Call us: +86-137-2353-4866

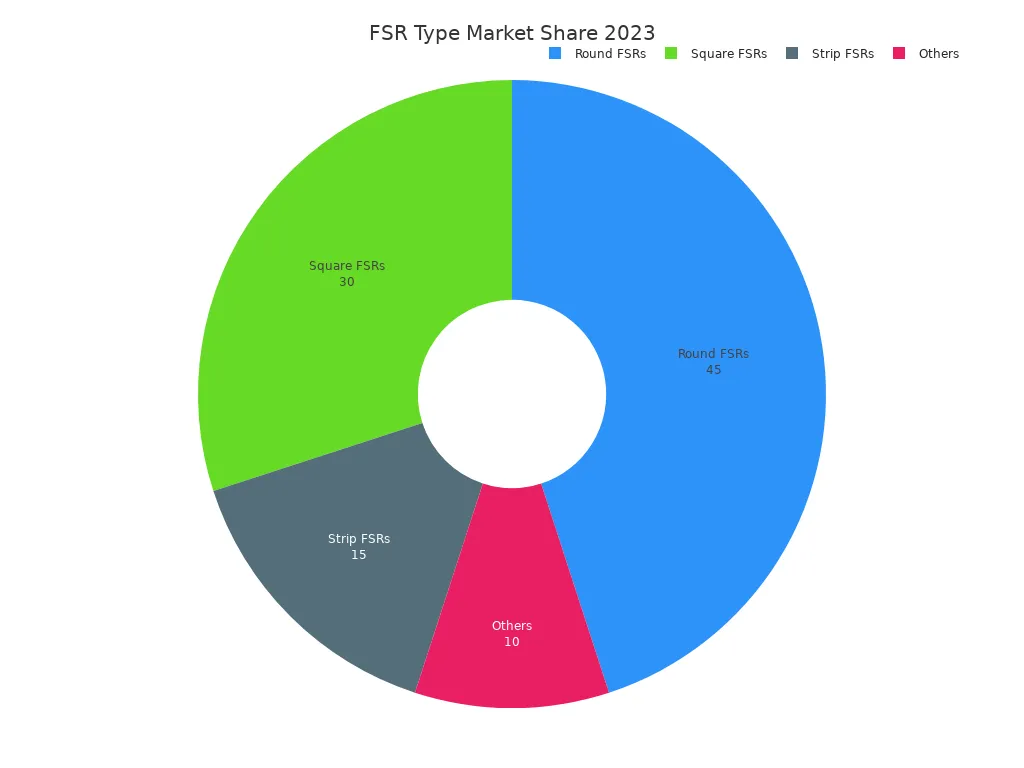

The force sensitive resistor is important in 2025 because it has special good points and some problems. Engineers like that it is very sensitive, can bend, and does not cost much. But some uses still want it to be more exact. More people are buying force sensitive resistors, mostly for things like electronics, cars, and machines that work by themselves.

| Metric/Aspect | Value/Detail (2023-2025) |

|---|---|

| Market Size (2023) | USD 3.2 billion |

| Projected Market Size (2032) | USD 6.8 billion |

| Key Growth Drivers | Electronics, automotive, healthcare, automation |

SOUSHINE is the top company with new force sensitive resistor ideas. Picking the best sensor is important for every job, like robots or smart gadgets.

Table of Contents

Key Takeaways

- Force sensitive resistors (FSRs) are thin and bendy sensors. They change resistance when you press them. This makes them useful in many gadgets.

- FSRs do not cost much, use little energy, and last a long time. This makes them good for wearables, robots, and medical devices.

- These sensors work best with low voltage and low force. They can notice small pressure changes with good sensitivity.

- FSRs are not the most exact sensors. They can have problems like signal drift and being affected by temperature. So, they need to be set up carefully.

- New designs and materials help FSRs bend more and cost less. They also work better with smart devices and artificial intelligence.

- SOUSHINE is a leader in making good FSRs. They have strong customer support and offer many types of sensors for different jobs.

