Call us: +86-137-2353-4866

Choosing the right force measurement solution helps your project work well. SOUSHINE is known for being a top company in force sensing resistor technology. They offer dependable choices for important industries. You can find force sensing products making jobs easier in automotive, healthcare, and robotics.

- The global force sensor market may reach USD 3.93 billion by 2035.

- The market will keep growing at a CAGR of 5.0% from 2025 to 2035.

- Automotive, healthcare, and robotics help this growth happen.

As you read, think about your needs, your budget, and what your project requires.

Table of Contents

Key Takeaways

Picking the right force measurement solution helps your project do well and saves time. SOUSHINE has many force sensing resistors that work in cars, hospitals, and robots. The global force sensor market will grow a lot, so more people want these tools. Look at important things like accuracy, how long it lasts, and the type of technology when you pick a force measurement tool. Force measurement tools help with quality control because they find and fix problems early. Using new sensors can save money by stopping big breakdowns and making things work better. Think about what you need, how much money you have, and where you will use it before you choose a force measurement solution. Good customer support and warranty choices are important for being happy with your force measurement tools for a long time.

Force Measurement Solutions Compared

Product Lineup Overview

There are many force measurement solutions to pick from. SOUSHINE makes Force Sensing Resistors that work well in cars, hospitals, and robots. Mark-10 sells digital force gauges for testing by hand or on a bench. Interface has load cells for factories and research labs. IMADA builds custom systems for special jobs. Tekscan’s ELF System lets you map pressure in different ways. DWS, AMTI, Transducer Techniques, and Cross all offer special gauges and sensors for different tasks. You can find something for every price and need.

Key Features Table

The table below shows the main features of top force measurement products. It helps you see what makes each product different.

| Brand/Product | Technology | Shape & Size Options | Power Use | Output Type | Accuracy | Durability | Typical Use Cases |

|---|---|---|---|---|---|---|---|

| SOUSHINE FSRs | Piezoresistive | Customizable | Low | Non-linear | Moderate | Strong | Cars, hospitals, robots |

| Mark-10 Force Gauges | Strain Gauge | Handheld/Bench | Moderate | Digital/Analog | High | High | Lab, manufacturing |

| Interface Load Cells | Strain Gauge | Various | Moderate | Linear | High | High | Industrial, R&D |

| IMADA Custom Solutions | Strain Gauge | Custom | Moderate | Digital/Analog | High | High | Custom, specialty |

| Tekscan ELF System | Resistive Film | Flexible | Low | Digital | Moderate | Moderate | Pressure mapping |

| DWS Force Gauges | Mechanical/Digital | Handheld | Low | Digital/Analog | High | High | Quality control |

| AMTI Load Cell Systems | Strain Gauge | Platform/Custom | Moderate | Linear | High | High | Biomechanics, research |

| Transducer Techniques | Strain Gauge | Tension/Compression | Moderate | Linear | High | High | Industrial, testing |

| Cross Gauges | Mechanical/Digital | Handheld/Panel | Low | Digital/Analog | Moderate | High | General measurement |

Tip: When you look at products, check the technology, accuracy, and durability. These things affect how well your force measurement tool works.

Applications Overview

Force measurement tools are used in many fields. In aerospace, engineers use sensors to test safety and performance. Car makers use force measurement for building and checking vehicles. Energy companies use these tools to watch equipment and keep things safe. Medical device makers use force measurement for patient care and rehab. Factories use force measurement to help machines work safely and well.

- Aerospace: Safety and performance testing

- Automotive: Manufacturing and vehicle testing

- Energy: Monitoring and safety

- Medical: Devices and equipment

- Industrial Automation: Machine safety and efficiency

You can pick a solution that fits your job. Some are best for research. Others are good for everyday use.

Benefits Summary

Picking the right force measurement solution gives you many good things. Each product has its own special strengths, but they all help you work better and faster.

- You get more control over your work. Good force data helps you make quick changes and keep things working well.

- You make fewer mistakes and get better quality. Reliable sensors and gauges help you find problems early, so you can fix them before they get worse.

