Call us: +86-137-2353-4866

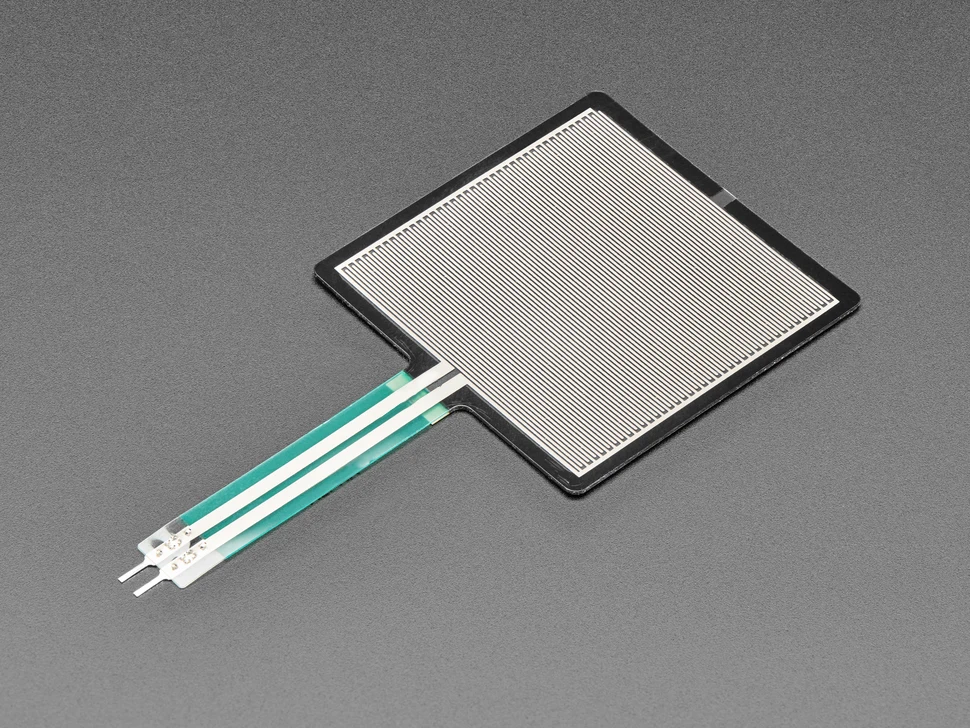

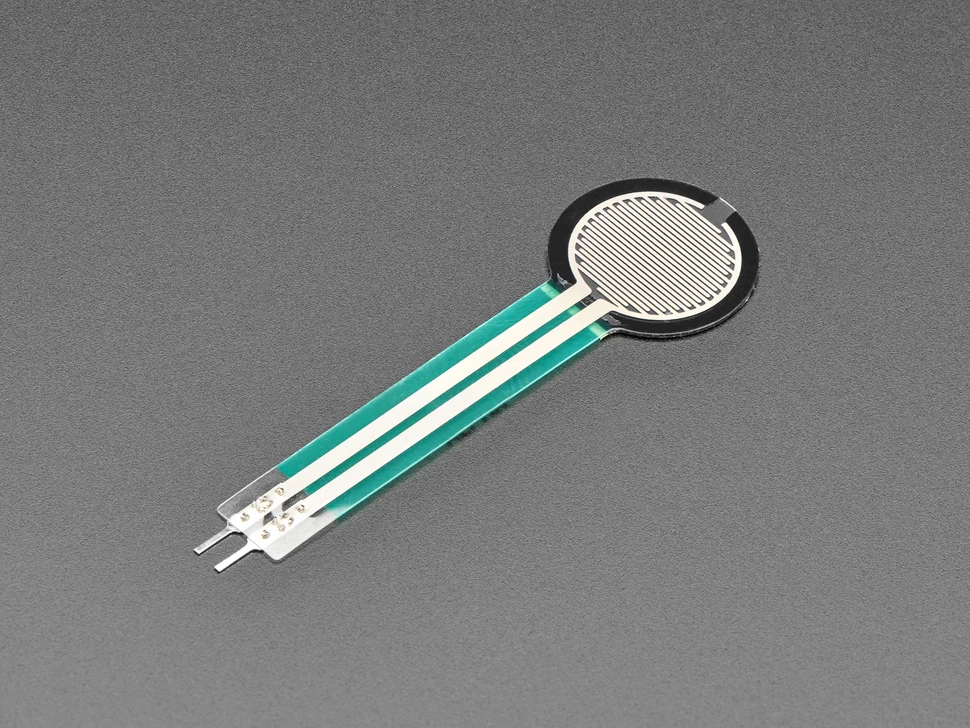

Have you ever seen your force sensitive resistor act weird? Sometimes, the numbers change quickly or do not work. This can make people upset when using force sensing technology. Problems often happen because of loose wires, harsh places, or old sensors. SOUSHINE makes sensors strong and reliable, but even the best ones can have issues. You can solve most problems by checking carefully and doing a few easy things.

Table of Contents

Key Takeaways

- Check your connections often. Loose wires can make the sensor act strange or not work.

- Keep your force sensitive resistor in a steady place. Changes in temperature or humidity can make it work differently.

- Press the sensor gently. Pushing too hard can break it and give wrong readings.

- Calibrate your sensor often. This helps it stay correct and dependable over time.

- Test your sensor with a multimeter. This tool helps you find problems with resistance or connections fast.

- Replace sensors that are old or broken right away. A new sensor can make your project work better again.

- Store your sensor the right way. Keep it clean and dry so it does not get ruined and lasts longer.

- Follow good steps when installing. Solder carefully or use good connectors to stop problems later.

Force Sensitive Resistor Issues

Erratic Readings

You might notice your force sensing resistors give numbers that jump around. This can make it hard to trust your pressure sensor. Several things can cause these changes:

- Temperature changes can affect how the sensor works.

- If you bend or curve the sensor, it may not read force correctly.

- Biological tissue, like skin, can press on the sensor in different ways, causing odd results.

If you see erratic readings, check if the sensor is flat and in a stable place. Try to keep the temperature steady. Make sure nothing soft or uneven is pressing on the sensor. You want your force sensitive resistor to sit on a solid surface for best results.

Tip: If you use force sensing resistors in a project, test them in the same spot and under the same conditions each time. This helps you spot problems faster.

No Response

Sometimes, your force sensing resistors do not react at all. You press down, but nothing happens. This can feel frustrating, especially when you need your pressure sensor to work right away.

