Call us: +86-137-2353-4866

The integration of health monitoring systems within automotive environments represents a significant advancement in passenger safety and wellness. Non-invasive blood pressure monitoring is a critical component of this evolution. At the core of these systems are force sensors, which provide the fundamental data required for accurate and consistent blood pressure measurement. SOUSHINE delivers high-precision force sensing solutions engineered for the specific demands of automotive-grade medical monitoring applications. Our technology enables the reliable detection of arterial pressure fluctuations, forming the basis for systolic and diastolic pressure calculation.

What is the Role of a Force Sensor in Blood Pressure Monitors?

In an automated, non-invasive blood pressure monitor, a force sensor is a transducer that converts a physical force—specifically, the pressure exerted by arterial blood flow—into a measurable electrical signal. Within the context of an inflatable cuff system, as the cuff pressure changes, the force sensor detects the subtle oscillations of the arterial wall. The amplitude of these oscillations is then processed by the device’s microcontroller to determine the patient’s blood pressure. SOUSHINE’s force sensors are designed to capture these minute pressure changes with high fidelity.

How Do Force Sensors Function in an Automated Blood Pressure Cuff?

The functionality of force sensors in blood pressure monitoring is based on the oscillometric method. The process unfolds as follows:

- Cuff Inflation: An inflatable cuff is placed around the user’s arm. A pump inflates the cuff to a pressure that temporarily occludes the brachial artery.

- Controlled Deflation: The cuff pressure is then released in a controlled, linear manner.

- Oscillation Detection: As the pressure in the cuff decreases and falls below the systolic pressure, blood begins to flow through the artery, causing the arterial wall to oscillate. These oscillations are transmitted to the cuff.

- Signal Transduction: The force sensor, integrated within the cuff’s pressure system, detects these pressure oscillations. The sensor’s material deforms under these pressure changes, causing a corresponding change in its electrical resistance.

- Data Processing: This change in resistance is converted into a voltage signal. The point of maximum oscillation corresponds to the Mean Arterial Pressure (MAP). Advanced algorithms then calculate the systolic and diastolic pressures based on the oscillation amplitude profile.

