Call us: +86-137-2353-4866

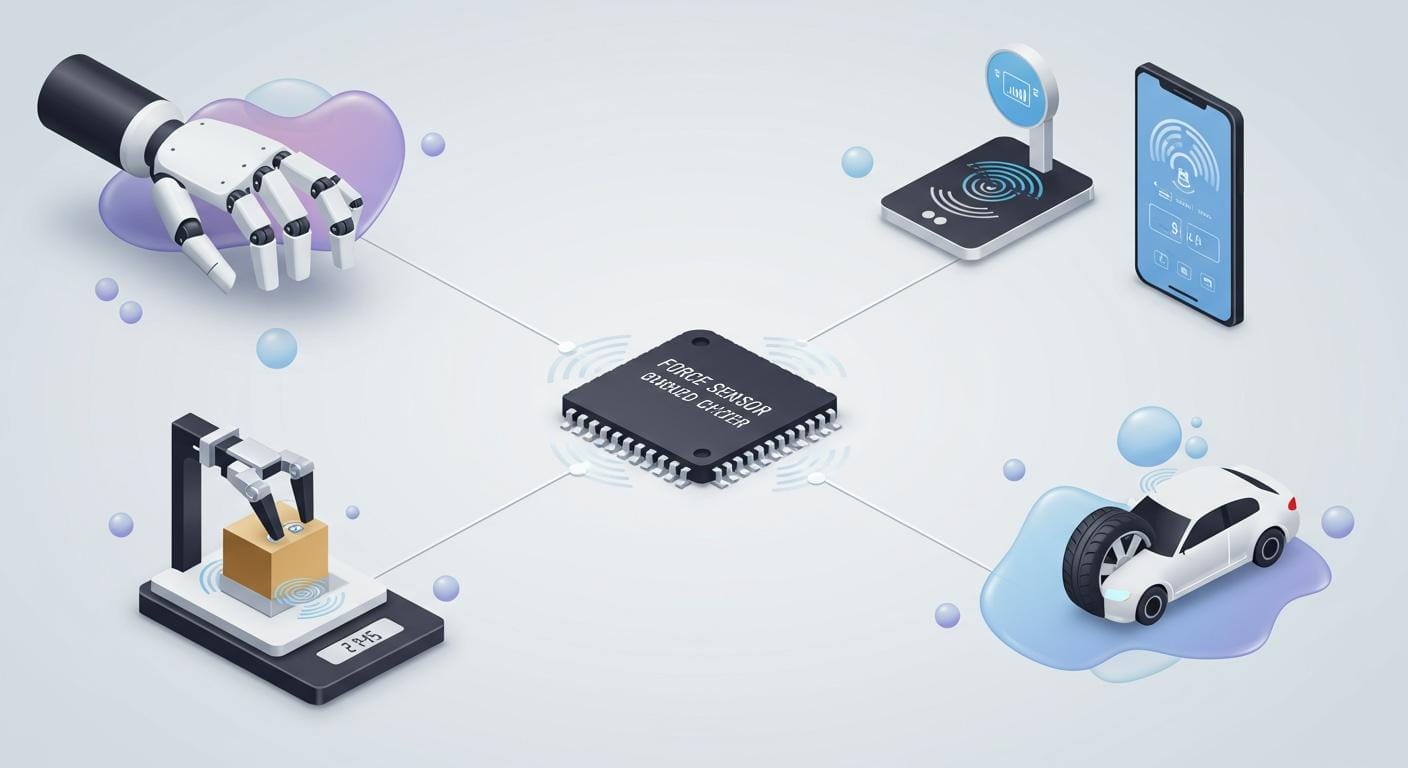

Force sensors help technology check touch, pressure, and weight. They do this with great accuracy. These devices make smartwatches safer. They also help robots and cars work better. The global market for force sensors is growing fast.

- In 2023, the force sensor market was worth between USD 2.3 billion and USD 4.28 billion.

- By 2030, experts think the market will be USD 3.40 billion. By 2035, it could be USD 7.65 billion.

- Growth rates are strong, with a CAGR from 4.7% to 5.8%.

SOUSHINE leads with new force sensing technology. Their solutions help many industries move forward.