A force sensitive resistor works when you press it, changing its resistance. If it does not respond, something is stopping this process. Here are some common reasons:

- Bad connections can stop the sensor from working.

- Incorrect wiring may block the signal.

- If you do not press hard enough, the sensor may not pick up any force.

If you see a reading of ‘0’ on your screen, check your wires first. Make sure everything is plugged in tight. Look at your code and see if you set up the sensor right. Try pressing a little harder, but do not use too much force. You want the sensor to last a long time.

Value Drift

You may notice your force sensing resistors start to show different numbers over time, even when you press with the same force. This is called value drift. It can make your pressure-sensing project less reliable.

Here is a table showing what causes value drift and how it affects your sensor:

| Cause | What Happens |

|---|---|

| Temperature Variations | Parts inside the sensor expand or shrink, changing resistance. |

| Power Supply Fluctuations | Changes in voltage can make the sensor give different numbers. |

| Long-Term Usage and Aging | Using the sensor a lot can wear it out, changing how it works. |

| Component Aging | Old parts inside the sensor can change how electricity moves through it. |

| Environmental Influences | Humidity or air pressure can make the sensor less stable and change its zero point. |

If you see value drift, try to keep your sensor in a dry, cool place. Use a steady power supply. Replace old force sensing resistors if they start to act up. This helps your pressure sensor stay accurate.

Note: Regular checks and simple fixes can keep your force sensitive resistor working well for a long time.

Causes of Force Sensing Resistor Problems

Electrical Connections

Loose Wires

Loose wires can make your force sensing resistors act strange. If your pressure sensor gives weird numbers or stops working, check the wires first. Wires that move around can break the connection. You might see the numbers jump or drop to zero. Always push connectors in all the way. If you use a breadboard, make sure the wires are tight. You want your force sensor to stay steady for good results.

Poor Soldering

Bad soldering can make your force sensitive resistor not work well. Solder joints that look dull or cracked can block signals. If your pressure sensor flickers or fails, look at the solder spots. You can fix this by heating the joint or adding new solder. Good soldering helps your force sensing resistors last longer and work better.

