Call us: +86-137-2353-4866

At SOUSHINE, we specialize in advanced sensing technologies, and our Force Sensing Resistors (FSRs) stand at the forefront of innovation. These remarkable devices are integral to a vast array of modern applications, offering unparalleled versatility and reliability in force and pressure detection.

What is a Force Sensing Resistor?

At their core, Force Sensing Resistors (FSRs) are sophisticated yet simple devices that exhibit a decrease in electrical resistance as more physical force or pressure is applied to them. This fundamental characteristic places them firmly within the broader category of piezoresistive devices. Unlike simple switches, FSRs provide a continuous change in resistance, allowing for a precise measurement of the applied force rather than just an on/off signal.

How FSRs Work: The Science Behind the Sensitivity

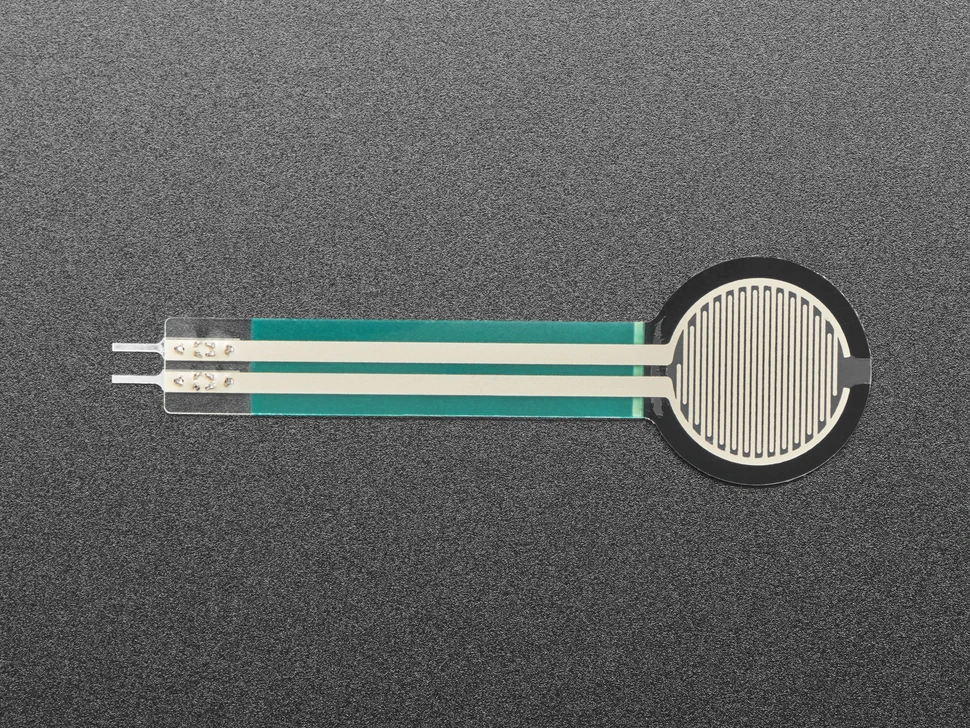

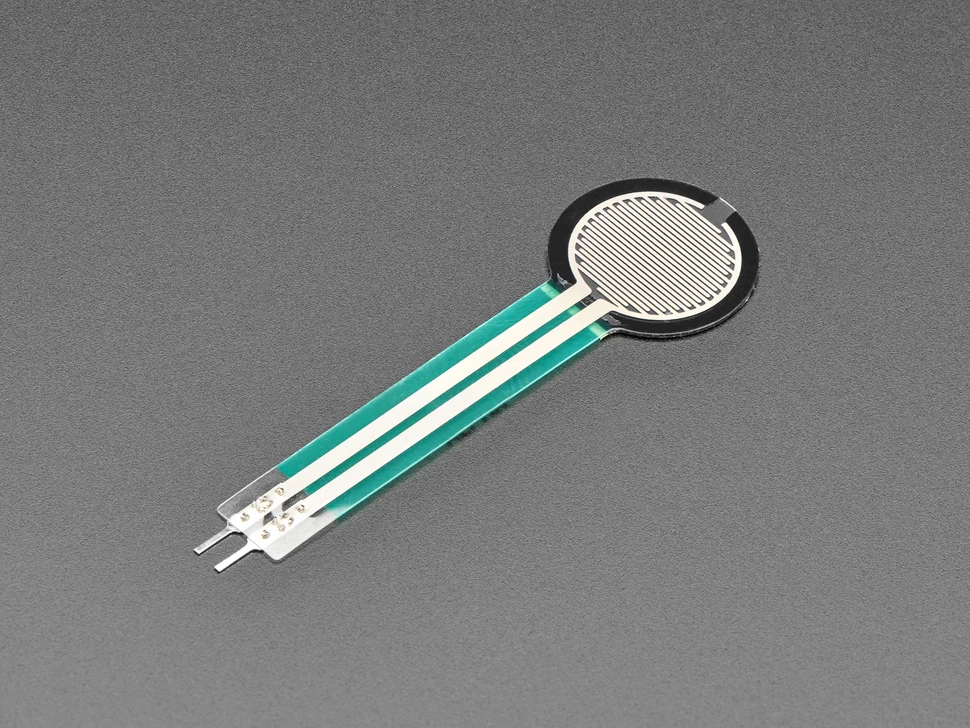

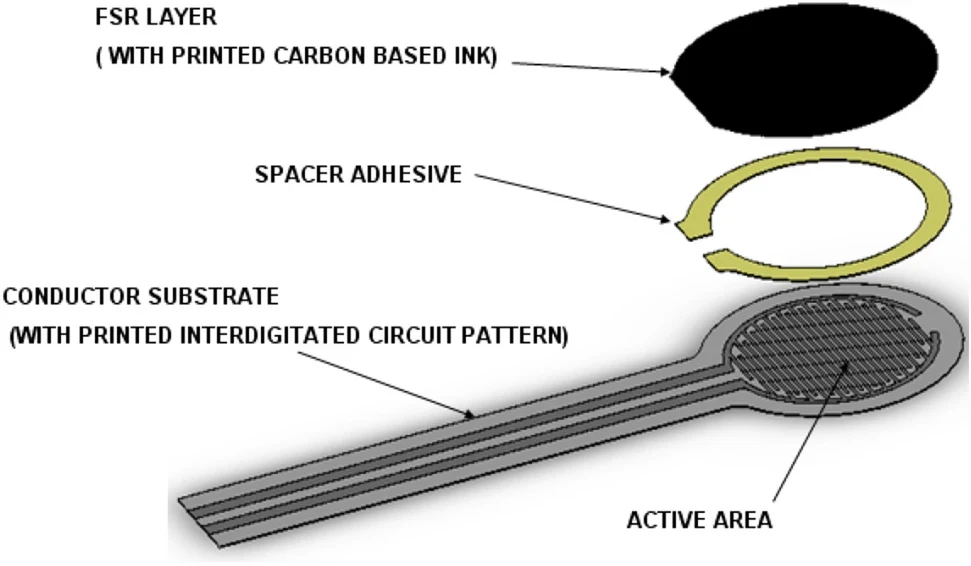

The seemingly straightforward construction of an FSR belies its ingenious operational principle. A typical FSR consists of several key components:

- Flexible Substrate: Often a thin, membrane-like material, this substrate is meticulously printed with two unconnected halves of an interdigitated circuit. When the sensor is in a neutral, unpressed state, this circuit remains open, preventing any electricity from flowing between the two wires.

- Spacer: A thin spacer is precisely affixed to this primary substrate. Its crucial role is to create a tiny, controlled separation between the printed circuit and the second, conductive layer. This ensures that in its resting state, the circuit remains open.

- Conductive Substrate: This second substrate is coated with a proprietary conductive ink or material. This material is specially formulated to change its conductivity in response to pressure.

When external force is applied to the sensor, the flexible conductive substrate is pressed down, making direct contact with the printed circuit on the first substrate. This contact allows electricity to flow from one wire to the other, closing the circuit.

