Call us: +86-137-2353-4866

The material of fsr helps sensors become smarter and safer. SOUSHINE force sensing resistors use a polyester base, FSR ink, and a conductive film. This setup makes force sensing more accurate and reliable. The right material makes sensors more sensitive, tough, and safe to use. The table below shows how new materials make force sensitive resistors work better and safer.

| Aspect | Description |

|---|---|

| Sensitivity | Better sensitivity helps sensors find force more exactly in many uses. |

| Durability | Stronger sensors last longer and need less fixing or replacing. |

| Integration Capabilities | Easier to use with other tech, which makes systems work better and safer. |

| Application Fields | Big safety gains in cars, healthcare, and robots. |

Material science keeps making force sensing resistors better.

Table of Contents

Key Takeaways

- The right materials help FSRs sense force better. This means they measure force more accurately.

- Sensors made with strong materials last a long time. They do not break easily. This lowers the need for fixing or replacing them.

- Force sensing resistors work well with other technologies. This makes systems safer and helps them work better.

- SOUSHINE FSRs are used in important areas like healthcare, cars, and robots. They help keep people safe in these fields.

- Using eco-friendly materials in sensors helps the planet. It also supports goals to protect nature.

- Custom FSR designs let sensors fit special spaces. This makes sure they work for different needs.

- Advanced materials like conductive polymers and carbon compounds make sensors faster. They also help sensors work well in many conditions.

- Engineers must think about cost and quality when picking materials. They want sensors that work well but are not too expensive.

Force Sensitive Resistor Basics

What Is a Force Sensitive Resistor

A force sensitive resistor is a sensor. It changes resistance when you press or put weight on it. Engineers use these sensors to measure force in many devices. These sensors are part of piezoresistive devices. Their resistance changes smoothly as force goes up or down. This lets them measure force exactly, not just on or off.

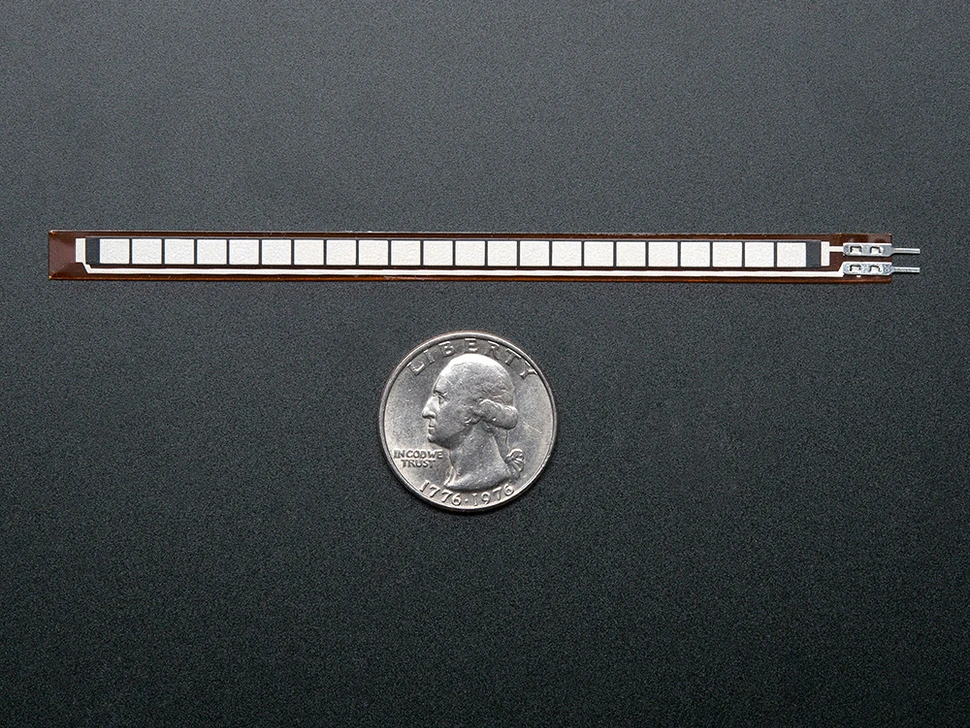

SOUSHINE force sensitive resistors have a special design. The sensor has two polyester base layers. The top layer has FSR ink. A conductive film is under it. A plastic spacer keeps the layers apart until you press down. This design helps the sensor notice even small pressure changes.