- Picking the right sensor depends on what you need it for. FSRs are good for flexible and cheap uses. They are not good for jobs needing high precision or lots of power.

- The market for force sensors is growing quickly. This is because more people want them for cars, healthcare, robots, and electronics.

Force Sensitive Resistor Overview

Structure

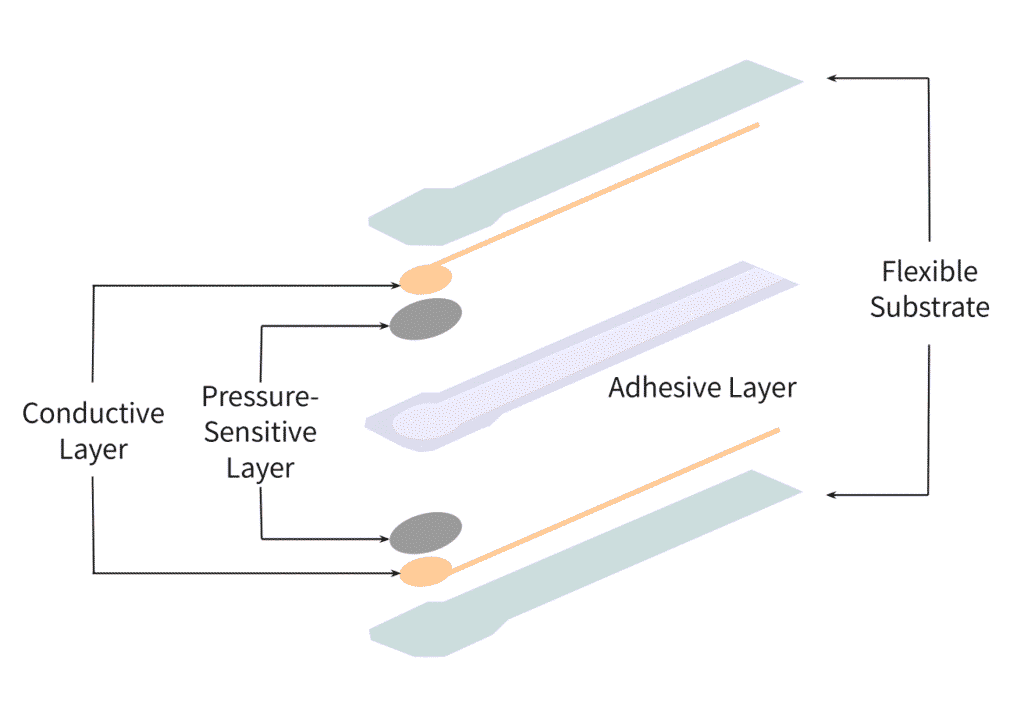

Membrane and Circuit

A force sensitive resistor has a simple design that works well. The main parts are a bendy membrane and a printed circuit. SOUSHINE makes its sensors with two layers. The first layer has a special circuit pattern. The second layer has a film made from a special polymer. This film holds tiny particles that can conduct or not conduct electricity. These particles are very small, less than a micrometer. The film sits between the sensor’s electrodes. When you press the sensor, the membrane bends. The particles touch the electrodes. This changes the resistance and lets electricity move.

- Key structural parts:

- Polymer film with tiny particles inside

- Printed circuit patterns on the surface

- Spacer layer keeps the circuit open until pressed

- Electrodes send out the signal

This design helps the sensor last longer and work better in heat. The top looks smooth, but under a microscope, you see small bumps from the polymer.

Conductive Ink

SOUSHINE uses a special ink that conducts electricity for its sensors. This ink covers one layer of the membrane. When you press down, the ink touches the circuit. The more you press, the bigger the contact area gets. This makes the resistance go down. The ink’s special mix helps the sensor last longer and work in many places.

