Call us: +86-137-2353-4866

SOUSHINE FSR, Interlink 408, and Ezweiji FSR are top extra-long force-sensitive resistor choices for 2025. These sensors help make projects smarter in cars, healthcare, robots, and electronics. The table below shows how many industries use them:

| Industry | Market Size | Key Applications |

|---|---|---|

| Automotive | Largest segment | Motor control, steering, brakes, ADAS |

| Industrial Automation | Rapid growth | Robotics, packaging, inspection |

| Healthcare | Expanding | Patient monitoring, diagnostics |

| Consumer Electronics | Growing | Touch interfaces, wearables |

Big improvements in force sensing resistor technology include being better for the environment, using nanotechnology, and working with AI. A force sensor can now be made to fit your needs, last longer, and cost less. It is easier to read an fsr or wire an fsr because of these changes. Users can find a simple fsr overview and helpful answers for tough projects.

Table of Contents

Key Takeaways

- Extra-long force-sensitive resistors help projects work better. They cover bigger spaces, so they fit many uses. People use them in cars, hospitals, and robots.

- Engineers like that extra-long FSRs are thin and bend easily. This makes it simple to put them in tight or curved spots. You do not have to change the main design.

- These sensors can sense both soft and hard pressure. This makes them useful for many jobs. You do not need lots of different sensors.

- When you pick an FSR, look at its length, shape, and how sensitive it is. Make sure it fits what your project needs.

- It is important that FSRs last a long time. Pick ones that can handle lots of use in tough places. This helps you spend less on fixing or replacing them.

- Make sure the FSR works with your system’s voltage and current. This helps it work its best. Always read the datasheet before you set it up.

- Signal conditioning helps FSRs give better and clearer data. This helps teams get good results in their projects.

- Cheaper choices like SOUSHINE, Interlink 408, and Ezweiji FSRs work well. They are good for many projects in schools and businesses.

Why Choose Extra-Long Force-Sensitive Resistors

Benefits of Extra-Long FSRs

Engineers pick extra-long force-sensitive resistor models because they cover more area. This means you can change the sensing spot to fit your project. These force-sensing resistors are very thin and easy to add to different systems. Teams can put them in small spaces or on curved things without changing the main design.

- The bigger area helps measure force better on large surfaces.

- You can change where the sensor goes to fit your needs.

- The thin shape makes it easy to use in small devices.

- The flexible design works with hard and soft materials.

Extra-long force-sensitive resistor choices can measure both light and strong pressure. You only need one sensor for different pressures. The sensor gives a clear and steady signal, so it is easier to use. Engineers can change the signal for different jobs, which makes the data better.

Applications in Modern Projects

Extra-long force-sensitive resistor technology is used in many fields. Car engineers use force-sensing resistors to make cars safer and more comfortable. These sensors help check if someone is sitting in a seat and watch pressure in brakes. In healthcare, force sensing resistor devices help doctors watch patients and use therapy tools.

- Micro-needle therapy uses force-sensitive resistors to give the right amount of medicine and find blockages.

- CPR treatment uses sensors to check how hard someone presses, so helpers use safe pressure.

- Connected devices use force-sensing resistors to watch health and track medicine in real time.

Robotics teams use extra-long force-sensitive resistor solutions to help robots feel things. This lets robots touch objects and people safely. The signal in these systems is easy to change, so robots can react fast and measure force well. People who design electronics use these sensors in touch screens and wearables, making devices work better and last longer.

Force-Sensing Resistors: Key Selection Criteria

Length and Form Factor

Project teams need to pick the right length and shape for their force-sensing resistor. The size and shape decide how well the sensor fits in a device. FSRs can be round, square, or rectangle. Square sensors are good for checking big areas. Round sensors are better for careful measuring. Extra-long FSRs are great for seats, mats, or medical pads because they cover more space.

| Characteristic | Description |

|---|---|

| Shape and Size | Circular for careful measuring, square for big areas, rectangle for more choices |

| Length | Longer sensors check force on wide spaces |

| Form Factor | Thin and bendy, easy to put on flat or curved things |

Designers like thin and bendy FSRs. These sensors fit in small spots and can go around curves. The right shape helps engineers keep their product design the same. Teams can put sensors where they need them most. This makes force measuring more correct.

