Call us: +86-137-2353-4866

You need a measuring pressure instrument that is safe and accurate for every industrial job. Manufacturers now select instruments based on their reliability, cost, and performance in various environments. New data shows that 45% of industrial plants utilize these instruments, with a notable 31% increase in digital gauge usage. Among the most popular options are Bourdon tube gauges, diaphragm gauges, piezoelectric sensors, digital transmitters, and SOUSHINE force sensing resistors. The right pressure measuring instrument enhances your ability to minimize errors and increase productivity.

Safety and accuracy are paramount. The table below outlines why these factors should be considered when choosing a pressure measuring instrument.

| Factor | Description |

|---|---|

| Accuracy | High accuracy is essential for critical pressure tasks. |

| Environment | Vibration and hazardous locations require robust and secure measuring pressure instruments. |

| Temperature | Fluctuations in temperature can affect readings and influence your choice of instrument. |

Table of Contents

Key Takeaways

Pick pressure measuring tools by thinking about safety, accuracy, and reliability. This helps you work better. Bourdon tube gauges work well for most jobs. But you must check and adjust them often to keep them correct. Diaphragm gauges are best for thick or harmful liquids. They help keep places safe and clean. Piezoelectric sensors give quick and correct results. They are good when you need fast answers. Digital pressure transmitters have special features like saving data and checking from far away. This helps you watch things better. SOUSHINE Force Sensing Resistors (FSRs) are strong and can be used in many ways. They work well in cars and hospitals. You must check and fix pressure tools often. This keeps them safe and correct. Think about where you will use the tool and what it is made of. This helps the tool last a long time.

Types of Pressure Measuring Instruments

Bourdon Tube Gauges

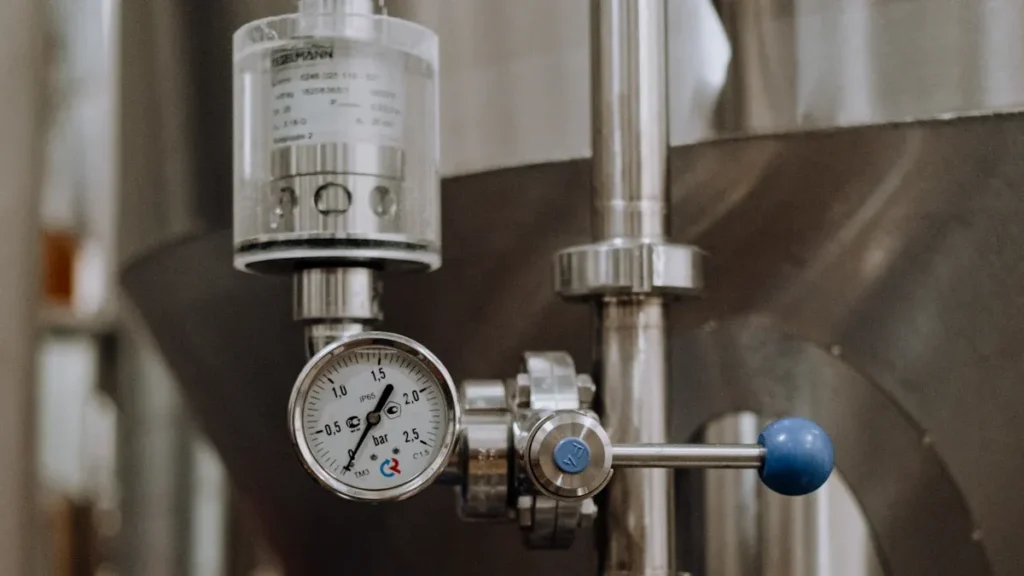

Bourdon tube gauges are common in many factories. They have a curved, hollow tube inside. When pressure goes up, the tube starts to straighten. This movement makes a pointer move on a dial. The dial shows the pressure reading. The simple design makes these gauges very reliable. You can use them for gauge, absolute, and differential pressure.

Bourdon tube gauges are good for most jobs. Their accuracy is between ±1.5% and ±2% of the full scale. Temperature changes and wear can change the readings. You should calibrate them often to keep them working well. These gauges are used in water treatment, power plants, and chemical factories.

Tip: Always look for damage or wear before using a Bourdon tube gauge. This helps you avoid mistakes and keeps your tools safe.

