Call us: +86-137-2353-4866

In industrial environments, the precise measurement and analysis of force are critical for quality control, process optimization, and equipment safety. SOUSHINE’s Force Sensing technology offers robust and reliable solutions for quantifying force distribution and magnitude across various applications, from machine calibration to assembly verification. Our sensors provide the actionable data necessary to improve efficiency and reduce manufacturing defects.

What is Industrial Pressure Mapping and Force Measurement?

Pressure Mapping refers to the measurement and visualization of force distribution over a specific surface area. It creates a “map” that shows how pressure is applied, identifying high-pressure points, low-pressure areas, and the overall uniformity of contact.

Force Measurement involves the quantification of a load applied at a single point or over a defined area. The primary goal is to obtain a precise numerical value of the force being exerted, typically measured in Newtons (N) or pounds-force (lbf).

In an industrial context, these technologies are applied to analyze the interaction between components, tools, and materials, ensuring that processes operate within specified force parameters.

How It Works: SOUSHINE’s Force Sensing Technology

Our solutions are built upon advanced Force Sensing Resistor (FSR) technology.

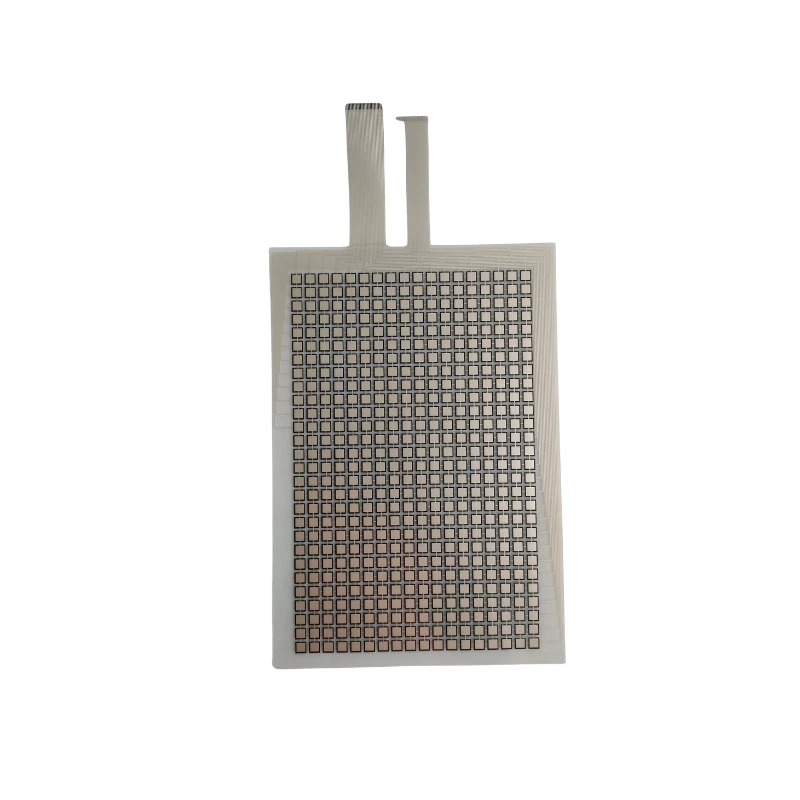

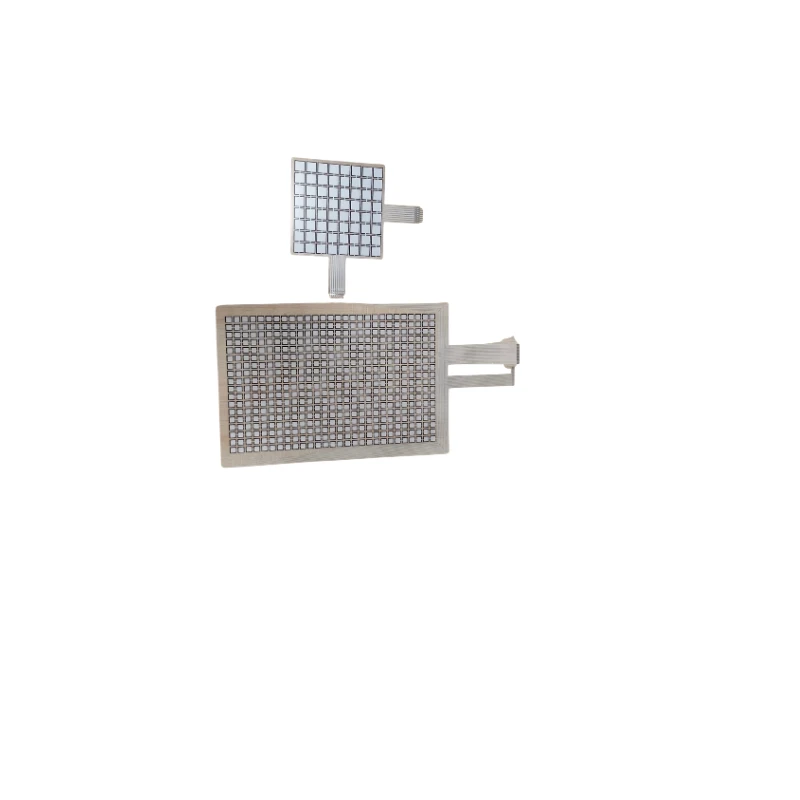

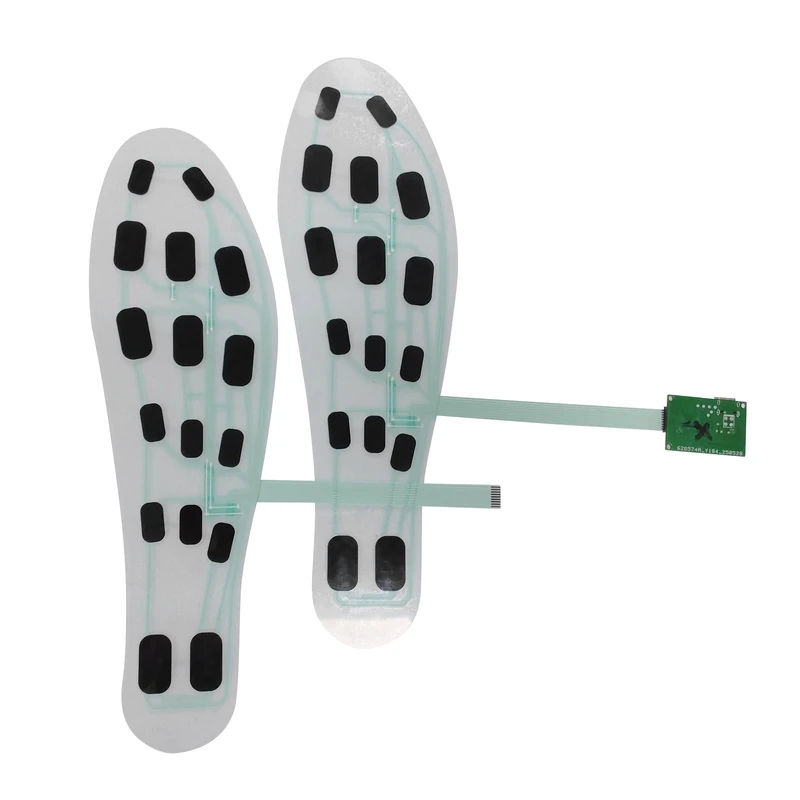

- Sensor Construction: SOUSHINE’s force sensors are constructed as thin, flexible polymer films. An FSR is composed of a conductive polymer that changes its electrical resistance in direct proportion to the amount of force applied to its surface.

- Data Acquisition: When pressure is exerted on the sensor, the resistance decreases. This change is measured by an electronic interface connected to the sensor.