Working Principle

Force sensitive resistors change their resistance when you press them. The resistance gets lower as you push harder. This happens because the ink and circuit touch more as you press. The table below shows how this works compared to other sensors:

| Sensor Type | Working Principle | Key Characteristics |

|---|---|---|

| Force Sensing Resistor (FSR) | Resistance goes down as you press harder because the contact area gets bigger. | Measures different forces; thin, bendy, cheap; not as exact. |

| Capacitive Sensor | Capacitance changes when the space between plates changes. | Very sensitive; used for many pressure tests. |

| Piezoelectric Sensor | Makes electricity when you press certain crystals. | Good for moving force; can’t measure still force. |

Types

Standard FSRs

Standard force sensitive resistors have one spot that senses force. They are thin, bendy, and simple to use. These sensors are good for touch, measuring force, and setting limits in many things.

Array Sensors

Array sensors have many sensing spots in a grid. This lets them show where pressure is on a surface. SOUSHINE’s array sensors help in robots, medical tools, and screens by giving lots of force data.

Resistive Varistors

Resistive varistors are a special kind of force sensor. They change resistance with both force and voltage. These sensors can do harder jobs, like protecting circuits or measuring changing forces in new systems.

Force sensors like these can be made in many shapes and sizes. They can be more or less sensitive. They fit in many things, like health trackers or smart robots. Studies show that changing the materials or design changes how much force the sensor can measure. This makes force sensitive resistors helpful in many areas.

Force Sensitive Resistor Advantages

Sensitivity

Force sensors today are very sensitive. New nanotechnology helps them sense tiny changes in force. Makers use very small materials to make force-sensing resistors better. These sensors now work well in hard places, like cars and planes. SOUSHINE force sensors can notice small force changes with good accuracy. Their special materials and designs help them measure soft touches. This makes them good for careful jobs.

- With better sensitivity, force sensors can:

- Find small forces in healthcare, like checking on patients.

- Help robots touch gently and hold breakable things.

- Make cars safer by checking seats and airbags with up to 90% accuracy.

- Help smart machines in factories and with keeping track of items.

When force sensors work with artificial intelligence, systems can react fast and smart. SOUSHINE’s force sensors give steady and correct readings. This makes them a great pick for jobs that need to find small forces every time.

Flexibility

Modern force sensors are flexible. They can bend and stretch because they use special materials. This is important for things you wear, which must fit your body and move with you. SOUSHINE makes its force sensors both bendy and strong. This means they are comfy and last a long time.

- Flexible force sensors can:

- Stay close to skin or surfaces to get good signals.

- Work well even when bent or stretched many times.

- Be washed and let air through, which is good for health monitors you wear.

- Be put into smart clothes and bendy electronics easily.

How the sensor is made, like how tough and sticky the layers are, matters too. SOUSHINE uses new materials and ways to build their sensors. This keeps them working well, even after lots of use.

Cost-Effectiveness

Force sensors do not cost a lot for many uses. They are cheaper than other types, like capacitive or very exact load cells. The table below shows how much different force sensors cost in 2025:

| Sensor Type | Typical Cost Range (USD per unit, 2025) | Notes |

|---|---|---|

| Force Sensitive Resistors (FSRs) | 10 – 50 | Basic sensors, low price, used for simple jobs |

| Mid-range Sensors | 100 – 500 | Used in factories and robots, cost more |

| High-accuracy Sensors | 1,000 – 5,000+ | Used in planes and hospitals, very exact, special features |

Force-sensing resistors are the cheapest choice. This low price makes them good for lots of gadgets, robots, and medical tools. SOUSHINE’s force sensors mix low cost and good work. This gives engineers a smart option for many needs.

Tip: Picking low-cost force sensors like SOUSHINE’s can save money on projects. You still get good quality and trust the results.

Low Power

Force sensors are great because they use little power. They need less than 20mA when working. When not in use, they do not use any power. This is why they are good for things that run on batteries. Many engineers use force sensors in wearables and smart gadgets. They also use them in medical tools to save energy.