The magic of the FSR lies in its ability to quantify force: the greater the pressure exerted on the FSR, the more of the conductive material comes into contact with the interdigitated wires. This increased contact directly translates to a lower electrical resistance and, consequently, a greater electrical output. This predictable relationship between applied force and electrical output is what allows FSRs to accurately detect and measure changes in force.

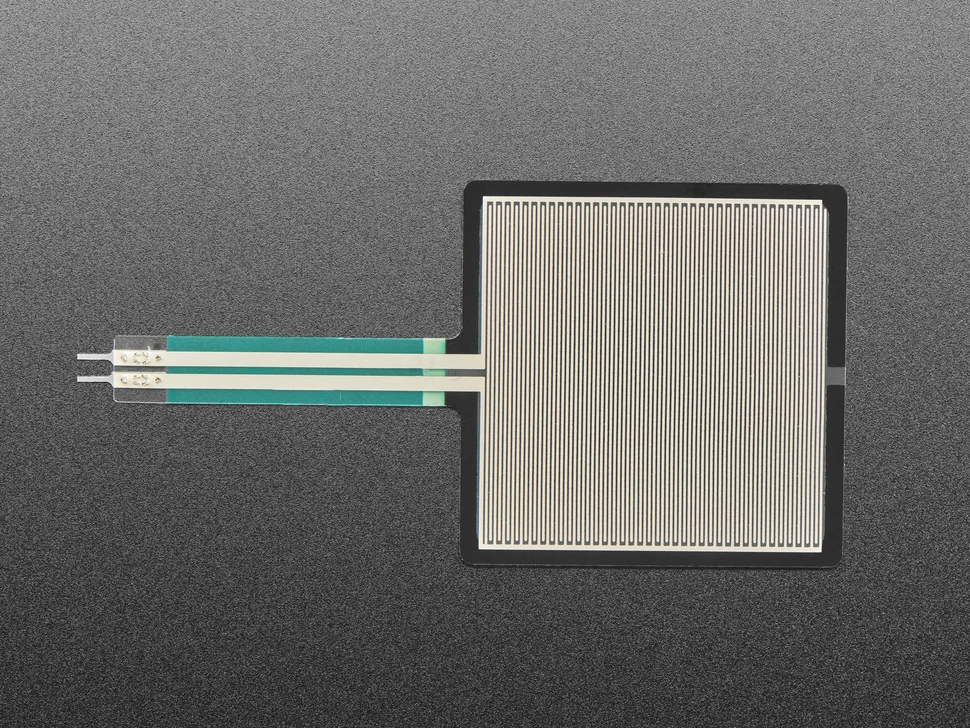

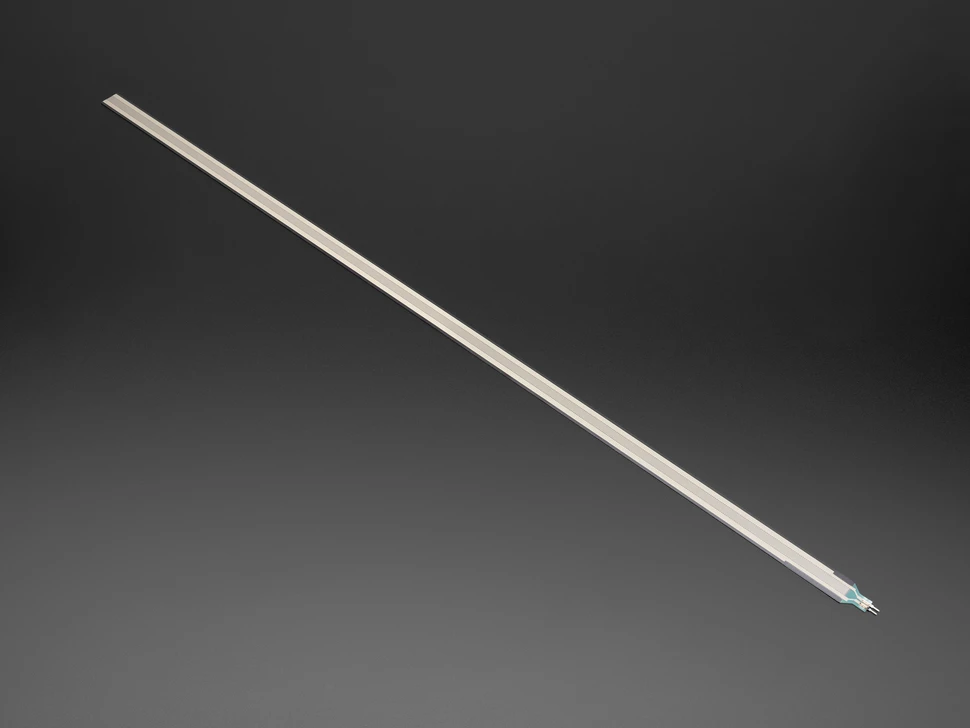

Standard Model Products

Key Application Areas

The Unmatched Versatility of FSR Technology

The relatively simple construction of Force Sensing Resistors is precisely what contributes to their incredible versatility and widespread adoption. FSRs offer a compelling combination of benefits that make them ideal for countless applications:

- Cost-Effective Manufacturing: Their design allows for economical mass production, making them accessible for a wide range of products.

- Customizable Shapes and Sizes: FSRs can be manufactured in virtually any shape, size, and even thickness, from tiny dots to large sheets, to perfectly fit specific design requirements. This adaptability opens up a myriad of design possibilities.

- Durability and Reliability: Designed for repeated use, FSRs are known for their robust performance and long operational lifespan, even in demanding environments.

- Low Power Consumption: Many FSR applications require minimal power, making them suitable for battery-operated and energy-efficient devices.

- Ease of Integration: Their straightforward electrical interface makes them easy to integrate into existing electronic systems.

Where Are FSRs Used? A Glimpse into Diverse Applications

The utility of FSRs spans across a myriad of industries, revolutionizing how we interact with technology and enhancing product functionality. Some key sectors where FSRs make a significant impact include:

- Musical Instruments: Certain electronic musical instruments utilize FSRs to detect the pressure of a player’s touch, allowing for expressive control over sound.

- Automotive Industry: From advanced seat occupancy detection systems for airbag deployment and seatbelt reminders to pressure sensors in braking systems and haptic feedback controls, FSRs enhance safety and user experience.

