Call us: +86-137-2353-4866

The global market for industrial force sensors will be $2.52 billion in 2025. Many manufacturers and engineers use these devices to make work safer and faster. Industry leaders also depend on them to help their businesses run better. SOUSHINE is a top company that creates new and reliable solutions. These solutions help smart manufacturing grow. Industrial force sensors give real-time feedback to control processes. They help stop accidents and keep quality high. Advanced force sensing resistors now work better with automation systems. They also help with predictive maintenance, so factories can be smarter and react faster.

Table of Contents

Key Takeaways

- The industrial force sensor market may reach $2.52 billion by 2025. This is because of new technology in automation and smart manufacturing.

- Smaller sensors give better accuracy and fit into small spaces. This helps machines work better and cuts down on waste.

- Wireless connections make it easier to set up sensors. They also let sensors send data right away without lots of wires.

- AI in force sensors helps with predictive maintenance. It lets factories find problems before machines break down.

- SOUSHINE is a top company with new sensors. These sensors help keep people safe and improve quality and efficiency in many industries.

- Sustainability is very important now. Companies want sensors that save energy and use eco-friendly materials to help the environment.

- New uses in healthcare and renewable energy show how useful force sensors are. They help make things safer and more efficient.

- Knowing about these trends helps businesses change and do well as the industry changes fast.

Key Trends In Industrial Force Sensors

The industrial force sensors market is changing quickly. Some important trends will shape the future in 2025. These trends are miniaturization, wireless connectivity, and AI integration. Each trend brings new ways to control processes, automate tasks, and keep people safe. SOUSHINE’s advanced force sensors lead this change and help industries get better results.

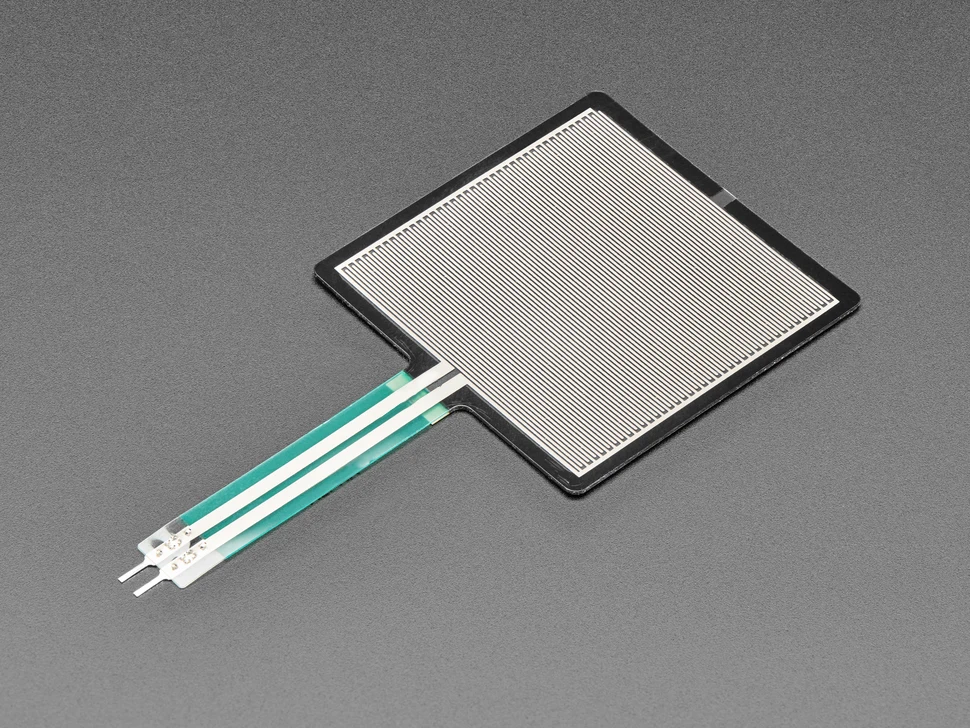

Miniaturization

Smaller sensors can fit into tiny spaces now. This helps machines work with more accuracy. Micro tension sensors give real-time data about force and tension. They help factories use materials better and waste less. Miniaturized sensors also help stop equipment from breaking by finding problems early.