Diaphragm Gauges

Diaphragm gauges are another way to measure pressure. They use a thin, bendable diaphragm that moves when pressure changes. This movement moves a pointer or shows a number on a screen. Diaphragm gauges protect against harmful fluids and work with thick or sticky liquids. You see them in chemical plants, oil pipelines, and food factories.

Here are some main benefits of diaphragm gauges:

- They protect your tools from getting corroded.

- They work with thick or sticky fluids without getting blocked.

- They measure pressure in hot places.

- They help keep things clean in sanitary jobs.

Diaphragm gauges help you follow safety and cleanliness rules. You find them in medicine labs, HVAC systems, and water plants. Their design means less wear, so they stay accurate for a long time.

Piezoelectric Sensors

Piezoelectric sensors use special materials that make electricity when pressed. They give fast and accurate readings, even when pressure changes quickly. These sensors are best when you need quick results, like in car tests or robots.

Piezoelectric sensors measure pressure by sensing electric changes from stress. They are very sensitive and can track fast pressure changes. But they only work well in certain frequency ranges. At low frequencies, the charge fades fast, so readings are less accurate. At high frequencies, they work their best.

You use piezoelectric sensors in manometer systems for research, factories, and airplanes. They help you watch pressure right away, which is important for safety.

Note: Piezoelectric sensors can change with temperature, so pick ones that handle temperature changes for better results.

Now you know how Bourdon tube gauges, diaphragm gauges, and piezoelectric sensors work. Each one has special uses for different jobs in industry.

Digital Pressure Transmitters

Digital pressure transmitters are a new way to measure pressure. They use electronic sensors to change pressure into digital signals. You can see the results on a screen or send them to a computer. These transmitters are good when you need fast and accurate readings.