The table below shows how much power different sensors use:

| Sensor Type | Power Consumption Characteristics |

|---|---|

| Force Sensitive Resistor (FSR) | Low power use (<20mA), no power needed when sleeping |

| Capacitive Sensor | Uses more power, needs power even when sleeping |

| MEMS Sensor | Low power use, no power needed when sleeping |

Force-sensing resistors only need simple and cheap electronics. This makes them good for companies making new products. Other sensors, like load cells, need more parts and cost more. These extra parts use more energy and take up more space.

SOUSHINE makes force sensors that work well with low power. Their sensors help batteries last longer in wearables and robots. This is important as more people want products that save energy in 2025.

Tip: Using force sensors that use less power helps make products smaller, lighter, and last longer.

Versatility

Force sensors can be used in many ways. They are thin and can bend to fit small or curved spaces. This makes them useful in lots of things, like robots and health tools.

The table below lists how force sensors are used in different areas:

| Field | Common Applications of Force Sensitive Resistors (FSRs) |

|---|---|

| Robotics | Used on robot arms and grippers to give feedback on force, so robots can hold fragile things safely. |

| Medical Devices | Put in prosthetics, pumps, beds, and bandages to check pressure, find blockages, and help care for patients. |

| Consumer Electronics | Used in touchpads, game controllers, drum kits, and controls to sense how hard you press. |

Force sensors are very important in robots. They help robot arms know how much force to use. This lets robots pick up breakable things without breaking them. In medical tools, force sensors check pressure in beds and prosthetics. They also help find blockages in pumps and watch over patients.

Putting force sensing resistors in drug pumps helps find pressure changes. This can warn people if there is a blockage. It keeps patients safer and makes devices smarter.

Force sensors are also used in electronics. Game controllers and touchpads use them to feel how hard you press. This gives more features and makes using the device better.

SOUSHINE’s force sensors work in many places. They are used in smart clothes, robots, and health tools. This helps engineers make new things for changing needs.

Disadvantages of Force Sensors

Precision

Many force sensors have trouble being very exact. Force sensitive resistors do not always give even results when you press harder. The numbers they show can jump or change in a strange way. This means you have to check and fix them often to keep them right. Other sensors, like MEMS and capacitive types, are better at giving steady and correct numbers.

The table below shows how different sensors compare for being exact and steady:

| Sensor Type | Sensitivity / Resolution | Response Characteristics | Precision / Linearity Notes |

|---|---|---|---|

| Force Sensitive Resistor (FSR) | Not explicitly stated; nonlinear response | Nonlinear response; limited detailed sensitivity data | Widely used but less precise and nonlinear response |

| MEMS Capacitive Sensors | High sensitivity | Improved linearity; advanced noise reduction | Generally higher precision and better performance |

| Capacitive Sensors | Moderate sensitivity | Linear response; good environmental compensation | Moderate precision and good stability |

Strain gauge force sensors are better at measuring force exactly. They use changes in electricity to tell how much force is there. These sensors are used in labs and factories where being exact is very important. Capacitive force sensors also give steady and repeatable numbers, so they are good for jobs that need high accuracy. In short, force sensitive resistors are cheap and easy to use, but they are not as exact. This can make them not the best choice for science or checking product quality.

Note: If you need very exact numbers, engineers usually pick strain gauge force sensors or MEMS sensors instead of FSRs.

Signal Drift

Signal drift is another problem with force sensors. Sometimes, the sensor’s number changes even if the force does not. Many things can cause this drift:

- The sensor material can slowly change shape, which moves the signal.

- Using too much voltage, more than 3 V, can make the signal worse.

- Sideways force can change how stiff or electric the sensor is.

- Things like heat, wetness, shaking, and electric noise can mess up the signal.

- If the sensor is squeezed over and over, it can drift too.

Scientists have some tips to help stop signal drift:

- Use less than 3 V, and try to use about 2 V.

- Use special cables that block electric noise.

- Use mounts that let the sensor move a little if needed.

- Cover the sensor to keep out water and wetness.

- Use mounts and filters to stop shaking.

- Make sure the sensor can move sideways if needed.

