Call us: +86-137-2353-4866

The reliable and accurate delivery of fluids is a critical function in medical applications. Infusion pumps are essential devices for the controlled administration of medications, nutrients, and other liquids to patients. The integration of force sensing technology is a key component in the safety and functionality of modern infusion pumps. SOUSHINE develops and manufactures advanced force sensors that provide the precision and reliability required for these critical medical devices.

What The Function of Force Sensors in Infusion Pumps

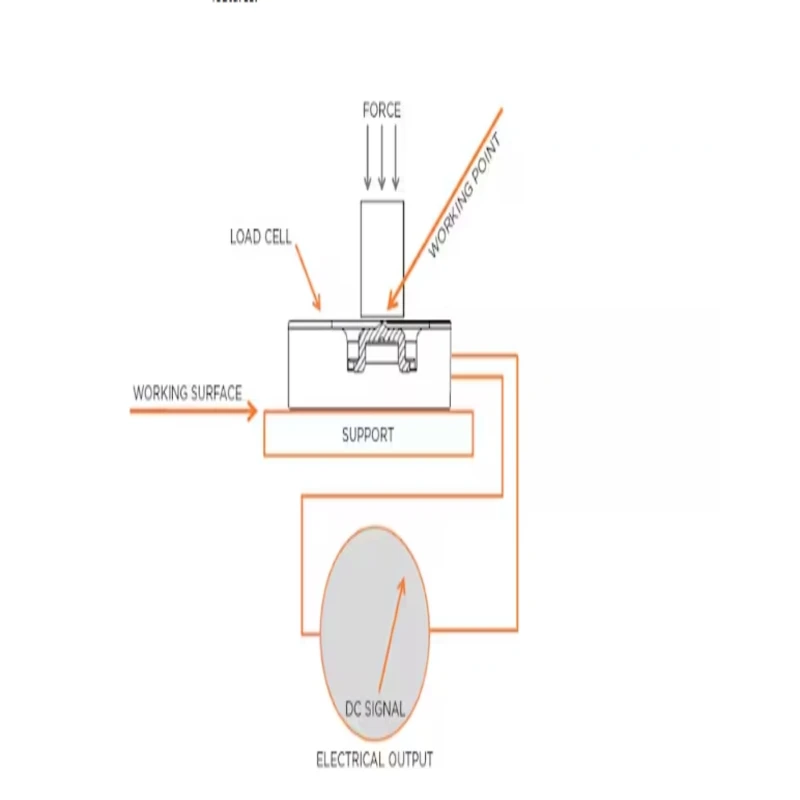

In the context of an infusion pump, a force sensor is a transducer that measures the physical force exerted by the fluid delivery system, typically the intravenous (IV) tubing. This measurement is converted into an electrical signal that the pump’s control system can interpret and act upon.

The primary application is the detection of occlusions. An occlusion is a blockage or closure in the fluid path. By continuously monitoring the force, the sensor can detect minute changes in the pressure within the tubing. This data allows the pump to identify potential blockages and trigger an alarm, preventing the under-delivery of medication and potential harm to the patient. Key functions include:

- System Diagnostics: Detects issues such as pinched or improperly loaded tubing, ensuring the device is operating correctly before and during infusion.

- Occlusion Detection: Identifies blockages in the IV line by sensing an increase in back-pressure.

- Flow Rate Monitoring: Contributes to maintaining a consistent and accurate flow rate by providing feedback to the pump’s motor control system.

How Integration and Operation of Force Sensors

SOUSHINE force sensors are engineered for seamless integration into various infusion pump designs, including peristaltic and syringe pumps. Mechanism of Operation:

- Placement: The force sensor is typically positioned within the pump mechanism where it makes direct or indirect contact with the infusion tubing. In many designs, a plunger or a solid interface rests against the tubing and transmits the force to the sensor.