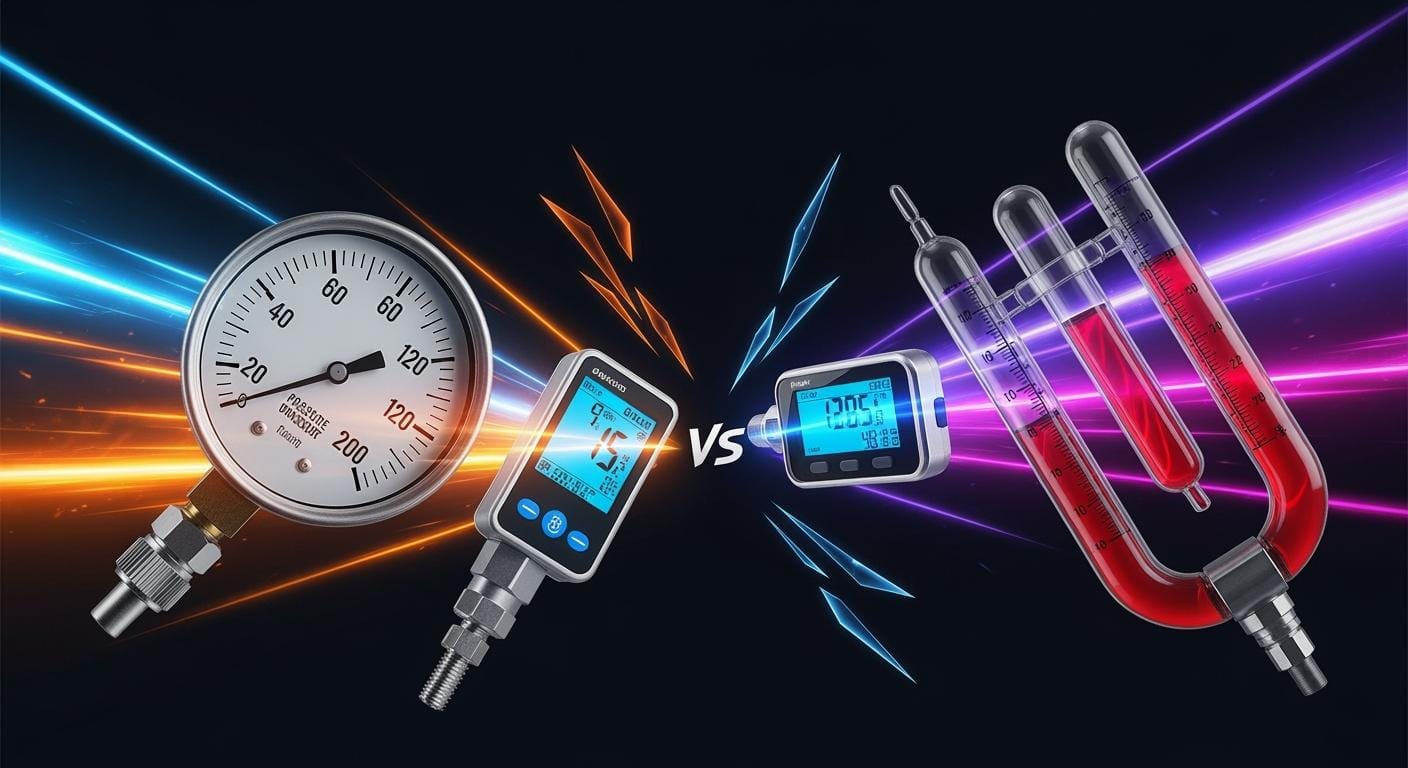

You can look at the table to see how digital and analog gauges are different:

| Feature | Digital Pressure Gauges | Analog Pressure Gauges |

|---|---|---|

| Accuracy | ±0.025% to ±1% FS | ±0.25% to ±3% FS |

| Response Speed | Millisecond-level instant response | Approx. 0.5 to 1 second |

| Operating Temperature Range | -20°C to 60°C | -40°C to 200°C |

| Display Resolution | Up to 0.00001 bar | Depends on total range and dial size |

| Additional Features | Data recording, peak memory, remote connection | Basic features (shock resistance, liquid fill) |

| Price Range | Approx. $150 to $500 | Approx. $10 to $100 |

Digital transmitters help you see pressure changes right away. You can use them in manometer systems to watch pressure in real time. Many companies use these because they are accurate and have extra features like saving data and remote access.

SOUSHINE Force Sensing Resistors (FSRs)

SOUSHINE Force Sensing Resistors (FSRs) are a special way to measure pressure and force. These sensors change their resistance when you press on them. This lets you get steady and exact readings. You can use SOUSHINE FSRs in cars, hospitals, robots, and electronics.

Here are some reasons why SOUSHINE FSRs are useful:

- You get steady and exact force readings over a surface.

- You can find pressure spots and check if the force is even.

- You can set up machines for the best force, which helps make better products and keeps tools from wearing out.

- You can watch force to stop overloads, which keeps your workplace safe.

SOUSHINE FSRs use special materials that react fast to touch, grip, or weight changes. These sensors work well in many places, so you get good readings even if things change. The FSR 402 model can sense very small pressure changes, so it is good for medical electronics and car brake systems. The strong design makes these sensors last a long time, so you can use them again and again in hard jobs.

If you want to know more about SOUSHINE FSRs and how they can help your business, visit SOUSHINE FSR Expert.

Other Specialized Instruments

There are other pressure measuring tools for special jobs. Some, like differential manometers, help you compare pressure at two places. Others, like barometers and vacuum gauges, measure air pressure or very low pressure. You might use these in labs, research, or places where you need very exact pressure control.

Special pressure tools help you with special problems. You can choose the best tool for your job, whether you need to measure high, low, or changing pressure. These tools help you get the best results every time.

Pressure Measurement Principles

Mechanical Sensing

Mechanical sensing is the base for many old pressure tools. You see this in Bourdon tube gauges and diaphragm gauges. These tools react when pressure changes. A Bourdon tube gets straighter as pressure goes up. This moves a pointer on a dial. Diaphragm gauges have a thin part that bends with pressure. This bending shows a number you can read. Mechanical sensing works well in rough places. It does not need any power. You can trust these tools for easy and steady pressure checks.

| Type of Sensor | Operational Principle |

|---|---|

| Mechanical Pressure | Uses a direct physical reaction to pressure, often with a Bourdon tube or diaphragm. |

| Electronic Pressure | Changes pressure into an electric signal using piezoresistive or capacitive sensing. |

Electronic Sensing

Electronic sensing has made pressure checks better. Digital pressure transmitters and piezoelectric sensors use electronics. They turn pressure into electric signals. These signals move fast and let you watch pressure right away. You get better accuracy and more features, like saving data and checking from far away. Electronic sensors use piezoresistive or capacitive parts. When pressure changes, the sensor’s electric parts change too. This makes a signal you can see on a screen or computer.