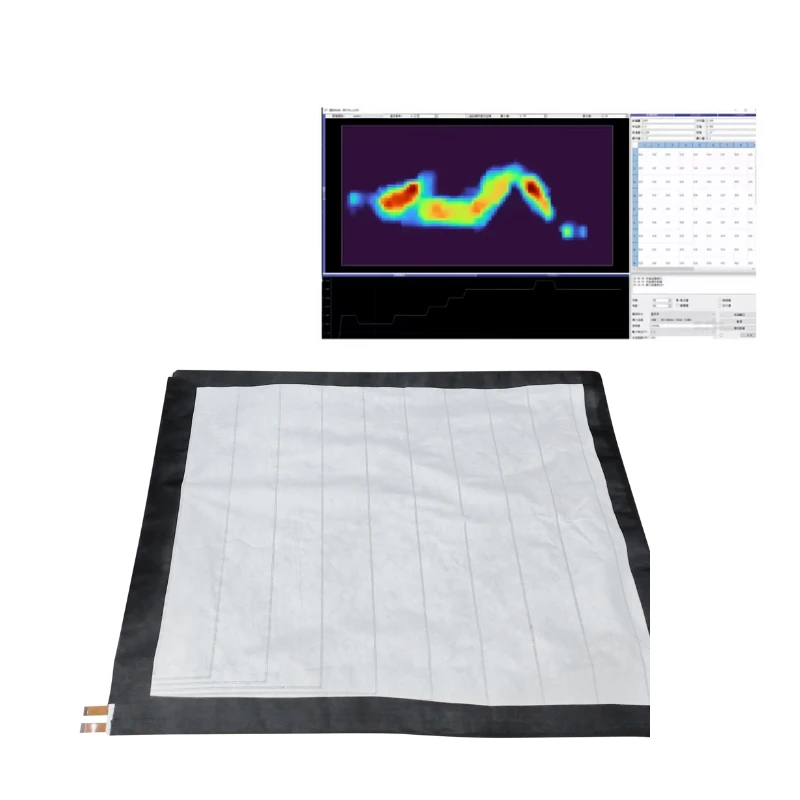

- Pressure Mapping System: For pressure mapping, a matrix of individual FSR sensors is arranged in a grid array. The electronics scan each sensing point in the grid to capture the force distribution across the entire surface.

- Data Output: The collected data is then processed by software to generate a visual pressure map—often a color-coded topographical image—and to provide discrete force values. This output can be integrated directly into a facility’s process control system.

Why Accurate Measurement is Critical in Industrial Settings

Implementing precise pressure and force measurement systems delivers direct operational advantages:

- Enhanced Quality Control: Verify that sealing surfaces, gaskets, and laminated components are subjected to uniform pressure, preventing leaks, delamination, and premature failure.

- Process Optimization: Calibrate machinery such as presses, rollers, and clamping fixtures to their optimal force settings. This ensures consistent product quality and reduces tool wear.

- Improved Safety: Monitor forces in robotic grippers, presses, and assembly lines to prevent overloads that could damage equipment or create unsafe operating conditions.

- Research & Development: Use detailed force data to characterize material properties, validate new product designs, and understand component interactions under stress.

- Waste Reduction: Identify process inconsistencies early to prevent the production of non-conforming parts, thereby saving materials and reducing scrap rates.

Common Applications

Our Force Sensing technology is engineered for a wide range of industrial measurement tasks:

- Gasket and Seal Analysis: Ensuring a uniform seal by measuring contact pressure distribution on engine heads, flanges, and enclosures.

- Lamination and Press Operations: Verifying uniform pressure in heat presses, lamination rollers, and composite manufacturing to ensure proper bonding.

- Machine Calibration: Measuring and adjusting contact force for CNC machine tools, welding equipment, and stamping presses.

- Component Mating Verification: Confirming proper contact and force distribution during the assembly of critical components.

- Impact Force Testing: Quantifying the force of impacts in product drop testing or material characterization.

The SOUSHINE Advantage

As a specialized developer and manufacturer of Force Sensing solutions, we provide:

- Customization: We design and produce sensors that match the specific shape, size, and pressure range requirements of your application.

- Durability: Our sensors are designed to function reliably in demanding industrial environments, resistant to vibrations and temperature fluctuations.

- High-Resolution Data: Our sensor arrays offer detailed and accurate pressure maps for in-depth analysis.

- Seamless Integration: We provide the technical support and interface electronics necessary to integrate our sensor data into your existing control and monitoring systems.

- Expertise: With a core focus on Force Sensing technology, our team at

fsrexpert.compossesses the specialized knowledge to help you solve your most complex measurement challenges.

Display

FAQ

What is the main difference between a Force Sensing Resistor (FSR) and a traditional load cell?

A load cell typically measures the total force applied to its structure at a single point and is known for very high precision. An FSR, particularly in a matrix array, is ideal for measuring the distribution of force over a surface. FSRs are also thin, flexible, and can be easily customized, making them suitable for applications where space is limited or the contact surface is complex.

What is the typical operating temperature range for your industrial sensors?

Our standard industrial-grade sensors are designed to operate within a range of -40°C to +85°C. We can also develop solutions for more extreme temperature requirements upon request.

Can SOUSHINE sensors be customized for unique shapes and sizes?

Yes. Customization is a core part of our service. We work directly with clients to design and manufacture sensors that fit the specific geometry and measurement parameters of their equipment.

What kind of data output can I expect from a pressure mapping system?

The system provides raw resistance or force data for each sensing point. Our software can visualize this as a 2D or 3D color map, display real-time force values, record data over time, and export data in standard formats (e.g., CSV) for further analysis in other programs.

How durable are the sensors in a high-cycle industrial environment?

Our FSRs are engineered for high durability and can withstand millions of actuation cycles when operated within their specified force limits. The lifespan depends on the specific application, including the magnitude of force and the nature of the contact surface. We can provide detailed specifications based on your operational requirements.