- You save money in the long run. Advanced force measurement tools give you the information you need to plan repairs and stop expensive breakdowns.

- You work more efficiently. When you know the exact force used, you can adjust machines and jobs for the best results.

- You spot and fix waste. Force measurement shows where energy or materials are lost, so you can make changes to save money.

- You help keep things safe and follow rules. Many jobs need careful testing and checking. These solutions help you meet those rules with confidence.

Tip: Using advanced force measurement products helps you find problems and make things better. This means you spend less and get more done.

You also get features like designs you can change, digital screens, and easy ways to connect with other systems. Brands like SOUSHINE have flexible choices that fit your needs, whether you work with cars, healthcare, robots, or factories. With expert help and trusted technology, you can focus on your work and trust your measurements every time.

Picking the right solution means you get correct results, save time, and keep your work safe. No matter what job you do, buying good force measurement tools helps you succeed for a long time.

Top Force Measurement Product Reviews

SOUSHINE Force Sensing Resistors (FSRs)

Usability & User Experience

SOUSHINE FSRs are simple to use in many projects. Their thin and bendy shape lets you put them in small or curved spots. You can connect them to electronics with easy wires. Many engineers say setup is fast. You do not need special tools or training to use them. The sensors react quickly to touch and pressure. You get feedback right away. This makes them good for beginners and experts.

Accuracy & Reliability

SOUSHINE FSRs give steady and exact results. When you press on them, the resistance changes in a way you can expect. This means you get correct readings each time. The sensors work well in many places, even if things change. You can count on them to last a long time. The table below shows how SOUSHINE FSRs and other brands compare:

| Feature | SOUSHINE’s FSRs | Competitors’ FSRs |

|---|---|---|

| Accuracy | Superior | Varies |

| Durability | High | Moderate |

| Customization | Extensive | Limited |

| Low Power Consumption | Yes | Varies |

| Ease of Integration | Simple | Complex |

You can see SOUSHINE FSRs are better for accuracy, strength, and easy use.

Customization & Versatility

You can change SOUSHINE FSRs to fit what you need. Pick the size, shape, and output that works for your project. You can also set the calibration for your job. This makes them useful in many fields like cars, healthcare, robots, and electronics. The sensors work well in tough jobs and hard places. Many people say SOUSHINE FSRs do well in tests and real life. Engineers like how easy they fit into new ideas. You can trust these sensors to work every time.

| Specification | SOUSHINE FSR | Industry Standard |

|---|---|---|

| Sensitivity | High sensitivity to force changes | Comparable to leading FSRs |

| Durability | Robust in demanding environments | Meets or exceeds benchmarks |

| Versatility | Customizable shapes and sizes | Widely adaptable |

Support & Service

SOUSHINE gives strong help from start to finish. Their team helps you pick the right sensor and shows you how to set it up. If you have questions, you get fast answers from experts. You can ask for custom options, and they will work with you. SOUSHINE also checks quality and helps after setup. This support helps you get the best from your force measurement system.

Mark-10 Force Gauges

Usability & User Experience

Mark-10 Force Gauges are easy to use. The digital screens are clear and simple to read. You can use them by hand or on a bench. The controls are easy, so you can start testing fast. Many people like the light weight and comfy grip. You do not need much training to use these gauges.

Accuracy & Reliability

Mark-10 Force Gauges are very accurate for many jobs. The sensors use strain gauge technology for exact results. You can trust the numbers for small and big forces. The gauges keep working well, even if you use them a lot. Many labs and factories use these gauges every day.

Versatility & Support

You can use Mark-10 Force Gauges in labs, factories, and quality rooms. The company has many models for different force levels. You can get help from their support team if you need it. Mark-10 gives manuals, videos, and quick help to make sure you do well.

Interface Load Cells

Usability & User Experience

Interface Load Cells are made for easy use in factories and labs. They come in many shapes and sizes, so you can pick what you need. You can set them up fast, and the connectors make it simple. The clear signals help you get data without trouble.