Table of Contents

Key Takeaways

Force sensors check touch, pressure, and weight. They help make technology safer and better. The world market for force sensors is growing fast. It may reach USD 7.65 billion by 2035. There are many types of force sensors. Strain gauges and piezoelectric sensors work in special ways. They measure force very well. Force sensors are very important in healthcare. They help watch patients and make surgeries better. In robotics, force sensors make things safer and more exact. They let machines work with people well. Cars use force sensors in airbags and seat checks. These sensors help keep passengers safe. Smart devices and game controllers use force sensors too. They make the user experience better by sensing different pressure. SOUSHINE makes force sensors that can be changed for many uses. These sensors help engineers build new and smart things.

Force Sensor Basics

What Is a Force Sensor

A force sensor checks how much force or pressure is on something. People use these sensors in many areas, like healthcare and robotics. The sensor turns the force into an electrical signal. This signal lets machines know about touch, weight, or pressure. Force sensors help smart devices react better and stay safe. They also let engineers make better products. The way force sensors work gives modern technology good control and feedback.

The materials used are important for how a force sensor works. Many sensors use metals such as stainless steel or aluminum. Some use semiconductors like silicon or quartz. Others use new materials like carbon nanotubes or graphene. These materials help sensors stay strong and work well, even after lots of use.

How Force Sensors Work

Force sensors use different ways to find and measure force. Each way has its own good points. The most common types are resistance change, piezoelectric effect, and capacitive sensing.

Tip: Knowing how each way works helps people pick the best force sensor for their needs.

Resistance Change

Many force sensors use resistance change to check force. When you press the sensor, it bends a little. This bending changes the resistance inside the sensor. The sensor then sends a signal that matches the force. Strain gauges and force-sensing resistors use this way. Engineers often use thin metal foils or wires for these sensors. They might also use a Wheatstone bridge circuit to make them more accurate.

Piezoelectric Effect

Some force sensors use the piezoelectric effect. When you push on the sensor, it makes an electrical charge. This charge tells the system how much force there is. Piezoelectric materials like lead zirconate titanate (PZT) are good for this. These sensors react fast and can find even small changes in force. Many industries use this technology for careful measurements.

Capacitive Sensing

Capacitive sensing works by moving two plates inside the sensor. When you press, the plates get closer together. This movement changes the capacitance, which the sensor checks. Capacitive sensors can find very light touches. They are often used in touchscreens and smart devices.

| Operating Principle | Description |

|---|---|

| Strain Gauge Technology | Resistance changes when force is added, making an electrical signal. |

| Piezoelectric Effect | Makes an electrical charge when stressed, measured to find force. |

| Capacitive Sensing | Plates move closer, changing capacitance, which is measured. |

| Hydraulic and Pneumatic | Uses fluid pressure to find force in an indirect way. |

Force sensors can also use optical or magnetic designs. These types use changes in light or magnetic fields to check force. Each way gives engineers more choices for different uses. The force transducer is still a big part of many modern systems.

Types of Force Sensors

Strain Gauge

Strain gauge force sensors are trusted in many industries. These sensors measure force by checking small resistance changes. Engineers make them with a zig-zag metal foil. When force stretches or squeezes the foil, resistance changes. This helps machines know how much force is there.

Strain gauge force sensors are used in many jobs. They help test bench machines work well. Material testing machines use them to check strength. Factories use them for press-fitting and joining. They also help with riveting, punching, and drawing. Fastening technology uses them to measure torque. Quality teams trust their accuracy.

Strain gauge force sensors give steady results and help industries keep high standards.

| Type of Force Sensor | Operational Principle |

|---|---|

| Strain Gauges | Measure deformation through changes in resistance using a zig-zag patterned metallic foil. |

Piezoelectric

Piezoelectric force sensors use special crystals to turn force into electric signals. When you press the sensor, the crystal makes a charge. Machines read this charge to know the force. This technology works fast and is good for moving measurements.

Piezoelectric force sensors are very sensitive and accurate. Each sensor gets checked and comes with a certificate. Experts use a hydraulic press and a reference standard to set sensitivity. For best results, measure within the first 1% of the time constant. The sensors respond in a straight line up to 20% of their resonant frequency.

- Every sensor has a certificate for sensitivity.

- Calibration uses a hydraulic press and reference standard.