Force sensitive resistors are used in many places. Hospitals put them in beds and wheelchairs to watch patient movement. Sports trainers use them to check grip strength or stance. Factories use them to measure weight or pressure in machines.

How FSRs Work

FSRs work using percolation and quantum tunneling. The sensor has a flexible base with a printed circuit. A spacer keeps the circuit and conductive layer apart. When you press the sensor, the conductive layer touches the circuit. This lets electricity flow. More pressure means more contact. Resistance goes down and electrical output goes up.

- FSRs have high resistance when no force is there.

- When force goes up, resistance drops and conductance rises.

- The sensor can find force at one spot or across many spots.

- People use them for touch detection, safety alerts, and grip strength.

FSRs are thin, bendable, and strong. They use little power and cost less than other sensors.

Why Material Matters

The material of fsr is very important for how well it works. The type of fsr material changes sensitivity, durability, and reliability. SOUSHINE uses a polyester base, FSR ink, and a conductive film. This mix helps the sensor react fast and last longer.

| Material Type | Examples | Advantages |

|---|---|---|

| Conductive Layer | Silver, Carbon | Low cost, durability |

| Resistive Layer | Polymer, Carbon Nanotubes, Carbon Black, Graphene | Custom shapes and configurations |

Temperature and humidity can change how the sensor works. High heat can make sticky layers weaker. Water can get inside and mess up readings. Picking the right materials helps the sensor stay accurate in different places.

Material of FSR: Key Properties

Sensitivity

Conductive Polymers

The sensitivity of a force sensitive resistor depends on the type of conductive polymers. Engineers put these polymers between metal electrodes in the sensor. The voltage used can change how well the sensor finds force. Picking the right voltage helps the sensor stay accurate and repeatable. SOUSHINE uses FSR ink printed on polyester to make sensitivity better. This fsr material reacts fast to pressure changes. It works well for exact measurements in many devices.

Particle Distribution

How particles spread inside the resistive polymer layer affects the sensor’s reaction to force. Even particle spread helps the sensor notice small pressure changes. If particles are spread evenly, the sensor gives steady readings. SOUSHINE makes its fsr material to keep particle spread the same. This helps the sensor give good results in medical, sports, and industrial uses.

Responsiveness

Dynamic Feedback

Responsiveness means how quickly the sensor reacts to force. The fsr material is important for this. Different fsr materials change how fast the sensor gives feedback. The table below shows how different materials affect speed and strength.

| Material Composition | Characteristics |

|---|---|

| Polymer Thick Film (PTF) | Good for many uses; works less well over time. |

| Metalized Polymer Thick Film | Lasts longer and works better; costs a bit more. |

| Velostat | High resistance when not pressed; cheap and useful. |

| Carbon/Graphite Loaded | Very strong and lasts long; costs more than PTF. |

| Force Range | Resistance changes from 100g to 10kg or more, depending on material and design. |

| Durability | PTF inks last 100,000 to 1 million cycles; metalized types last 10-50 million cycles. |

SOUSHINE uses special fsr material for fast and correct feedback. The sensor reacts to touch, grip, or weight changes right away.

Environmental Adaptability

Things like temperature and humidity change how the sensor works. The fsr material must handle these changes to keep readings steady. The table below shows how temperature and humidity change sensor resistance.

| Environmental Factor | Effect on Sensor Resistance |

|---|---|

| Temperature | Resistance changes from 15.0 °C to 65.0 °C; sensitivity stays steady when stretched or pressed. |

| Humidity | Resistance drops fast under 60.0% or 80.0% humidity; gets steady quicker at higher humidity. |

| Joint Influence | Temperature mostly changes resistance; humidity makes resistance drop faster at high temperatures. |

SOUSHINE picks fsr material that can handle temperature and humidity changes. This keeps the sensor working well in hospitals, sports, and factories.

