Call us: +86-137-2353-4866

Hydraulic and pneumatic systems are foundational to industrial automation, providing the power for everything from heavy lifting and pressing to precise gripping and clamping. The performance, safety, and efficiency of these systems are critically dependent on the accurate monitoring of operational forces. At SOUSHINE, we provide advanced force sensing solutions that offer real-time insights into your hydraulic and pneumatic applications, enabling precise control, predictive maintenance, and enhanced safety. This page details the application of our force sensing technology in monitoring these powerful systems.

What is Force Sensing in Hydraulic and Pneumatic Systems?

In the context of hydraulic and pneumatic systems, force sensing is the measurement of the output force generated by an actuator, such as a cylinder or a press. While pressure sensors measure the internal pressure of the fluid or gas that powers the system, force sensors directly measure the mechanical force being exerted by the system on an external object or component.

This direct measurement provides a true reflection of the system’s operational output, accounting for internal variables like friction, seal integrity, and minor pressure fluctuations. It allows for a more accurate understanding of the work being performed, from the clamping force of a pneumatic gripper to the tonnage of a hydraulic press.

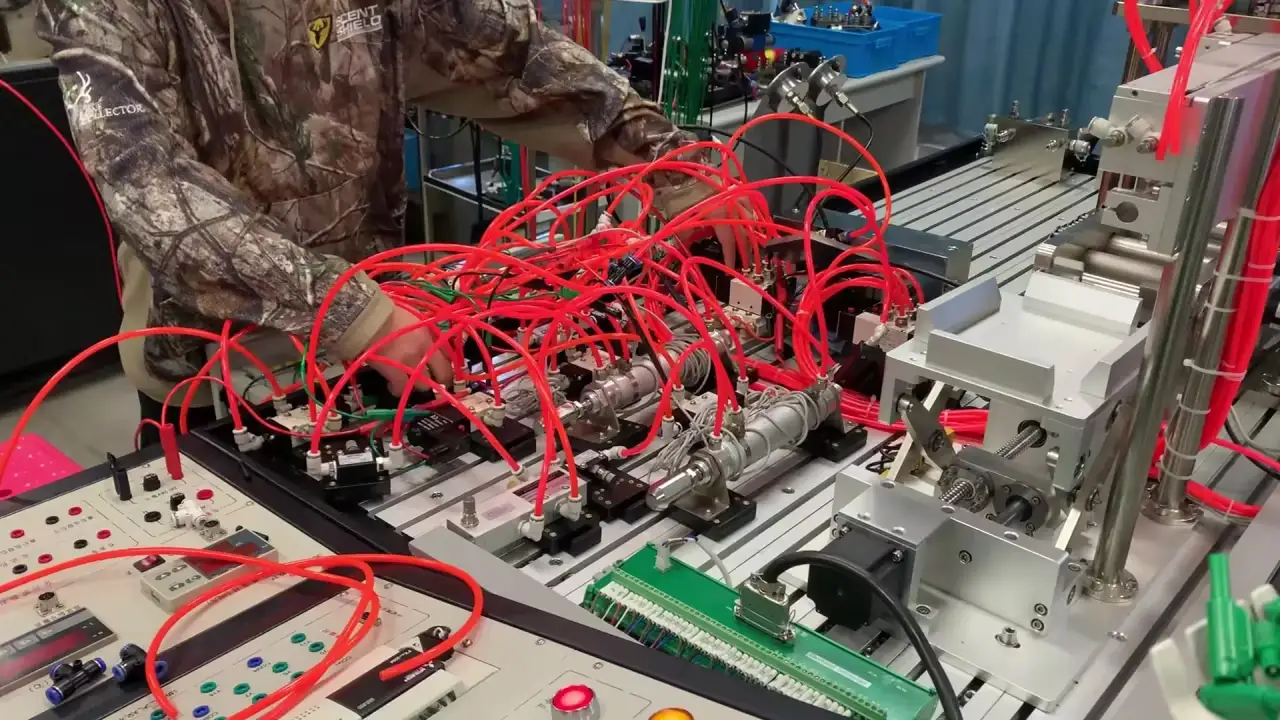

How Force Sensors are Applied in Hydraulic and Pneumatic Monitoring

SOUSHINE’s force sensors are integrated into various points within and around hydraulic and pneumatic systems to provide critical operational data. The implementation is determined by the specific monitoring objective.