- Measurements within 1% of the time constant reach 1% accuracy.

- Sensors respond in a straight line up to 20% of their resonant frequency.

Piezoelectric force sensors help engineers who need quick and exact force measurements.

| Type of Force Sensor | Operational Principle |

|---|---|

| Piezoelectric Force Sensors | Generate electric charges in crystalline materials under mechanical stress, converting them into measurable signals. |

Capacitive

Capacitive force sensors use two plates to measure force. When you press the sensor, the plates move closer. This changes the capacitance. The sensor reads this change and tells the system the force.

Capacitive force sensors react quickly. Their capacitance settles in 55 milliseconds under a light load. After you stop pressing, they recover in 42 milliseconds. This speed is like human skin. The sensors keep working after thousands of cycles. Some last through 100,000 cycles with no problems. Their waveforms stay the same, showing they are strong and stable.

- Capacitance settles in 55 ms under load.

- Recovery time is 42 ms after force removal.

- Sensors work well after 1,000 cycles at 0.8 kPa.

- Some sensors last through 100,000 cycles with no loss of performance.

- Protective coatings help them last longer and need less care.

Capacitive force sensors help make devices that last and work well. Their fast response and strength make them popular in smart technology.

| Type of Force Sensor | Operational Principle |

|---|---|

| Capacitive Force Sensors | Measure changes in capacitance due to alterations in the distance between conductive plates under force. |

Force Sensing Resistor

Force sensing resistors, or FSRs, are special because they can bend and fit many places. These sensors check force by changing resistance when you press on them. SOUSHINE’s FSRs have a flexible base and a layer that carries electricity. This lets them fit into lots of shapes and sizes. They are great for new inventions and cool technology.

SOUSHINE has FSRs that work in different ways. The table below shows the main kinds:

| Configuration Type | Description |

|---|---|

| Single-zone | Simple setup for easy jobs. |

| Discrete array | Has many points to sense in a small space. |

| Matrix array | Uses a grid for harder sensing jobs. |

Designers can pick what they need:

- Shape

- Size

- Sensitivity

- Electrical ending

- Working temperature

SOUSHINE’s FSRs do more than just bend. They last a long time, even in rough places. They use little power, so smart devices save energy. Many companies trust these sensors because they work well and are easy to use. SOUSHINE also helps teams make custom sensors for any job.

SOUSHINE’s FSRs help engineers think bigger and build better. Their sensors help turn ideas into real things, one touch at a time.

Optical

Optical force sensors use light to check force without touching. These sensors are great when you need very careful and steady results. Engineers pick them when other sensors might not work well.

Some good things about optical force sensors are:

- Very sensitive for careful checks

- Not bothered by electromagnetic noise

- Work well in tough places

- Can measure without touching

- Good for medical tests and factory robots

The optical force sensor helps make new technology. It helps doctors, scientists, and engineers do their work better. Many people use these sensors to get safe and correct results for important jobs.

In Medical Devices

Patient Monitoring

Medical teams use force sensors to get real-time data. These sensors are important in blood pressure monitors and infusion pumps. Blood pressure monitors check the pressure inside the cuff with force sensors. This helps doctors get exact readings. Infusion pumps use force sensors to control fluid flow. The sensors notice pressure changes and warn caregivers if there is a blockage. This keeps patients safe and makes sure treatments work.

SOUSHINE’s force-sensing technology is special for patient monitoring. Their wrist device has a pressure sensor with 46 parts and a smart chip. Tests on a wrist model showed steady readings, even when the patient moved or the temperature changed. Clinical studies proved SOUSHINE’s device is as accurate as regular cuff monitors. The table below shows these strong points:

| Feature | Benefit |

|---|---|

| Multi-element pressure sensor | Accurate readings in real time |

| Smart chip integration | Reliable performance during movement and temperature |

| Clinical accuracy | Matches traditional monitors for patient safety |

SOUSHINE’s FSRs help healthcare teams feel confident. They give patients reliable care and peace of mind.

Surgical Robots

Surgical robots have changed how doctors do surgery. Force sensors help robots feel touch. They give feedback so robotic arms move with care. Surgeons can feel the force from the robot’s tools. This helps them avoid hurting soft tissues. The sensors collect data and adjust movements during surgery. This makes surgery safer and more exact for patients.