SOUSHINE Force Sensing Resistors (FSRs) are a special kind of sensor. These sensors lower their resistance when you push on them. This helps you measure pressure all the time, not just on or off. You can watch small changes in force or pressure. SOUSHINE FSRs can fit many shapes and sizes. They react fast and last long, so they are good for cars, hospitals, and robots. If you want to know more about SOUSHINE FSRs, visit SOUSHINE FSR Expert.

Tip: Electronic sensors give you more information and choices. This helps you make your work safer and better.

Calibration Methods

Calibration keeps your pressure tools correct and safe. You should use main standards that come from national labs for calibration. Other standards, like digital gauges, use these main standards to check themselves.

- Calibrate your tools at least once a year to keep them right.

- Checking every month helps you find changes in your tools.

- If your workplace changes a lot, check your tools more often.

- Always use a standard that is four times more correct than your tool.

- For example, if your gauge is ±1% correct, use a standard with ±0.25 psi or better.

- Calibration checks and records your tool’s accuracy. This is very important when pressure readings matter for your work.

You get good results and safe work when you use the right calibration steps.

Accuracy, Precision, and Safety

Resolution and Sensitivity

When picking a pressure measuring instrument, you want it to be sensitive. High sensitivity helps you notice small pressure changes. High resolution lets you see tiny differences in readings. Precision pressure gauges show very detailed results. You can check the table below to see how accurate they are:

| Type of Pressure Gauge | Accuracy Grade |

|---|---|

| Precision Pressure Gauge | 0.1 |

| Precision Pressure Gauge | 0.16 |

| Precision Pressure Gauge | 0.25 |

| Precision Pressure Gauge | 0.4 |

| General Pressure Gauge | 1.0 |

| General Pressure Gauge | 1.6 |

| General Pressure Gauge | 2.5 |

| General Pressure Gauge | 4.0 |

A smaller number means the gauge is more accurate. Digital pressure transmitters and SOUSHINE FSRs are also very sensitive. You can trust these tools for jobs that need exact measurements, like in hospitals or robots.

Error Sources

There are many things that can cause errors when you measure pressure. These errors can change your results. The table below shows some common error sources and ways to fix them:

| Error Source | Description | Mitigation Strategies |

|---|---|---|

| Calibration errors | Problems from drift, hysteresis, or nonlinearity. | Calibrate often, use good reference standards, and follow instructions. |

| Environmental factors | Things like temperature, humidity, or vibration. | Pick the right sensors, use shields, and do regular maintenance. |

| Installation and operation errors | Mistakes from how you set up or use the tool. | Install correctly, check for leaks, and train your team. |

| Measurement uncertainty | Not being sure about your results. | Use better methods, fix mistakes, and check for uncertainty. |

You can stop many errors by using good habits. Always calibrate your tools and check for leaks. Teach your team how to use the equipment the right way. SOUSHINE FSRs help you get steady readings and are easy to calibrate.

Tip: Keep your tools working well by doing regular checks and training your team.

Safety Features

New pressure measuring instruments have features to keep you safe. These features protect you and your equipment. The table below lists some important safety features:

| Safety Feature | Description |

|---|---|

| High and Low Pressure Switches | These switches shut down systems if pressure gets too high or low. |

| Pressure Cutout Mechanisms | These stop too much pressure and help prevent danger. |

| Explosion Hazard Design | This design lowers the chance of explosions in risky places. |

| Consistent Water Pressure Management | This keeps water pressure steady so systems work well. |

You should look for these safety features when you pick a pressure measuring instrument. SOUSHINE FSRs work well and help keep things safe. Each instrument uses special parts to stop accidents and keep systems from failing.

Remember: Picking the right instrument with good safety features keeps your team and your workplace safe.

Reliability and Durability

Harsh Conditions

Industrial places can be very tough. Hot or cold temperatures and strong chemicals can hurt your pressure measuring tools. You need tools that keep working even when things get hard. The table below shows what can go wrong and what materials help your tools last longer:

| Condition | Challenges | Solutions/Materials Used |

|---|---|---|

| Extreme Temperatures | Oil can get hard, water can freeze, sensors can bend, parts can break | Keep things warm, use special sensors for cold, use better materials for heat |

| Corrosive Environments | Acids, bases, saltwater, and germs can eat away at tools | Use titanium, nickel superalloys, and Viton o-rings to stop corrosion |

Bourdon tube gauges and diaphragm gauges use strong metals like stainless steel or brass. These metals help them fight rust and heat. Digital pressure transmitters have sealed cases to keep their parts safe. SOUSHINE FSRs use tough and bendy materials that handle hot and cold and fight off many chemicals. You can trust these sensors in places where other tools might stop working.