Tip: Picking the best fsr material makes sensors more sensitive and quick. Good sensors help keep people safe and systems working well.

Safety in Force Sensitive Resistors

Durability

Wear Resistance

Durability is very important for sensors in tough places. SOUSHINE makes sensors that can be used many times and handle pressure. In factories, force sensitive resistors face some problems:

- Flexible and light sensors might not last long if pressed hard or often.

- Testing how long sensors last takes a lot of time and work, especially when used millions of times.

- Very thin sensors may break if used too much.

SOUSHINE fixes these problems by picking strong materials and making the sensor design better. This helps the sensors keep working well, even in hard situations.

Environmental Protection

New sensor materials help protect the environment. Makers now use safe materials and save energy when making sensors. These choices help lower harm to nature. SOUSHINE’s way of making sensors matches these ideas, so their sensors are good for companies that care about the planet.

Stability

Temperature Tolerance

Changes in temperature can change how sensors work. SOUSHINE force sensitive resistors work well in hot and cold places. The table below shows the temperature range:

| Specification | Value |

|---|---|

| Working temperature | -30~80℃ |

| Operating temperature | -40°C to 85°C |

This big range lets the sensors work in hospitals, factories, and outside.

Signal Consistency

Signal consistency means the sensor gives correct readings every time. The materials inside the sensor, like the resistive polymer, affect how the sensor acts after being pressed. Some materials take longer to go back to normal, which can slow down the sensor. Things like heat and wetness also matter. If the sensor does not react the same at high force, it is harder to get exact numbers. SOUSHINE picks materials that help stop these problems, so the sensor gives steady and true signals in important jobs.

Non-Toxic Materials

Human Safety

Safety is very important for sensors in medical and wearable things. SOUSHINE uses safe materials in its sensors. This makes them okay to touch skin and good for hospital beds, wheelchairs, and safety gear.

Eco-Friendly Design

Eco-friendly materials help make electronics better for the earth. The table below shows how these materials help the planet:

| Contribution to Sustainability | Description |

|---|---|

| Reducing Environmental Impact | Eco-friendly materials help lower harm from making electronics. |

| Aligning with Regulatory Standards | Following rules for the environment is important for makers. |

| Promoting Circular Economy Practices | Using and recycling materials helps save resources in the industry. |

Makers now use ways to make sensors that are better for the earth. People want electronics that are safe for the planet, so companies keep finding new green ways to make them.

SOUSHINE uses smart, safe, and earth-friendly materials. This makes their sensors a good pick for hospitals, safety, and factories.

Applications of Force Sensitive Resistors

Medical Devices

Force sensitive resistors are important in medical technology. Hospitals use these sensors to watch patients and give better care. SOUSHINE FSRs are found in hospital beds and wheelchairs. They help track how much patients move and how much they weigh. This helps stop bedsores and other problems. The sensors also help tools that measure pressure very well. Grip strength devices use FSRs to help patients and therapists see how recovery is going.

| Application | Description |

|---|---|

| Wearable pressure monitors | Find bedsores and check patient weight. |

| Diagnostic tools | Measure pressure for medical tests. |

| Grip strength monitoring | Watch grip strength for getting better. |

Robots in hospitals use FSRs to build things with gentle parts. These sensors make sure each device is made the right way. The fsr material helps the sensors stay steady and work well in careful places.

Sports Equipment

Athletes and coaches use force sensitive resistors to get better and stay safe. SOUSHINE FSRs are in sports training tools, like golf trainers and smart shoe insoles. These sensors give quick data about form, balance, and muscle use. Runners use FSRs to check their steps and fix how they run. Coaches use this data to help athletes avoid getting hurt and do better.

- New FSR materials give athletes fast feedback on moves.

- The sensors help check balance and steps for better results.

- Sports gear with FSRs helps stop injuries by watching muscles.

FSRs are also in drum pads for musicians. The sensors react to touch, so players can change sound by pressing harder.