Sensitivity and Response

Sensitivity and response are important for advanced projects. The sensing range shows the smallest and biggest pressure the sensor can feel. Lower force ratings make the sensor more sensitive. Too much force can break the sensor. The turn-on threshold means the sensor only works when enough force is there. If the force is too low, the resistance stays high and the signal does not change much.

FSRs measure pressure all the time, not just on or off. This helps with signal conditioning, which makes the sensor’s output better. Engineers use signal conditioning to match the sensor’s range to their needs. A big range lets the sensor feel both soft and hard pressure. This makes it good for many jobs.

Tip: Always look at the sensor’s sensing range and turn-on threshold before picking an FSR for your project.

Durability and Build

Durability and build are important for sensors that last a long time. FSRs need to handle lots of pressing and tough places. Makers use bendy bases and special layers to make strong sensors. These parts help the sensor last longer and not wear out fast.

Teams should pick FSRs that are made well. A strong sensor means less fixing and fewer replacements. In cars and healthcare, sensors must work well all the time. Engineers often choose FSRs that are built tough to make sure they work right.

A good FSR keeps working and gives the right signal, even after many uses. This helps teams make smart projects and safe products.

Compatibility

Compatibility is very important when picking force-sensing resistors. Engineers need to check if the FSR works with their system’s voltage and current. Some FSRs need special circuits for signal conditioning. These circuits help the sensor’s output match the device’s input. If the sensor does not fit the system, the signal may not work right.

Project teams use FSRs with microcontrollers and control boards. The sensor’s output must fit the input range of these devices. Some FSRs work best with certain signal conditioning types. This step helps make the data more accurate and reliable.

Note: Always look at the datasheet for voltage and current limits before you connect the sensor.

Engineers also check the connector type. Some FSRs use solder pads. Others use snap connectors or flexible cables. The right connector makes it easier to install and helps avoid mistakes. Teams should think about the sensor’s size and shape. The FSR must fit in the space and work with other parts.

Compatibility affects how well the sensor works in the product. A good match between the FSR and the system means better performance and fewer problems during testing.

Price and Value

Price and value are important for every project. Teams want sensors that fit their budget and work well. Extra-long force-sensitive resistors often cost less than other sensors. Makers use simple materials and easy steps to make them. This keeps prices low and makes FSRs a good choice for many projects.

A study shows FSRs made from pencil graphite and silicone sealant can work like commercial sensors. These hand-made sensors cost less and work well for tight budgets. This makes FSRs smart for schools, startups, and big companies.

FSRs can measure both light and heavy pressure. This adds value because one sensor can do many jobs. Teams do not need to buy different sensors for each task. This saves money and time.

Signal conditioning adds more value. With the right circuits, teams can adjust the sensor’s output. This helps get the best data from the FSR. Good signal conditioning means fewer mistakes and better results.

When looking at price and value, teams should check the sensor’s lifespan, how easy it is to use, and support from the maker. A sensor that lasts longer and works well with other parts gives better value over time. Teams should also see if the supplier helps with installation or fixing problems.

Tip: Pick FSRs that balance cost, performance, and support for the best results in your project.

Top Extra-Long Force-Sensitive Resistor Picks 2025

SOUSHINE Force Sensing Resistor

Key Specs

| Specification | SOUSHINE FSR | Industry Standard |

|---|---|---|

| Sensitivity | High sensitivity to force changes | Comparable to leading FSRs |

| Durability | Robust in demanding environments | Meets or exceeds benchmarks |

| Versatility | Customizable shapes and sizes | Widely adaptable |

| Power Consumption | Low power requirements | Standard for similar devices |

| Application Areas | Automotive, Healthcare, Robotics, Consumer Electronics, Industrial, Aerospace & Defense | Common across industries |

Pros and Cons

Pros:

- It can measure force very accurately.

- You can change its shape for different uses.

- It is strong and works in tough places.

- It does not use much power.

Cons:

- Making special shapes can take more time.

Best Use Cases

- It checks if someone is sitting in a car seat.

- It helps doctors watch patients in hospitals.

- Robots use it to feel how hard they grip things.

- Factories use it to map pressure in machines.

- It is used in airplane control panels.

User Feedback

People say SOUSHINE FSRs work well in tests and real products. Engineers like that it is easy to fit into their designs. Teams also say it works well with microcontrollers. Many users trust it because it gives good results again and again.