Mechanical Stress

Over-pressing

Pressing too hard on your force sensing resistors can break them. If you push past the limit, you might damage the sensor. Pushing too hard over and over can make the sensor wear out faster. Shear forces, like sliding or twisting, can also hurt the sensor. Use gentle, even pressure for the best results.

- Too much force can break the sensor.

- Pressing hard many times wears out the sensor.

- Shear forces can damage the sensor fast.

Wear and Tear

Using your force sensing resistors every day can wear them down. Over time, the sensor’s parts change. You might see the numbers drift or get less accurate. If your force measurement system acts strange, check for signs of aging. Replace old sensors to keep your pressure sensor working well.

Environmental Effects

Temperature Sensitivity

Temperature changes can affect your force sensing resistors. If the room gets hot or cold, the sensor’s resistance can change. This makes your numbers less accurate. You need to set up your force sensitive resistor in the same place you use it. Very hot or cold places can move the baseline resistance and mess up your numbers.

Here’s a table showing how temperature and other things affect calibration:

| Variable | Impact on FSR Calibration | Notes |

|---|---|---|

| Temperature | Affects sensor conductance | Calibrate in the use environment for best accuracy. |

| Curvature | Affects sensor conductance | Curved sensors need special calibration. |

| Compliance | Affects sensor conductance | Calibrate each sensor for its own environment. |

Humidity Impact

Humidity can change how your force sensing resistors work. Water in the air can get inside the sensor and mess up the numbers. If you use your pressure sensor in a wet place, you might see unstable readings. Water can lower insulation resistance and cause signal problems. Keep your force sensing resistors dry for better results.

- Temperature and humidity can change baseline resistance.

- Water can cause signal problems.

- Dry, cool places help your sensors stay accurate.

Tip: Always check the room before you use force sensing resistors. Stable temperature and low humidity help your sensors work better.

Here’s a table showing common problem types for force sensing resistors:

| Problem Category | Description |

|---|---|

| Sensitivity Issues | Sensors may miss small forces or show too much, causing less precision. |

| Linearity | Non-linear responses can cause mistakes in robotic arms and other devices. |

| Hysteresis | Sensors act different when force goes up or down, leading to data changes. |

| Temperature Effects | Changes in temperature can cause mistakes; calibrate for best results. |

| Overload | Too much force can break the sensor or mess up calibration. |

| Crosstalk | Forces on one side can change numbers on another, causing mistakes. |

| Noise | Vibrations and bumps can make measurements less accurate. |

| Calibration | Checking sensors often keeps them accurate as they get older. |

| Installation Issues | Bad mounting can cause force problems and lower accuracy. |

You can stop most problems by checking wires, using gentle pressure, and keeping your sensors in a good place. If you do these things, your force sensing resistors will work better.

Circuit and Code Errors

Wrong Resistor Choice

When you build a circuit with force sensing resistors, the resistor you use is very important. Picking the wrong resistor can make your pressure sensor act strange. The resistor in your voltage divider helps show changes in the sensor’s resistance. If the resistor is too high, small pushes might not show up. If it is too low, only strong presses will change the numbers.

Here’s a simple checklist to help you choose the right resistor for your force sensor:

- Think about the force range you want to measure.

- Check the sensor’s datasheet for resistor suggestions.

- Try different resistors to see which works best for you.

- Make sure your readings change smoothly when you press harder.

If your force sensitive resistor only works with very strong or weak pushes, try a different resistor. You want your system to notice all the pressures you need.

Tip: Start with a resistor value in the middle of the suggested range. Change it up or down until your force sensing resistor gives clear and steady numbers.

Calibration Issues

Calibration helps your force sensing resistors give correct numbers. If you skip calibration or do it wrong, your sensor can show bad results. You might see numbers that drift or jump, even if you press with the same force.

Common calibration problems are:

- Using easy math that does not match how the sensor really works.

- Not pressing evenly when you calibrate.

- Forgetting about temperature or humidity changes during setup.

Many force sensitive resistor models, like the Interlink 402, do not have a straight line between force and voltage. You need to use more complex math for better accuracy. If you use simple math, you might get errors as high as 20% at about 1kg of force. Static compression drift can also make your numbers change over time, even if the force stays the same.