Accuracy & Reliability

Interface Load Cells are known for being very accurate. The company makes high-performance load cells for testing and automation. The table below shows how Interface compares to other brands:

| Brand | Accuracy and Precision | Notes |

|---|---|---|

| Interface Inc. | High | Focuses on high-performance load cells for automation and testing. |

| HBM | Ultra-high | Best for applications demanding high accuracy. |

| Zemic | Reliable | Affordable options for cost-sensitive projects. |

| Honeywell | Seamless integration | Preferred for smart diagnostics. |

| Hitec Products | Specialized | Tailored solutions for industrial/aerospace. |

You can trust Interface Load Cells for jobs that need exact force measurement.

Versatility & Support

You can use Interface Load Cells in many fields like factories, research, and automation. The company has many models for different needs. If you need help, Interface gives technical support and clear guides. You can get advice on picking the right load cell and tips for setup.

IMADA Custom Solutions

Usability & User Experience

IMADA Custom Solutions are made for special projects. You get a tool that fits your needs. The instructions are clear and easy to follow. The controls are simple, so you can start fast. You do not need to be an expert to use them. You can hold the device in your hand or add sensors to machines. IMADA helps you from the start to make things easy.

Note: IMADA’s team talks with you to learn what you need before they suggest a solution.

Accuracy & Reliability

IMADA Custom Solutions give you exact results every time. The readings stay the same, even in tough places. The sensors use strain gauge technology for high accuracy. They work for both small and big forces. You can trust the numbers for checking quality, research, or making things. IMADA checks each system before sending it to you, so you get a product you can count on.

| Feature | IMADA Custom Solutions |

|---|---|

| Technology | Strain Gauge |

| Accuracy | High |

| Calibration | Customizable |

| Reliability | Excellent |

Versatility & Support

IMADA Custom Solutions work in many jobs. You can use them in factories, labs, or for special tests. There are many models and custom choices. Experts help you with answers fast. IMADA gives you guides, videos, and help when you need it. You can ask for service or calibration to keep your system working well.

Tekscan ELF System

Usability & User Experience

The Tekscan ELF System helps you see pressure and force on surfaces. The sensors bend to fit small or odd spaces. You set up the system with easy software. The digital screen shows results right away, so you see changes fast. You do not need special skills to use it. The sensors react quickly and give you instant feedback.

Tip: The ELF System lets you see how force spreads out, so you can find problems easily.

Accuracy & Reliability

Tekscan ELF System gives you steady data for force measurement. The resistive film sensors notice small pressure changes. The accuracy is moderate, which is good for mapping and study. The system works well in many places. You can set the sensors for your job, so you get the best results.

| Feature | Tekscan ELF System |

|---|---|

| Technology | Resistive Film |

| Accuracy | Moderate |

| Output | Digital |

| Reliability | Good |

Versatility & Support

You can use the ELF System for research, making new products, or medical tests. The flexible design lets you measure force on curved or bumpy surfaces. Tekscan gives you help, training, and online guides. You can ask their team for help or advice. The company updates the software often, so you get new features.

DWS Force Gauges

Usability & User Experience

DWS Force Gauges are easy to use. The handheld shape feels good in your hand. The digital screen shows numbers clearly. You start testing with simple buttons. DWS has both mechanical and digital models, so you choose what you like. You do not need much training to use them. The gauges react fast, so you get results quickly.

Alert: DWS Force Gauges help you keep quality high on production lines.

Accuracy & Reliability

DWS Force Gauges give you very accurate results. The sensors use trusted technology for good data. You can trust the numbers for quick checks or deep tests. The gauges work well in busy places and last through lots of use. DWS checks each gauge before you get it, so you know it will work.

| Feature | DWS Force Gauges |

|---|---|

| Technology | Mechanical/Digital |

| Accuracy | High |

| Output | Digital/Analog |

| Reliability | High |

Versatility & Support

You can use DWS Force Gauges in factories, labs, or for checking quality. The company has models for many force levels and uses. You get help from manuals, online guides, and customer service. DWS offers calibration and repair to keep your gauges working well. You can ask for help any time during your project.