Tip: Always make sure your tool’s materials fit the place you will use them.

Maintenance Needs

You want tools that work well without much work. Doing regular checks keeps your tools safe and correct. The table below shows some common jobs and why they help:

| Maintenance Task | Frequency | Benefit |

|---|---|---|

| Cleaning | Monthly/Quarterly | Gets rid of dust, helps tools work faster |

| Inspection | Monthly | Finds broken parts, stops problems early |

| Recalibration | As needed | Fixes mistakes, keeps readings right |

| Replacement | When required | Keeps tools working well |

Bourdon tube and diaphragm gauges need cleaning and checking often. Digital transmitters may need updates and sensor checks. SOUSHINE FSRs only need simple cleaning and quick checks. Their design makes them easy to care for, so you do not spend much time fixing them. You can learn more about how long they last and how easy they are to care for at SOUSHINE FSR Expert.

Material Quality

The kind of material your tool is made from matters a lot. Good metals and strong plastics help tools fight heat, pressure, and chemicals. SOUSHINE FSRs use the best materials that keep their shape and work well for a long time. This helps your products stay good and your machines run smoothly.

You should always pick tools made from strong and trusted materials. This helps your pressure readings stay right and your tools stay safe. SOUSHINE FSRs are known for being tough, using little power, and being easy to use. These things help your work go smoothly without problems.

Remember: Picking tools with good materials means fewer problems and better results for your work.

Cost and Value

Initial Investment

When you choose a pressure measuring instrument, you first look at the price. Bourdon tube gauges and diaphragm gauges usually cost less. You can buy these for $10 to $100 each. They work well for basic jobs and do not need extra equipment. Piezoelectric sensors and digital pressure transmitters cost more. You might pay $150 to $500 for a digital transmitter. These tools give you more features and higher accuracy.

SOUSHINE Force Sensing Resistors (FSRs) offer a smart balance. You can get high-quality FSRs at a competitive price. SOUSHINE also lets you pick custom shapes and sizes. This helps you fit the sensor to your project without spending extra money on changes. You save money and get a sensor that matches your needs.

Tip: Always match your budget to your project’s needs. Do not pay for features you will not use.

Operating Costs

You need to think about more than just the first price. Some instruments need regular care. Bourdon tube and diaphragm gauges need cleaning and calibration. This adds to your costs over time. Digital transmitters may need software updates and sensor checks. These steps keep your readings correct but can cost more.

SOUSHINE FSRs need very little care. You only need to clean them sometimes and check them quickly. Their strong design means you do not replace them often. This lowers your operating costs. You spend less time and money on upkeep, which helps your team focus on other jobs.

| Instrument Type | Initial Cost | Maintenance Needs | Typical Lifespan |

|---|---|---|---|

| Bourdon Tube Gauge | Low | Moderate | 5-10 years |

| Diaphragm Gauge | Low | Moderate | 5-10 years |

| Piezoelectric Sensor | Medium | Moderate | 3-7 years |

| Digital Transmitter | High | Moderate to High | 7-12 years |

| SOUSHINE FSR | Medium | Low | 8-12 years |

Value for Money

You want a tool that gives you the best value. Bourdon tube and diaphragm gauges work well for simple jobs. They cost less but may not give you the features you need for complex tasks. Piezoelectric sensors and digital transmitters give you fast and accurate data. They help you track changes and improve your process.

SOUSHINE FSRs stand out because they give you steady readings, long life, and low upkeep. You can use them in many places, from cars to robots. Their design ensures machine efficiency and helps you avoid costly breakdowns. When you choose SOUSHINE, you get a sensor that fits your project, saves you money, and boosts your efficiency.

Remember: The right pressure measuring instrument saves you money and helps your business grow.

Industrial Applications and Use Cases

Automotive

Pressure measuring instruments are used a lot in cars. Car makers use Bourdon tube gauges to check tire pressure. They also use them to watch oil systems. These gauges help keep engines safe and running well. Diaphragm gauges work in fuel systems. They handle thick liquids and stop leaks.

Piezoelectric sensors test engines and brakes. They give fast feedback during crash tests. They also help with performance checks. Digital pressure transmitters let you watch pressure right away. You can find problems before they get worse.

