial | Helps factories work better and waste less. |

| Aerospace & Defense | Works well in tough and changing places. |

You use load cells for weighing and safety checks. Load cells are in scales, machines, and for testing buildings. Elastic force transducers are good for steady force in labs and factories. Force sensing resistors work well in moving jobs like robots, health tools, and electronics. You see force sensors in material tests, cable checks, elevators, bridges, and quality checks.

- Material tests use sensors to check how strong things are.

- Cable checks keep systems safe.

- Elevators use sensors to make rides safe.

- Bridges and buildings use sensors to check tension.

- Machines in factories use sensors to watch tension.

- Cranes and hoists use sensors for safe lifting.

- New designs are tested with sensors in research.

- Special machines use sensors for custom checks.

- Quality control uses sensors to make sure things are right.

Note: You must pick the right sensor for your job to get the best results.

SOUSHINE Product Recommendations

SOUSHINE has force sensors for many jobs. You can use SOUSHINE FSRs in cars, health tools, and electronics. These sensors give you quick and correct results. They last a long time and meet strict rules.

| Industry | Recommended Product | Reason for Recommendation |

|---|---|---|

| Automotive | SOUSHINE FSRs | Tough, low power, flexible design for many products |

| Healthcare | Medical Grade Sensors | Accurate, quick response, trusted for patient monitoring |

| Consumer Electronics | SOUSHINE FSRs | Versatile, durable, customizable for different applications |

You can trust SOUSHINE sensors for force checks in many places. Health workers use SOUSHINE sensors to keep patients safe. Factories use them to check quality. You can find SOUSHINE sensors in robots, cars, and smart gadgets.

- SOUSHINE sensors give you correct force readings.

- They react fast to changes in force.

- You can use them in many jobs because they are flexible.

- They last long and follow strict rules.

Tip: SOUSHINE FSRs work in many fields. You can use them for easy and steady force checks.

You have many choices for force sensors. Elastic force transducers give you steady readings. FSRs work well in flexible designs. Load cells offer high accuracy. Other sensors fit special needs. When you pick a sensor, check these points:

- Look at temperature, humidity, and possible contaminants.

- Decide if you need real-time data.

- Make sure the sensor matches your load needs.

- Check if it fits your equipment.

- Think about calibration and if you want wired or wireless.

SOUSHINE can help you find the best sensor for your project.

FAQ

What is an elastic force transducer?

You use an elastic force transducer to measure force. The device bends or stretches when you apply force. It changes resistance and gives you a signal you can read.

How do force sensing resistors (FSRs) work?

You press on an FSR. The resistance drops as you increase force. You get a signal that matches the pressure. SOUSHINE FSRs respond quickly and fit many designs.

Where can you use SOUSHINE FSRs?

You use SOUSHINE FSRs in cars, medical devices, robots, and electronics. The sensors help you track pressure, touch, and force in many products.

What makes load cells different from other force sensors?

You use load cells for high accuracy. They measure static loads and give repeatable results. Load cells work best in weighing and quality control.

Can you use force sensors in harsh environments?

You can use some force sensors in tough places. SOUSHINE FSRs work in hot and cold conditions. Always check the sensor’s specifications before you choose.

How do you choose the right force sensor?

You match the sensor to your job. Check the force range, accuracy, size, and cost. Think about where you will use the sensor and how often you need to measure.

Do force sensors need calibration?

You need to calibrate force sensors to keep readings correct. Regular calibration helps you avoid mistakes and keeps your data reliable.

Are force sensors easy to install?

You can install most force sensors with simple steps. Follow the instructions from the manufacturer. Make sure you place the sensor in the right spot for best results.