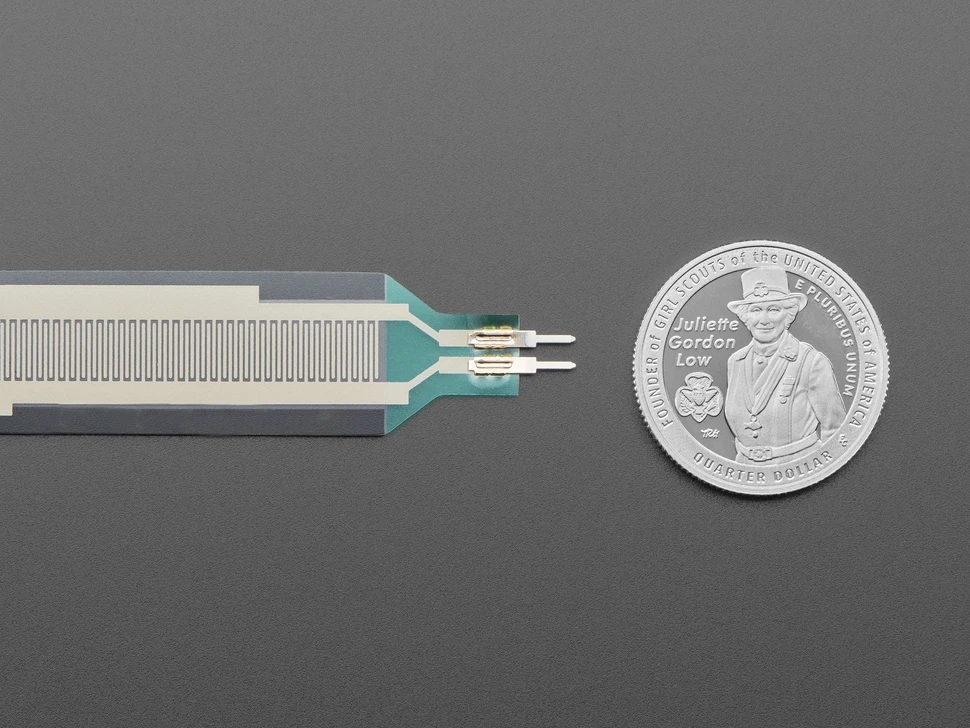

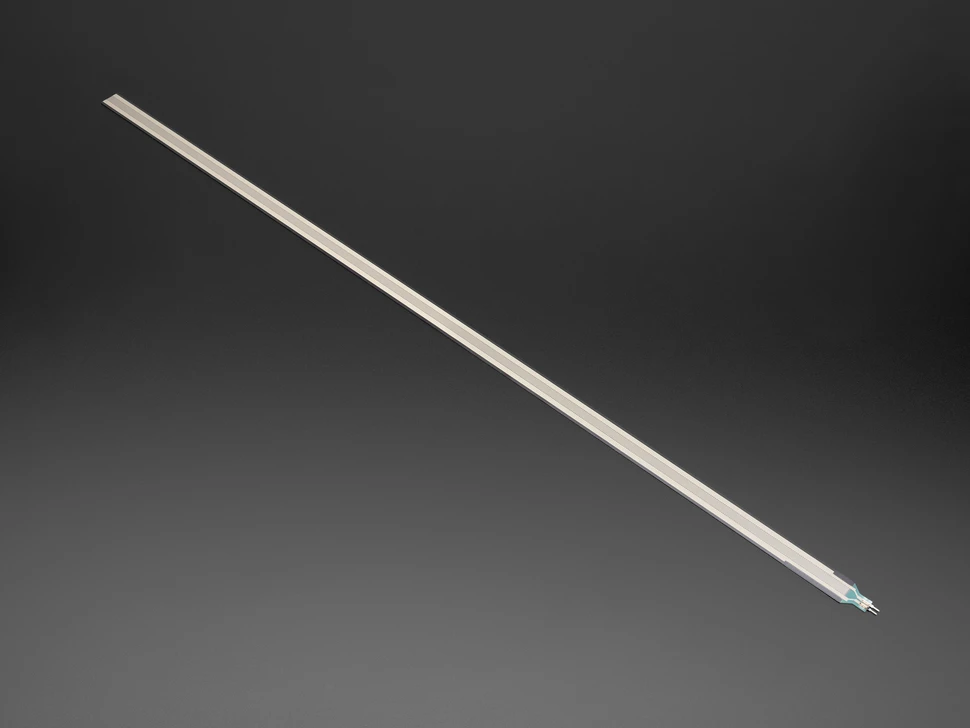

Interlink 408 Extra-Long FSR

Key Specs

| Feature | Specification |

|---|---|

| Model | FA408 |

| Dimension | 171.61 × 12 mm |

| Sensing Dimension | 160 × 12 mm |

| Force Measuring Range | 200g ~ 20KG |

| Thickness | ≤0.3 mm |

| Force Repeatability (Single Part) | ±2.5% (8KG, 10 times) |

| Force Repeatability (Part to Part) | ±20% |

| Off Resistance | 2MΩ |

| Hysteresis | 10% average |

| Response Time | <1 ms |

| Working Temperature | -30℃~60℃ |

| Connector | Multiple options |

Pros and Cons

Pros:

- It is very thin and fits in small spaces.

- It can measure light and heavy forces.

- It reacts very fast to changes.

- It lasts a long time before wearing out.

Cons:

- Sensors may not match exactly in big groups.

Best Use Cases

- Robots use it to sense how hard they grab things.

- It helps measure how people or animals walk.

- It checks if someone is sitting in a wheelchair.

- It is used in electronic music tools.

- It goes in smart boxing gloves.

- It helps measure pressure in shoe insoles.

User Feedback

Teams pick the Interlink 408 for its high sensitivity and long life. Many people say it is simple to set up and reacts quickly. Some engineers say you need to adjust it when using many sensors together.

Ezweiji Force-Sensing Resistor

Key Specs

| Specification | Description |

|---|---|

| Force Sensitivity Range | 0.2N (20g) to 20N (2kg) or more, model dependent |

| Operating Voltage | 1V to 5V, microcontroller compatible |

| Response Time | Milliseconds, suitable for real-time use |

| Durability | Withstands millions of actuations |

| Linearity | Non-linear, often linearized by calibration |

| Operating Temperature Range | -30°C to +70°C |

| Thickness and Flexibility | 0.2mm to 1mm, integrates into many surfaces |

| Resistance Range | Several megaohms (no load) to a few hundred ohms (max load) |

| Actuation Force | Minimum 20g for measurable resistance change |

| Repeatability and Drift | ±2% to ±5% repeatability |

Pros and Cons

Pros:

- It can sense both small and big forces.

- It reacts quickly for real-time jobs.

- It is thin and bends to fit many places.