SOUSHINE Force Sensing Resistors (FSRs) add new features to cars. You can use FSRs in seat sensors to see if someone is sitting. They help airbags go off at the right time. FSRs also measure brake pressure and make safety systems better. You can change SOUSHINE FSRs to fit any car part. This helps you design safer and smarter cars. Learn more about SOUSHINE FSRs and car safety at SOUSHINE FSR Expert.

Tip: Pick the right pressure sensor to make cars safer and work better.

Healthcare

Pressure measuring instruments are important in hospitals. Hospitals use diaphragm gauges in oxygen tanks and ventilators. These gauges help keep patients safe by showing the right pressure. Bourdon tube gauges are also used in medical gas systems.

Piezoelectric sensors help check blood pressure and heart activity. They give quick and correct results. Digital pressure transmitters work in patient monitors. You can see changes and act fast.

SOUSHINE FSRs are special in healthcare. You find them in smart beds that check patient movement and pressure spots. FSRs help stop bedsores by showing where pressure builds up. You also see FSRs in rehab equipment. They measure force during therapy and help doctors see progress. SOUSHINE FSRs are reliable and comfortable for patients and staff.

Robotics

Robots need accurate pressure measurement to work well. Robots use piezoelectric sensors to feel touch and grip things. These sensors help robots pick up fragile items without breaking them. Digital pressure transmitters help control robot arms with care.

SOUSHINE FSRs give robots a sense of touch. You can put FSRs on robot fingers or feet. This helps robots feel how hard they press or step. FSRs make robots safer around people and better in factories. You can shape SOUSHINE FSRs to fit any robot. Their fast response and strength make them great for advanced robots. Learn more about SOUSHINE FSRs in robots at SOUSHINE FSR Expert.

Note: Pressure sensors help robots work safely and interact better with their world.

Consumer Electronics

You use pressure measuring tools every day, but you may not notice. These tools help make your devices smarter and easier to use. Pressure sensors are inside touchscreens, game controllers, and smart watches. Bourdon tube and diaphragm gauges are too big for small gadgets. Instead, piezoelectric sensors and digital pressure transmitters are used. These sensors give fast and accurate feedback in your devices. For example, piezoelectric sensors help your phone know when you touch or press. Digital transmitters send signals to your device’s computer. This helps your device respond quickly to what you do. SOUSHINE Force Sensing Resistors (FSRs) are special in this area. You find SOUSHINE FSRs in smart watches, fitness trackers, and remotes. These sensors measure how hard you press a button or screen. Your device can tell if you tap lightly or press hard. This makes using your device feel better and more fun. SOUSHINE FSRs also use little power, so your battery lasts longer.

Tip: If you want a device that feels natural and reacts fast, look for products with advanced pressure sensors like SOUSHINE FSRs.

Industrial Automation

Factories and machines need good pressure measuring tools. You use these tools to control machines and keep things safe. Bourdon tube gauges and diaphragm gauges help you check pressure in pipes and tanks. They let you see if everything is working right. Digital pressure transmitters and piezoelectric sensors give you more control. You can connect them to computers and get live data. This helps you find problems before they stop your machines. You can also use these sensors to set up safety shutoffs and alarms. SOUSHINE FSRs give you new ways to measure pressure in factories. You can put them on robot arms, conveyor belts, or assembly lines. They measure force and pressure at many spots. This helps you make your process better and safer. You can change SOUSHINE FSRs to fit any machine or setup. This makes your work faster and keeps your workplace safe.

Note: The right pressure sensors in automation help you avoid mistakes and keep your systems working well.

Aerospace

Aerospace jobs need the best pressure measuring tools. You need tools that work in very hot, cold, or shaky places. Bourdon tube gauges and diaphragm gauges watch fuel and hydraulic systems in planes. They help keep flights safe and running well. Piezoelectric sensors track fast pressure changes in jet engines and wind tunnels. Digital pressure transmitters send data to flight computers. This lets you make quick choices during flight. SOUSHINE FSRs are helpful in aerospace too. You can use them in pilot seats to check pressure and make seats more comfy. They also help test plane parts by measuring force and stress. SOUSHINE FSRs work well in tough places and give correct results. This makes them a smart pick for aerospace engineers.

Remember: In aerospace, every detail is important. Good pressure sensors like SOUSHINE FSRs help you meet strict safety and performance rules.