Wearables

Wearable tech needs force sensitive resistors to sense things well. SOUSHINE FSRs are in smart clothes, fitness bands, and safety gear. Thick and stretchy fabrics make the sensors work better. Thick fabric keeps the sensor away from skin, which helps it be more exact. Stretchy fabric keeps the sensor in shape, so it does not give wrong readings from folds or movement.

- Thick fabric keeps the sensor apart for better sensing.

- Stretchy fabric helps the sensor keep its shape.

- Wearables with FSRs count steps, watch posture, and find falls.

The right fsr material makes sure wearable devices are comfy and work well every day.

Industrial Uses

SOUSHINE Force Sensing Resistors are important in factories. These sensors measure weight, pressure, and force in machines. Workers use FSRs to watch conveyor belts and robotic arms. They also help with packaging systems. The sensors keep production lines safe and working well.

Picking the right material makes FSRs tough for hard jobs. Engineers use materials that do not react with chemicals. They add thick layers to protect sensors from heat and chemicals. The sensors can handle millions of uses without breaking. SOUSHINE adds extra layers and special ingredients. These steps stop the sensor from coming apart and make it stronger.

Machines in factories get pushed and heated a lot. Designers make special parts in FSRs to take these hits. Packaging uses safe materials and zones that handle stress. This keeps sensors working when there is oil, dust, or shaking.

| Approach Type | Specific Strategies |

|---|---|

| Materials | Chemically safe, high melting temperature, thick materials to block radiation, mixing materials and alloys |

| Technology | Making methods, conditions, heating, extra layers to stop breaking and add strength, special ingredients |

| Device Design | Special parts to take hits or heat, picking what to measure |

| Packaging | Safe materials, special parts for taking hits or chemicals |

| System | Keeping electronics away from bad stuff, ways to stop overheating or save power |

SOUSHINE FSRs are used in control panels for machines. Workers use these sensors to touch and change machine settings. The sensors work fast and give good feedback. This helps stop accidents and makes work better.

Robots in factories use FSRs to check grip and pressure. The sensors help robots hold things without breaking them. FSRs also watch force in assembly lines to make sure products are good.

Tip: Engineers pick FSR materials for each job and place. This helps sensors last longer and work better in factories.

SOUSHINE FSRs help with fixing machines before they break. Sensors warn workers if something is wrong. This means less waiting and saves money. The sensors also watch safety gear like stop buttons and mats.

Good material choices let FSRs work in many factory jobs. The sensors can take heat, chemicals, and hard hits. SOUSHINE keeps making better materials and designs. This makes sensors smarter and safer for factories.

Innovations in FSR Materials

New Materials

Material science helps make force sensitive resistors better. Engineers use new materials like conductive polymers, carbon compounds, and nanomaterials. These materials make sensors more sensitive and tough. SOUSHINE uses FSR ink printed on polyester bases. This mix lets sensors work in rough places. Aerospace-grade materials help sensors handle very hot or cold temperatures. Biocompatible choices make sensors safe for people to use. New materials also help sensors last longer and give correct readings.

| Material Type | Benefit |

|---|---|

| Conductive Polymers | Fast response |

| Carbon Nanomaterials | High sensitivity |

| Aerospace-grade | Extreme durability |

| Biocompatible | Safe for human contact |

Engineers pick materials based on what each job needs. This helps sensors work well in many different fields.

Custom Designs

Custom designs are important for making force sensitive resistors. Companies like SOUSHINE and Cubbison make prototypes to test sensors. Custom shapes help sensors fit special spaces and devices. Engineers change how sensors react to force for each device. This makes sensors more exact and steady.

- Custom designs let sensors have special shapes and reactions.

- FSRs come in many sizes and forms for different jobs.

- Changing resistance with force makes sensors more exact.

- Ultra-thin sensors fit in small spaces.

- High accuracy helps measure force exactly.

- Cost-saving designs match what clients need.

SOUSHINE keeps making custom FSRs for medical, sports, and factory uses. Their sensors follow strict rules for safety and how well they work.

Future Trends

New materials will change force sensitive resistors in the future. Scientists make new mixes to help sensors work better. Advanced materials like conductive polymers, carbon compounds, and nanomaterials make sensors faster and more sensitive. These changes help sensors work in hard places.