- It gives steady results over time.

Cons:

- You must adjust it to get exact numbers.

Best Use Cases

- Hospitals use it to check if someone is in bed.

- It helps watch fluid levels in medical pumps.

- It tracks supplies in hospitals.

- Robots use it to feel objects with their fingers.

- It helps robots balance by sensing foot force.

- It keeps people safe by sensing touch on robots.

User Feedback

Doctors use Ezweiji FSRs to watch patients and supplies. Robot teams use them for grip and balance. People like that it reacts fast and works for a long time. It is trusted for projects that need a wide range and strong signals.

Extra-Long Force-Sensitive Resistor Comparison

Feature Overview

Engineers look at the main features when they compare extra-long force-sensitive resistors. The table below shows how SOUSHINE, Interlink 408, and Ezweiji FSRs are different in important ways:

| Feature | SOUSHINE | Interlink 408 | Ezweiji |

|---|---|---|---|

| Principle | Piezoresistive | Changes resistance with force | Piezoresistive |

| Shape and Size Options | Customizable | Thin and flexible | Thin, flexible, various lengths |

| Power Consumption | Low | Low | Low |

| Applications | Cars, hospitals, robots, industry | Smart insoles, pressure mapping | Healthcare, robotics, wearables |

| Pros | Versatile, strong design | Affordable, easy to use | Fast response, steady output |

| Cons | No major issues reported | Limited durability tests | Needs calibration |

This table helps teams pick the right sensor for their project. SOUSHINE can be made in many shapes and works in hard places. Interlink 408 is very thin and simple to set up. Ezweiji reacts quickly and gives a steady signal.

Performance Differences

SOUSHINE FSRs are very accurate when measuring force. They last through many uses without breaking. Teams use them in cars, hospitals, and robots because they are reliable. Interlink 408 is good for projects that need a thin sensor. It reacts fast and fits in small spaces. Some teams see small changes between sensors when they use a lot of them. Ezweiji FSRs give quick feedback and work right away. They need to be adjusted for best results but stay steady after many uses.