- Robotics: FSRs provide robots with a sense of “touch,” enabling them to grasp objects with appropriate force, detect obstacles, and navigate complex environments more effectively. They are crucial for delicate manipulation and human-robot interaction.

- Medical Devices: In the healthcare sector, FSRs are used in applications such as patient monitoring (e.g., bed and chair occupancy sensors to prevent falls), rehabilitation equipment, surgical tools, and prosthetic limbs, providing critical feedback and control.

- Consumer Electronics: Think of the intuitive touch controls on your smart devices, gaming controllers with pressure sensitivity, or even smart home appliances that react to your touch. FSRs are behind many of these seamless user interfaces.

- Industrial Automation: For precise force control in manufacturing processes, quality control, and safety systems, FSRs ensure accuracy and efficiency.

- Sporting Goods: From smart insoles that analyze gait to pressure-sensitive sensors in sports equipment for performance tracking, FSRs help athletes optimize their training.

Why Choose SOUSHINE for Your Force Sensing Needs?

At SOUSHINE, we are committed to delivering high-quality, reliable Force Sensing Resistors tailored to your specific project requirements. With our expertise and dedication to innovation, we offer:

- Competitive Pricing: We offer cost-effective solutions without compromising on quality, making advanced force sensing technology accessible.

- Customization: We understand that every application is unique. We can work with you to design and manufacture FSRs in custom shapes, sizes, and specifications to perfectly fit your product.

- Quality Assurance: Our FSRs are manufactured under stringent quality control standards, ensuring consistent performance and durability.

- Technical Support: Our team of experts is available to provide comprehensive technical support, from initial design consultation to post-integration assistance.

Now that you have a deeper understanding of what a Force Sensing Resistor is and its vast potential, we invite you to explore SOUSHINE’s comprehensive collection of FSR products. Whether you’re developing a groundbreaking new product or enhancing an existing one, our FSRs provide the precision and reliability you need.