Chemical and Petrochemical

You work where chemicals and gases move in pipes every day. Pressure measuring instruments help keep these systems safe. Bourdon tube gauges let you check pressure in tanks and pipes. You can find leaks or blockages before they cause problems. Diaphragm gauges work with thick or sticky fluids. You use them to measure pressure in reactors and mixing tanks.

Piezoelectric sensors help you watch fast pressure changes during reactions. Digital pressure transmitters send real-time data to control rooms. This helps you act fast if something goes wrong.

SOUSHINE Force Sensing Resistors (FSRs) give you another way to measure pressure. You can put FSRs on valves or pumps to track force and pressure. Their strong design stands up to harsh chemicals and high heat. You can also change SOUSHINE FSRs to fit special equipment. This helps you keep your plant safe and running well.

Tip: Always check your pressure sensors before starting a new batch. This keeps your team and your plant safe.

Food and Beverage

You need clean and safe tools when working with food and drinks. Diaphragm gauges help you measure pressure in pasteurizers and bottling lines. Their design keeps bacteria out and makes cleaning easy. Bourdon tube gauges help you check steam pressure in cooking and sterilizing equipment.

Digital pressure transmitters give you fast and accurate readings. You can use them to control filling machines and keep products fresh. Piezoelectric sensors help you watch pressure changes during mixing or carbonation.

SOUSHINE FSRs fit well in food processing machines. You can use them to measure force in packaging lines or check pressure in sealing machines. Their flexible design lets you put them in tight spaces. SOUSHINE FSRs use safe materials, so you can trust them in food and drink plants.

Note: Clean your pressure sensors often. This helps you meet food safety rules and keeps your products safe.

Power Generation

You help keep the lights on by using pressure measuring instruments in power plants. Bourdon tube gauges let you check steam pressure in boilers and turbines. Diaphragm gauges help you measure pressure in cooling systems and fuel lines.

Digital pressure transmitters give you real-time data. You can use them to spot problems before they cause shutdowns. Piezoelectric sensors help you track fast pressure changes in turbines and pumps.

SOUSHINE FSRs offer new ways to watch force and pressure in power plants. You can use them to check pressure on control panels or measure force in safety systems. Their strong build and long life make them a smart pick for tough power plant jobs.

Remember: The right pressure sensor helps you avoid costly breakdowns and keeps your power plant safe.

Water Treatment

You help keep water clean and safe for everyone. Water treatment plants need accurate pressure checks at every step. You use different pressure measuring instruments to watch pumps, filters, and pipes. Each tool helps you keep things working and stops expensive problems.

Bourdon tube gauges check pressure in big pipes and tanks. You can find leaks or blockages early. Diaphragm gauges work with dirty or chemical water. You use them for sludge lines or chemical dosing systems. These gauges fight corrosion and keep working in tough places.

Piezoelectric sensors give quick feedback when pressure changes fast. You use them to watch pumps that start and stop a lot. Digital pressure transmitters show real-time data on screens or send it to a control room. You can set alarms for high or low pressure. This helps you act fast and keep the plant safe.

SOUSHINE Force Sensing Resistors (FSRs) give new choices for water treatment. You can put FSRs on valves, pumps, or filter presses. They measure force and pressure at many spots. You get steady readings, even when things are wet or dirty. SOUSHINE FSRs use strong materials that fight water and chemicals. You can shape them to fit tight spaces or special equipment.

Tip: Use SOUSHINE FSRs to watch pressure in hard-to-reach places. Their flexible design makes them easy to install.

Here is a quick comparison of how each instrument helps in water treatment:

| Instrument Type | Common Use in Water Treatment | Key Benefit |

|---|---|---|

| Bourdon Tube Gauge | Main pipelines, storage tanks | Simple, reliable readings |

| Diaphragm Gauge | Sludge lines, chemical dosing | Handles harsh fluids |

| Piezoelectric Sensor | Pump monitoring, rapid changes | Fast response |

| Digital Transmitter | System-wide monitoring, alarms | Real-time data, remote access |

| SOUSHINE FSR | Valves, filter presses, tight spaces | Flexible, durable, adaptable |

You need good tools to keep water treatment safe and working well. SOUSHINE FSRs help you solve special problems. You can trust them to last long and be easy to care for. When you pick the right pressure sensor, you protect your equipment and give clean water to your community.

