Call us: +86-137-2353-4866

Medical devices demand control interfaces that are not only user-friendly but also exceptionally reliable and capable of withstanding rigorous cleaning protocols. SOUSHINE specializes in the design and manufacturing of membrane switch control panels tailored for the unique requirements of the medical industry. Our solutions provide a seamless and durable interface between the medical professional and the device’s core functions.

This page details the application of our membrane switch technology in constructing high-performance control panels for various medical instruments.

What are Membrane Switches Control Panels in Medical Instruments?

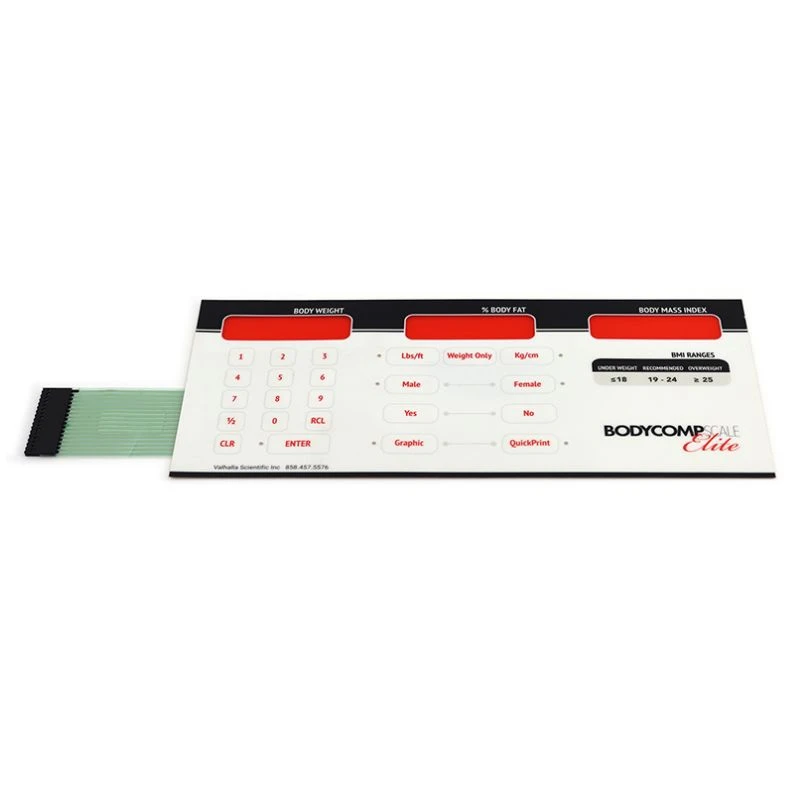

A membrane switch control panel for a medical instrument is a user interface built from multiple layers of flexible polymer films and adhesives. The top layer, known as the graphic overlay, is printed with the specific button functions and branding. Beneath this are conductive circuit layers that register a keypress when a specific point on the overlay is touched.

For medical applications, these panels are engineered as completely sealed units. This design is critical for preventing the ingress of liquids and contaminants, making them easy to clean and sterilize, which is a fundamental requirement in any clinical environment.

How We Engineer Control Panels for Medical Devices

SOUSHINE follows a stringent, stage-gated process to develop and manufacture membrane switch control panels that meet the precise specifications and regulatory demands of the medical device industry.

- Material Selection: We utilize medical-grade polyester and polycarbonate for graphic overlays due to their high resistance to chemicals and surface abrasion. Sub-surface printing protects the graphics from wear and cleaning solvents. Adhesives are selected for their biocompatibility and bond strength.

- Circuit Design and Reliability: Circuits are printed using highly conductive silver inks on heat-stabilized polyester substrates. Our engineering process focuses on designing for high actuation life, often exceeding one million keypresses, ensuring long-term device reliability.

- Sealing and Ingress Protection (IP): Panels are designed and assembled to meet specific IP ratings, such as IP65 or IP67, providing certified protection against dust and liquid ingress. This is achieved through precision die-cutting and the use of perimeter sealing gaskets.

- Integration of Components: We can seamlessly integrate various components into the control panel assembly, including:

- LEDs: For status indication and backlighting.

- Tactile Feedback: Metal domes or polydomes provide a distinct feel for positive confirmation of a keypress.

- EMI/RFI Shielding: Layers of conductive material are added to shield the device’s electronics from electromagnetic and radio frequency interference.

- Transparent Display Windows: Clear windows for viewing LCD or LED displays are integrated directly into the graphic overlay.

- Quality and Compliance: Our manufacturing facilities operate under an ISO 13485-compliant quality management system, ensuring that every component meets the stringent traceability and quality requirements of the medical device industry.

Why Choose SOUSHINE Membrane Switches for Medical Control Panels?

Integrating a SOUSHINE membrane switch into your medical instrument provides distinct advantages in performance, safety, and usability.

- Enhanced Hygiene and Sterilization: The smooth, crevice-free surface of our membrane panels simplifies cleaning and disinfecting, helping to reduce the risk of cross-contamination in clinical settings. The materials used are compatible with standard medical sterilants.

- Improved Durability and Lifespan: By eliminating the moving parts found in traditional mechanical switches, our membrane panels are inherently more durable. They are resistant to moisture, dust, and chemicals, ensuring reliable operation throughout the device’s lifecycle.

- Customization and User Interface Design: Every aspect of the control panel can be customized, from the button layout and graphics to the tactile feel and backlighting. This allows for the creation of an intuitive user interface that aligns with the device’s function and your brand identity.

- Streamlined Profile: The low-profile design of a membrane switch saves valuable space within the medical device and contributes to a modern, streamlined aesthetic.

- Regulatory Compliance: Our understanding of the medical device landscape means we design and manufacture components with regulatory standards, such as IEC 60601-1, in mind, facilitating a smoother compliance process for your final product.

Display

FAQ

What materials do you use to ensure chemical resistance to hospital-grade disinfectants?

We primarily use high-grade polyester for the graphic overlay because of its superior resistance to a wide range of chemicals, including common cleaning agents like isopropyl alcohol, and other disinfectants used in medical environments. We can provide a detailed list of material compatibilities upon request.

Can your control panels be backlit for use in low-light environments?

Yes. We offer several backlighting options, including embedding discrete LEDs for specific button illumination or using fiber optic layers for uniform and distributed backlighting across the entire panel.

How do you ensure the reliability of the switches over millions of actuations?

Our reliability is a factor of design, material selection, and quality control. We use high-quality conductive inks and durable substrate materials. The design of the switch contacts and the use of high-life tactile domes are specified to meet and exceed the required actuation lifecycle for the device, which is verified through rigorous in-house testing.

Can you incorporate EMI/RFI shielding into the control panel?

Absolutely. We can integrate layers of aluminum foil or a printed conductive grid (e.g., carbon or silver) within the membrane switch construction to provide effective EMI/RFI shielding, protecting the device’s sensitive electronics from external interference.

What is your process for developing a custom control panel?

Our process begins with a detailed consultation to understand your specific technical requirements, use-case environment, and regulatory needs. Our engineering team then collaborates with you to design the panel, providing drawings and prototypes for approval before proceeding to mass production. Our quality management system ensures full traceability from raw materials to the finished product.

Are your components ISO 13485 compliant?

Our manufacturing processes are aligned with the principles of ISO 13485. We operate with a robust quality management system that provides the documentation, process controls, and traceability required by medical device manufacturers to support their regulatory submissions.