- Load Monitoring on Actuators: Force sensors can be installed on the end of a piston rod or integrated into the mounting of a hydraulic or pneumatic cylinder. This placement allows for the direct measurement of the pushing or pulling force being exerted by the actuator.

- Clamping and Gripping Force Verification: In applications such as robotic end-effectors or industrial clamps, force sensors are embedded within the gripping or clamping mechanism. This ensures that the correct amount of force is applied to securely hold an object without causing damage.

- Press Force Control: For hydraulic and pneumatic presses used in applications like stamping, molding, or assembly, force sensors are placed in line with the press ram. This provides precise feedback on the amount of force being applied, ensuring product quality and consistency.

- System Overload Protection: By continuously monitoring the output force, our sensors can detect overload conditions in real-time. This data can be used to trigger an immediate system shutdown or alert, preventing damage to machinery and ensuring operator safety.

Why Monitor Force in Hydraulic and Pneumatic Systems?

Integrating direct force measurement into your hydraulic and pneumatic systems provides significant operational advantages, enhancing process control, safety, and equipment longevity.

- Improved Process Control and Quality: By monitoring the actual force output, you can ensure consistent and repeatable performance. In applications like assembly or molding, precise force application is critical to maintaining product quality and reducing defects.

- Enhanced Safety: Real-time force monitoring is crucial for preventing system overloads that can lead to catastrophic failures. It ensures that equipment operates within its designated safe limits, protecting both machinery and personnel.

- Predictive Maintenance: Deviations in force measurements can indicate underlying mechanical issues such as seal wear, internal leaks, or increased friction. By tracking force data over time, you can identify these trends and schedule maintenance proactively before a failure occurs, minimizing unplanned downtime.

- Increased Efficiency: By understanding the precise force required for a given task, you can optimize system pressure and flow. This prevents the use of excessive energy, leading to more efficient operation and reduced running costs.

Display

FAQ

What is the difference between a pressure sensor and a force sensor in hydraulic systems?

A pressure sensor measures the pressure (force per unit area) of the hydraulic fluid or compressed air within the system. A force sensor, on the other hand, measures the total mechanical output force exerted by an actuator, such as a cylinder rod. While system pressure is related to output force, direct force measurement provides a more accurate indication of the work being done, independent of factors like friction or component wear.

Can SOUSHINE’s force sensors be integrated into existing hydraulic or pneumatic equipment?

Yes, our force sensors are designed for versatile integration. They can be retrofitted onto existing machinery, often with minimal modification. We offer a range of sensor geometries and mounting options to accommodate various industrial applications.

Are your force sensors durable enough for harsh industrial environments?

Our force sensors are constructed with robust materials designed to withstand the demanding conditions often associated with industrial hydraulic and pneumatic systems. They are resistant to vibration, shock, and, with appropriate housing, exposure to industrial fluids and contaminants.

How does force monitoring contribute to preventing equipment damage?

By providing real-time data on the output force, our sensors can detect immediate overload conditions or spikes in force that could damage tooling, the workpiece, or the machine itself. This allows for automated shutdowns or alerts that can prevent costly repairs and extend the operational life of your equipment.

What kind of output do your force sensors provide?

Our force sensors provide a reliable electrical signal that is proportional to the applied force. This signal can be integrated with your existing control systems, such as a PLC (Programmable Logic Controller) or a dedicated data acquisition system, for real-time monitoring, analysis, and control.