Doing these things helps keep the sensor’s numbers steady and makes it work better in real life. Strain gauge force sensors are built strong, so they drift less than FSRs. But all sensors can drift a little, so you should check and set them up often.

Temperature Sensitivity

Force sensors can act differently when the temperature changes. Studies show that force sensitive resistors work best at room temperature on hard, flat places. If it gets hotter, like in medical tools or things you wear, the sensor’s numbers can change. This makes the readings less right.

Temperature is not the only thing that matters. The shape and softness of what the sensor touches also change the numbers. For example, in body tests, both heat and bending the sensor can change what it shows. Experts say you should check and set each sensor in the same temperature where you will use it. This helps make the numbers more correct.

Capacitive force sensors and MEMS sensors are better at handling temperature changes. They give steady numbers in more places and different weather. But even these sensors can change a little with heat, so engineers must think about where the sensor will be used.

Tip: Always check and set up force sensors in the same place and temperature as where you will use them. This helps you get the best numbers.

Durability

Durability is very important when engineers pick force sensors for long use. Most force sensitive resistors can take over 10 million presses. This means they last a long time in many devices. How long they last depends on a few things. The amount of force, the sensor’s materials, and the way you press all matter. Pressing straight down helps the sensor last longer. If you push from the side, called shear force, it can wear out faster.

Many industries use force sensors in things that must work for years. Medical devices, robots, and electronics need sensors that can be pressed many times. But there are some problems with force sensors. You have to think about how you will use them. If a device gets heavy or sideways force a lot, engineers may pick strain gauge force sensors. These sensors are better for hard jobs and keep working after many uses.

Tip: For the longest life, use force sensitive resistors where the force is steady and comes from one direction.

Voltage Limitations

Voltage limits change how engineers use force sensitive resistors in electronics. These sensors work best at low voltages, about 3.3 volts. The voltage across the sensor stays low. It goes from about 157 millivolts with no force to almost 3.3 volts with full force. Keeping voltage and current low helps the sensor give good numbers and not break.

Force sensors do not work well in high-power or high-voltage systems. Too much voltage or current can break the sensor or make it show wrong numbers. So, engineers use force sensitive resistors in low-power circuits. These are found in wearables, small robots, and medical tools. Big machines or systems that need to measure large forces use other sensors.

The table below shows where force sensitive resistors work best:

| Application Type | Typical Voltage | Sensor Choice |

|---|---|---|

| Wearables | 3.3 V | Force sensitive resistor |

| Medical Devices | 3.3 V | Force sensitive resistor |

| Industrial Machinery | >5 V | Strain gauge force sensors |

| High-Power Robotics | >5 V | Strain gauge force sensors |

Engineers must always check the voltage and current in their designs. Using the right sensor for the job helps stop problems and keeps devices safe.

Force Sensors in 2025 Trends

Market Adoption

In 2025, many industries use force sensitive resistors. The global market for force sensors will reach $3.01 billion. It is growing at a rate of 5.3% each year. The automotive industry uses the most force sensors. They help control motors, steering, brakes, and ADAS. Factories use force sensors for robots, packaging, and checking products. Hospitals and doctors use them in medical devices. These devices help watch patients and find health problems.

| Industry | 2025 Market Size | Key Applications |

|---|---|---|

| Automotive | Largest segment | Motor control, steering, brakes, ADAS |

| Industrial Automation | Rapid growth | Robotics, packaging, inspection |

| Healthcare | Expanding | Patient monitoring, diagnostics |

| Consumer Electronics | Growing | Touch interfaces, wearables |

Force sensitive resistors are important because they work well and can be used in many ways. Smaller sensors and the need for better control make more people want them.

Innovations

New force sensitive resistors are thinner and bend more easily. They also cost less to make. Top companies add artificial intelligence and IoT to their sensors. This lets them check data right away and fix problems before they happen. Companies make FSRs for new uses in health, robots, and medicine. These new sensors can measure force and pressure more exactly.