AMTI Load Cell Systems

Usability & User Experience

AMTI Load Cell Systems are simple to use in labs and factories. The instructions are clear, so you know what to do. The screens and buttons are easy for anyone to understand. You can set up the load cells fast with normal connectors. Many people like how easy it is to adjust the settings. The digital displays show force numbers right away, so you see changes as they happen. You do not need special training to use these systems. This makes them a good pick for busy places.

Accuracy & Reliability

AMTI Load Cell Systems give you exact and steady results. You can trust the numbers, even in tough places. The sensors keep working well over time, so your data stays the same for every test. This is important when you need to keep things safe and high quality. Many jobs, like building and healthcare, use AMTI for trusted force measurement.

- Exact and steady results help you do good work in labs and factories.

- Safety and steady results are most important in places like building sites, where you must measure loads right to keep people and gear safe.

- More healthcare jobs now use AMTI load cells to help medical devices that need exact force numbers.

Versatility & Support

You can use AMTI Load Cell Systems in many kinds of work. They are good for biomechanics, robots, and factory machines. You can pick from different models for your job. AMTI gives strong help, like tech support and fixing services. If you have a question, you can ask their team and get a quick answer. The company also helps with setup and repairs to keep your tools working well.

Tip: AMTI’s team can help you pick the best load cell system for your project, making your work easier from start to finish.

Transducer Techniques Tension Load Cells

Usability & User Experience

Transducer Techniques Tension Load Cells make testing easy and quick. You can put them in place with normal tools. The small size fits into tight spots. The wiring guide shows you how to connect the sensors. You can see force numbers fast on digital screens or with data systems. Many people like how quickly the sensors react and how easy they are to use with other tools.

Accuracy & Reliability

You can trust Transducer Techniques Tension Load Cells for high accuracy and a big range. The TLL Series can measure from 500 to 3,000 pounds. These load cells give steady and repeatable results, so your data is always right. The table below shows how the TLL Series matches up with other tension load cells:

| Feature | TLL Series Load Cells | Other Tension Load Cells |

|---|---|---|

| Measurement Range | 500 to 3,000 lb | Varies by model |

| Accuracy | High | Varies by model |

You can use these load cells for testing materials, wires, and machines. The strong build means the sensors last a long time.

Versatility & Support

Transducer Techniques has load cells for many jobs. You can pick models for pulling, pushing, or both. The company gives clear guides and tech help to set up and care for your tools. If you need help, you can call their team for fast answers. The load cells work well in labs, factories, and field tests.

- Material testing

- Wire and cable testing

- Industrial machinery

Note: Transducer Techniques’ team can help you pick the right load cell for your force measurement needs.

Cross Mechanical & Digital Gauges

Usability & User Experience

Cross Mechanical & Digital Gauges make measuring force simple. You can use the mechanical ones for quick checks. The digital ones have screens that are easy to read. The gauges fit well in your hand, and the buttons are simple. Many people like that the gauges are light and easy to carry around.

Accuracy & Reliability

You can count on Cross Gauges for steady and correct numbers. The mechanical models use trusted parts for good results. The digital gauges give exact numbers and can save your data. You can use these gauges for quick checks or deeper tests. The strong build means the gauges last, even if you use them a lot.

Versatility & Support

Cross has many types of gauges for different jobs. You can pick handheld or panel models for your work. The company gives helpful guides and answers your questions. If you need to fix or check your gauge, Cross can help you keep it working well.

Tip: Cross Gauges are a good choice for measuring force in labs, shops, and on the production line.

Choosing a Force Measurement Solution

Define Your Application

You need to start by understanding your specific needs before selecting any sensor or system. Ask yourself a few key questions to guide your decision:

- Decide if you need one sensor or several for your project.

- Identify the type of force you want to measure—dynamic, static, or both.

- Determine how many axes you need to measure.

- Think about which force data matters most for your work.

- Check the environment where you will use the sensor. Look for electrical noise, temperature swings, humidity, pressure, vibration, and cleanliness.