Integration

Engineers can put small sensors inside robotic arms and assembly lines. These sensors work with other machine parts. They send data to computers that control everything. This makes machines smarter and more dependable.

Robotics

Robots use small sensors for careful jobs. For example, a robot hand can hold a fragile item without breaking it. In factories, collaborative robots use force sensors to keep workers safe. These robots stop if they feel too much force or hit something. Miniaturization lets robots work in tight spaces and do delicate tasks.

Wireless Connectivity

Wireless connectivity is changing how factories use data. Sensors do not need long wires anymore. This makes setting up easier and costs less. Wireless sensors work well in places that are hard to reach or dangerous. They send real-time data to control systems so problems get fixed fast.

Flexibility

Wireless sensors make factories more flexible. Machines can move or change without new wires. This saves time and money. Wireless systems also make it easy to add new sensors when needed.

Security

Wireless networks must be safe. Factories use strong encryption to keep data safe from hackers. Secure wireless connectivity keeps information safe and lets sensors talk to control systems quickly.

Tip: Wireless sensors help factories find problems fast. They let workers act right away, so machines keep working well.

AI Integration

Artificial intelligence is making force sensors smarter. AI systems look at sensor data right away. They help machines learn from past actions and get better over time. This means better performance and fewer mistakes.

Predictive Maintenance

AI-powered sensors watch for trouble signs. They notice small changes like extra shaking or heat. These signs can mean a machine might break soon. Predictive maintenance uses this info to fix problems before machines stop working. This saves money and keeps production going.

Quality Control

AI helps with quality control too. It checks products for defects using sensor data and pictures. If it finds a problem, it tells workers right away. This quick action cuts waste and makes sure every product is good.

| Benefit of AI Integration | Description |

|---|---|

| Real-time data analysis | AI checks sensor data fast for quick choices. |

| Adaptive force control | Robots change their grip using feedback. |

| Improved precision | Machines handle tiny or fragile parts better. |

| Continuous learning | Systems get smarter with each job. |

These trends show how industrial force sensors are getting better. SOUSHINE’s solutions help these changes and keep industries ahead. Factories now have safer work, better quality, and more efficient processes because of new force sensing technology.

High-Performance Force Measurement

SOUSHINE’s force sensors help factories measure force very well. These sensors use new materials and fast data processing. They give results that workers can trust. Manufacturers and engineers use these sensors to check quality and keep equipment safe.

Advanced Materials

SOUSHINE picks strong and smart materials for their sensors. The material changes how tough and sensitive the sensor is. It also helps sensors work in hard places.

| Material Type | Properties |

|---|---|

| Stainless Steel | Strength, durability |

| Semiconductors | Sensitivity |

| Composite Materials | Balance of strength and sensitivity |

| Aerospace-grade 17-4 Stainless Steel | Sturdiness, elasticity |

| Aluminum | Sturdiness, elasticity |

Durability

Sensors made with stainless steel and special alloys last a long time. These materials help sensors work in places with high pressure or heat. Qorvo Piezo-Resistive MEMS Force Sensors are very tough. Their strong design keeps them working well for years. Workers trust these sensors to keep machines safe and working.

Flexibility

Composite materials and aluminum make sensors more flexible. Flexible sensors fit into many machines and change when needed. This helps factories try new ideas and use automation. Sensitive sensors find small force changes. This makes them more accurate and helps keep workers safe.

Real-Time Data

SOUSHINE’s sensors look at data right away. Real-time data helps factories fix problems quickly. This keeps everything running smoothly.

Edge Computing

Sensors with edge computing study data where it is made. This means there is less waiting and faster choices. Factories use this to find problems early and fix them fast. Edge computing also helps save energy by watching how much power is used.

Smart Sensors

Smart sensors measure force and rotation very carefully. They help keep products the same and stop mistakes. Real-time data from these sensors means fewer bad products and less fixing. Smart sensors also keep equipment safe by finding overloads or too much torque. They can set off alarms or shut down machines to protect workers.