Here’s a table showing common calibration problems and what they mean for your force-sensing setup:

| Calibration Issue | Description |

|---|---|

| Non-linear pressure-voltage relationship | The sensor’s output does not follow a straight line, so you need more complex math to calibrate. |

| Static compression drift | The sensor’s readings change slowly over time, even if you keep the same force on it. |

| Calibration techniques | You often need higher-order polynomial fits, not just simple equations, to get good results. |

To calibrate your force sensing resistors, use weights and a flat plate to press evenly. Fit your resistance output to a log-log linear curve or a polynomial equation. Test your sensor with different forces to check for drift or non-linearity.

Note: Good calibration makes your force sensitive resistor much more trustworthy. Take your time and check your results often.

If you want your pressure sensor to work well, pay close attention to both the resistor choice and calibration steps. These small things can make a big difference in how your force sensing resistors work.

Troubleshooting Force Sensitive Resistor Hookup

Inspecting Connections

Start by checking every wire and connector in your force sensitive resistor hookup. Loose wires or weak connections can cause your pressure sensor to act up. You want to see solid connections at every point.

- Look at the sensor tabs and make sure they are not bent or damaged.

- Push each jumper wire into the breadboard until it feels secure.

- If you use solder, check for shiny, smooth joints. Dull or cracked solder can break the signal.

- Try using ZIF sockets or a pin adapter for easier and safer connections. These tools help you avoid damaging the flexible part of the sensor.

Tip: If you see numbers jump or drop to zero, wiggle each wire gently. If the readings change, you found a weak spot.

Testing with a Multimeter

A multimeter helps you test your pressure sensor quickly. You can check if the sensor changes resistance when you press it.

- Set your multimeter to resistance mode.

- Touch the probes to the sensor tabs.

- Press the sensor gently. Watch the numbers on the screen. The resistance should drop as you press harder.

- Use an auto-ranging multimeter for easy testing. If you use a manual one, try ranges between 1 MΩ and 100 Ω.

- If the resistance does not change, check your connections again or try a different sensor.

Regular calibration helps your force sensing resistors stay accurate. Test your sensor often to catch problems early.

Note: A multimeter can also help you spot shorts or broken wires. If you see a very low resistance with no pressure, you might have a short.

Cleaning and Handling

You want your pressure sensor to last. Good cleaning and handling make a big difference.

- Store your sensor in ESD-safe containers to prevent static damage.

- Use anti-static mats and flooring in your workspace. These tools help you avoid static shocks.

- Keep the room between 18-25°C. This temperature range protects the sensor from thermal stress.

- Control humidity between 30-60%. This level helps balance static protection and sensor stability.

- Use ionizers if you work in a dry area. Ionizers release ions that neutralize static charges.

- Make sure the air is clean. Dust and dirt can get inside the sensor and cause problems.

Tip: Always handle your force sensitive resistor by the edges. Avoid touching the sensing area with your fingers. Oils and dirt can change how the sensor works.

If you follow these steps, you help your force sensing resistors stay reliable and accurate. Clean sensors and safe handling keep your pressure sensor working longer.

Reviewing Code and Circuit

You want your pressure sensor to work every time you use it. If you see strange readings or no response, check your code and circuit. Many problems come from small mistakes in wiring or programming. Here are steps you can follow to review your setup:

- Connect one end of the force sensitive resistor to 5V. Attach the other end to Analog 0 on your microcontroller.

- Place a 10K resistor between Analog 0 and ground. This setup helps your pressure sensor give clear readings.

- Add an LED to pin 11. Use a resistor between the LED and ground to protect the LED.

- Write code that reads the analog value from the pressure sensor. Use this value to control the brightness of the LED. When you press harder, the LED gets brighter.

- Open the Serial monitor in your coding software. Print the analog readings so you can see how the sensor reacts when you press it.

- Check your wiring again. Make sure each wire goes to the right spot. Look for loose connections or swapped pins.

- Review your code for errors. Make sure you use the correct pin numbers and variable names.

Tip: If you see numbers that do not change or look wrong, try printing extra information in your code. This helps you find where the problem starts.

Testing each part of your circuit and code helps you find mistakes fast. You can fix most problems by following these steps.