- Real-time feedback helps keep robots under control.

- Haptic feedback lets surgeons feel what the robot touches.

- Sensors help robots move carefully in the body.

- Continuous checks make surgery safer.

Doctors trust force sensors to guide surgical robots. These sensors help save lives and help patients heal faster. Surgery will keep getting better with this technology.

Prosthetics

Modern prosthetics use force sensors for better control and comfort. These sensors help people grip things with the right force. They also give data for walking analysis, so users walk smoothly. Force sensors help with balance, even on rough ground. Some devices let users feel the weight and texture of objects.

- Grip force control helps users hold light or heavy things.

- Walking data helps improve how people walk.

- Sensors help with balance during movement.

- Tactile feedback lets users feel touch again.

Custom force sensors in prosthetics do more than measure force. They help users interact with the world in a natural way. SOUSHINE’s FSRs give flexible, reliable, and exact solutions. People with prosthetics can move with confidence and independence.

In Robotics

Industrial Robots

Industrial robots have changed how factories work. These machines use force sensors to feel touch. Robots change their grip to protect fragile things. Strain gauge sensors help robots pick up delicate parts safely. Workers trust robots to polish, grind, and put together products. Force sensors give feedback so robots do jobs with care and accuracy.

Robots in factories face many surprises. Force sensors find collisions and help robots react fast. This keeps workers safe and stops damage to machines. Engineers add these sensors to make robots work smoothly and reliably.

Industrial robots with force sensors help factories feel safe. They help teams work better and keep everyone protected.

Collaborative Robots

Collaborative robots, called cobots, work with people. These robots use force sensors to sense touch and move safely. Cobots slow down or stop if they touch a person. This keeps people safe when working with robots.

Force sensors help cobots learn new jobs by hand guiding. Workers move the robot arm, and sensors record the force used. This makes programming quick and simple. Cobots use force sensors to hold soft things or heavy tools. They change their grip for each job.

SOUSHINE FSRs are important in collaborative robots. Their flexible design fits into robot hands and arms. These sensors give good feedback, so cobots work smartly. Teams trust SOUSHINE FSRs for safety and strong performance.

Automation Lines

Automation lines need force sensors to run safely and smoothly. Factories use sensor arrays to check machine pressure and stop problems. Robots on these lines handle boxes and products gently. Force sensors measure pressure at every step to keep items safe.

SOUSHINE FSRs work well in tough automation lines. They last long and handle hard jobs. Factories use these sensors to watch joint movement in wearable robots. This helps workers move better. In warehouses, robots with SOUSHINE FSRs check force when handling boxes. This keeps robots and people safe.

| Application Area | SOUSHINE FSR Benefit |

|---|---|

| Robotic Grippers | Checks grip force, protects items |

| Remote Surgery | Gives feedback for careful control |

| Wearable Robots | Watches joint movement, helps mobility |

| Factory Machines | Stops breakdowns, keeps things safe |

| Warehouse Handling | Keeps robots and people safe |

SOUSHINE FSRs help robotics grow and improve. They let engineers build smarter and safer machines.

In Automotive

Airbag Systems

Car engineers use force sensors to make airbags safer. These sensors help cars act fast in a crash. When a crash happens, the sensor feels the impact. It sends a signal to open the airbag at the right time. The system often has a steel ball that moves quickly. This ball starts an electric circuit when the car stops fast. This setup makes sure airbags protect people at the right moment.

- Force sensors help airbags open at the right time.

- Crash detection is quicker and works better.

- Electric circuits turn on fast when the car slows down.

SOUSHINE’s Force Sensing Resistors (FSRs) give new options for airbags. Their flexible shape fits in small spaces in the dashboard. The sensors react fast, so airbags open with good timing. Drivers and passengers feel safer because their car uses smart technology.

Safety begins with smart sensors. SOUSHINE FSRs help keep every trip safe.

Seat Detection

Seat detection makes cars safer for everyone. Cars use seat weight sensors to decide how airbags should work. Without these sensors, airbags might open when they should not. This could hurt lighter people. The sensors check the weight when someone sits down. They help the car know if a child seat or an adult is there.