- Real-time data helps find problems early and stops downtime.

- Watching machines all the time makes them work better.

- Force and torque data shows where things are not working well and helps cut waste.

- Better processes mean smoother work and fewer machine problems.

SOUSHINE’s sensors help factories follow new automation trends. Their sensors are tough, flexible, and accurate. These things help factories make better products and keep equipment safe. They also help workers stay safe.

Industrial Force Sensors Market

Market Growth

Projections

The industrial force sensor market is getting bigger fast. Experts think it will grow by 8.3% each year from 2025 to 2032. This shows people trust the future of industrial force sensors. More industries use these sensors for better control and safety. The market will get even larger as this happens.

- The industrial force sensor market will grow a lot.

- Automation, robotics, and IoT help the market get bigger.

- People want more exact measurements every year.

Drivers

Many things make the industrial force sensor market grow. Factories use more robots to do jobs. The Industrial Internet of Things (IIoT) lets companies use sensor data better. Manufacturers, car makers, and airplane companies want sensors for good measurements. Consumer electronics and wearables also use force sensors for new things.

- More factories want robots

- IIoT is getting better

- More use in manufacturing, cars, airplanes, and electronics

- Fast-changing industries need exact measurements

- Automation in factories is growing

Segmentation

Industry

The industrial force sensor market helps many industries. Manufacturing uses sensors to check quality and control processes. Car companies use sensors for safety and to make cars work better. Aerospace companies use multi-axis force measurement for big projects. Healthcare uses sensors in robot surgery and medical tools.

| Segment Type | Categories |

|---|---|

| End Use Industry | Mining, Oil and Gas, Manufacturing, Chemical, Energy and Power, Healthcare, Water and Wastewater Treatment, Aerospace and Defense, Others |

- Manufacturing is 11% of U.S. GDP and uses strain gauge technology 40% of the time.

- The car industry could be worth US$2.5 trillion in 2025.

- Healthcare grows 20% in medical uses.

- Aerospace spends more on new ways to make things.

Region

The industrial force sensor market is in many places. North America grows fast with more robots and sensors. Asia Pacific is growing quickly as factories get modern. Europe, Latin America, and the Middle East and Africa also want more sensors.

| Segment Type | Categories |

|---|---|

| Region | North America, Asia Pacific, Europe, Latin America, Middle East and Africa |

Key Players

SOUSHINE

SOUSHINE is a leader in the industrial force sensor market. The company makes force sensors that can be changed for different needs. Good prices help customers save money, especially when buying a lot. Strong technical support helps customers trust the products. SOUSHINE’s new solutions help industries be safer, better, and more efficient.

Competitors

Many companies are in the industrial force sensor market. The top companies are:

- Siemens AG

- NXP Semiconductor

- Infineon Technologies AG

- Texas Instruments Incorporated

- Analog Devices, Inc.

- STMicroelectronics

- Bosch Sensortec GmbH

- Microchip Technology Inc.

- Honeywell International Inc.

- OMRON Corporation

Note: The industrial force sensor market keeps growing as companies buy new technology and use more automation. SOUSHINE and other top companies help shape the future with reliable and new solutions.

Trends In Automation And Applications

Cobots

Cobots are robots that work with people in factories. They use industrial force sensors to check force and weight. These sensors help cobots do jobs safely and very accurately.