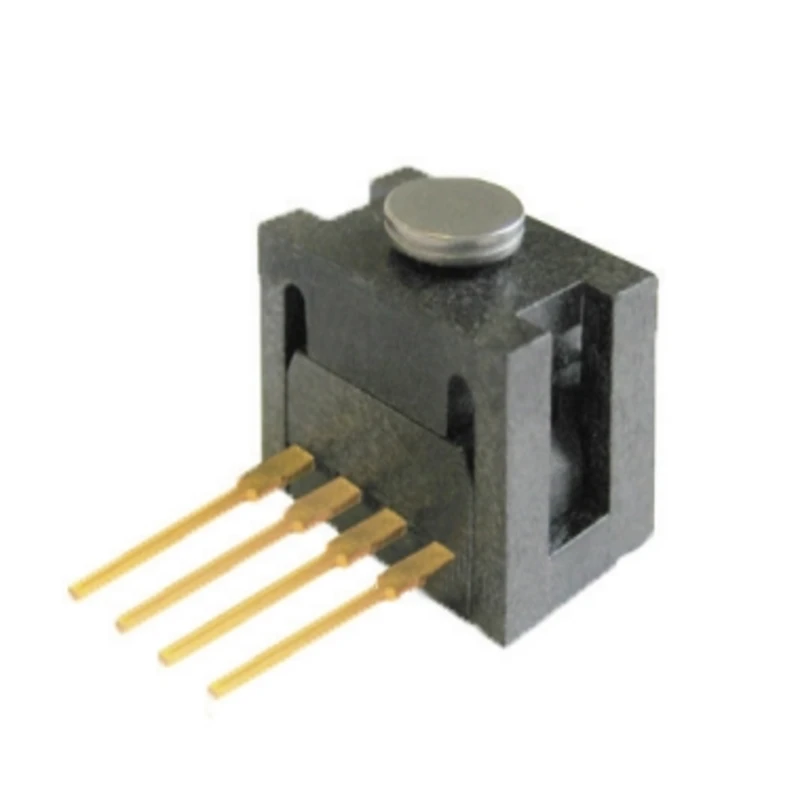

- Force Transduction: As the pump operates, the fluid inside the tubing exerts a specific, consistent force on the sensor. SOUSHINE primarily utilizes strain gauge technology, where a change in force causes a microscopic deformation in the sensor’s structure. This deformation alters the electrical resistance of the integrated strain gauges (ΔR).

- Signal Processing: The change in resistance is measured and converted into a calibrated electrical signal, typically in millivolts (mV).

- System Response: This signal is sent to the pump’s microcontroller. If the force level deviates from the preset normal range (e.g., rises sharply), the microcontroller interprets this as an occlusion. It then triggers an audible and visual alarm and can be programmed to stop the infusion process.

Our sensors are designed with a minimal physical footprint and low power consumption, making them suitable for both stationary and ambulatory infusion pump designs.

Why The Importance of High-Quality Force Sensors in Infusion Pumps

The integration of precise and reliable force sensors is fundamental to the safety and efficacy of an infusion pump.

- Compliance with Medical Standards: Regulatory bodies worldwide, such as the FDA, have stringent requirements for the safety and performance of medical devices. The inclusion of a validated force sensing system for occlusion detection is a key part of meeting these standards (e.g., IEC 60601-2-24).

- Enhanced Patient Safety: The primary benefit is the prevention of adverse medical events. Timely occlusion detection is critical to avoid complications such as interruptions in the delivery of vital medications, tissue damage from infiltration, or damage to the catheter.

- Improved Treatment Efficacy: Accurate fluid delivery is essential for achieving the desired therapeutic outcome. By providing feedback that helps regulate the flow rate, force sensors ensure that patients receive the correct dosage (mL/hr) as prescribed.

- Increased Device Reliability: Force sensors provide a constant diagnostic check on the physical state of the fluid line. This reduces the incidence of false alarms (nuisance alarms) and increases clinician confidence in the device’s performance. It also helps detect improper setup, a common source of infusion errors.

Display

FAQ

What is the typical force range your sensors measure in an infusion pump application?

Our force sensors for infusion pumps are typically designed to operate in low force ranges, often from 0 to 15 Newtons (N). The precise range can be customized based on the specific pump mechanism, tubing material (durometer), and desired occlusion detection sensitivity.

How does your strain gauge technology compare to piezoelectric sensors for this application?

Strain gauge-based sensors, which are a core technology for SOUSHINE, are generally preferred for infusion pump applications due to their excellent stability and accuracy in measuring static or slowly changing forces. This is ideal for monitoring the steady-state pressure in an IV line. Piezoelectric sensors are better suited for dynamic force measurements and can exhibit signal drift when measuring static loads, making them less ideal for baseline pressure monitoring in this context.

Can your force sensors be calibrated for different tubing materials and diameters?

Yes. Our force sensors are integrated into the pump’s control system, which includes a calibration function. During the device’s manufacturing, the system is calibrated to establish a baseline “normal” force for the specific disposable tubing sets intended for use. This ensures high accuracy and reliable occlusion detection across different operational conditions.

How do SOUSHINE sensors account for environmental factors like temperature changes?

Our sensors are designed with integrated temperature compensation. We utilize advanced strain gauge configurations (e.g., a full Wheatstone bridge) and material selection to minimize the effects of thermal expansion and contraction on the sensor’s output. This ensures the force readings remain accurate and stable across the device’s specified operating temperature range.

What is the typical lifecycle of a SOUSHINE force sensor within an infusion pump?

Our force sensors are engineered for high durability and a long operational life, designed to exceed the lifecycle of the infusion pump itself. As solid-state components with no moving parts, they are not subject to the same wear as mechanical components. They undergo extensive testing to ensure they maintain their accuracy and reliability over many years of continuous or intermittent use without requiring recalibration in the field.