Force sensing resistors from SOUSHINE make seat checks more exact. They measure how weight spreads on the seat. The system uses this to tell who is sitting there, with about 90% accuracy. The sensors help the car know if it is a child or an adult. The airbag then works the right way for each person. The Supplemental Restraint System (SRS) needs these sensors to keep everyone safe.

SOUSHINE FSRs work well for seat detection. They last a long time and stay accurate. The sensors help cars make smart choices and keep families safe.

Smart seats help make rides safer. SOUSHINE FSRs help every rider feel safe.

Tire Monitoring

Tire monitoring uses force sensors to keep cars running well. These sensors watch tire pressure and wear. They help drivers avoid crashes and save money. Engineers make systems that check strain signals in the tire. These signals show how much the tire wears out while driving. Drivers can guess tire health and change tires before trouble starts.

Modern tire monitoring checks many things, like pressure and wear. This tech helps cut rubber waste and keeps tires in good shape. Cars with these systems use less energy and are safer on the road.

| Study Title | Key Findings |

|---|---|

| Improvement in and Validation of the Physical Model of an Intelligent Tire Considering the Wear | Strain signal curves show tire wear, so drivers can guess tire health while driving. |

| A Comprehensive Study on Technologies of Tyre Monitoring Systems and Possible Energy Solutions | Tire monitoring now checks strain and wear, making tires smarter and safer. |

| Tire pressure remote monitoring system reducing the rubber waste | Watching tire pressure cuts tire wear and waste, helping drivers in real ways. |

SOUSHINE FSRs are important for tire checks. Their flexible shape fits inside tires and wheels. The sensors give good data, helping drivers stay safe and save money. With SOUSHINE FSRs, every drive is safer and more reliable.

Every mile counts. SOUSHINE FSRs help cars stay strong and safe, mile after mile.

In Consumer Electronics

Smart Devices

Smart devices have changed how we use technology. Touch screens now feel easy and quick. Force sensors help make this happen. They let devices know where you touch and how hard you press. A light tap can open an app. A hard press can show more choices. Devices react to different pressure levels. This makes using them more fun.

Companies use force sensors to stop mistakes. These sensors work with touchscreens to tell real presses from quick brushes. This helps people use smart devices without problems. SOUSHINE FSRs help make thin and fast products. These sensors save energy and react quickly. They help build smart home controls and wearable gadgets. Designers get new ideas for personal assistants.

Force sensors in smart devices help people do more and feel sure about their actions.

Gaming Controllers

Gaming controllers are now more fun and advanced. Force sensors give players better control. When you press a button, the sensor checks how hard you press. This lets you steer gently or attack with power. Every move in the game feels important.

- Force sensors help players control games smoothly.

- Players can move at different speeds or aim better.

- Games use different commands based on how hard you press.

Some controllers use sensors that last longer. These sensors stop problems like stick drift. SOUSHINE FSRs help make strong controllers. Players can play for hours and enjoy new ways to win.

Every press matters. Force sensors make gaming more exciting and real.

Bathroom Scales

Bathroom scales use force sensors to show your weight. When you step on the scale, the sensor checks the force. It turns this into a number you can read. Digital scales use smart designs for better results. Strain gauges inside the scale find small pressure changes. Load cell circuits turn these changes into clear numbers.

| Sensor Series | Features | Applications |

|---|---|---|

| ESP Series | High accuracy, single-point design, affordable | Electronic scales, bathroom scales |

| LSP Series | Low capacity, low cost, highly accurate | Electronic scales, bathroom scales |

SOUSHINE FSRs help scales work well and save power. Their flexible shape fits slim, modern scales. Families trust these scales to watch health and reach goals. Every step on the scale helps people live better and healthier lives.

Choosing Force Sensors

Application Needs

Picking force sensors starts with knowing what they need to do. Engineers think about what the device will measure. Some devices need to sense a soft touch. Others must handle strong pressure. Where the sensor goes is important too. Car sensors face heat and shaking. Medical sensors must be safe near people. Designers pick sensors that fit their product’s shape. Small gadgets need thin sensors. Big machines need larger, tougher ones.