Safety

Cobots use force sensors to know if they touch people or things. If a cobot feels a strong force, it stops to keep people safe. Cobots slow down when someone comes close. Power and force limits help lower the risk of injury. Most cobots have smooth edges and move slower than other robots. Force-limiting sensors make the area safer for everyone.

| Safety Improvement | Description | Source(s) |

|---|---|---|

| Human Detection | Sensors help cobots find humans nearby. | Benmessabih et al., 2024; Xue et al., 2020 |

| Environmental Awareness | Cobots notice changes in their surroundings. | Zacharaki et al., 2020 |

| Robotic Joint Control | Sensors help cobots move more efficiently. | Cheng et al., 2020; Faroni et al., 2022 |

| Learning Algorithms | Cobots learn to work better with people. | Liu et al., 2024a |

| Integrated Safety Features | Collision avoidance and force control keep workers safe. | Ge et al., 2022; Maric et al., 2020 |

Efficiency

Cobots use real-time force data to work better. They can do careful jobs without breaking things. Cobots change how hard they grip for each task. They check weight and force to avoid carrying too much. This helps machines last longer and saves money for factories.

| Benefit | Description |

|---|---|

| Safety Enhancement | Accurate force measurement allows cobots to work safely alongside human counterparts. |

| Operational Precision | Real-time weight and force data allows cobots to perform tasks with high precision. |

| Adaptive Responsiveness | Force sensors help cobots adapt to dynamic working conditions. |

| Efficiency Improvement | Precise weight measurements enhance cobots’ efficiency and productivity. |

| Load Regulation | Real-time weight data helps avoid overloading, ensuring safe operation and longevity. |

- Force sensors feel pressure so cobots can do gentle work.

- They give exact readings for better control in jobs like assembly.

Industry 4.0

Factories now use smart systems to make work easier. Industry 4.0 mixes machines, computers, and sensors to help factories do better. Industrial force sensors are important in these smart factories.

IoT Integration

Force sensors give feedback about how machines touch each other. They let workers watch and control machines right away. Good force measurements help with automation and make work faster. These sensors also help fix machines before they break.

Smart Manufacturing

Smart manufacturing uses sensors to collect data and make things better. Sensors help factories work well and make good products. They make it easier to see what is happening in the factory. Cheap sensors let factories get more data from many places. SOUSHINE’s advanced force sensors help factories be more exact and dependable.

| Key Points | Description |

|---|---|

| Role in Automation | Force sensors are crucial for advancing industrial automation. |

| Enhancements | They facilitate operational efficiencies through robotics. |

| Data Collection | Force sensors enable real-time data collection for smart factories. |

Emerging Uses

Industrial force sensors are now used in new areas like medicine and clean energy.

Medical

Doctors use force sensors in drug pumps to check blood sugar and give insulin. Peristaltic pumps use sensors to find blockages in IV tubes. Surgical tables use strain gauge transducers to move patients. Surgeons measure joint forces to make better choices. Foot rehab systems use sensors to help people walk better. Laparoscopic surgery uses strain gauges to measure force and see better.

Renewable Energy

Force sensors help watch hydrogen production, storage, and moving. They measure pressure and temperature to keep storage safe. Sensors also check conditions during transport to keep things working. Good force measurements help hydrogen systems work better and waste less.

| Application Area | Description |

|---|---|

| Hydrogen Production | Sensors monitor production processes for efficiency and less waste. |

| Hydrogen Storage | Sensors measure pressure and temperature for safe storage. |

| Hydrogen Transportation | Sensors track conditions during transport for safety and reliability. |

| Overall Monitoring | Sensors help optimize hydrogen systems for better performance. |

SOUSHINE’s solutions help these trends by giving reliable and exact force sensors for every use.

Sustainability

Industrial sensor technology is changing to help the planet. Companies want sensors that use less energy and are better for nature. SOUSHINE makes new sensors that help factories be greener and use resources wisely.

Energy Efficiency

Energy-saving force sensors help factories be more eco-friendly. These sensors use less electricity and help cut down pollution. They also help machines work better and waste less stuff.

Low Power

SOUSHINE’s sensors are made to use little power. This helps factories save money on electricity. Sensors that use less energy last longer and work well far away. In hospitals, these sensors mean fewer trips to the doctor. Home dialysis machines use them to save power and make less trash.

- Using eco-friendly materials in sensors helps the planet.

- Energy-saving sensors lower pollution in hospitals and factories.

- Using less energy and materials means less trash in factories and hospitals.

Green Materials

SOUSHINE picks green materials for its sensors. These materials do not hurt the earth. Using recycled metals and safe plastics keeps the air and water cleaner. Green materials make sensors safer for workers and easier to recycle later.