- New material science is key for better force sensing resistors.

- Advanced materials like conductive polymers, carbon compounds, and nanomaterials are being made.

- These materials make sensors more sensitive, tough, exact, and quick, so FSRs work in rough places.

SOUSHINE studies new materials and designs to make sensors better. The company wants sensors that work faster and last longer. Future FSRs might use smart materials that change with the environment. This will help sensors work with new technology in health, sports, and factories.

New materials help force sensitive resistors keep up with new needs. Companies like SOUSHINE lead by making better materials and designs for smarter, safer sensors.

Challenges and Opportunities

Balancing Cost and Performance

Manufacturers have a big problem when picking FSR materials. They need to keep costs low but also want good performance. Materials that work really well usually cost more money. Cheaper materials might not be sensitive or last as long. SOUSHINE engineers try many mixes of materials. They want sensors that work well and do not cost too much.

| Factor | Impact on FSRs |

|---|---|

| Material Cost | Affects final product price |

| Sensitivity | Influences measurement range |

| Durability | Determines sensor lifespan |

| Production Scale | Impacts cost per unit |

Tip: Engineers can save money by making better ways to build sensors or by using new mixes of materials.

Overcoming Technical Barriers

Technical problems can make it hard to improve FSRs. Some materials do not work well in very hot or wet places. Other materials may stop working right after being used a lot. SOUSHINE tests sensors in real-life places to fix these problems. They use special FSR inks and strong polyester bases. These choices help sensors work in hospitals, factories, and sports gear.

Engineers also have trouble making sensors small. Devices keep shrinking. Sensors must fit in tiny spaces and still work well. SOUSHINE makes thin, bendy sensors that still give exact results.

- Engineers check sensors for:

- Hot and cold changes

- Wet and dry places

- Many times being used

- Fitting into small gadgets

Next Steps

FSR technology has lots of chances to get better. Material science keeps getting smarter. New mixes and shapes will make sensors safer and smarter. SOUSHINE spends time and money to find better materials and designs.

Engineers have some ideas for the future:

- Make eco-friendly materials so sensors are safer to throw away.

- Build sensors that are even more sensitive for doctors and factories.

- Design FSRs that work outside or in tough places.

- Make sensors cheaper and easier to get.

Note: Picking the best materials will help make the next group of FSRs. Companies like SOUSHINE are leading by caring about safety and how well sensors work.

The materials picked for force sensing resistors affect how smart and safe they are. SOUSHINE uses special materials to make sensors that react fast and last a long time. Engineers need to look at what each material can do before picking or making FSRs. New ideas in material science will help sensors work in more ways.

Choosing the right materials makes technology safer and more dependable.

FAQ

What is the main material in SOUSHINE Force Sensing Resistors?

SOUSHINE makes sensors with a polyester base, FSR ink, and a conductive film. These parts help the sensor find force changes fast and work well.

How do FSR materials affect sensor sensitivity?

The kind of conductive polymer and how particles are spread in the ink decide how well the sensor finds small force changes. Picking good materials helps the sensor be more exact.

Are SOUSHINE FSRs safe for medical use?

SOUSHINE picks materials that are safe and work with the body. These sensors follow safety rules for hospital beds, wheelchairs, and other medical tools.

Can FSRs handle extreme temperatures?

SOUSHINE FSRs can work in very hot or cold places, from -40°C to 85°C. This means they can be used in hospitals, factories, and outside.

How long do SOUSHINE FSRs last?

Engineers make SOUSHINE FSRs to be used many times. The materials are strong and keep giving good readings after lots of use.

What industries use SOUSHINE FSRs?

SOUSHINE FSRs are used in hospitals, sports, wearable tech, and factories. The materials are picked to help in each job.

Do FSRs harm the environment?

SOUSHINE uses materials and ways of making sensors that are better for the earth. These choices help lower harm and make recycling easier.

Can SOUSHINE customize FSRs for special projects?

SOUSHINE can make special sensors. Engineers change the size, shape, and how sensitive they are to fit what each job needs.