- Measure the space you have for the sensor and see if you have limits on size or shape.

- Review your budget and the time you have for setup.

- List the electrical and mechanical connections you need.

- Make sure you have the right tools and people to install and use the sensor.

- Separate your must-have features from those that are just nice to have.

Tip: Write down your answers. This will help you compare products and find the best fit for your job.

Set Measurement Range & Accuracy

You must match the sensor’s range and accuracy to your application. Each sensor has a range it can measure and a level of accuracy it can deliver. For example:

- Load cell accuracy is often shown as a percentage of the reading or the full scale. If a sensor has ±0.5% accuracy, your reading may vary by 0.5% from the true value.

- A 10 kN load cell can measure forces as low as 100 N at 1/100th of its capacity, or even 10 N at 1/1000th.

- Measurement resolution tells you the smallest change in force the sensor can detect. With a 10 kN load cell and a 32-bit system, you can see changes as small as 4.7 micro-Newtons.

Note: Pick a sensor with a range that covers your highest expected force, but also gives good accuracy at lower levels.

Consider Budget & Cost

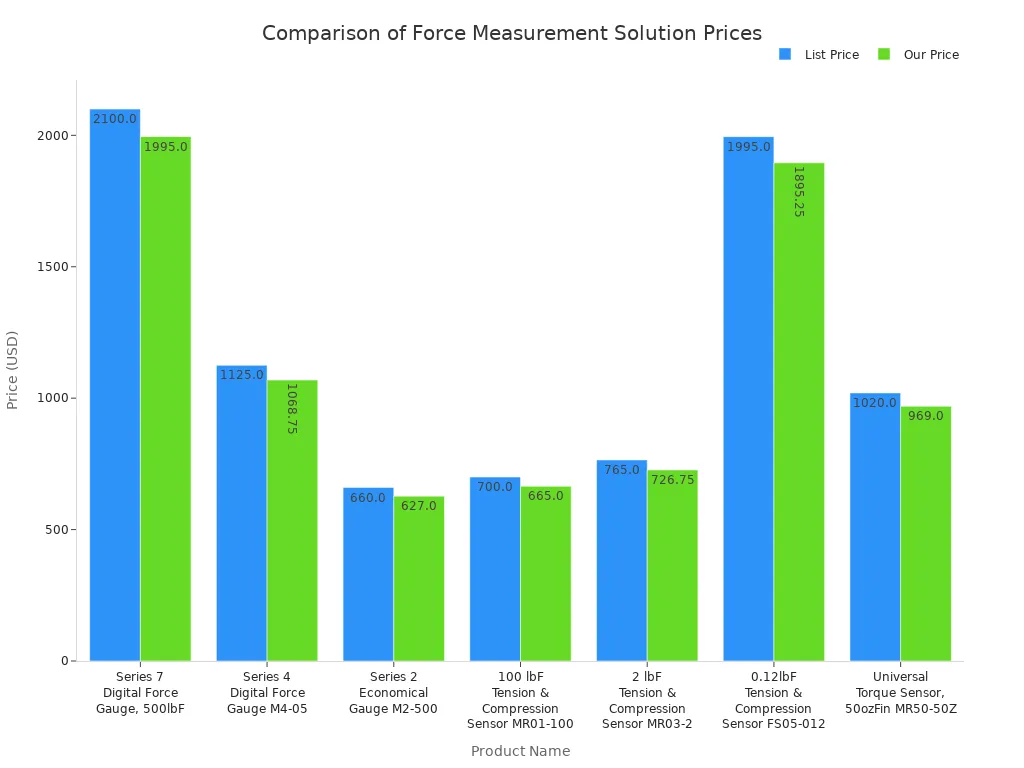

You should always compare prices and look at what you get for your money. Some sensors cost more because they offer higher accuracy, special features, or extra support. The table below shows sample prices for popular force sensors and gauges:

| Product Name | List Price | Our Price |

|---|---|---|

| Mark-10 Series 7 Digital Force Gauge, 500lbF, M7-500 | $2,100.00 | $1,995.00 |

| Mark-10 Series 4 Digital Force Gauge M4-05 | $1,125.00 | $1,068.75 |

| Mark-10 Series 2 Economical Digital Force Gauge M2-500 | $660.00 | $627.00 |

| Mark-10 100 lbF Tension & Compression Force Sensor MR01-100 | $700.00 | $665.00 |

| Mark-10 2 lbF Tension & Compression Force Sensor MR03-2 | $765.00 | $726.75 |

| Mark-10 0.12lbF Tension & Compression Force Sensor, FS05-012 | $1,995.00 | $1,895.25 |

| Mark-10 Universal Torque Sensor, 50ozFin, MR50-50Z | $1,020.00 | $969.00 |

Prices can change based on accuracy, size, and extra features. You may pay more for sensors that offer custom shapes or advanced data options. Always check if the price includes support, calibration, or software.

Tip: Set your budget early. This helps you focus on products that meet your needs without overspending.

Evaluate Usability & Integration

You need to make sure your force measurement tool fits smoothly into your workflow. Start by checking if the device is easy to set up. Look for clear instructions and simple connectors. A good tool should not slow you down. You want a sensor or gauge that works with your current equipment. Many brands offer plug-and-play options. These save you time and reduce mistakes.

Think about how you will use the device each day. Digital displays help you see results fast. Some products let you connect to computers or data systems. This makes it easy to track and share results. If you work in a busy place, pick a tool that is tough and easy to clean. You should also check if the device works with your software. Some brands offer apps or programs that help you collect and review data.

Tip: Test the device with your team before you buy. This helps you find any problems early.

Assess Support & Warranty

You want strong support and a good warranty for your force measurement tools. Good support means you get help when you need it. Many top brands offer phone, email, and online help. Some even have videos and guides to walk you through setup and use.

For example, Mark-10 gives you a 3-year warranty on all products. This warranty covers repairs, replacements, or refunds if you find defects in materials or workmanship. Their technical support team can answer your questions and help solve problems. If you use the product the right way, you keep your warranty. If you change or misuse the device, the warranty may not apply.

Always check what the warranty covers before you buy. A strong warranty and helpful support team give you peace of mind. You know you can fix problems quickly and keep your work on track.

Product Selection Steps

Follow these steps to pick the best force measurement product for your needs:

- Understand your requirements. Write down what you need to measure and the size or type of objects.

- Choose the right measuring range. Make sure the product can handle the forces you expect.

- Check the precision and accuracy. Compare your needs with the product’s specs.

- Think about the environment. Make sure the tool works well in dust, moisture, or other tough places.

- Look for extra features. Digital displays and data logging can make your job easier.

- Balance your budget and future needs. Pick a product that fits your budget and can grow with your work.

Note: Take your time with each step. Careful planning helps you get the right tool and avoid costly mistakes.

Features That Simplify Force Measurement

Digital Displays & Interfaces

Digital displays and easy interfaces make your job simpler. You can see results fast and without confusion. Big LED screens show load cells and torque transducers clearly. Multi-channel indicators let you adjust calibration for better accuracy. You do not have to work hard to get good results. Clear data helps you trust every measurement you take.

| Feature | Benefit |

|---|---|

| Large LED Readouts | Lets you check load cells and torque transducers quickly |

| Multi-Channel Indicators | Makes calibration easier and improves accuracy |

| Clear Data Presentation | Helps you trust and understand your measurement results |

You can use digital displays to check numbers right away. This helps you find problems early and fix them fast. Many systems have touchscreens or simple buttons, so anyone can use them. You do not need special training to get started. The numbers you see are easy to trust, which makes your work smoother.

Tip: Pick devices with screens that are big and easy to read. This helps you make fewer mistakes and saves time.

Wireless & Remote Monitoring

Wireless and remote monitoring change how you watch force and pressure. You get data and alerts right away, so you can act fast. These systems help keep your workplace safe and your machines working. You can check your data from anywhere, even if you are not there.

