Call us: +86-137-2353-4866

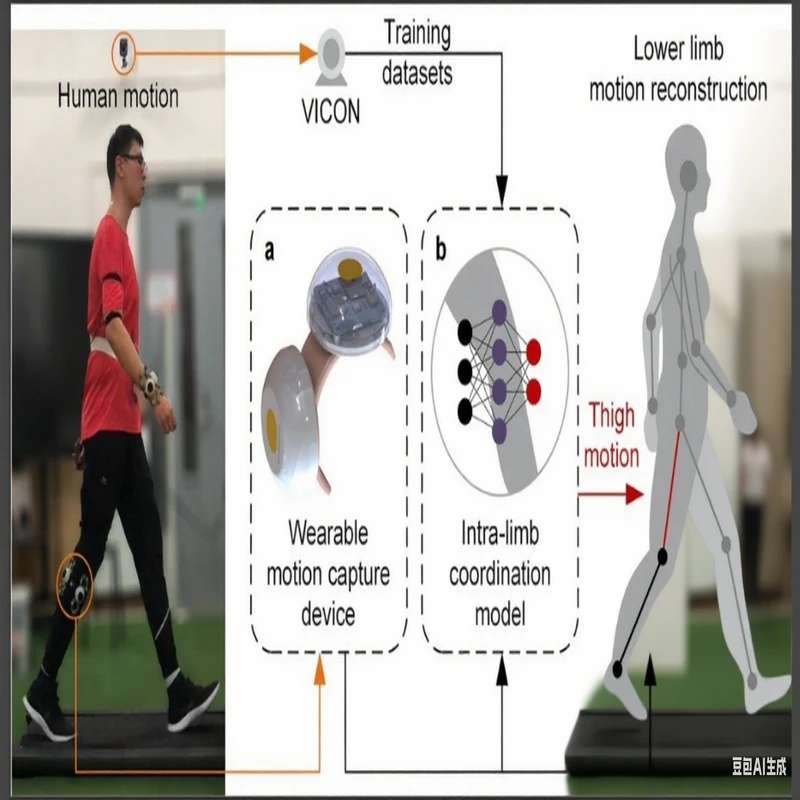

The evolution of robotics is moving towards greater collaboration between humans and machines in shared workspaces. This proximity necessitates advanced safety and control systems. Human-Robot Interaction (HRI) is a field dedicated to developing these intuitive and safe interfaces. Force sensing technology is a critical component in this field, providing robots with the equivalent of a sense of touch. It allows a machine to detect, measure, and react to physical contact, transforming it from a pre-programmed tool into a responsive collaborator.

SOUSHINE specializes in the design and manufacture of Force Sensing Resistors (FSR) that provide the reliability and precision required for demanding HRI applications.

What is Force Sensing in Human-Robot Interaction?

In the context of HRI, force sensing is the measurement of forces and torques resulting from direct physical contact between a robot and a human or its environment. This data is processed in real-time by the robot’s controller to execute a specific response, such as stopping, reducing speed, or adjusting its path. The primary objective is to ensure human safety while enhancing the robot’s utility and ease of use.

- Responsiveness: It allows the robot to perform tasks that require delicate force application, similar to a human touch.

- Safety: It acts as a primary safety mechanism to prevent injury from unintentional contact.

- Intuition: It enables more natural and intuitive control methods, such as hand guiding.