Makers use better materials to make sensors last longer and bend without breaking. Some companies make MEMS-based silicon force sensors. These can feel tiny changes under thick covers. These new sensors can work in water and do many jobs at once. Some teams mix force sensing with capacitive touch. This helps stop mistakes and makes the sensors more trustworthy. More companies now care about the environment. They use green materials and save energy when making sensors.

Note: New research helps force sensitive resistors work better for smart machines and things you wear.

User Demands

In 2025, what users want shapes how force sensitive resistors are made. Hospitals want better sensors for health checks and fake body parts. Robots need sensors that feel touch better and help them move safely. People want phones and games that react fast when touched.

Car makers want safer cars and smart dashboards. This is even more important as electric and self-driving cars become popular. Factories want to make work safer and faster by watching force and pressure all the time. More people want sensors that are good for the planet.

- Key user demands:

- Small and bendy sensors

- Low-cost options

- Sensors that measure force well

- Sensors that work with new smart devices

- Sensors made in ways that help the environment

These trends show that force sensitive resistors must keep changing. They need to fit new uses in robots, health, and everyday gadgets.

Choosing the Right Force Sensor

Best Use Cases

Picking the right sensor depends on what you need it for. Engineers think about many things before they choose a force sensor. They look at how accurate and sensitive it is. They also check the size, how much power it uses, and if it fits in the device. The table below shows where force sensitive resistors work best:

| Application Area | Why FSRs Excel Here |

|---|---|

| Wearable Devices | Thin, flexible, and light for smart clothing and bands |

| Medical Devices | Fit in small spaces, low power, and safe for patients |

| Consumer Electronics | Easy to add to touchpads, controllers, and gadgets |

| Robotics (Grippers) | Detect gentle touch and grip force on fragile objects |

SOUSHINE FSRs are great for these uses. Their sensors fit into small spaces and can bend to fit curves. They use little power, so batteries last longer in wearables and tools you carry. In robots, these sensors help robots hold things without breaking them. Medical devices use FSRs to check pressure in beds or fake body parts. Consumer electronics like their thin shape and fast reaction.

When choosing a sensor, engineers should think about:

- How accurate and sensitive it needs to be.

- What kind of signal it gives and if it works with the system.

- The size and how to attach it.

- How much power and voltage it needs.

- The biggest and smallest force it must measure.

- How fast it needs to react.

- If the readings are clear and easy to understand.

- If it can handle heat, cold, or dust.

- If it meets safety rules.

- How it connects to other parts.

- If there is a warranty or help if it breaks.

- If the price fits the project’s money plan.

Tip: If you need a sensor that is thin, bends, and does not cost much, SOUSHINE FSRs are a good pick.

When to Avoid FSRs

Force sensitive resistors are not right for every job. Some jobs need more exact numbers or special features. The table below shows when you should use a different sensor:

| Situation | Why Avoid FSRs | Better Choice |

|---|---|---|

| Precise Weight Measurement | FSRs lack high accuracy | Load cell |

| High-Temperature Environments | FSRs may drift or degrade | Strain gauge or MEMS sensor |

| Need for Solder-Free Connections | FSRs can be heat-sensitive | Use clincher connectors |

| Complex Multi-Axis Force Sensing | FSRs measure single direction | Force torque sensor |

Engineers should not use FSRs for jobs that need very exact weight, like scales or lab tools. Load cells are better for these jobs. In hot places or where there are strong chemicals, strain gauges or MEMS sensors work better and last longer. If you need to measure force from many directions, use a force torque sensor.

Note: Always pick the sensor that matches the job. Using the wrong sensor can cause mistakes or make the device stop working.

Checking sensors often and putting them in the right way helps them last longer. For the best results, follow the maker’s tips and use the right sensor for each job.