- Real-time data and alerts help you fix problems quickly

- Watching all the time keeps your workplace safer

- You can plan repairs based on real data, not guesses

- You save money by having fewer accidents and less downtime

- Wireless systems are easy to add or move when you need

You can use wireless tools to watch things like clean rooms or medical devices. These systems help you follow rules by giving you steady data. You also save money because you need fewer people on site. Wireless setups are simple to put in and can grow as your needs change.

Note: Wireless monitoring lets you keep working, even if there is an emergency or you work at night.

Software Integration

Software integration makes force measurement faster and smarter. You can connect different systems and see all your data together. Real-time data shows you what is happening right now. You can make reports that fit what you need.

| Feature/Benefit | Description |

|---|---|

| Seamless integration | Connects different systems for easier data checks |

| Real-time data visualization | Shows you results right away with easy reports |

| Customizable reporting options | Lets you make reports that fit your needs |

| User-friendly analysis | You can look at data without being a software expert |

| Digitization of manual processes | Makes data entry and reports faster and easier |

You do not need to be a computer expert to use these tools. Most systems have simple menus and clear steps. You save time because the system does the data entry and reports for you. This lets you focus on doing good work, not paperwork.

Tip: Choose software that works with what you already use. This helps you get the best results from your data.

Portability & Design

You need small tools when you work in different places. Many force measurement devices are now light and easy to carry. You can move them from one job site to another without trouble. These tools fit in small spaces where big ones cannot go. You can set them up fast and start using them right away. Most have simple controls, so you do not waste time learning how to use them.

Some advanced models, like the Model 9330, have extra features. They show numbers in two ways and can save your data. You can use the amplifier function for better results. You can store more than one sensor calibration, so switching jobs is easy. These features help you work faster, whether you are at a desk or outside.

Tip: Pick a device with a strong case and a screen you can read easily. This keeps your tool safe and helps you see results anywhere.

Calibration & Maintenance

You need to keep your tools working right and giving correct numbers. Regular calibration and care stop mistakes and help your tools last longer. If you treat your devices gently, they will not break as fast.

Here are some good ways to care for your tools:

- Be gentle with your equipment. Do not drop it or let it get too hot or cold.

- Make a schedule to clean and check your tools often.

- Keep your workspace steady so temperature and shaking do not hurt your tools.

- Teach your team how to use and care for the equipment.

- Check your readings with trusted standards to catch mistakes early.

- Write down when you calibrate and fix your tools to spot problems soon.

You should use calibration standards that can be traced and follow the rules for how often to check your tools. Good records help you know when to fix or check your equipment and keep your results good.

Safety & Compliance

You must follow safety rules and meet industry standards when using force measurement tools. Many jobs need you to follow strict rules to keep people safe and make sure products are good. Some devices have safety features like overload protection and warning lights to help stop accidents.

Always check if your tools meet the newest safety and quality rules. This means looking for certifications for things like electrical safety and protecting the environment. Using the right tools shows you care about safety and doing a good job.

Note: Training your team and having clear safety steps help stop accidents and keep everyone safe.

By focusing on easy-to-carry tools, good care, and following rules, you make force measurement safer, easier, and more dependable.

Real-World Force Measurement Applications

Manufacturing & Quality Control

Force measurement is used a lot in factories. Machine builders use sensors to weigh materials and products. This helps you follow rules and stop accidents. In quality checks, you measure weight to keep products safe. This is very important for medicine and medical devices. Automation systems use load cells to get data from robots and machines. Many factories add new sensors to old machines to make them better.

- Sensors help you watch for danger in factories and stop accidents.

- You track force or weight to make sure products are right.

- Sensors help you check machines, so you avoid big problems.

Some advanced uses are:

- Robotic grinding and polishing use 6-axis load cells. These control the force on parts for better results.

- Feed roller systems use pillow block load cells. These keep the feed straight by measuring force at both ends.

Tip: Using force measurement in factories makes work safer, better, and faster.

Research & Development

Force measurement tools help you make new things in labs. You test new materials and products by checking how much force they can take. Sensors help you study strength, bending, and how long things last. This helps you design better and safer products.