Here is a table with key things to look for when picking force sensors:

| Criteria | Description |

|---|---|

| Durability | The sensor should last through hard use and tough places. |

| Environment | Sensors must work in dust, wet spots, or hot and cold areas. |

| Form Factor | The sensor’s size and shape should match the device. |

| Repeatability | Sensors need to give the same results every time. |

| Sensitivity | The sensor should sense the right amount of force for the job. |

| Cost | The sensor should have good features and not cost too much. |

Tip: Engineers who know what their project needs can pick force sensors that help them do well.

Performance Criteria

How well force sensors work matters a lot. Each sensor has special things that help it do its job. Sensitivity shows if the sensor can find small changes. Response time tells how quickly the sensor reacts. Linearity means the sensor’s output matches the force put on it. Repeatability helps users trust the sensor’s results. Durability keeps the sensor working after lots of use.

Important performance points include:

- Sensitivity level affects how well the sensor finds force.

- Linearity shows if the output matches the force put on it.

- Hysteresis affects how the sensor reacts to changes in force.

- Repeatability checks if the sensor gives the same result each time.

- Temperature changes can change how the sensor works.

- Overload protection keeps the sensor safe from harm.

Engineers look at these things before picking custom force sensors for their projects. They want sensors that work well, last long, and fit their needs.

SOUSHINE Selection

SOUSHINE helps engineers get the best custom force sensors for any job. Their team helps from design to delivery. Customers can ask for sensors in special shapes or sizes. SOUSHINE offers choices for logos, boxes, and pictures. They even make sensors from drawings or samples. Small orders can start with just two pieces for some custom options.

Here is a table showing SOUSHINE’s custom choices:

| Customization Type | Minimum Order |

|---|---|

| Customized logo | 2 pieces |

| Customized packaging | 2 pieces |

| Graphic customization | 2 pieces |

| Minor customization | N/A |

| Drawing-based customization | N/A |

| Sample-based customization | N/A |

| Full customization | N/A |

SOUSHINE is known for quality and expert help. Their custom force sensors help teams make products that help people. Engineers trust SOUSHINE to give sensors that work for every challenge.

SOUSHINE’s focus on custom options and support helps inventors reach new goals.

Force sensors help us every day and make technology better. People use them to keep balance, get support, and use smart devices. The table below shows how these sensors make life easier and safer:

| Finding | Description |

|---|---|

| Small forces matter | Help people stay balanced and supported |

| Personalized solutions | Work for many different people |

| Better design | Make things safer for older adults |

SOUSHINE FSRs come in many shapes, last a long time, and are simple to add to products. New ideas, like bendy electronics, will bring force sensors to healthcare, games, and smart shoes. There are many new ways force sensors can help us in the future.

FAQ

What is a force sensor?

A force sensor checks how much pressure touches something. Engineers put these sensors in lots of devices. They help machines know about touch, weight, and movement. You can find force sensors in smartwatches, cars, and robots.

How do SOUSHINE FSRs improve technology?

SOUSHINE FSRs give very accurate force readings. Their flexible shape fits many different products. These sensors last long and use little power. Teams trust SOUSHINE FSRs to make devices smarter and safer.

Where can people find force sensors in daily life?

People see force sensors in bathroom scales, gaming controllers, and smart devices. Cars use them for airbags and seat checks. Hospitals use force sensors in patient monitors and prosthetics.

Why do engineers choose force sensing resistors?

Engineers pick force sensing resistors because they bend and last long. These sensors fit in small spaces. They work with many shapes and sizes. SOUSHINE FSRs have custom choices for special projects.

Can force sensors help keep people safe?

Force sensors help protect people in cars and factories. Airbags open at the right time because of these sensors. Robots use force sensors to stop accidents. Hospitals use them to keep patients safe.

How do force sensors save energy?

Force sensors use very little power. Smart devices with SOUSHINE FSRs last longer without charging. Energy-saving sensors help homes and businesses spend less money.

What should teams consider when choosing a force sensor?

Teams check durability, sensitivity, and size. They see if the sensor fits their device. SOUSHINE helps with custom designs. Engineers pick sensors that match their project.

Are SOUSHINE FSRs easy to add to new products?

SOUSHINE FSRs come in many shapes and sizes. Their team helps with design and support. Engineers add these sensors to products fast. SOUSHINE makes adding sensors simple and reliable.