Replacing the Sensor

Sometimes, your pressure sensor stops working even after you check everything. If you see no change in readings or the sensor feels damaged, you may need to replace it. Old sensors can wear out after many uses. You want your project to stay reliable, so swapping in a new sensor is a smart move.

Here’s how you can replace your force sensitive resistor:

- Turn off your device before you remove the old sensor.

- Gently pull the sensor out of its socket or unsolder it from the board.

- Check the new sensor for any damage before you install it.

- Place the new sensor in the same spot as the old one. Make sure the connections match.

- Power up your device and test the new sensor with a multimeter or your code.

- Calibrate the new sensor if needed. Use weights or steady pressure to set the baseline.

If you need a reliable replacement, SOUSHINE offers force sensitive resistors that work well in many projects. You can choose the size and shape that fits your needs. Their sensors last longer and give steady readings.

Note: Always keep a spare sensor on hand. Quick replacement helps you avoid long delays in your work.

Replacing your pressure sensor keeps your project running smoothly. You can solve most problems with a new sensor and a careful setup.

User Experiences with Force Sensing Resistors

Common Problems and Fixes

You might run into a few problems when you use force sensing resistors in your projects. Many users share similar stories. Sometimes, the sensor starts to drift, or the numbers change for no reason. You may see the sensor act differently when the room gets hot or cold. Some people notice the sensor wears out faster if they press it sideways or use too much force.

Here’s a table that shows common problems and how you can fix them:

| Problem | Effective Fixes |

|---|---|

| Signal Drift | Use less than 3 V, around 2 V works well. Use special cables to block noise. |

| Mount the sensor so it can move a little. Protect it from water and moisture. | |

| Add filters to reduce shaking. Let the sensor move sideways if needed. | |

| Temperature Sensitivity | Calibrate the sensor at the same temperature you plan to use it. |

| Durability | Press straight down. Think about the force and materials you use. |

| Avoid shear forces to make the sensor last longer. |

One SOUSHINE user shared that their sensor started to drift after a few weeks. They fixed it by lowering the voltage and using shielded cables. Another user found that pressing straight down helped the sensor last longer. You can learn from these stories and try these fixes in your own setup.

Best Practices for Reliability

You want your force sensitive resistor to work every time you use it. Many users follow simple steps to keep their sensors reliable. You can test your sensor before you install it. You can check the output voltage when there is no force. If the sensor shows a strange number, you might want to use a different one.

“You can use the output voltage at zero force to find sensors that do not work right. Adjusting the input voltage helps you fine-tune the sensitivity. These steps help you get steady results and avoid surprises.”

You can also keep your sensor clean and dry. Store it in a safe place when you are not using it. If you work in a hot or cold room, calibrate your sensor there. You can use mounts that let the sensor move a little. This helps stop signal drift and keeps your readings steady.

Many SOUSHINE users say their sensors work well when they follow these tips. You can get better results by checking your setup often and making small changes. If you see a problem, try one of the fixes above. You can keep your force sensing resistors working for a long time.

Preventing Future FSR Issues

Proper Installation

You want your pressure sensor to work well. Installing it the right way matters a lot. If you solder wires, do it carefully. Too much heat can hurt the sensor. You can use special connectors instead of soldering. The Amphenol FCI Clincher connector gives a strong link. It also helps stop strain on the sensor tabs.

Here is a table with two ways to install your sensor:

| Technique | Description |

|---|---|

| Careful Soldering | Solder wires or a PCB to the tabs, but use little heat. |

| Alternative Connection | Use the Amphenol FCI Clincher connector for a strong and easy connection. |

When you put in your sensor, keep the surface flat and clean. Do not bend or twist the sensor. Use gentle pressure when you mount it. This helps your force measurement system stay accurate and last longer.

Tip: Always check your connections before you turn on your project.

Environmental Protection

You can help your pressure sensor last longer by keeping it safe. Keep your sensor away from water and dust. Store it in a dry place when you are not using it. If you use your sensor outside, cover it with a shield or case.

Many people use eco-friendly materials now. These materials help lower harm from making electronics. You should follow rules for the environment. This keeps your project safe and responsible. Some people recycle old sensors and parts. This saves resources and helps the industry.