Choosing the Right Measuring Pressure Instrument

Decision Checklist

You want to find the best pressure measuring tool for your job. Making a checklist helps you pick the right one. Use the table below to compare your choices and see what matters most.

| Criteria | Description |

|---|---|

| Accuracy | High precision is crucial, especially for applications sensitive to minute pressure changes. |

| Operating Range | The gauge must accurately measure within the specific pressure range relevant to the application. |

| Display Type | Consider digital features like data logging and connection capabilities for enhanced functionality. |

| Power Source | Ensure the gauge has a reliable power source suitable for the operational environment. |

| Response Time | A quick response time is essential for real-time monitoring and adjustments. |

| Environmental Rating | The gauge should be rated for the environmental conditions it will be exposed to. |

| Installation Considerations | Evaluate ease of installation and compatibility with existing systems. |

| Safety and Compliance | Ensure the instrument meets relevant safety standards and regulations. |

Tip: Check each point before you buy or set up new pressure tools. This step helps you save time and money.

Expert Recommendations

Experts say you should match your tool to your needs. The table below shows how SOUSHINE FSRs and traditional tools are different. This helps you see which one fits your job.

| Factor | SOUSHINE FSRs | Traditional Pressure Instruments |

|---|---|---|

| Accuracy | High accuracy and resolution | Varies, often lower than FSRs |

| Response Time | Fast response suitable for quick jobs | Generally slower |

| Output Signal Type | Flexible options for different setups | Typically fixed signal types |

| Media Compatibility | Works with various media types | Limited to specific media |

| Installation Requirements | Flexible design for tight spaces | May require more space and specific setup |

Pick SOUSHINE FSRs if you want high accuracy, fast response, and easy setup. These sensors fit in small spaces and work with many things. Traditional tools are good if you need something simple or use normal fluids and gases.

Note: Always check what your system needs before you choose. The right tool keeps your work safe and running well.

Future Trends

Pressure measuring tools keep getting better. You will see new features and smarter tools soon. Here are some trends to watch:

- Wireless sensors give you more freedom and help you grow your system.

- Smart sensors can look at data right where it is made, saving time and making things work better.

- Pressure mapping sensors help make batteries safer and better in new industries.

- AI-powered sensors can warn you about problems before they happen.

- IoT sensors let you check pressure from anywhere and get updates right away.

- Eco-friendly designs use less energy and safer materials, helping you protect the planet.

Pressure measuring tools will get smarter, faster, and more connected. These changes help you stay safe and make better choices.

Keep learning about new tools and trends. Knowing what’s new helps you do your job better.

You can pick from many tools to measure pressure at work.

- Manometer gauges are good for easy jobs that do not need to be exact.

- Pressure sensors help you get very accurate numbers and quick updates for hard jobs.

- If you calibrate your tools often, your readings will stay safe and correct.

Experts say you should check if the tool’s material matches your job, if it can handle the place you use it, and if it meets safety rules. SOUSHINE Force Sensing Resistors are trusted and can be made to fit many kinds of work. You can talk to experts to help you choose the best tool for what you need.

FAQ

What is the most accurate pressure measuring instrument for industry?

Digital pressure transmitters and SOUSHINE FSRs are the most accurate. These tools give exact readings and respond very fast. You can use them for important jobs in factories, labs, and automation.

How often should you calibrate your pressure measuring instruments?

You should calibrate your tools at least once every year. If you work in tough or changing places, check them more often. Regular calibration keeps your readings safe and correct.

Can SOUSHINE FSRs handle harsh industrial environments?

Yes, SOUSHINE FSRs are made from strong materials. You can use them in hot, cold, or wet places. They resist chemicals and last a long time, even in hard jobs.

What industries use SOUSHINE Force Sensing Resistors?

You find SOUSHINE FSRs in cars, hospitals, robots, electronics, factories, planes, and more. These sensors work in many jobs and help make things safer and better.

How do you choose the right pressure measuring instrument?

You should think about accuracy, range, where you use it, and safety. Use a checklist to compare your choices. Pick the tool that fits your job and keeps your workplace safe.

Do digital pressure transmitters need regular maintenance?

Yes, you need to check digital transmitters for updates and sensor health. Clean them and recalibrate when needed. This keeps your data right and your system working well.

Are SOUSHINE FSRs customizable for special projects?

Yes, you can get SOUSHINE FSRs in many shapes and sizes. This helps you fit them into special designs or small spaces. Custom sensors give you better results for your project.

What safety features should you look for in pressure measuring instruments?

You should look for high and low pressure switches, cutout systems, and explosion-proof designs. These features keep your team and equipment safe from accidents.