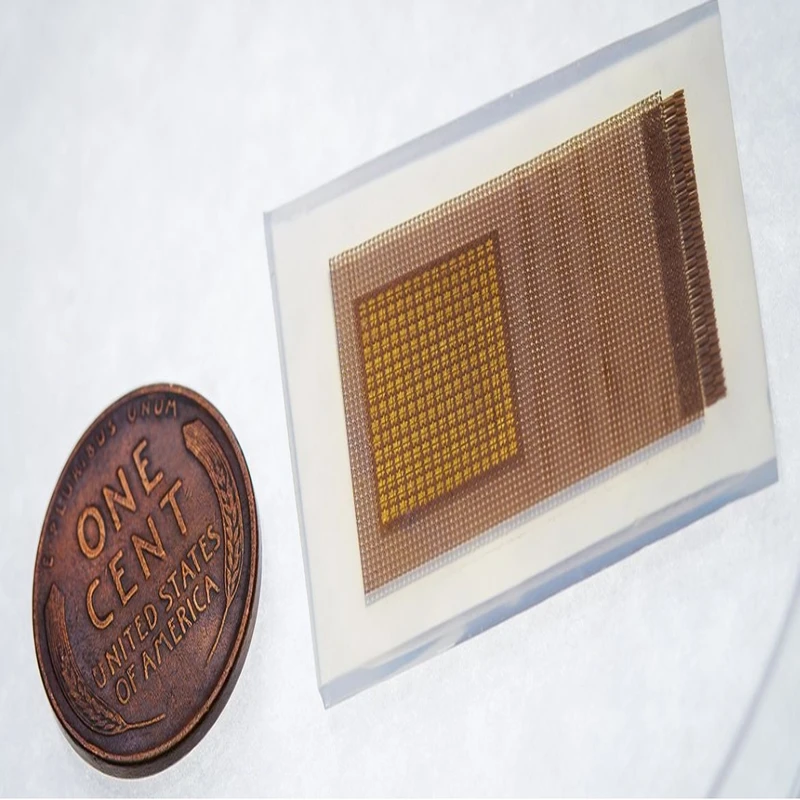

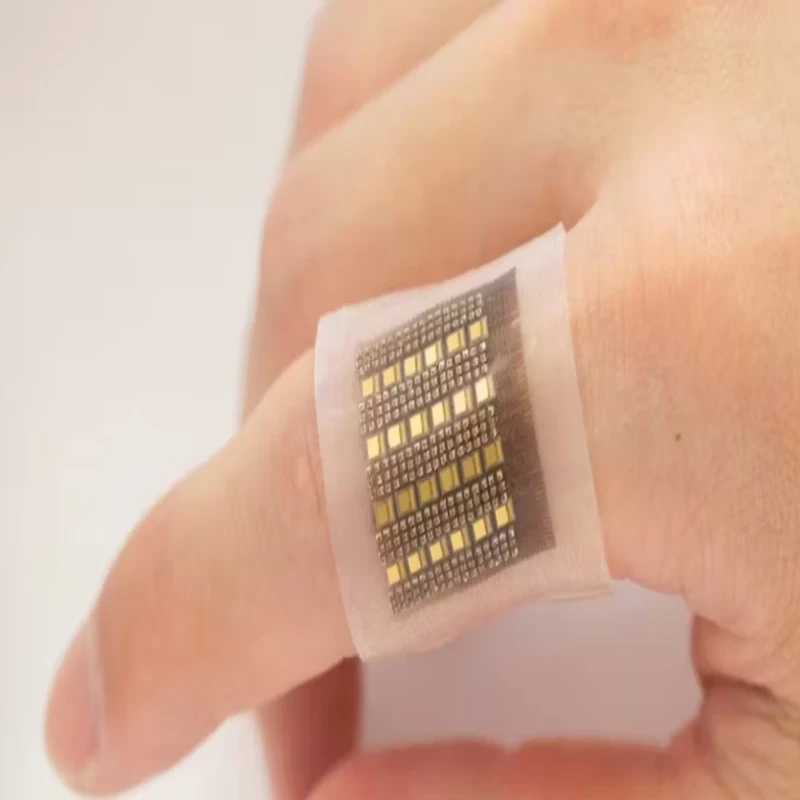

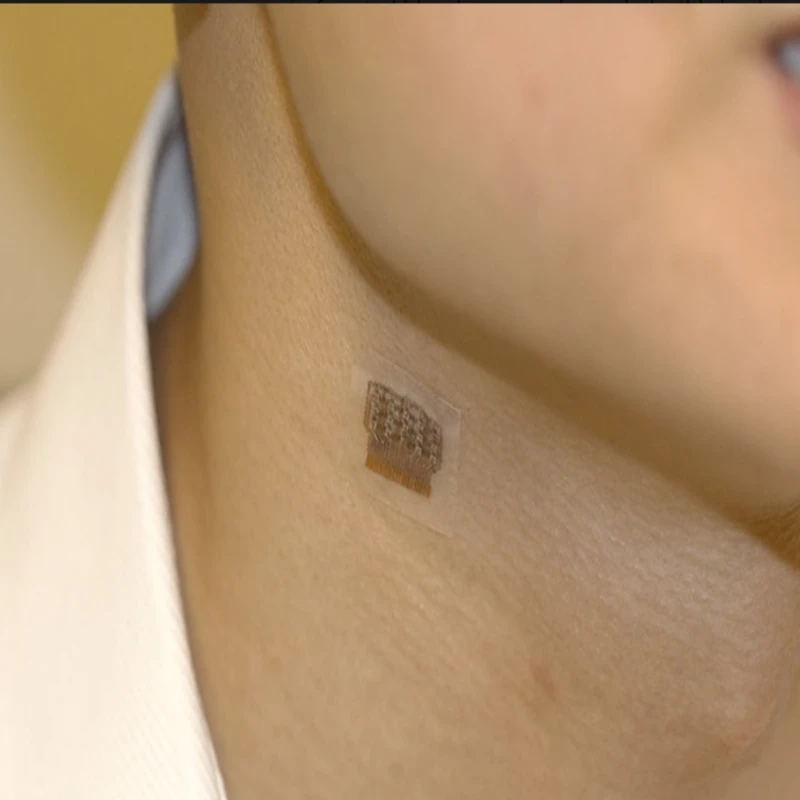

SOUSHINE’s Force Sensing Resistors (FSRs) are ideally suited for this application, offering a thin profile, high sensitivity, and excellent repeatability.

Why is Advanced Force Sensing Technology Critical?

The accuracy and reliability of an automated blood pressure monitor are directly dependent on the quality of its force sensor. The selection of a high-performance sensor is critical for several reasons:

- Accuracy: The sensor must be sensitive enough to detect very small pressure fluctuations in the arterial wall against the background pressure of the cuff. This is essential for the precise determination of systolic and diastolic points.

- Reliability: The sensor must provide consistent performance over a wide range of operating temperatures and humidity levels, as expected in an automotive environment. It must also withstand the mechanical stress of repeated cuff inflation and deflation cycles.

- Repeatability: For effective long-term health monitoring, successive measurements must be consistent. A high-quality force sensor ensures that the device produces repeatable results under identical conditions.

- Noise Immunity: The sensor and its associated electronics must be designed to filter out noise and vibrations from the vehicle, which could otherwise interfere with the low-amplitude pressure oscillations.

SOUSHINE’s expertise in Force Sensing technology ensures that our sensors meet these stringent requirements, providing a robust foundation for any blood pressure monitoring system.

Display

FAQ

What type of force sensor is typically used in a blood pressure monitor?

Piezoresistive force sensors, such as Force Sensing Resistors (FSRs), are commonly used. Their resistance changes predictably in response to applied pressure, making them highly effective for detecting the subtle oscillations in a blood pressure cuff.

How does the sensor’s performance affect the accuracy of the blood pressure reading?

The sensor’s sensitivity, linearity, and repeatability are paramount. A highly sensitive sensor can detect faint arterial oscillations, which is crucial for patients with weak pulses. Good linearity ensures that the electrical signal accurately represents the pressure change, and high repeatability guarantees consistent readings over time.

Can SOUSHINE sensors be integrated into different types of blood pressure monitoring systems?

Yes, our force sensors are designed for versatile integration. With their thin and flexible form factor, they can be incorporated into a variety of cuff designs and monitoring device architectures, including those intended for in-vehicle use.

What is the typical pressure range for a force sensor in this application?

The sensor must operate accurately within the typical range of human blood pressure and the pressures exerted by the cuff, which generally spans from 0 to 300 mmHg (millimeters of mercury).

How does SOUSHINE ensure the reliability of its force sensors for medical applications?

Our sensors undergo rigorous testing for durability, accuracy, and performance under various environmental conditions. We adhere to strict quality control processes in our manufacturing to ensure every sensor meets the high standards required for medical device integration.