How Force Sensors Enable Safe and Intuitive HRI

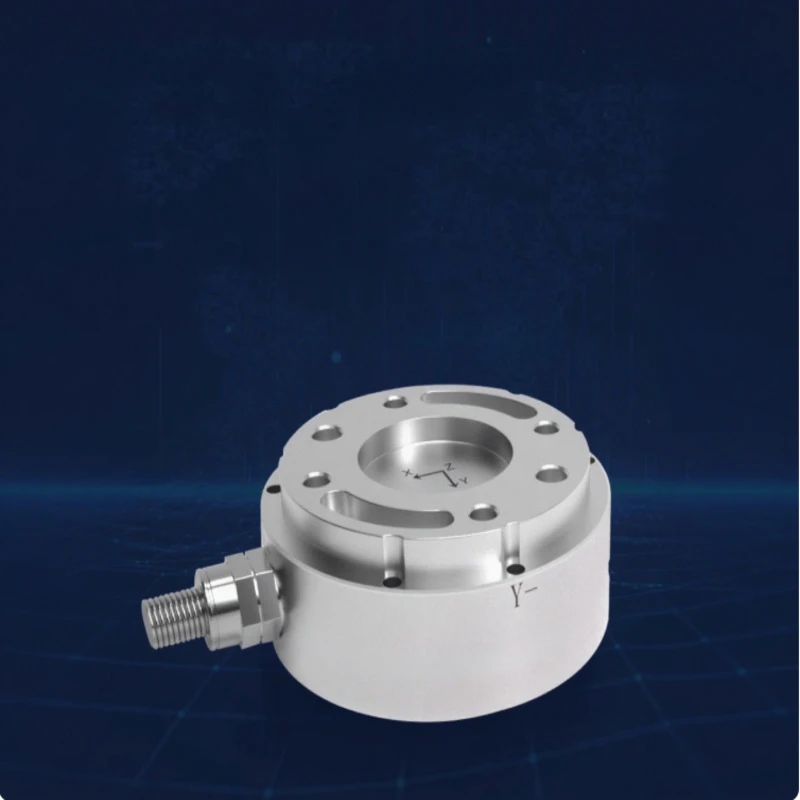

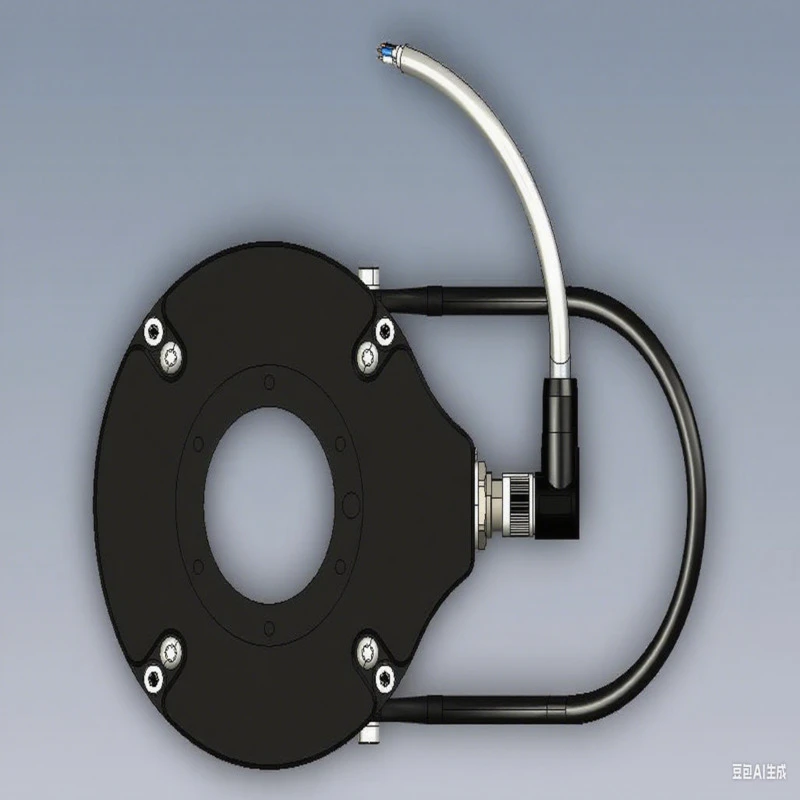

SOUSHINE’s Force Sensing Resistors are integrated into various points of a robotic system to quantify physical interaction. The principle is based on a material whose electrical resistance changes in proportion to the force applied to its surface. This simple yet robust mechanism enables several key HRI functionalities:

- Collision and Contact Detection: Our thin-film FSRs can be applied as a “skin” to the robot’s chassis or integrated into its joints. When a human makes contact with the robot, the sensors register the applied force instantly. This signal is sent to the robot controller, which can immediately halt or reverse the robot’s motion, mitigating the risk of injury long before a standard motor current sensor would react.

- Force Limiting for Collaborative Operations: In collaborative robots (“cobots”), force sensors are essential for meeting safety standards (e.g., ISO/TS 15066). The sensors continuously monitor the forces exerted by the robot arm. If these forces exceed a pre-defined, safe threshold during an operation or a collision, the system triggers a protective stop.

- Hand Guiding and Teach Programming: By integrating force sensors into the robot’s wrist or end-effector, users can physically guide the robot arm to teach it new paths or positions. The sensors measure the direction and magnitude of the force applied by the operator’s hand, and the controller translates this data into corresponding motor commands. This “teach-by-demonstration” method significantly reduces programming time and complexity.

Why Integrate SOUSHINE Force Sensors into HRI Systems?

The integration of force sensing is not merely a feature; it is a fundamental requirement for modern collaborative robotics. Utilizing SOUSHINE’s specialized sensors provides distinct, measurable advantages:

- Enhanced Safety Compliance: Our sensors provide the high-speed, reliable data necessary for systems designed to comply with international safety standards for collaborative robots.

- Increased Productivity: By enabling robots and humans to work in close proximity without extensive physical barriers, force sensing technology reduces factory floor footprint and streamlines workflows. Simplified programming through hand guiding also accelerates deployment and task changeovers.

- Improved System Performance: With a sense of touch, robots can perform delicate assembly, polishing, or inspection tasks that require precise force control, leading to higher quality output and reduced product damage.

- Customization and Integration: SOUSHINE’s FSR technology is highly adaptable. Our sensors can be produced in custom shapes and sizes to fit complex geometries, allowing for seamless integration into robot joints, grippers, or external surfaces without significant design modifications.

Display

FAQ

What is the difference between a force sensor and a torque sensor in a robot arm?

A force sensor measures linear force (push/pull) along an axis, while a torque sensor measures rotational force (twisting). In HRI, multi-axis force/torque sensors are often integrated into the robot’s wrist to detect both types of forces, providing comprehensive data about any interaction with the end-effector. Our FSRs are primarily used to detect distributed normal forces on a robot’s body or gripper.

How durable are SOUSHINE’s FSR sensors in industrial environments?

Our sensors are designed for high-cycle industrial applications. They are built with robust materials to withstand repeated actuation, and can be sealed to provide resistance to dust, moisture, and common industrial chemicals, ensuring long-term operational reliability.

Can your force sensors be customized for our specific robot’s design?

Yes. Customization is a core part of our business at SOUSHINE. We can manufacture FSR sensors in various shapes, sizes, and force sensitivity ranges to meet the precise mechanical and electronic requirements of your robotic application.

Do your sensors help a robotic system meet safety certifications?

Our sensors provide the fundamental data required for a safe HRI system. While the final certification applies to the entire robotic system, our sensors are designed with the reliability and fast response times necessary to enable a system to meet standards like ISO/TS 15066 for power and force limiting.

What is the typical data output from your force sensing solutions?

Our FSRs produce a change in resistance that is inversely proportional to the applied force. This analog signal is typically processed through a simple electronic circuit (like a voltage divider) to produce a voltage output that can be read by a microcontroller or the robot’s main controller. We provide detailed integration guidelines to support this process.