- Green materials help make products in a better way.

- Recycled metals and safe plastics make less pollution.

- Eco-friendly sensors are easier to recycle when they are old.

Lifecycle

How long a sensor lasts matters for the earth. SOUSHINE makes sensors that last a long time and can be recycled. This helps factories follow rules and care for nature.

Recycling

Many programs help companies recycle old sensors. SOUSHINE follows world rules for recycling. The table below lists some big programs for recycling industrial sensors:

| Program/Standard | Description |

|---|---|

| NI Global Take-Back Program | Pays for sending back old hardware so it gets recycled, not thrown away. |

| WEEE Directive | Helps people in the EU reuse and recycle old electronics. |

| EU Battery Directive | Tries to make battery recycling better and help the earth in the EU. |

Sensors that follow these programs help keep trash out of landfills and save nature.

Standards

SOUSHINE follows tough rules for being green. These rules tell companies to use safe stuff and recycle old things. Following these rules helps factories pollute less and follow world laws.

Note: Companies that recycle and use green materials are leaders in helping the planet.

SOUSHINE works hard to make sensor technology better for the earth. By using less power, picking green materials, and recycling, SOUSHINE helps factories be smarter and kinder to nature. New sensor ideas help make factories cleaner for the future.

Industrial force sensors will change how factories work in 2025. Companies want sensors that are tiny, bendy, cheap, and accurate. They also want sensors that connect to smart devices and help the planet.

| Key User Demands | Description |

|---|---|

| Small and bendy sensors | Tiny and flexible sensors are liked by many. |

| Low-cost options | Saving money is important for companies. |

| Sensors that measure force well | Sensors must give exact force readings. |

| Sensors that work with new smart devices | Connecting to IoT and AI is getting popular. |

| Sensors made in ways that help the environment | Making sensors eco-friendly matters a lot. |

Manufacturers use new sensor ideas to make work faster and better. These sensors help factories make good products and fix machines before they break.

- Automation makes production lines move quicker.

- Watching machines closely helps make better things.

- Predictive maintenance saves money and stops long breaks.

SOUSHINE is a leader with smart and strong sensor solutions. The market will grow as more companies use smart and green technology. Learning about new trends helps businesses do well as things change.

FAQ

What is industrial force sensor monitoring?

Industrial force sensor monitoring means checking machine force during work. Engineers use sensors to watch pressure, tension, and weight. This helps keep machines safe and working well in factories. Monitoring also helps workers find problems early.

How do wireless and IoT-enabled sensors improve monitoring?

Wireless and IoT-enabled sensors send data without using wires. They help workers see force changes from far away. Monitoring is easier because sensors fit in hard-to-reach places. These sensors help factories fix problems quickly.

Why is real-time performance monitoring important?

Real-time performance monitoring lets workers see force changes right away. This helps stop accidents and keeps machines running. Watching in real time helps workers make fast choices and keep products safe.

What are smart sensor applications in factories?

Smart sensor applications include robots, assembly lines, and safety systems. These sensors help monitor force and movement. They make machines work better and help keep workers safe. Smart sensors also help factories make better products.

How does AI and smart sensor integration help with monitoring?

AI and smart sensor integration lets sensors learn from data. Sensors use AI to spot problems and predict when machines need fixing. Monitoring with AI helps factories save money and avoid long breaks.

What force measurement capabilities do SOUSHINE sensors offer?

SOUSHINE sensors measure pressure, tension, compression, and torque. These force measurement abilities help monitor machines and products. Workers use these sensors to check quality and keep equipment safe.

How does technology support real-time analysis and monitoring?

Technology helps sensors study data quickly. Real-time analysis lets workers see force changes right away. Monitoring with new technology helps factories fix problems before they get worse.

Why is market demand for force sensors growing?

Market demand grows because more factories use sensors for monitoring. Companies want safer machines and better products. Sensors help with automation and smart manufacturing. Monitoring helps factories work faster and save money.