SOUSHINE Brand Focus

Product Range

SOUSHINE makes many products for different industries. Their products include standard force sensing resistors, array sensors, and resistive varistors. These help engineers fix problems in electronics, robots, healthcare, and smart homes. You can find SOUSHINE sensors in touchscreens, wearables, medical tools, and smart furniture.

| Product Type | Application Areas / Needs Addressed |

|---|---|

| Adult product sensor | Sensitive force detection for specialized adult products |

| Smart seat sensor | Pressure monitoring in automotive and furniture seating for comfort and safety |

| Mattress sensor | Sleep quality and health monitoring through pressure point detection |

| Robot sensor | Measuring grip force and interaction pressure for robotic safety and manipulation |

| Smart tide play sensor | Interactive pressure sensing for gaming and smart toys |

| Car seat sensor | Occupant presence and safety system integration in vehicles |

| Flexible pressure sensor | Adaptable for curved or moving surfaces in electronics and wearables |

| Thin film pressure sensor | Ultra-thin design for compact or delicate devices |

| Membrane switches & panels | Pressure-sensitive user interfaces for consumer electronics and smart home devices |

SOUSHINE’s force sensors measure force in all these areas. Robot sensors help machines hold things safely. Mattress sensors watch how you move to help you sleep better. The company also makes sensors for new smart devices. These sensors make using gadgets easier and more fun.

Key Features

SOUSHINE is known for new ideas and making good products. The company started in 2008 and has almost 20 years of experience. SOUSHINE does everything from designing to selling its sensors. They have two big factories and over 100 skilled workers. Ten production lines and special machines help them make lots of sensors.

SOUSHINE’s sensors pass tough tests and meet strict rules. They have ISO9001:2015, RoHS, UL, CE, and ZHB certificates. Big brands like Panasonic, Haier, TE, and Huawei use SOUSHINE’s sensors. Their products are used in communication, factories, the military, hospitals, cars, and smart homes. SOUSHINE also makes special sensors, like the force torque sensor, for hard jobs.

Support and Availability

SOUSHINE gives great help to customers so projects do not stop. You can call their free service line any time, day or night. Certified experts are ready all over the country to install and fix sensors fast. Service teams work all day and night to send help quickly. SOUSHINE keeps sensors in stock for overnight delivery, so clients do not have to wait.

A group of approved partners covers the whole country. This means customers get parts and help fast. Online ordering will start soon, but SOUSHINE already answers quickly and helps right away. This way, engineers and companies keep their force sensors working with no long waits.

SOUSHINE is a trusted leader because it cares about quality, new ideas, and helping customers.

The force sensitive resistor has many good points in 2025. It can bend, does not cost much, and is simple to use. Some people want it to be more exact or last longer. New ideas and better materials help these sensors work in more places. Many companies use them in smart gadgets and robots. SOUSHINE gives engineers lots of good choices. Check out SOUSHINE products to pick the best force sensor for your project.

FAQ

What is a force sensitive resistor (FSR)?

A force sensitive resistor finds out how much pressure is on it. When you press it, the resistance gets lower. This change helps tell how hard you push. Engineers put FSRs in many things, like wearables and robots.

Where do engineers use SOUSHINE FSRs most often?

Engineers put SOUSHINE FSRs in robots, medical tools, car seats, and electronics. These sensors are good for things that need to be thin, bendy, and not cost a lot.

How does an FSR differ from a capacitive sensor?

FSRs work by changing resistance. Capacitive sensors work by changing capacitance.

Can FSRs measure very small forces?

Yes, FSRs can find small forces. SOUSHINE makes its sensors to feel soft touches. This helps in health care and things you wear.

How long does a SOUSHINE FSR last?

SOUSHINE FSRs can take more than 10 million presses. Their strong build lets them last a long time in many uses.

Do FSRs work in high-temperature environments?

FSRs work best when it is not too hot. High heat can make the numbers wrong. For very hot places, engineers pick other sensors.

What support does SOUSHINE offer for its sensors?

SOUSHINE gives help all day and night, sets up sensors, and ships fast. Trained workers help with setup and fixing problems.

Are SOUSHINE FSRs easy to integrate into new products?

Yes. SOUSHINE FSRs are thin and bendy. Engineers can put them in many products with simple parts and little space.