- You get live data during tests, so you see how things act under force.

- Load cells and force sensors help you test new machines to make sure they work.

- You can do tests again and compare results to find the best answers.

Note: Good force measurement tools help you turn ideas into real products more quickly.

Healthcare & Medical Devices

Force measurement is important in new medical tools. Sensors help prosthetics by giving live feedback and exact data. Small load cells in prosthetic hands stop things from slipping or breaking. In prosthetic legs, sensors check resistance and bending, helping people walk steady on rough ground.

- The Precision Knee Aligner uses thin-film capacitive sensors. These measure force during knee surgery and help doctors balance ligaments for better results.

- Medical sensors in infusion pumps check pressure and flow. This makes sure patients get the right medicine.

- In dialysis machines, sensors measure force during cleaning, keeping treatments safe.

- Force-sensing catheters in heart procedures help doctors watch patients better.

Tip: Using force measurement in healthcare helps make treatments and devices safer and work better.

Automotive & Aerospace

When you work in cars and planes, force measurement is important. These jobs need high safety and quality. You must check force at every step, like design, building, and testing. Sensors and gauges help make cars and planes safer and stronger.

In car factories, sensors test how strong parts are. You check how much force a car door can take in a crash. You measure brake pressure to make sure brakes work right. Engineers use load cells and force sensing resistors on assembly lines. These tools help find problems early, so cars are safe before leaving the factory.

Force sensors are also used in research and new designs. When making new cars, you test models with sensors to see how they handle stress. You collect data on how parts bend or break. This helps you build safer cars and trucks. In electric cars, you measure force on battery packs to stop damage and keep people safe.

Aerospace engineers use force measurement for every flight. Sensors test airplane wings, landing gear, and engines. In wind tunnel tests, you measure force on plane parts. This helps design planes that fly better and use less fuel. Sensors also check spacecraft parts before launch to make sure they are strong.

Here are some ways force measurement is used in these jobs:

- Measure crash forces on car frames and seats.

- Watch robots to make sure they use the right force.

- Check tension in airplane cables and moving parts.

- Measure pressure in landing gear and brake systems.

- Track force on engine mounts during vibration tests.

Tip: Advanced sensors like SOUSHINE FSRs fit in small or curved spaces. This lets you get data from hard-to-reach spots in cars and planes.

Using the right tools helps keep people safe. You also save money by finding problems early. Force measurement gives you the facts you need to follow rules and make new technology.

Now you know about the best force measurement solutions. Use the guide to help you pick the right product for your needs. If you want help or want to see a demo, ask for more info about SOUSHINE or other brands. The right technology helps you do better work and feel sure about your results.

FAQ

What is a force sensing resistor (FSR)?

A force sensing resistor (FSR) checks force or pressure. When you press it, the resistance changes. You can use FSRs in many devices to find touch, weight, or pressure.

How do I choose the right force measurement product?

First, write down what you need. Look at the force range, accuracy, and size. Compare features and support. Pick a product that matches your job and budget.

Can I use SOUSHINE FSRs in harsh environments?

Yes, SOUSHINE FSRs work in tough places. Their strong design handles shaking, heat, and lots of use. Always check the product specs for your own environment.

Do I need special tools to install force sensors?

Most force sensors, like SOUSHINE FSRs, do not need special tools. You can connect them with normal wires and easy steps. Always read the setup guide before you start.

How often should I calibrate my force measurement device?

You should check calibration often. Many people do this once a year or after heavy use. Follow the maker’s rules for the best results.

What industries use force measurement solutions?

Force measurement tools are used in cars, healthcare, robots, planes, and factories. These tools help make jobs safer, better, and faster.

Can I get custom shapes or sizes for my force sensor?

Yes, many brands, like SOUSHINE, make custom shapes and sizes. You can ask for a sensor that fits your project’s needs.

Who can I contact for technical support?

You can talk to the support team from the company. SOUSHINE and other brands give expert help by phone, email, or online chat. Always have your product details ready when you ask for help.