All these sensors can use signal conditioning. This helps engineers make the sensor’s output match their system. Teams get better data and make fewer mistakes with the right circuits.

Value Comparison

SOUSHINE is a good choice for teams that want custom shapes and long-lasting sensors. Its design works for many jobs, like cars and airplanes. Interlink 408 costs less and is good for simple projects. It is best for projects with lots of sensors or small spaces. Ezweiji is a good value for teams that need fast and steady signals. It works well in healthcare and robots.

Note: Teams should choose a sensor that matches what their project needs. The right sensor saves time and money.

Choosing the Right Force Sensing Resistor

Matching Features to Projects

Teams pick force-sensing resistors by thinking about their project. They check how big the area is that needs measuring. Big seats or mats need extra-long FSRs. Small gadgets use shorter sensors. Teams also look at how much force the sensor must sense. Some projects need to feel light touches. Others need to sense strong pressure.

Engineers pick sensors with shapes that fit their design. Flexible sensors bend to fit curves. Thin sensors fit in small spaces. Teams check how fast the sensor reacts. Fast sensors help in robots and healthcare. They also see if the sensor works with their microcontroller. Signal conditioning helps match the sensor’s output to the system. Teams want sensors that last a long time for cars or hospitals.

Tip: Always pick the right length, shape, and force range for your job. This helps you get good data and better results.

Installation Tips

Good installation makes sure the sensor works right. FSRs do not have a set direction, so you can connect them either way. Many engineers use breadboards or clamp connectors for easy setup. Terminal blocks are also used. Soldering is okay, but you must work fast to keep the sensor safe.

Here is an easy way to connect an FSR to a microcontroller:

- Connect one end of the FSR to power.

- Attach the other end to a pull-down resistor that goes to ground.

- Link the spot between the FSR and resistor to the analog input on the microcontroller.

Teams often add a fixed resistor to make a voltage divider with the FSR. This lets the sensor act like a potentiometer. Placing the sensor in the right spot helps get good readings. Testing the setup before finishing helps stop mistakes.

Mistakes to Avoid

Teams sometimes make mistakes with FSRs. Soldering too slowly can melt the plastic and break the sensor. Soldering quickly keeps it safe. Picking the wrong resistor changes the readings. Bigger resistor values make bigger jumps in the output. Putting the sensor in the wrong place gives bad measurements. Testing the spot before sticking it down helps stop problems.

- Solder wires fast to keep the sensor safe.

- Pick the right resistor for good scaling.

- Place the sensor carefully and test before finishing.

Note: Careful planning and testing help teams avoid mistakes and make their projects better.

Engineers think extra-long force-sensitive resistors help make projects smarter. SOUSHINE can be made in different shapes and is strong for cars and factories. Interlink 408 works well in robots and hospitals because it reacts fast and bends easily. Ezweiji is good for electronics because it is thin and gives steady signals. Teams need to look at how tough, sensitive, and expensive the sensor is before picking one. If you want to learn more, Melexis and XJCSENSOR have guides about advanced force-sensing and how to use them.

FAQ

What is an extra-long force-sensitive resistor?

An extra-long force-sensitive resistor checks force on big areas. Engineers put it in seats, mats, and medical pads. The sensor can bend and fit many shapes.

How does a force-sensitive resistor work?

A force-sensitive resistor changes resistance when you press it. The sensor sends a signal to a microcontroller. The device reads the signal and shows the force.

Where can teams use extra-long FSRs?

Teams use extra-long FSRs in cars, hospitals, robots, and electronics. The sensor checks seat pressure, patient moves, robot grip, and touch in devices.

How do you connect an FSR to a microcontroller?

Connect one end of the FSR to power. Attach the other end to a resistor and ground. Connect the middle spot to the analog input on the microcontroller.

What is signal conditioning for FSRs?

Signal conditioning changes the sensor’s output. Engineers use circuits to match the sensor’s signal to the system. This step helps get the right data.

Can FSRs measure both light and strong pressure?

FSRs can measure both light and strong pressure. One sensor works for many force levels. Teams use it for different jobs without changing the sensor.

How long do force-sensitive resistors last?

A force-sensitive resistor lasts through many uses. Makers build it for tough places. The sensor keeps working and gives steady signals for a long time.

What mistakes should teams avoid when installing FSRs?

Teams should solder wires fast. They must pick the right resistor for scaling. Putting the sensor in the right spot helps get good readings.