Here is a table with ways to protect your sensor and the environment:

| Contribution to Sustainability | Description |

|---|---|

| Reducing Environmental Impact | Eco-friendly materials help lower harm from making electronics. |

| Aligning with Regulatory Standards | Following rules for the environment is important for makers. |

| Promoting Circular Economy | Using and recycling materials helps save resources in the industry. |

Note: A simple cover or case can keep dust and water away from your sensor.

Regular Maintenance

You can keep your pressure sensor working well by checking it often. Look at the sensor and wires every few weeks. Clean off dust or dirt with a soft cloth. If you see damage, replace the sensor right away. Test your sensor with a multimeter to make sure it still works when you press it.

Write down your test results in a notebook. This helps you see changes over time. If you notice numbers drift or the sensor stops working, you can fix it before it gets worse.

- Check wires and connectors for damage.

- Clean the sensor gently.

- Test the sensor often.

- Replace old sensors when needed.

Doing these steps helps your projects work well and saves you time later.

Choosing Force Sensing Resistors

Comparing Brands and Models

If you need a pressure sensor, you want the best one. Different brands and models have special features. You should look at some key things before you pick. Here’s a table to help you compare:

| Criteria | Description |

|---|---|

| Durability | Sensors should last long and handle rough use. |

| Environmental | Sensors must resist dust and water in tough places. |

| Form Factor | The size and shape should fit many devices. |

| Repeatability | Sensors need to work the same way every time. |

| Sensitivity | Sensors should measure many different forces. |

| Cost | The price should fit your project needs. |

Use this table to see which sensor matches your needs. If you work in a rough place, pick a sensor that keeps out water and dust. If you need a small sensor, choose one with a tiny size. Always check if the sensor gives the same reading each time. You want your pressure sensor to be reliable.

SOUSHINE FSR Advantages

SOUSHINE is a good choice for force sensing resistors. These sensors are very accurate and use little power. They last a long time and come in many shapes and sizes. You can find one that fits your device easily.

Here’s a table that shows how SOUSHINE compares to other brands:

| Feature | SOUSHINE’s Technology | Competitors |

|---|---|---|

| Accuracy | High | Lower |

| Durability | Long-lasting | Varies |

| Customization | Many choices | Fewer choices |

| Power Consumption | Low | Higher |

| Integration Ease | Simple | Harder |

You can also make SOUSHINE sensors special for your brand. You can add your logo, packaging, and graphics. You can pick the size, shape, output signal, and calibration. SOUSHINE sensors work well in tough places and last a long time.

Tip: If you want a sensor that fits your project, ask SOUSHINE about custom options. You can get a pressure sensor made just for you.

SOUSHINE helps you with setup and answers your questions. Many people say SOUSHINE sensors work well in robots and medical devices. You can trust these sensors to give steady results.

When you pick a sensor, think about what matters most for your project. Look at how strong, accurate, and easy to use the sensor is. SOUSHINE gives you choices that help you build better products.

You can solve most force sensitive resistor problems by looking at the wires, cleaning the sensor, and using a multimeter to test it. If your sensor starts to drift or stops working, try swapping it for a new one. Checking your sensor often helps your projects work well. SOUSHINE has good sensors and can help if you need a replacement.

Do you have a story or question? Write it in the comments. Your advice can help other people!

FAQ

Why does my force sensitive resistor give different readings each time?

You might see different numbers because of loose wires, changes in temperature, or pressing the sensor in new ways. Try to keep your setup the same every time.

How do I clean my force sensitive resistor?

Use a soft, dry cloth. Avoid water or chemicals. Handle the sensor by the edges to keep the sensing area clean.

Can I use my force sensitive resistor outdoors?

You can use it outside, but protect it from water and dust. A simple cover helps keep your sensor safe.

What is the best way to connect my force sensitive resistor?

Solder wires carefully or use a connector like the Amphenol FCI Clincher. Make sure every wire feels secure.

How do I test if my sensor works?

Grab a multimeter. Set it to resistance mode. Press the sensor and watch the numbers change. If nothing happens, check your wires.

Why does my sensor stop working after a while?

Sensors can wear out from heavy use or rough handling. Replace old sensors to keep your project running.

Can I adjust the sensitivity of my force sensitive resistor?

Yes! Change the resistor in your circuit. Try different values until you get the response you want.

What should I do if my sensor drifts over time?

Calibrate your sensor often. Keep it in a stable place. Replace it if the numbers keep changing.